Having good success with the AS 1194 watches I decided to work on this watch again. A couple weeks ago (A fortnight) I got an assortment of Val-23 screws. Some of the existing screws were little lumps of rust.

The first step was to soak the screws into the Evap-O-Rust for an evening (around 2 or three hours.) This actually did a good job and many more of the screws were in better shape than I though. Having spares probably helped.

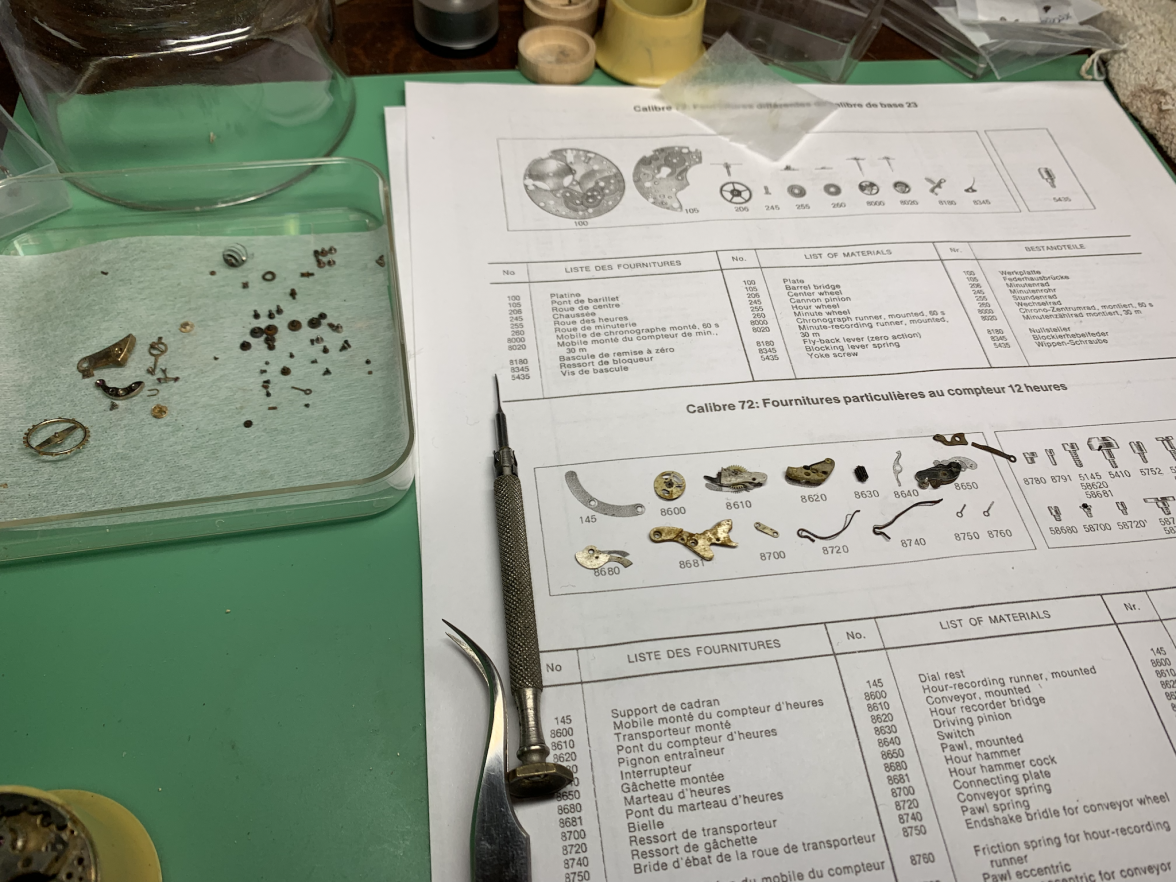

Encouraged I then soaked the plates and wheel train. In order to match screws I disassembled the Val-23 I was going to use for a parts movement. This turned out to be a Bulova AK 13 with a wrecked dial. As this is parts sorting I sorted then directly onto the data sheet.

