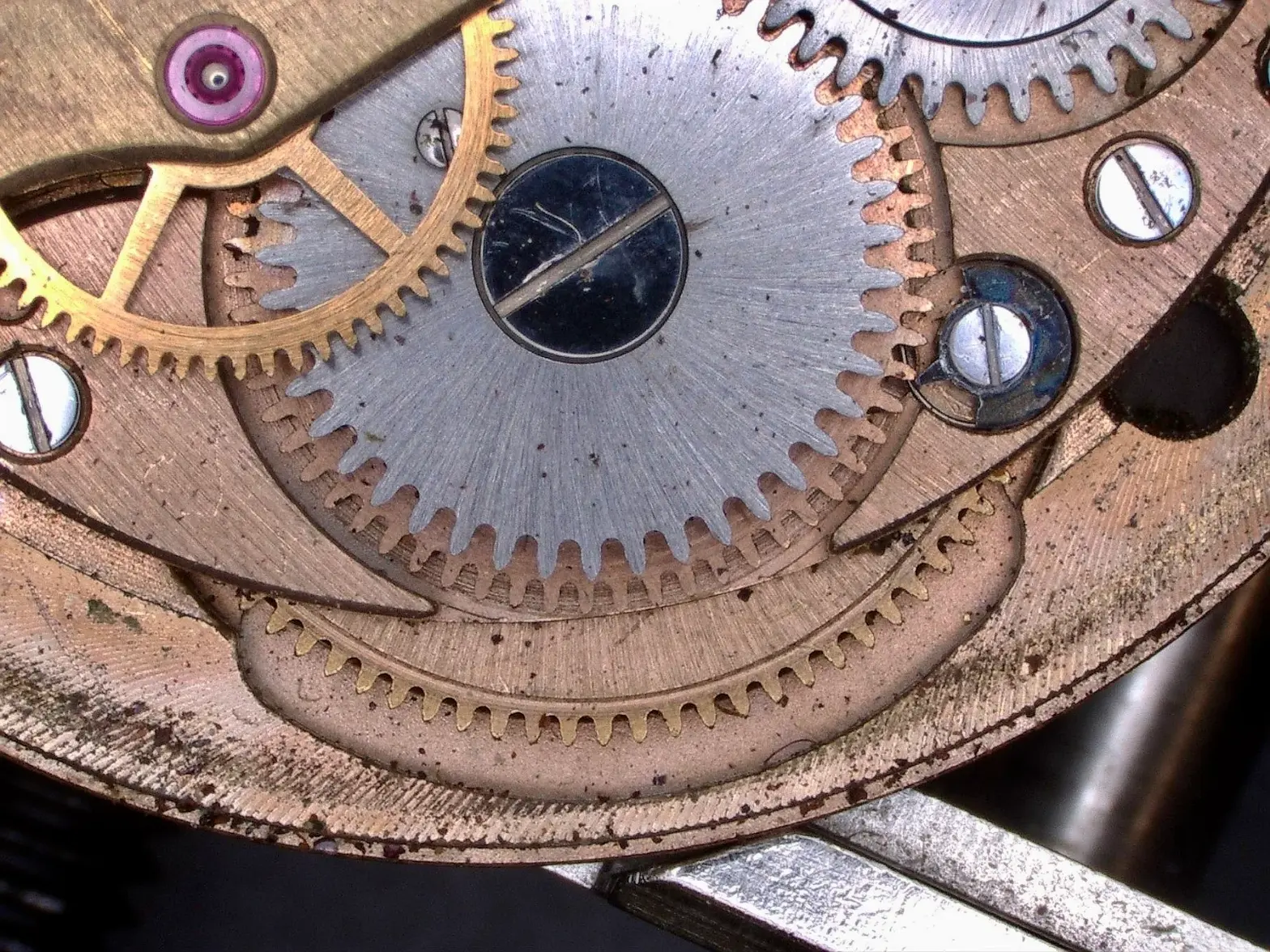

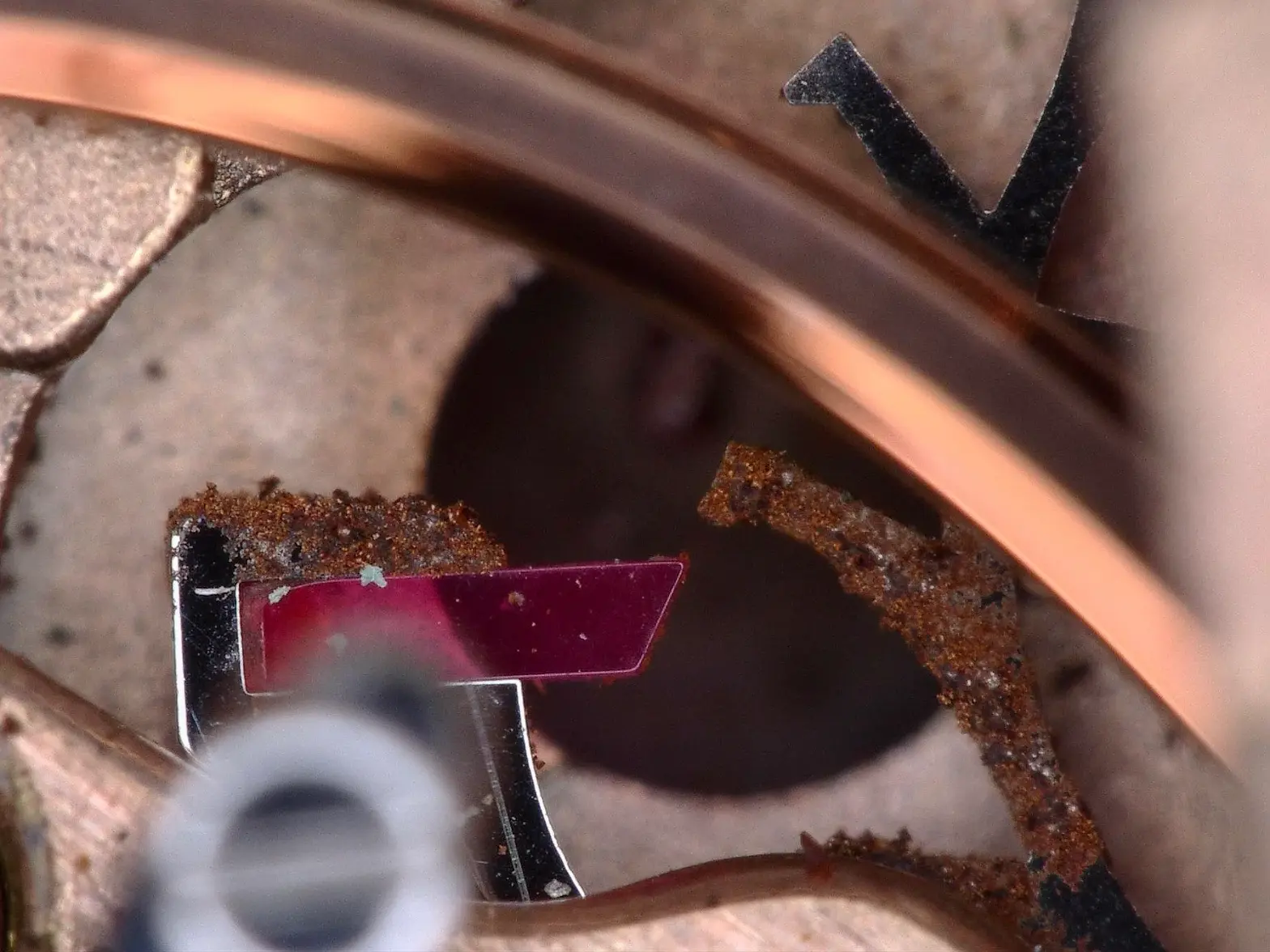

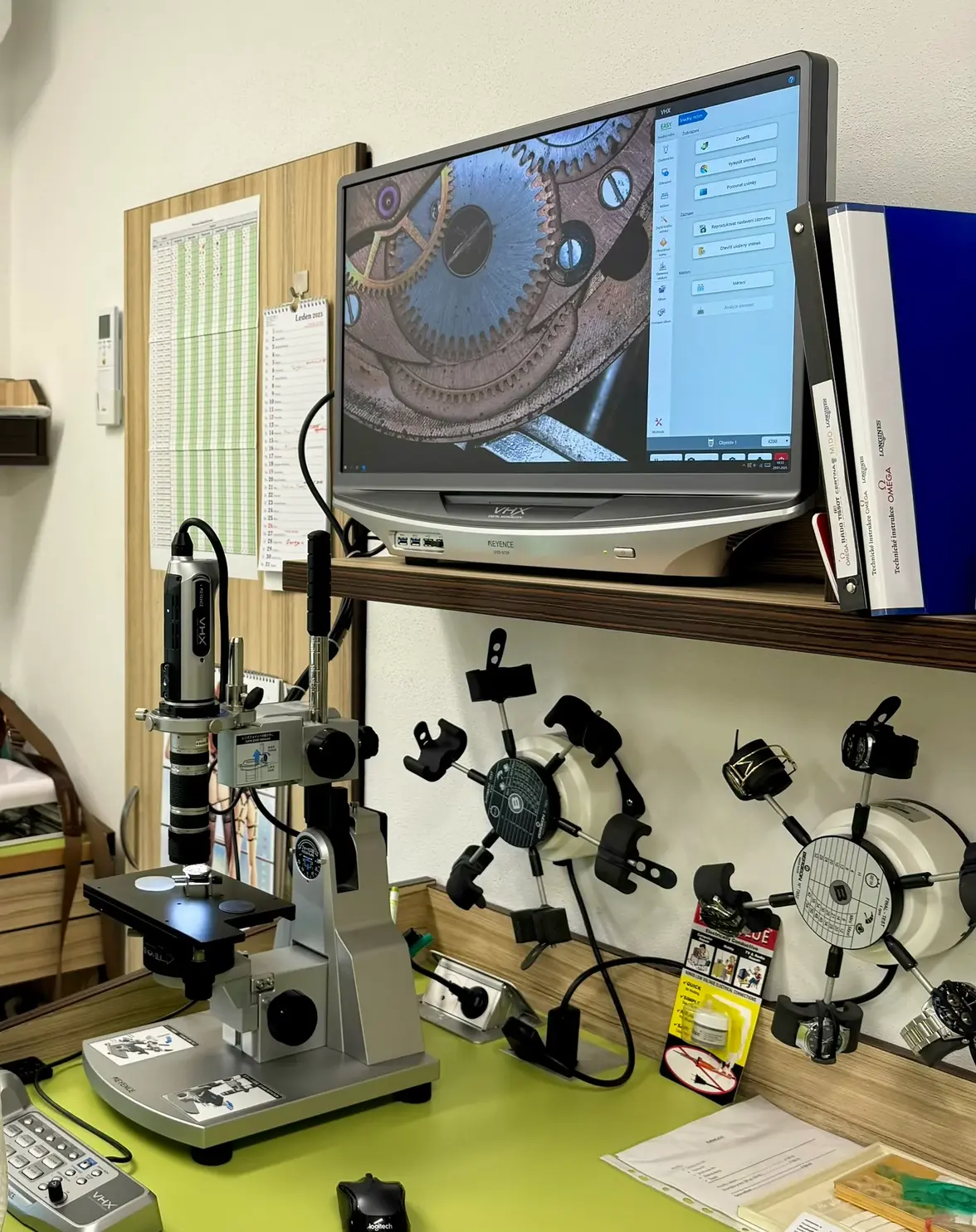

So, it has arrived, I had not much time to spend dealing with it so far, but...first impressions: this is how looks a never serviced watch, spending whole life near the sea.

The movement runs, but stops quite fast, which is expected. The bezel was completely frozen, but I was able to remove it and clean it and working as new now.... .

Congratulations!! These models are a favorite of many collectors.

..what would you do with it? If it was not corroded, I`d keep it as is, as the case is quite straight, but now it seems, that some laser welding will be necessary anyway...

It would have been beneficial for you to have asked for more photos from the seller before pulling the trigger!! You could have posted your question to the forum with some of those photos to get better pre-sale advice before sending the funds. More knowledgeable members here have helped me in the past avoid making regrettable costly mistakes.

