Archer

··Omega Qualified WatchmakerStupid question:

Is it possible (or even desirable) to "upgrade" some/many/most movements by adding jewels/stones where the manufacturer did not? For example, can an Omega 1861 movement be made into a 21 or higher jeweled movement and would it improve any performance measures?

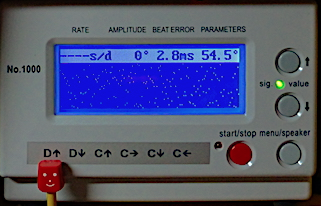

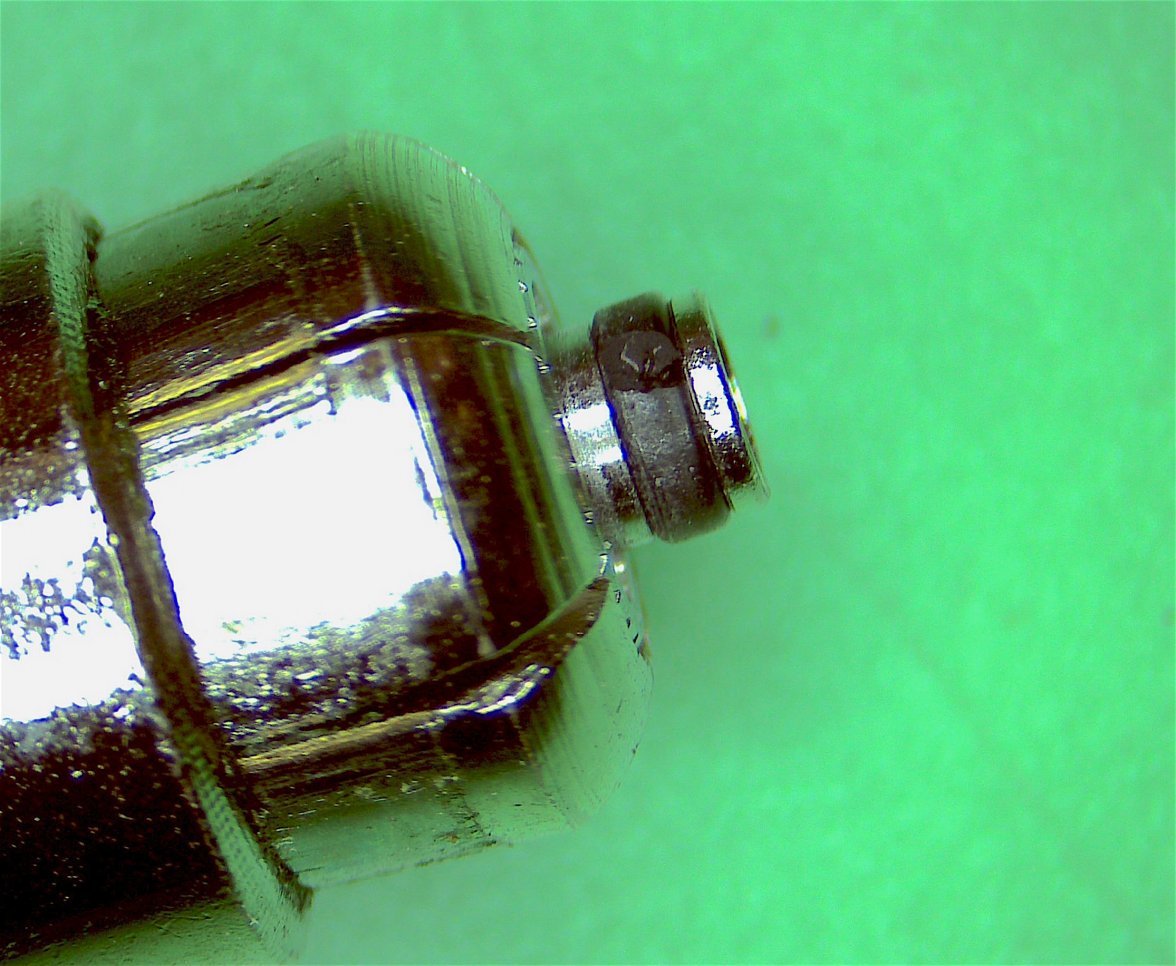

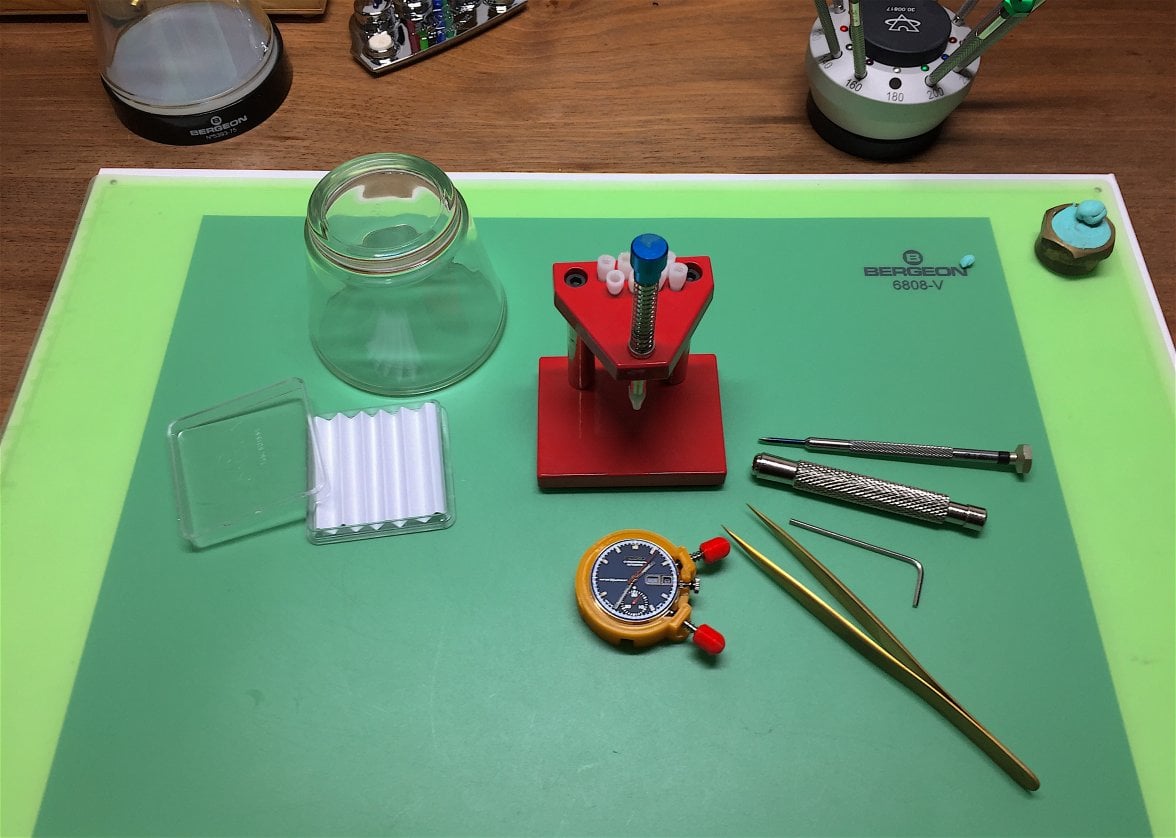

Yes it's possible, but it would depend on the specific situation. For example there would have to be enough material surrounding the existing hole to enable a separate jewel to be installed, so if you look at the 7750 main plate above where I have added a bushing, I had to ream the hole large enough that there isn't a lot of material left to seat the bushing - jewel might be larger on the OD, and in that case it would be iffy trying to put a jewel there.

On the 861 that I have shown, the barrel bridge is often worn in this location, and on the new 3861 they have added jewels foe the barrel arbor in both the main plate, and the hour recorder bridge. To me this is a worthwhile upgrade, as I bush these very frequently (will be doing another one today). But it doesn't have to be a jewel - even putting a bushing in is a huge step up from just making a hole in the plate. I use bronze bushings, so they wear much better than the soft brass plate does, and if it already had a bushing this would be 30 seconds job to replace it, instead of me having to spend 15 minutes.