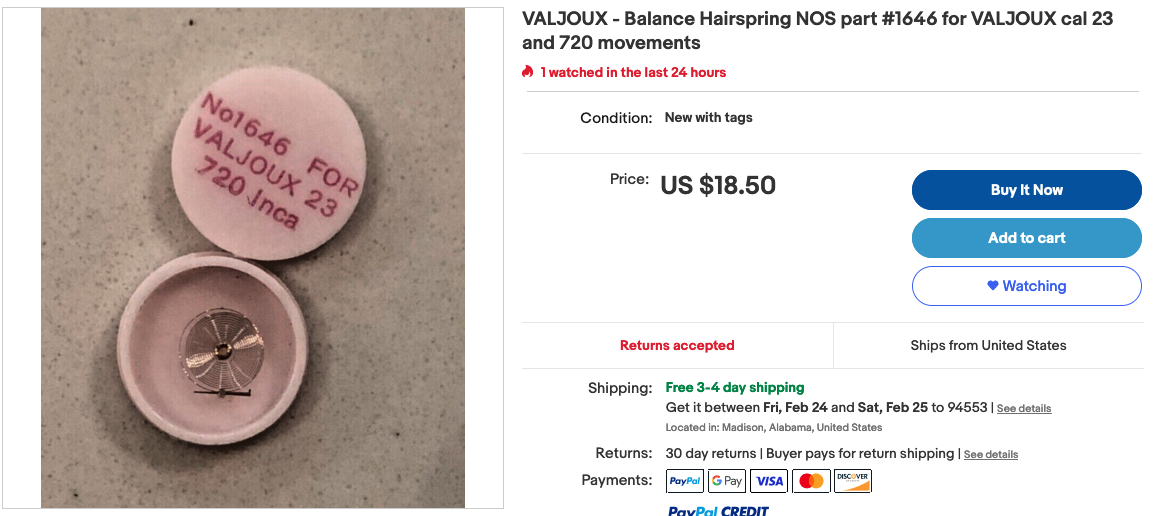

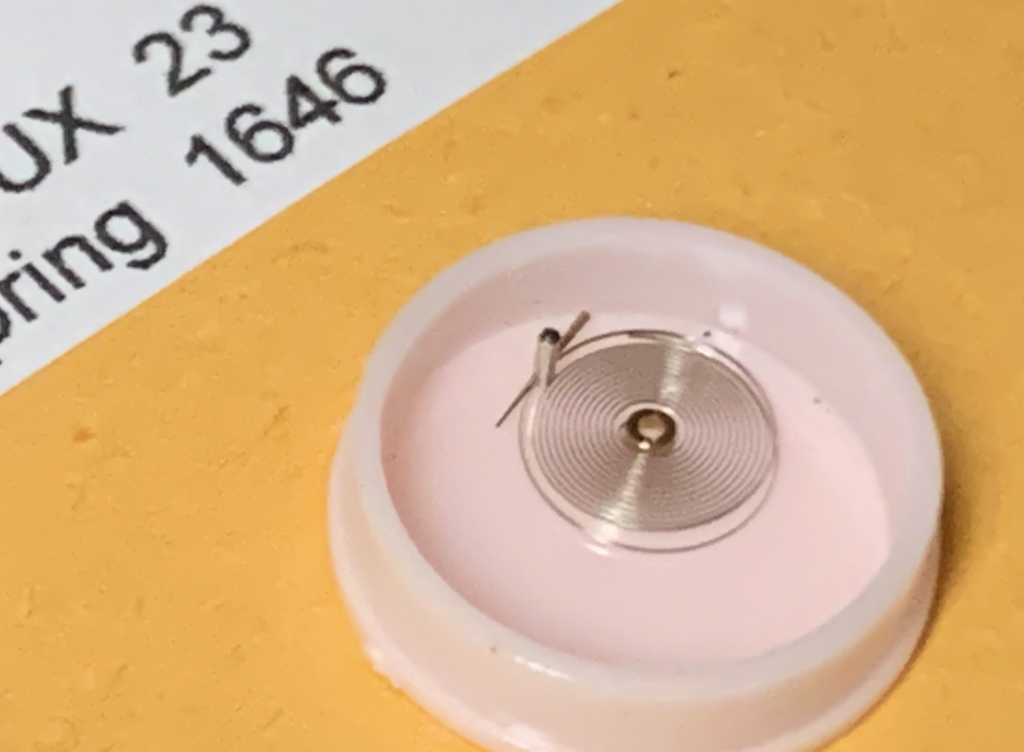

Sadly while the balance looked to be in good shape it was damaged by light rust. Worse was I tangled the hairspring attempting to remove it some months ago. I can not swap balances as the Bulova does not have shock absorbers and the plates are drilled differently on the Val-72.

The new wheel train and motion works parts all went together. The train actually spins really nice. A disappointment though was the 4th wheel is for a Val-23 and has a shorter pivot on the dial side. Some parts are more interchangeable than others. One has to really look close as these are often sold by base caliber. On the other hand, looking at the photo of the rusted dial, it looks like the remains of a rusted extension tube were on this. So there may be a workaround.

I really do not like having more than one watch apart at a time (apart from watches purchased disassembled.) More of a guideline as I have some of the Landerons still apart waiting for tools or materials. Still I figured that since I was on a roll I would fit all the chronograph parts back together. Made more urgent as I took the Bulova AK 13 apart to match screws.

