rob#1

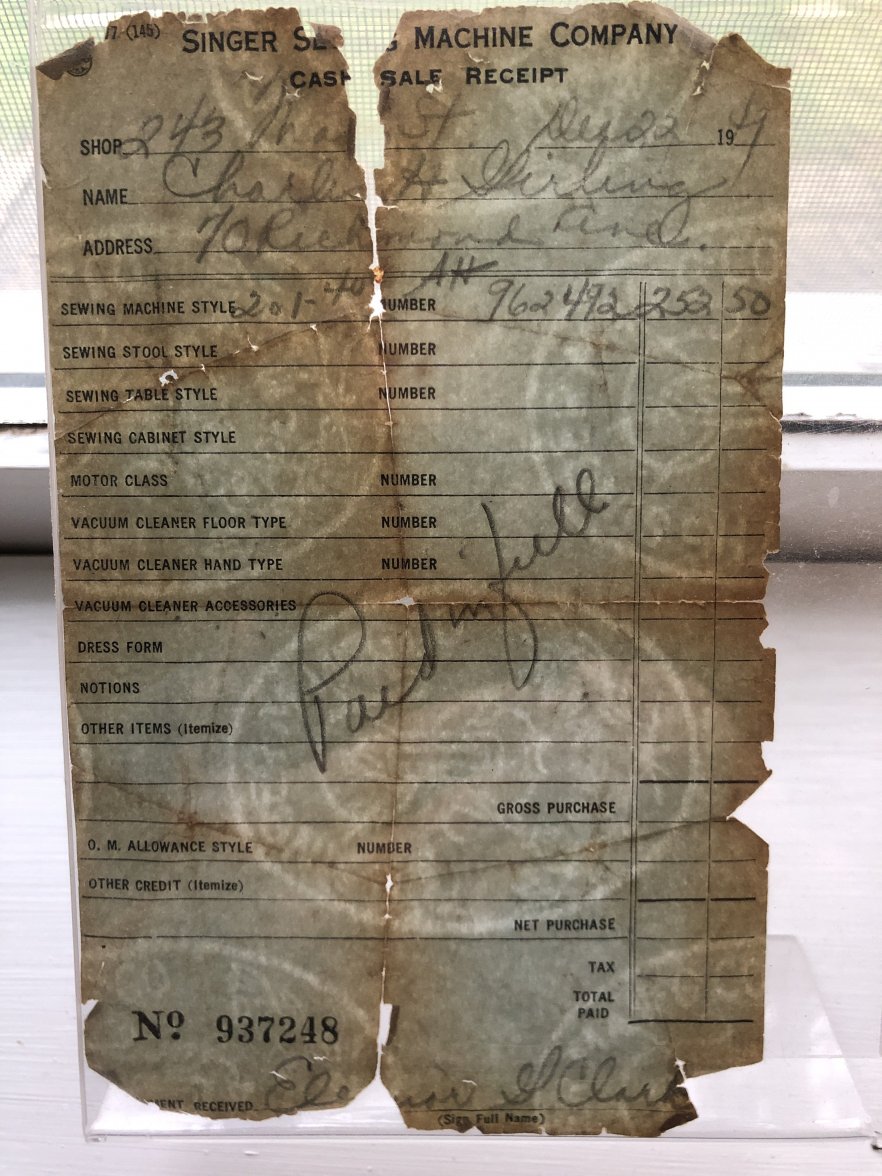

·A while back I was at a thrift shop and picked up this nice wood display case for a corkscrew & wine-stopper kit for $3.99. The corkscrew and wine-stoppers were of surprisingly crap quality, and went in the trash. The case though, this is what I was after, and it was easily 10x superior in quality to the contents. And this is weird, who sells a crap product but puts it in a nice box? Anyway, I’m glad they did. I got home and put the case in the freezer for a few weeks, as I do with anything else that I drag home from a thrift shop.