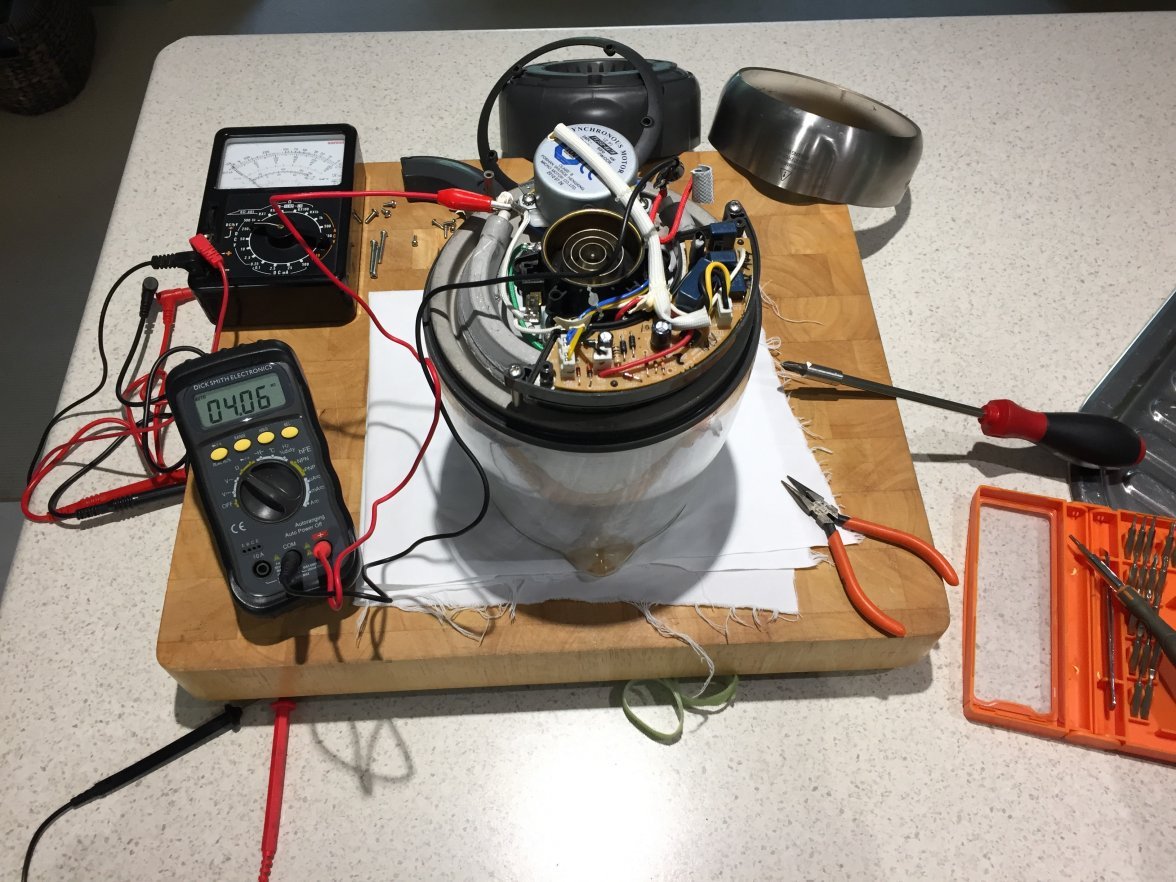

In this case there is no pure "performance" gain in that the watch won't run better with a jewels for the barrel arbor than it would with a new main plate with an unworn hole. The only time the barrel arbor moves in these holes are when you are manually winding the watch. In an automatic watch like the one Jim is working on, reducing friction here can assist the automatic winding in keeping the watch wound - most Seikos are very efficient anyway, so not sure it is a huge performance boost.

Jewels in other areas may improve the performance. With a lot of old American made pocket watches, they came in different grades with different jewel counts. If the jewel count was low, say a 15 jewels version, it would often require a much stronger mainspring than say a 23 jewel version, because there is more friction in the 15 jewel watch. So the brands would make mainspring of differing strengths that would be used for the different models. If you have more jewels it can reduce the torque required, allowing a weaker spring, and less pressure on all the working parts - this can mean better performance and longer life for those parts.

If I were designing the new Speedmaster movement, I would add jewels for the barrel arbor as they have done. I would then add jewels for the center wheel, so on in the main plate and one in the main bridge - these are currently just holes in the plate with no jewel or bushing. You could go on to add jewels in other places, but I don't think they would give you much benefit, and in some cases may cause problems.

Cheers, Al