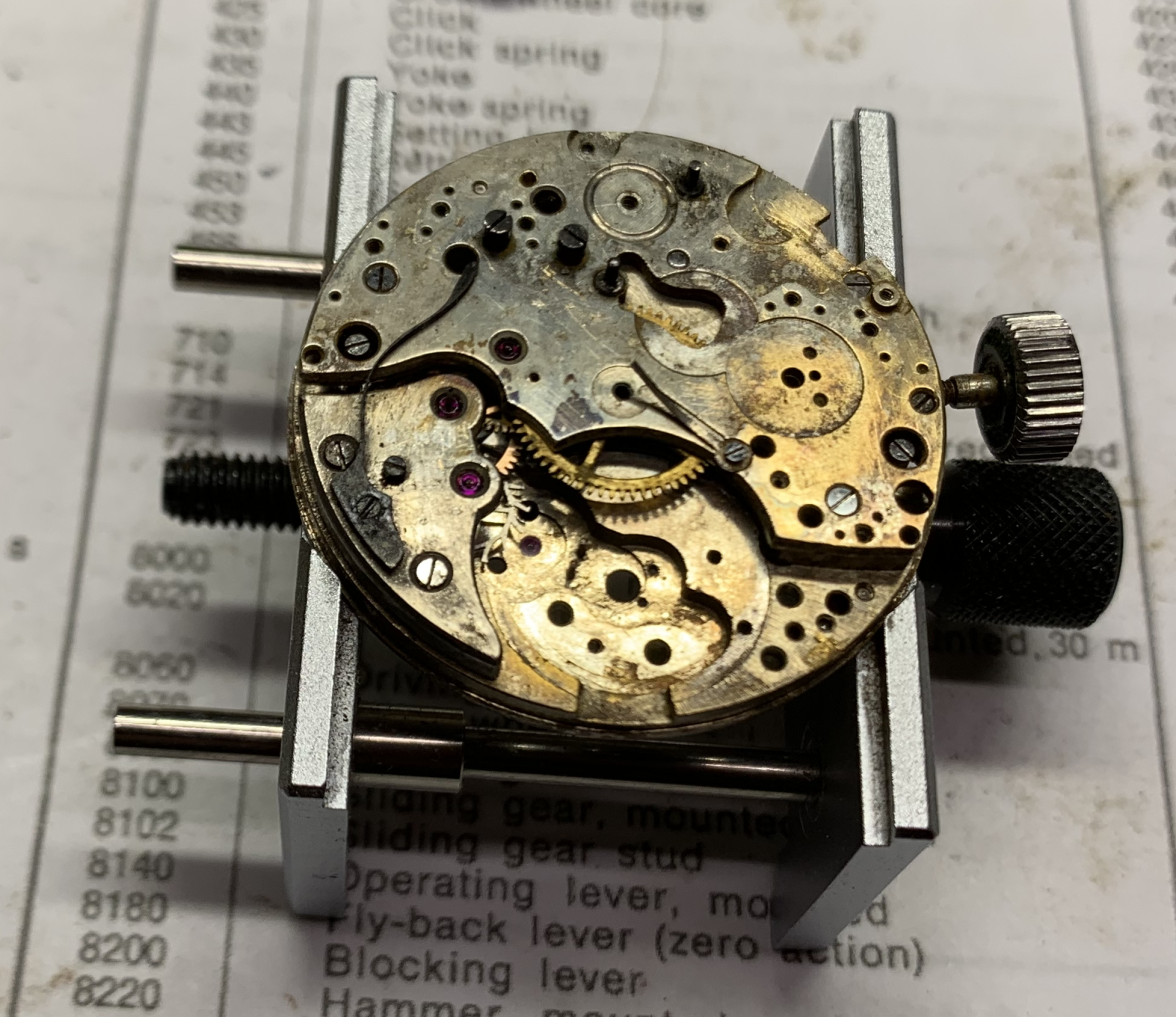

Notice the screws on the left of the above photo. Those are the hour recorder screws.

The results of this re-assembly are mixed. I am glad I did this. I am also finding I can take the chrono down and back in about 45 minutes. A huge disappointment was that the new pillar wheel is missing one of the pillars. I did not check this on arrival. I think I got this from oFrie It has however been about 4 or 5 months and who is to say I did not break it myself. I will put this down as noob tax or a sacrifice to the watch gods. The part is good enough for testing.

