We are getting off-topic, i apologise to Jim, but are there small CNC that would be useful for this? I am thinking with an overhead camera to locate and set positions.It would make the location setting easier, and after time you would have a pre-set coordinates to use. Load, punch in and go?

Hopefully Jim doesn't mind the slight diversion...it is related to his work in a way...

Doing this with hand tools at the bench that I already own would be the better option. I don't have, nor do I want to buy a CNC machine of any kind, and since it's probably been 30 years since I last programmed one, I don't really want to spend my time learning all those G-codes again to be honest. Maybe if I show how I do one bridge now it will help explain what I am working on....this is an 861 Speedmaster movement:

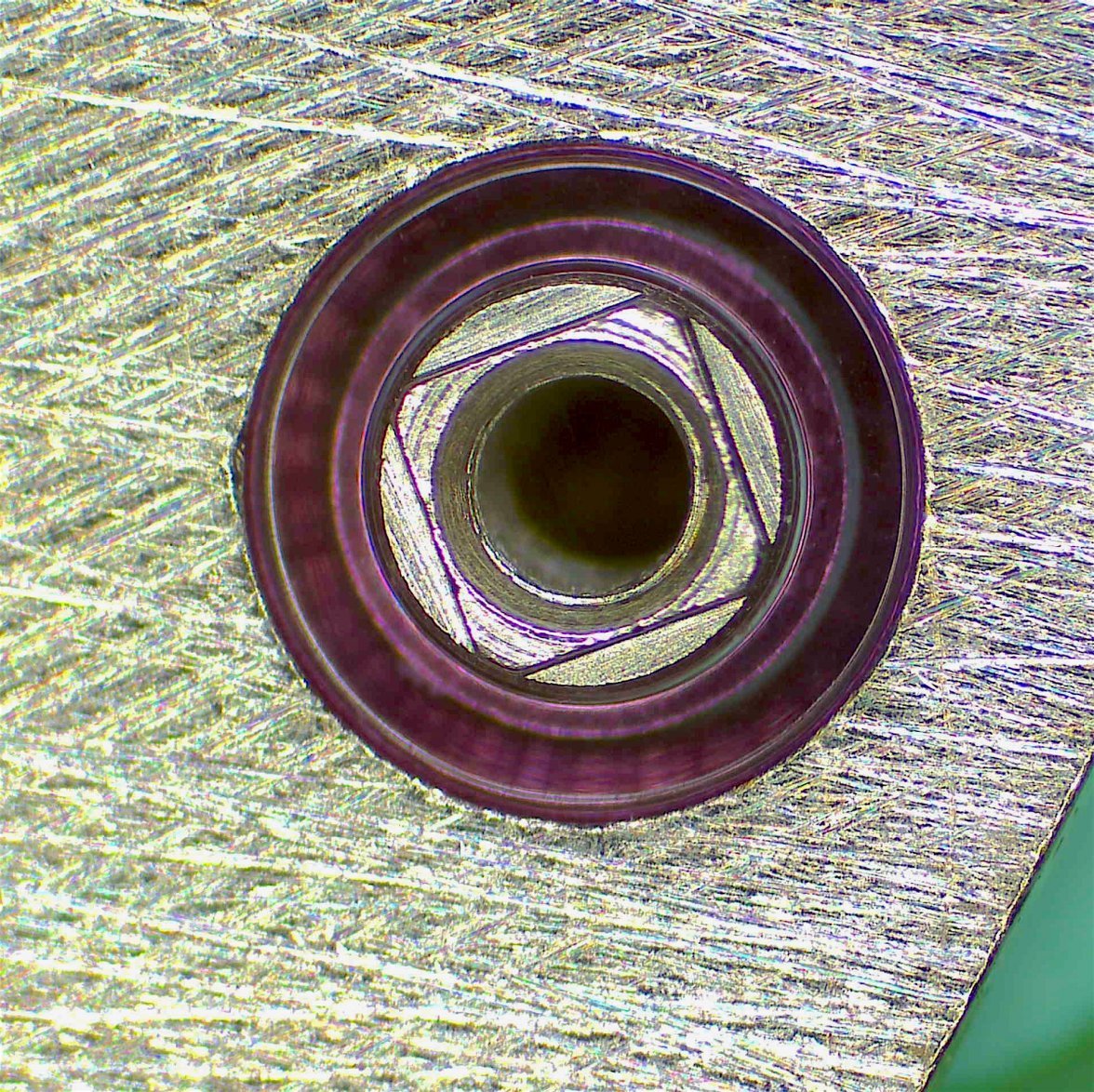

The barrel arbor (steel) rides in a simple hole that is made in the large barrel and wheel train bridge (brass) but the arbor doesn't go all the way through the bridge - it's maybe half way. When the soft brass is worn away, the resulting hole looks like this:

Since only a portion of the hole is worn oblong, I can use the unworn portion to ream the hole larger for a bushing, without doing any centering on a lathe - the good part of hole will keep the center of that hole if I ream from the top of the bridge using my Seitz tool, like so:

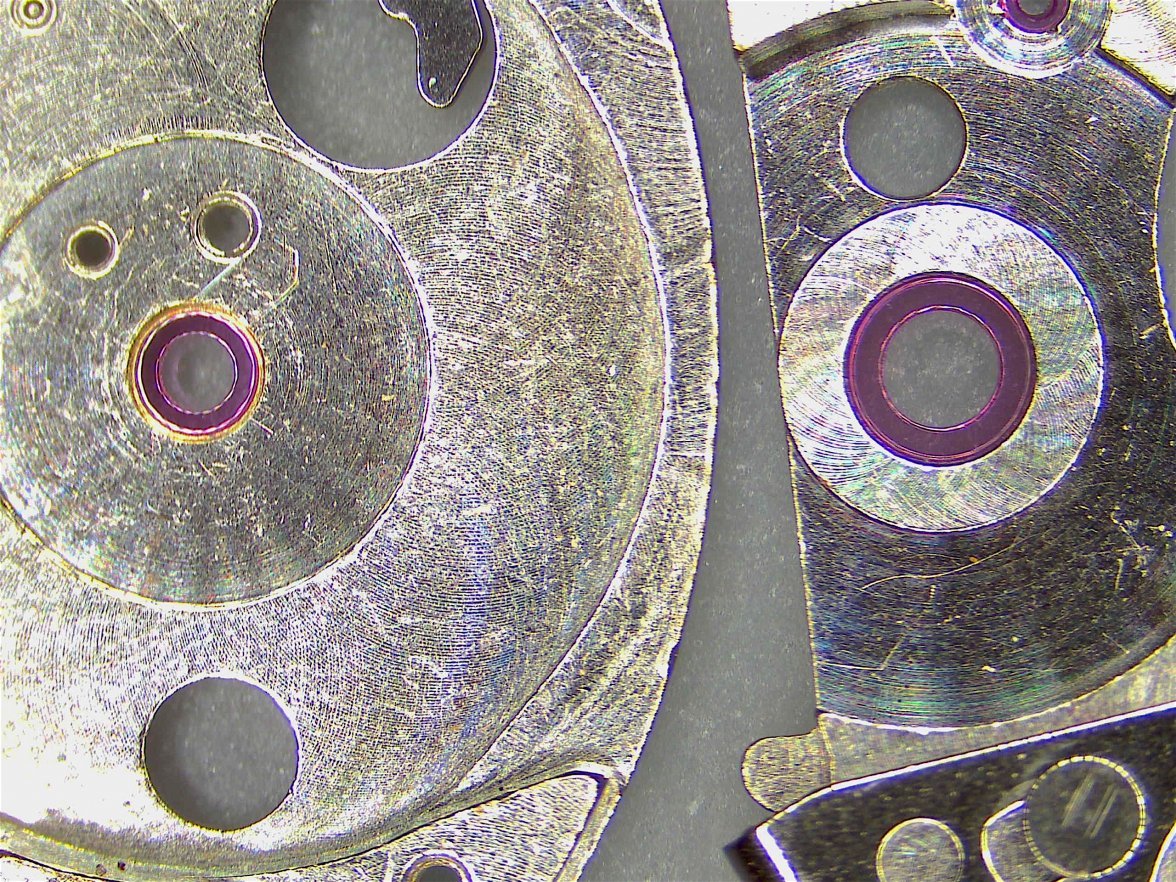

Once I've reamed it large enough, I press in a bushing using the Horia tool:

That bushing is then reamed to the exact size required for the barrel arbor:

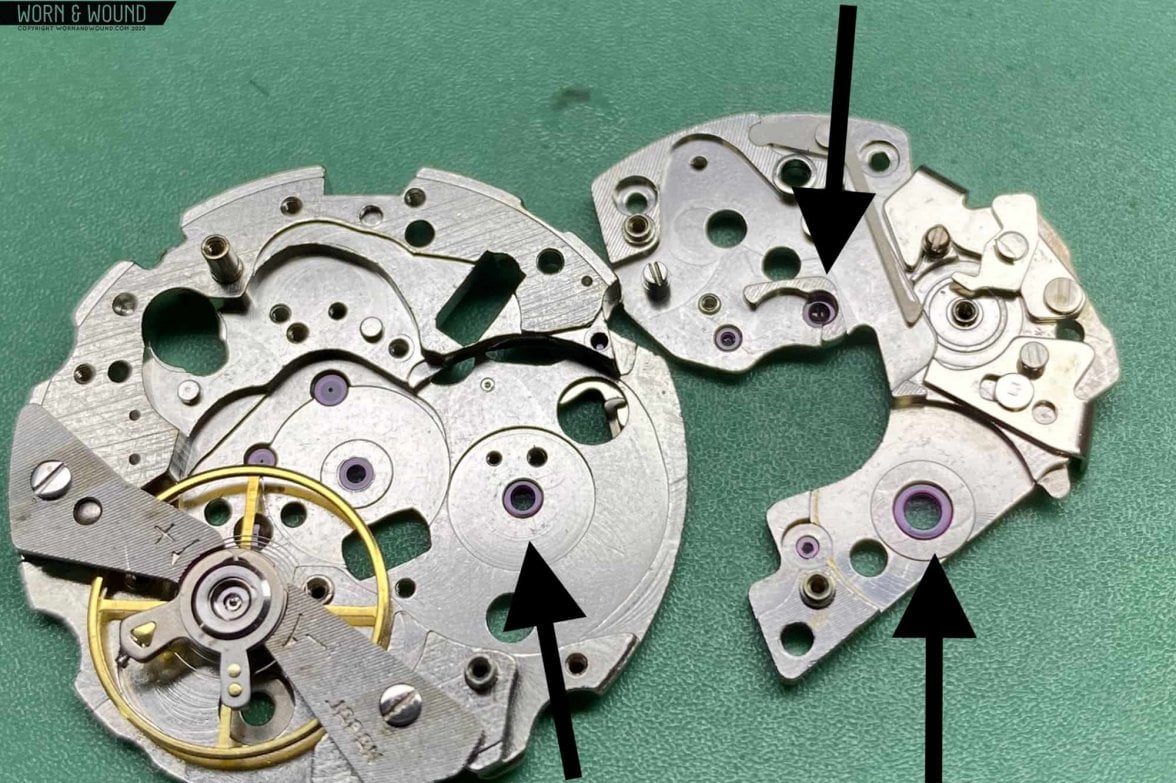

Here it is in the movement being assembled again:

The whole thing isn't visible due to other parts for the chronograph:

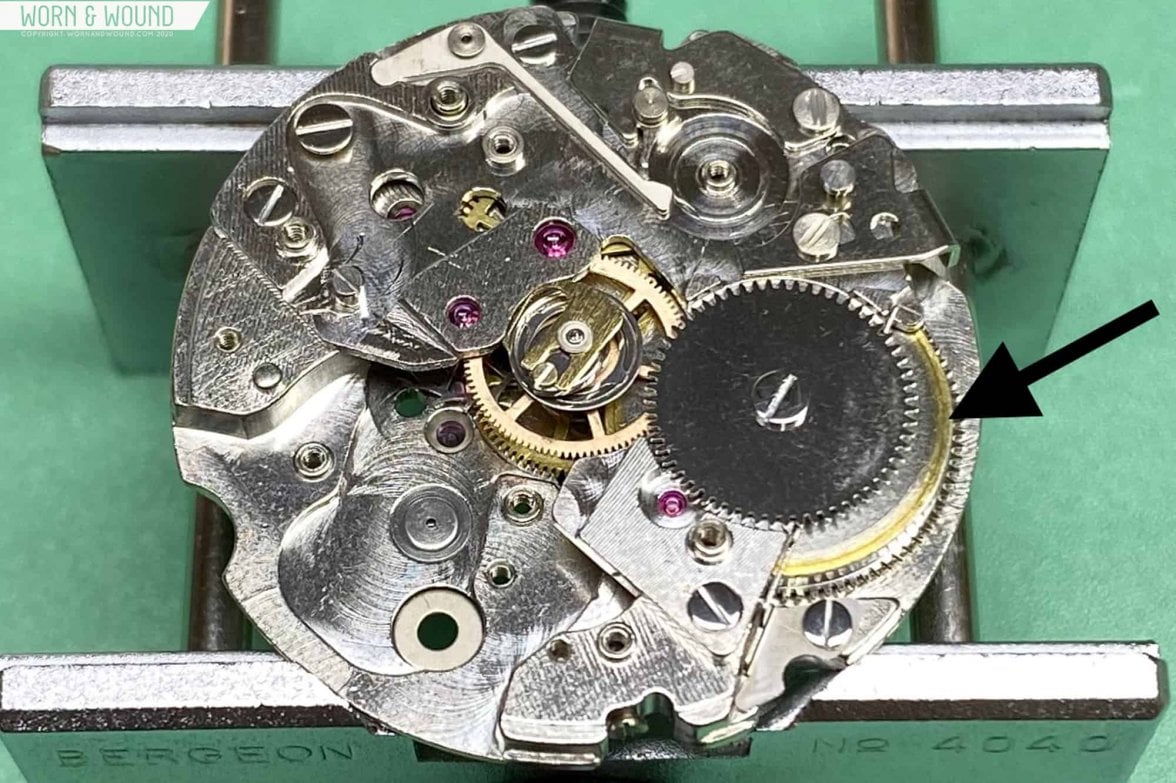

This is a repair I do all the time on vintage 861's, and even on some 1861's. This process is very quick and accurate, and I'm looking to duplicate that sort of ease at the bench by making a small locator that fits in the base of the Seitz tool shown above. So here is what I've done so far - I've machined a locator with very close tolerances to fit into the Seitz tool, and to fit the hole in the main plate of the movement. Here it is in the base of the Seitz tool (this is near my lathe where I was turning this locator, so it's a bit messy):

Here is the barrel bridge I need to bush the hole - it is mounted to a brand new 7750 main plate, so the smaller hole you see through the bridge is in perfect shape, and will be used to locate this assembly for reaming:

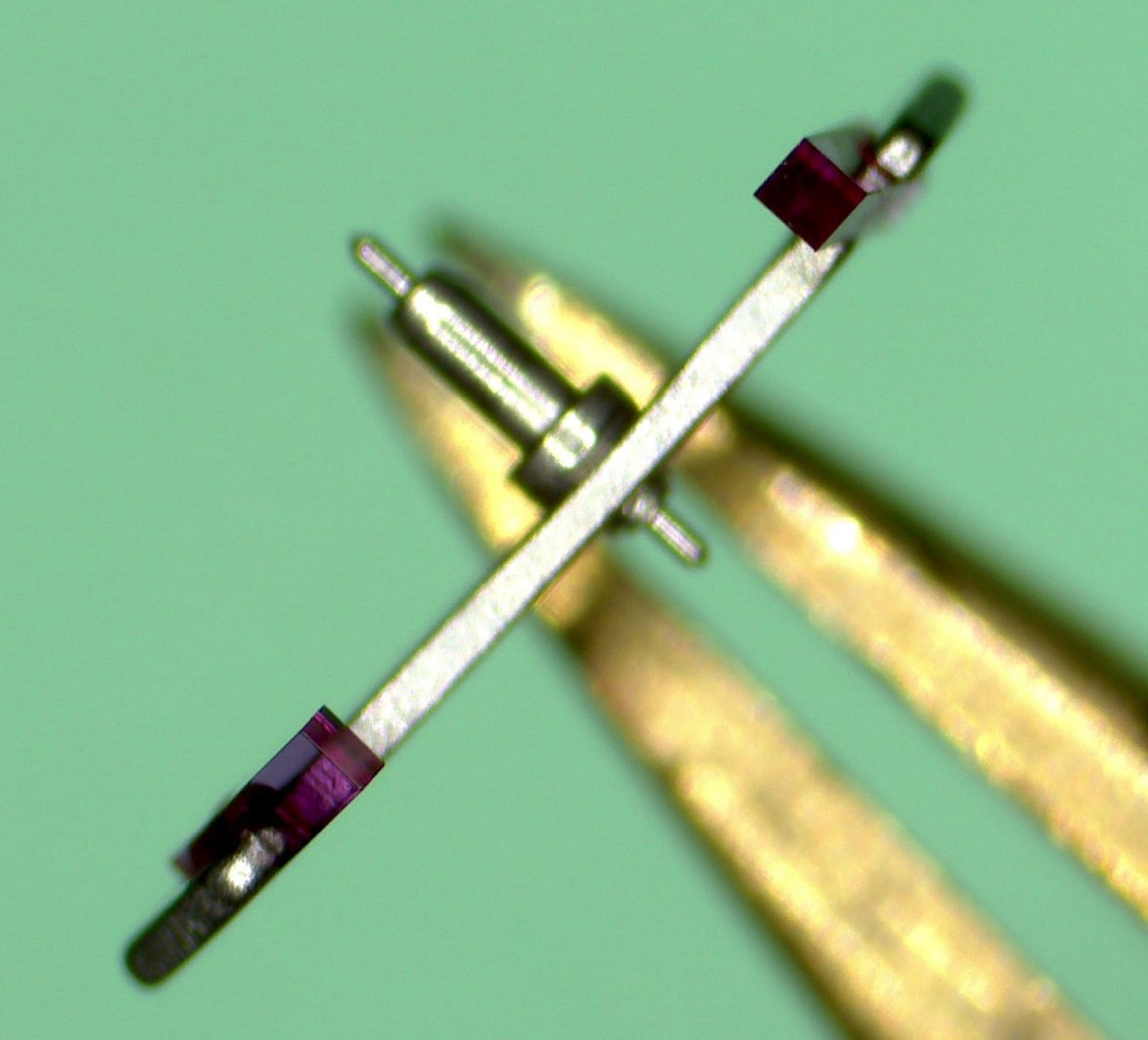

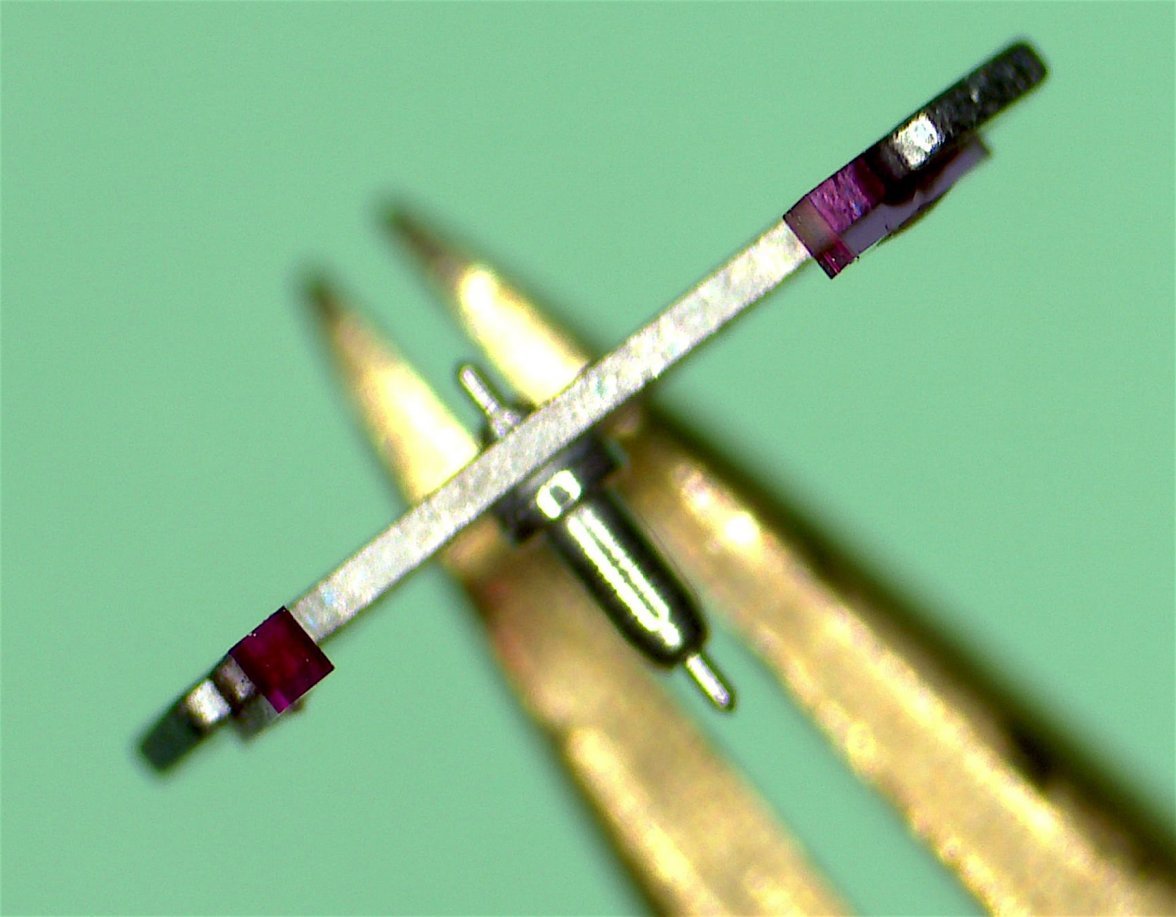

Here it is mounted in the Seitz tool - the only issue is that the reamers I have are very tapered, and long, so they bottom out before cutting the hole in the barrel bridge:

Once I'm able to get some spares in to cut down, I'll be ready to give this a try. Once I know it works, I'll simply turn locators for other applications. The first one will be one for this 7750 barrel bridge, so I can invert what you see here and install a bushing in the main plate. If it works, this will be as quick and as accurate as the Speedmaster bridge, and will save me a lot of time.

Cheers, Al