Here are the full-wind numbers...

Fully wound at 4:08 CST Friday 11:29

Measurements starting at 4:53.

DD +2 s/d 298 deg 0.0 ms

DU +2 s/d 294 deg 0.1 ms

PD +23 s/d 260 deg 0.1 ms

PL -1 s/d 260 deg 0.0 ms

PR +7 s/d 262 deg 0.1 ms

PU -13 s/d 261 deg 0.1 ms

I assume the -13 to +23 isn't ideal

😀

But the numbers seem pretty good to me (not really knowing what to expect).

I assume the variance in the vertical positions indicate a heavy (or light) spot in the rotating (oscillating) mass?

Should the 24 hour numbers be taken 24 hours from the wind? or 24 hours from the first measurement?

-Paul

Sorry - had some surgery this week, so not posting much as I recover...

Anyway, seeing these numbers, they actually fall within Omega's accepted tolerances for this movement.

For the Cal. 266, the tests at Omega are only done over 3 positions, and the average daily rate should fall between -1 and +16 seconds per day at full wind. Your watch has an average daily rate of just under 3 seconds, so that's well within tolerance.

The Delta (positional variation) is allowed to be as much as 40 seconds at full wind, and 50 seconds 24 hours after full wind - remember this is only over 3 positions, and the larger number of positions you measure, the more difficult it is to keep the Delta number low. Your Delta at full wind is 34 seconds, so it meets the standards. Your Delta gets better at 24 hours after full wind, so again well within Omega's tolerances.

So what does this tell us? Mostly that Omega has very loose tolerances for these movements, and why I personally use them just as a starting point only. But overall this is a pretty good result for a watch of this age and with an inexperienced repair person. Often these movement have worn holes in the main plate and barrel bridge, worn out barrels, worn wheels, and all these lead to low amplitudes and timing issues, but none of that is present here, so I can pretty safely assume that the movement is actually in very good condition, and is not really worn out. So if that was all you had to report, I would say job well done.

Now about the strange noises, increase in beat error, and reduction in amplitudes, this is unusual. All I can say is that you need to observe what positions this happens in, and see if anything is rubbing, such as the overcoil of the balance spring contacting a wheel for example.

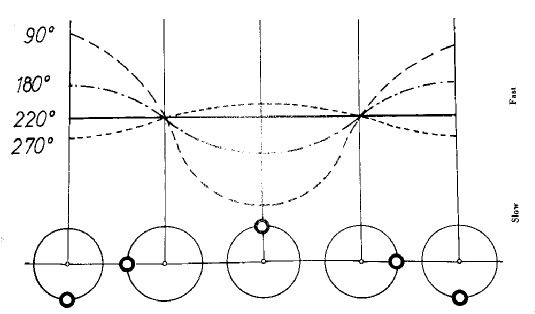

Until you sort this issue out, then set aside issues of poise and timing, because you need the fundamentals to be absolutely perfect before you move on to that process. Many things that may appear to be poise errors can be errors in the shape of the balance spring, so that in particular has to be absolutely perfect before you move on - you don't want to correct errors in the balance spring by messing with the poise, and that is a trap many inexperienced people run into when they learn dynamic poising as it becomes the "go to" solution for every vertical timing issue. It's like when the only tool you have is a hammer, everything starts to look like a nail...

You might also want to look for something like debris in the teeth of slower turning wheels, or perhaps a bent or damaged tooth. Ideally all these would have been inspected before assembling the movement, so you don't have to take it apart again, but check the barrel teeth for defects and the center wheel teeth in particular, since this sounds like a very intermittent issue that could be related to slow moving parts.

Regarding the "almost no wind" readings, these aren't really used unless you have already detected a poise error and are doing something about it. You don't need these readings to detect poise errors, as they are typically very evident in the full wind timing numbers, but low amplitude numbers (below 180 - I usually use readings in the 160's in vertical positions) to locate the heavy spot during dynamic poising. They may be usefuly for understanding how things change with poise errors and if the balance is accelerating or decelerating as it comes into and out of the lift angle, but they aren't used as a normal set of readings done in timing checks.

Let us know what you find with that noise...

Cheers, Al