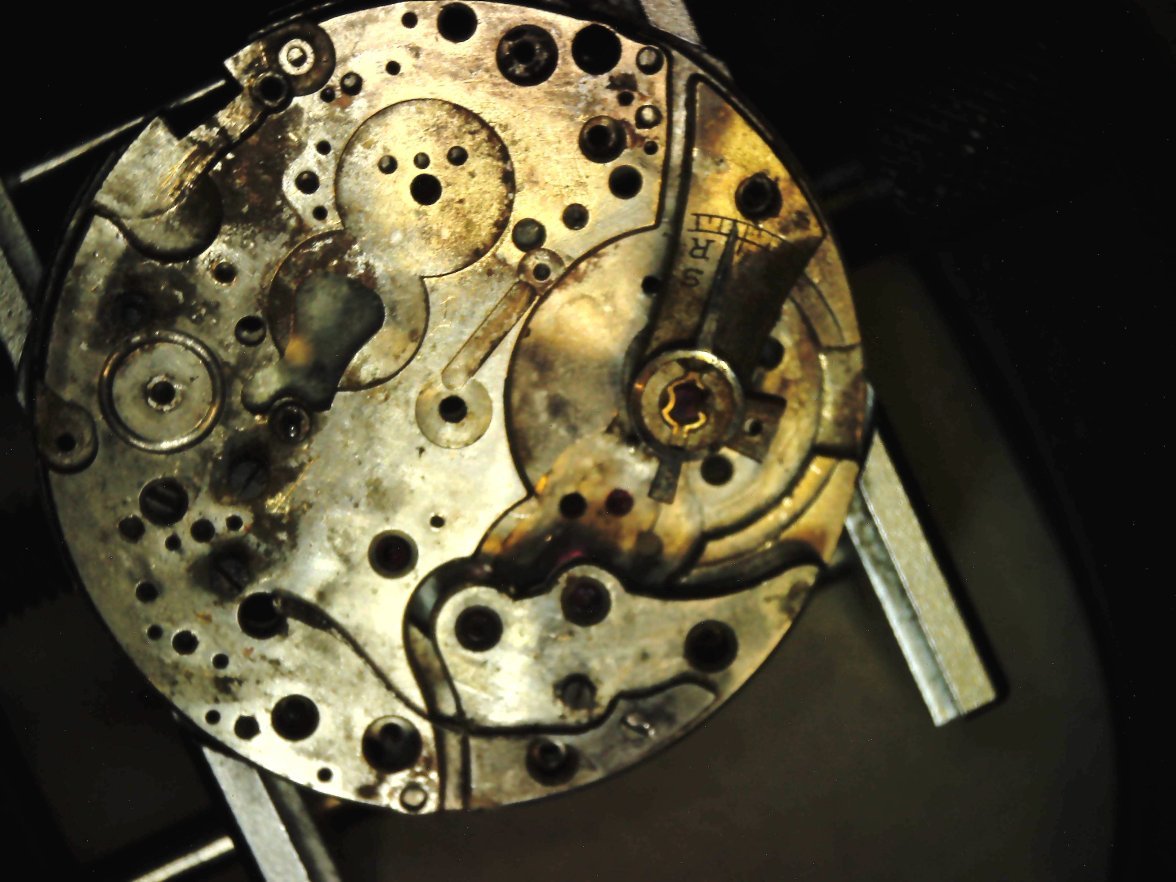

A worse disappointment was that the breaking arm was not releasing. Comparisons with the equivalent bulova part and old photographs show the tail had completely rusted away. It can be seen that the Evap-O-Rust turns the surface rust black. The plating however is unaffected. The finish on the Heuer is much more polished than the Bulova and (generic?) spares from oFrie which have a brushed finish.

