I haven’t done this for the new exchanged 3861 (call it 3861W standing for “wide”), since it’s already dark when I got home.

But before heading to the AD I took these pictures for my 1863 sapphire case and the first 3861 (Call it 3861N standing for “narrow”):

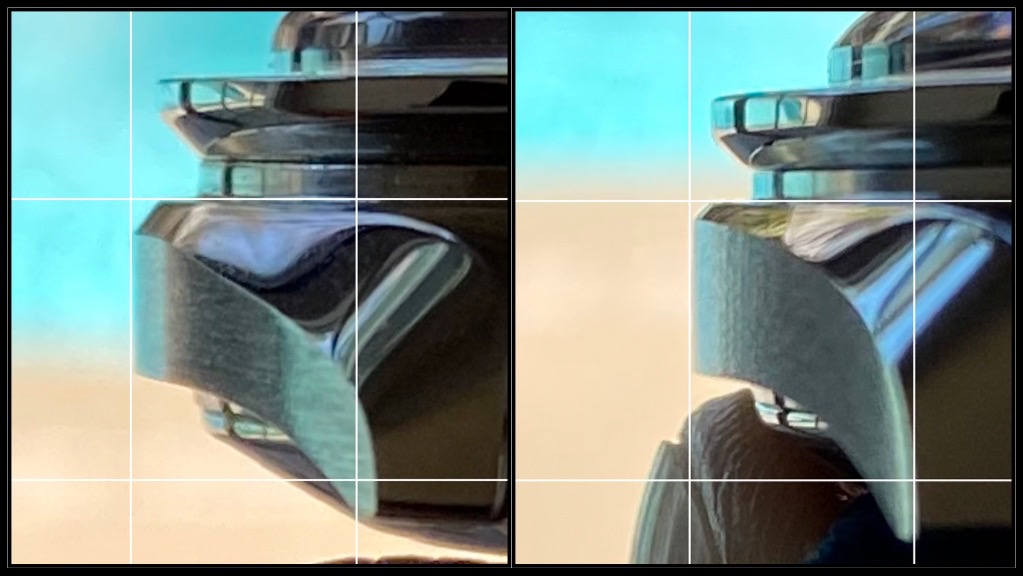

I processed them trying to capture the case side profiles. Sorry the angle and proportions are slightly off as they are not taken in an controlled environment. But I think it still tells something about the bevels.

My theory is as follows:

1. The outer edges of the case side in both should extend out of the bezel edges to a similar length, making the case diameter the same 42mm.

2. Think of the square metal block before cutting the bevel, as indicated as the grid lines, the “cutting” of the bevel actually is steeper in the 1863, removing more metal. The 3863N case actually keeps more metal.

3. The “starting point” of the bevel on the topside actually extends out slightly on the 3863N case.

4. When it comes to potential future polish tho, the 1863 case is still easier because it only need to shave the vertical outer side of the case. There will be room of bevel above for it to cut in. The 3863N case can still take a polish, but since there’s not much room of the bevel, it’ll need to work on both surfaces: shaving the vertical side, and also re-work on the bevel, which could be difficult but there’s metal on the topside to do that.

Just my theory. Will attempt the same picture for my new 3863W when I get a chance.