Wait... what 🤨

A bit of backstory. Vancouver is a lovely place, and so many people want to live here. Unfortunately, bed bugs also love it here, in vast numbers. They come for the sunsets, lattes and yoga pants, I suppose. With that, all 2nd-hand acquisitions get the deep freeze, just to be safe. 👍

Anywho, with much more spare time on my hands lately, I pulled the case out of the freezer and set to repurposing it to house my small, sharp, and pricey leather working tools. With a bit of time, a razor and some pluck-foam, I was very happy with the results 😀

Before

After

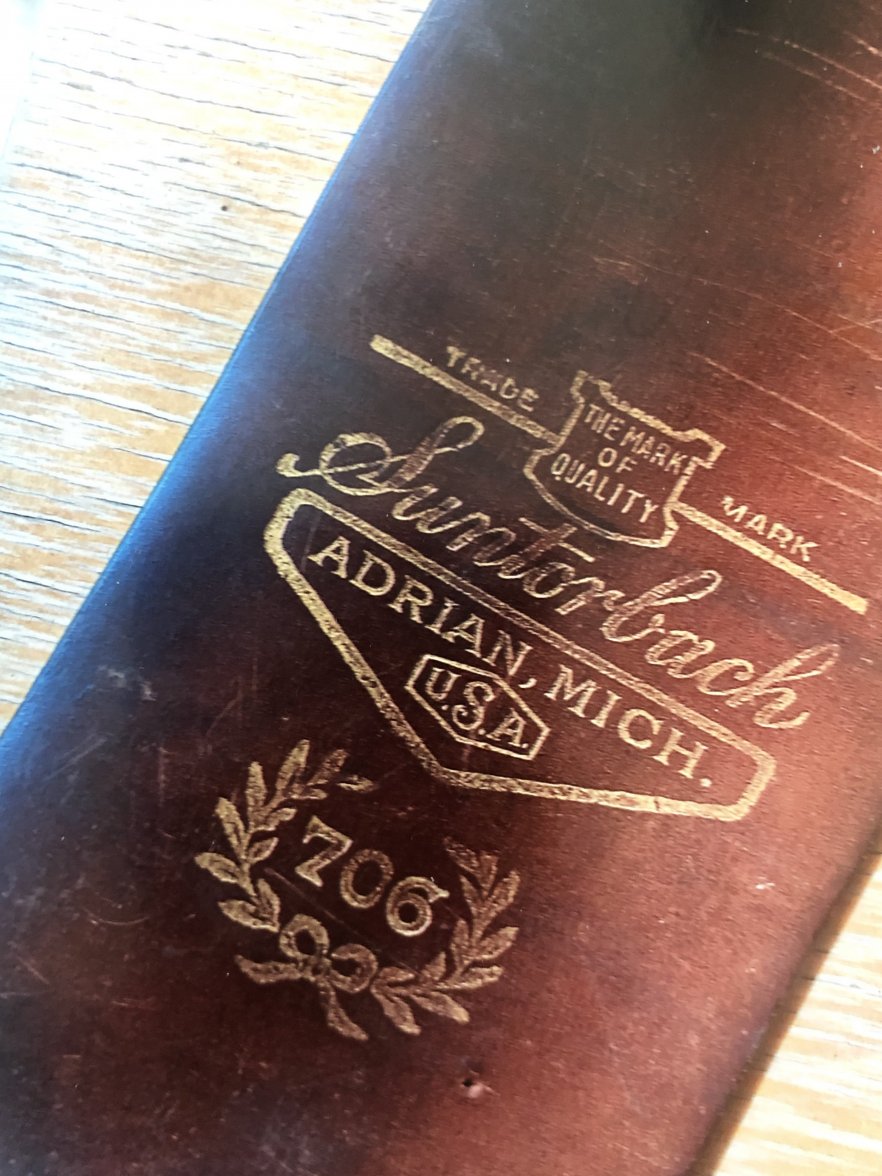

And next, a silverwear box will become home to other bits and tools

Keep entertained and healthy everyone

Very cool, though your hairdressing implements look a tad different to mine 😗