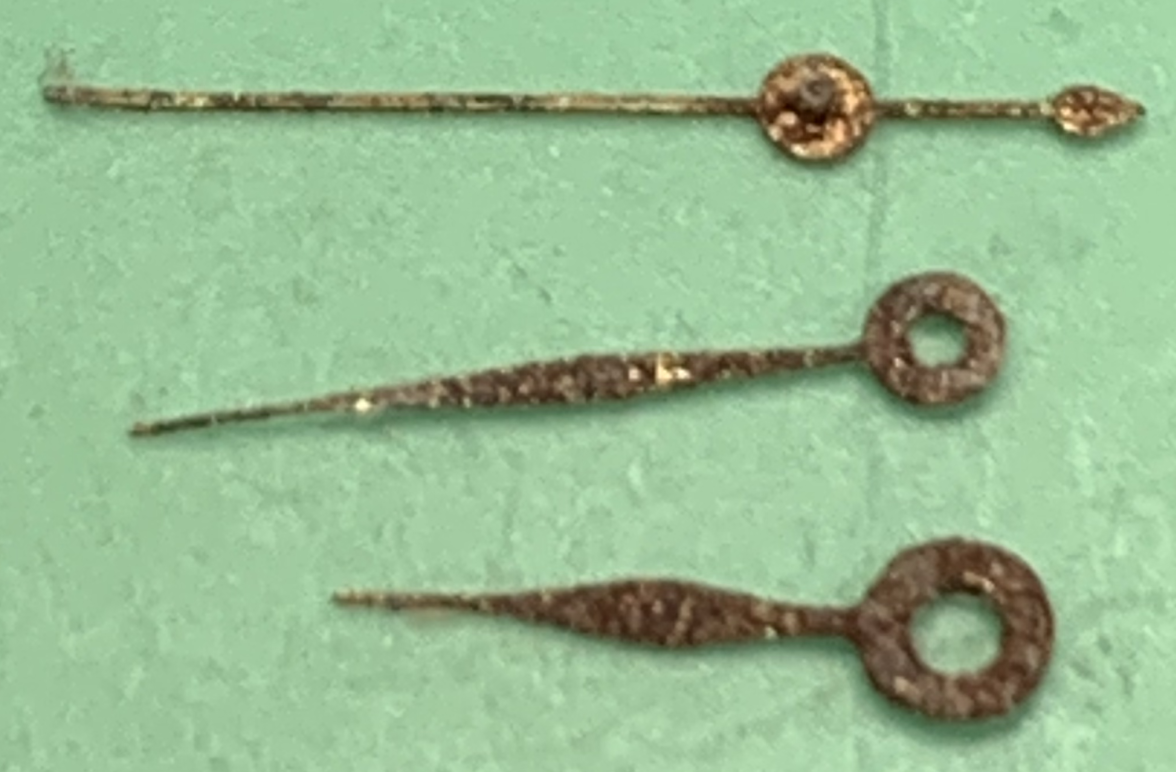

The minute recorder is also problematic. This part seems to be riveted together. The arbor is rusted through at the top pivot. It turns freely but it wobbles. The jumper for this is around 80 or 90 USD with S&H, so that would be the last part I get. Sadly this jumper was broken on both watches as it crosses the dial dog screw. The dial dog screw was missing from the Bulova which was probably ripped out of a gold case. (what remains of the hands are gilt as is the dial furniture.)

