PaulHelmuth

·Related question (about alternatives to waiting on a spring from Cousins).

@Archer - Hear you loud and clear. 👍

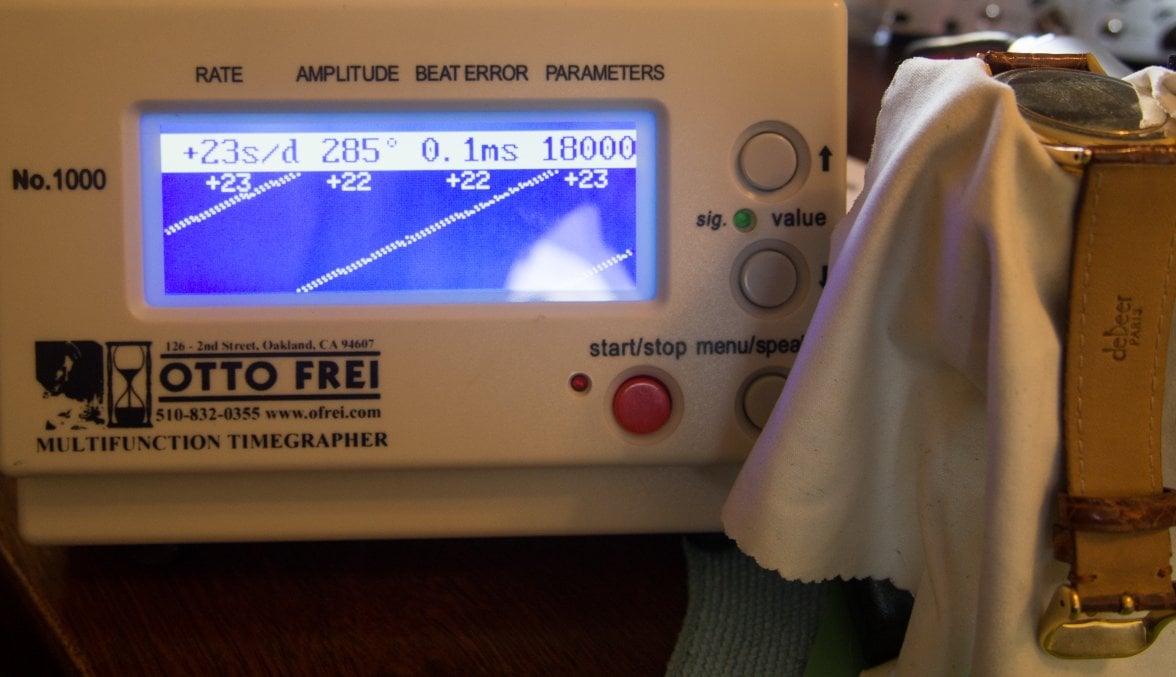

So, if I may ask a related question. I mentioned that it appears to me that the watch has been serviced in reasonably recent history. I saw no signs of trouble with the existing spring - or the barrel (the spring lays nice and flat with no kinks or unusual bends). If I wanted to use the current spring until the next service, what procedure would you recommend for cleaning and lubrication? Mostly thinking about the lubrication.

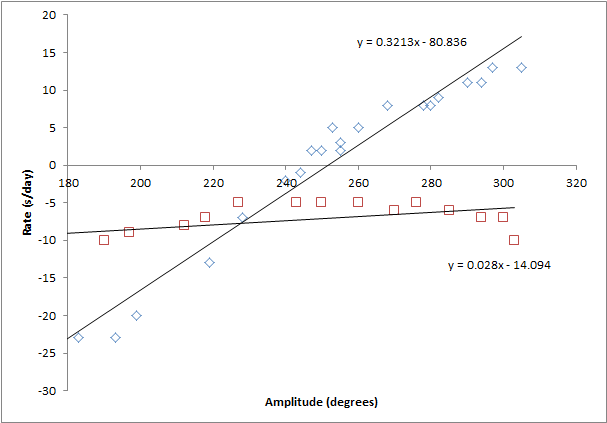

I can't tell you what to do, but if it were me, I would wait for the right spring. Keep in mind these are older movement, parts are likely worn slightly, and even with the right spring you may struggle to get amplitude. If you put in a spring that you know is already weak, then you are certainly not helping yourself.

Thickness is the least tolerant to change of the three mainspring dimensions. you can often get away with one where the width might be slightly less, or the length ay be a bit long or short, but strength is the one you don't want to compromise on.

@Archer - Hear you loud and clear. 👍

So, if I may ask a related question. I mentioned that it appears to me that the watch has been serviced in reasonably recent history. I saw no signs of trouble with the existing spring - or the barrel (the spring lays nice and flat with no kinks or unusual bends). If I wanted to use the current spring until the next service, what procedure would you recommend for cleaning and lubrication? Mostly thinking about the lubrication.