It would have also been a good bargaining strategy for you to compensate for the laser welding that you are intending to do ( which isn't cheap and you will always risk introducing other problems when laser welding - especially 18-8(10) / 304L stainless steel) .

Whenever I buy a watch regardless of brand, especially stainless steel,

I always ask for photos of where corrosion and pitting is expected such as between the lugs, under the case back seals and mid case where the 2 mating metal parts can trap oxidants ( salts and sweat residue for example) which feed corrosion. Once corrosion begins ( breaking of that SS passive layer)), it cannot be stopped and you get a chain reaction just like rust on normal iron.

Personally, any stainless steel watch I ever had in my collection, the very first step I always did was cleaned the case back sections and used a coating such protectaclear or clear nail polish as a coating to stop anything trapped between these mating areas attacking the stainless steel passive layer which cannot be cleaned regularly like the rest of the exposed case.

Stainless steel is good for utensils and kitchen appliances, pans spoons etc as you are always washing them clean to avoid any oxidants damaging the passive layer of stainless steel. Watch cases should also be cleaned the same way to keep them from corroding

BUT that is not always possible as they are

not all water proof.

Prior to 2014, I have worked with stainless steel metallurgists for almost 27 years and have been exposed to quite a lot regarding different grades of stainless steel corrosion and it is a complete science all to itself ( Avesta - Sheffield Outokumpu laboratories in Sweden)

As others have suggested to you, I would not overdo it and would keep everything in line with how it blends with the dial ageing.

Most importantly, enjoy the watch in good health!!!