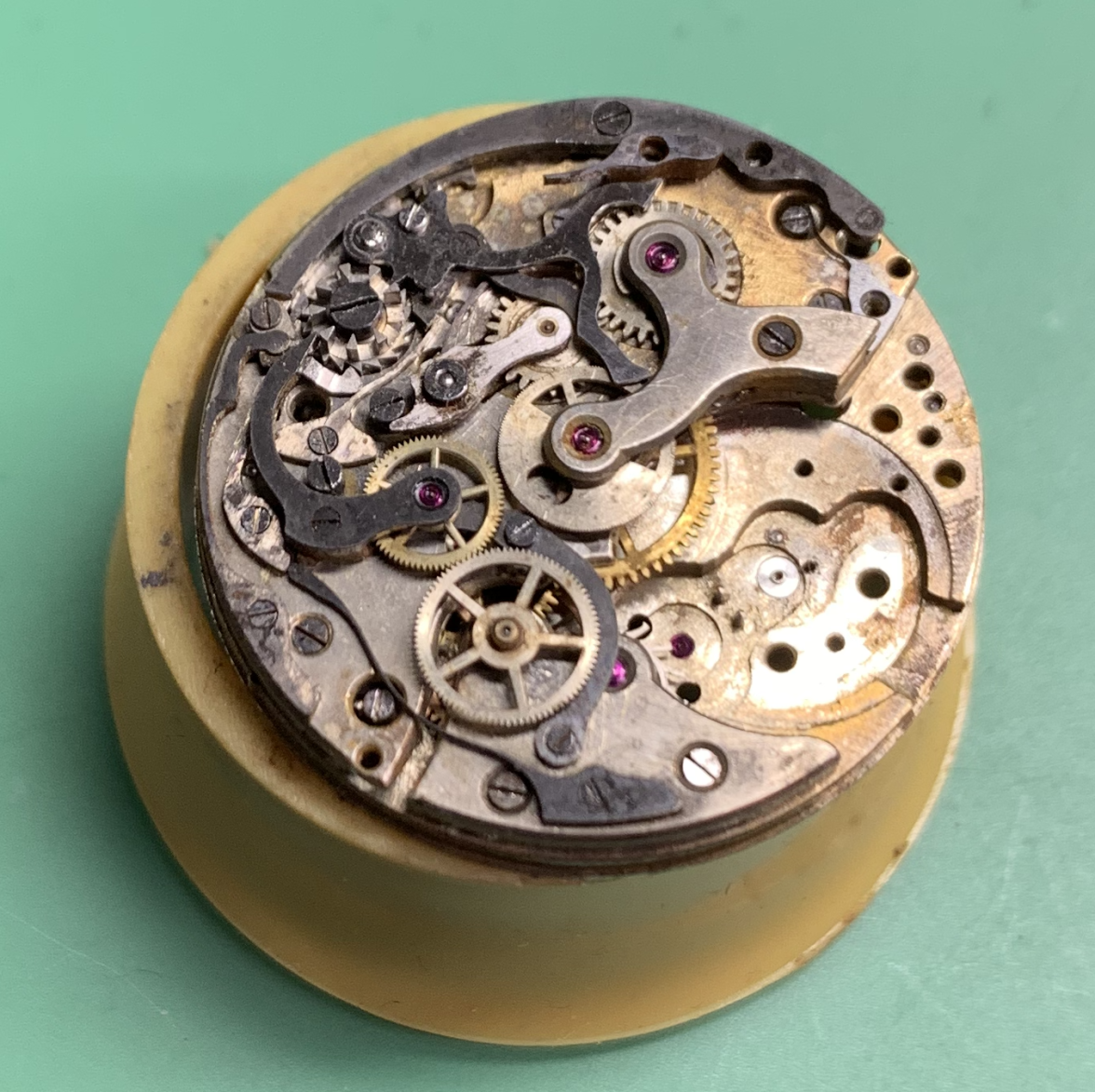

Still the results are encouraging. I also include the before photograph for those to lazy to scroll the thread or search the other threads about this disaster.

It is also interesting that the discoloration patina is not that noticeable in the after photograph. The hammer is a NOS hammer from oFrie and it seems to reflect the same as the other salvaged parts. On the whole I am pleased with the results of Black tea and Evap-O-Rust. The back of this case is missing, so If I ever do get it working I will put a display back on it.

Hard to believe they are the same watch. I see that all the pillar wheel teeth are in the before photo What can not bee seen is the rust wraps around the bottom of the pillar wheel all the way to the hammer break. All the motion works had to be replaced as the watch was pretty much rusted through. Surprisingly the stem was not affected. Looks like the leak was from the case tube or one of the pushers. As noted the hands are now shadows of rust stains on the dial.

The balance looks deceptively good in the before photo. I am really bummed out about this. What can not be seen is the under balance damage to to the pallet fork bridge which was months of work and entailed a new bridge. This damage also included some of the train bridge. Fortunately thanks to a kind person on eBay, who did not have the correct part had the needed Bridge screws.

I did get a new staff, but want more practice before attempting to stake it into the old (rusted) balance. New balances seem to be around 200USD listed give or take 50USD. Always the debate to throw more funds at this watch, or other watches that have cheaper parts. I can get AS balances complete for less than 20 Bucks.

