eBay parts I ordered before I got

@ErichKeane 's project watch ...

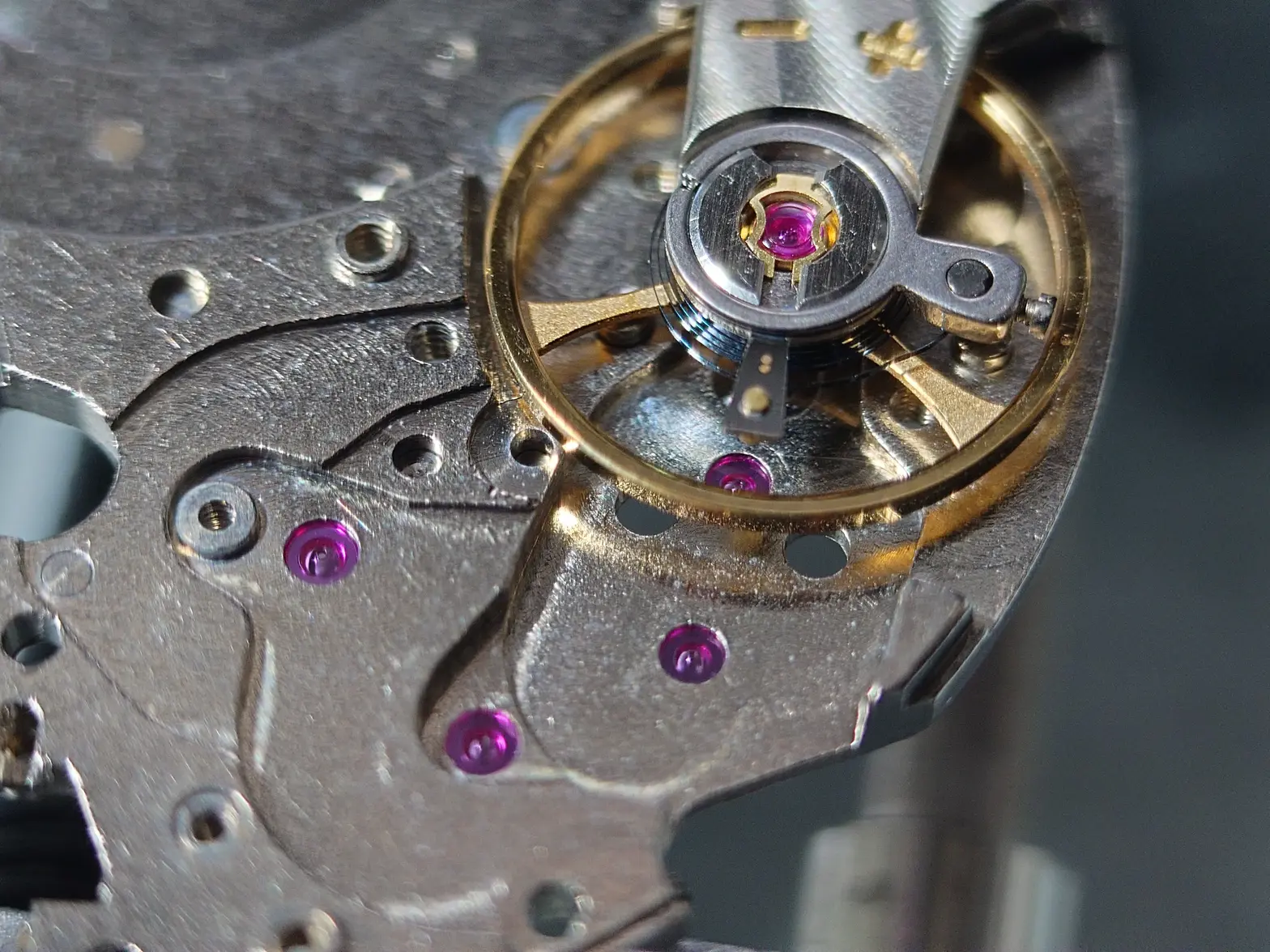

these were advertised as 550 parts. Most are actually 33x parts. I suspect the bridge marked 24 jewels and the set spring are from a 563. The forks and bridges are from the old collection -- these were out as I was trying to see if I had a set of 33x/34x wheels or 55x wheels. They are 33x subseconds wheels. This gives me another set of tick tock parts for one of the 342 plates.

Balance hairsprings remain in short supply. For some reason I am missing a bunch of 33x barrel arbors. Barel cover seems to be from 33x.

Of all the parts though the 55x rotor gib is the most useful, as for some reason I am short rotor gibs and these tend to list for the price I paid for this set.

The 33x pawel bearing bridge is the best bonus, as I managed to lose and still have not found the missing pawel screw. I had ordered the 350 winding ratchet wheel to replace the rusted one. What I lost the first screw from.

Screws are a mix of 55x and 33x. Always interesting how one finds up with extra screws that never seem to fit anything.

With What I got from Erich and these parts I probably have enough for 4 movements sans hairsprings. Ignoring that these are missing the lower rotor jewels.

should figure out the tool for dissembling the 55x 1464 winding wheel set. These came disassembled. I have one from the rust rat what is frozen solid even after a week soaking in siliKroil. These are not much use as the little nanoscopic star wheels were not included. The big winding wheel is also a nice bonus. The one on the rust rat has a huge chunk missing that turned to dust. Curious how, looking for those parts lead to finding this massive hoard of 33x parts. Why is it we can never find what we are looking for, but always seem to find other lost stuff?

Only one of the 7 35x canon pinions is in frame. Learned that 34x cannon pinions are slightly smaller so they are not interchangeable, even though both are drilled through. The 7 are also of different heights. So like 55x base calibers 33x also have different height dials.