I have also been procrastinating getting a new mainspring and spare stem. I swap the stem back and forth between the two movements to test. A new barrel plate part #105 is really needed do to wear and damage. That part is really hard to come by as it only works on VAL-72 and Val-88. It is really easy to start throwing more and more at this. I probably have about 300USD or more invested so far plus about two or three months of evening entertainment. Looks like there is another 250 to 500USD worth of parts needed. There seems to be a reason the cheapest I see scrap movements listed is about 1200 to 1500USD.

There are also parts needed for the hour recorder. Specifically a screw that connects a link on the reset hammer. The tail of this screw is still stuck in the activating lever, which is steel so I can not use Alum. The set of screws only came with the basic V23 screws

On the left can be seen the remaining screws. Unlike the top of the watch, I do not have an assembled plate like I did with the Bulova Val-23. So I will need to use photographs taken for these threads to see what goes where.

The silver lining though, Is I cleaned and lubricated the Bulova movement, and it runs. Not only that but I engaged the chronograph and it ran for 24 hours. (Something I have not been able to get the Landerons to do.) I really do like how the pillar wheel turns. Too bad the movement is a Bulova. I have a personal disdain for Bulova watches which is a lesson on how to destroy something that once had value. I must not be alone as that Bulova farm of time wasters still has not sold for a fair value.

For some reason Omega reminds me of the best of the 1960s. Bulova on the other hand reminds me of the worst. I recall not liking their advertisements. On the other hand I loved the Timex advertisements. I guess the watch gods and the Universe is trying to tell me something. But that is another thread unto itself.