I’m 100% confident that I will damage whatever I touch.

😁 I’ll spare these for now. Most of the tiny movements I have are actually nicely finished Bulovas and a couple Hamiltons I don’t want to ruin either. I’ll probably start looking for some cheap pocket watch movements on eBay again. Maybe I’ll just start using my practice movement sooner than later. They’re relatively cheap.

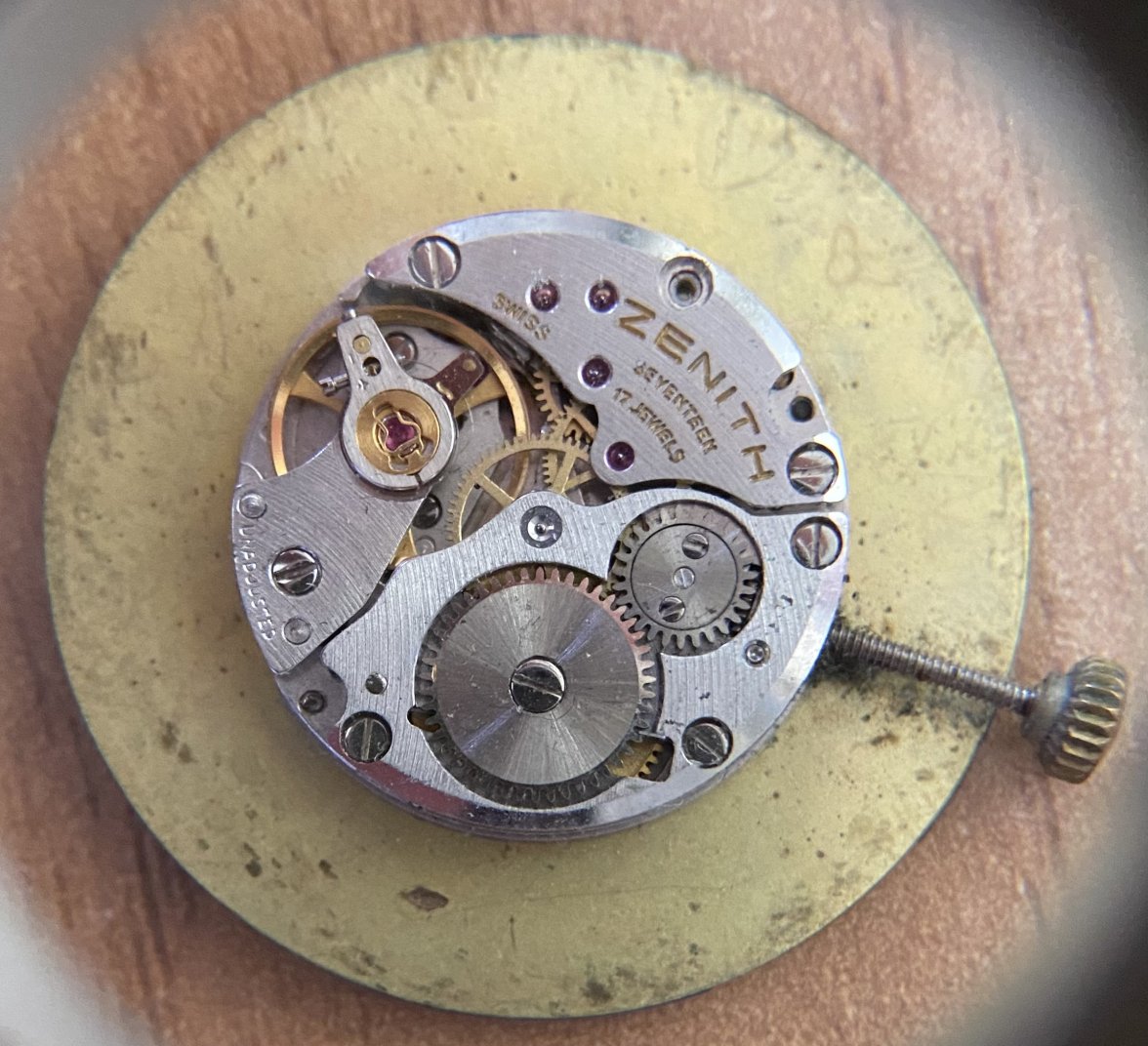

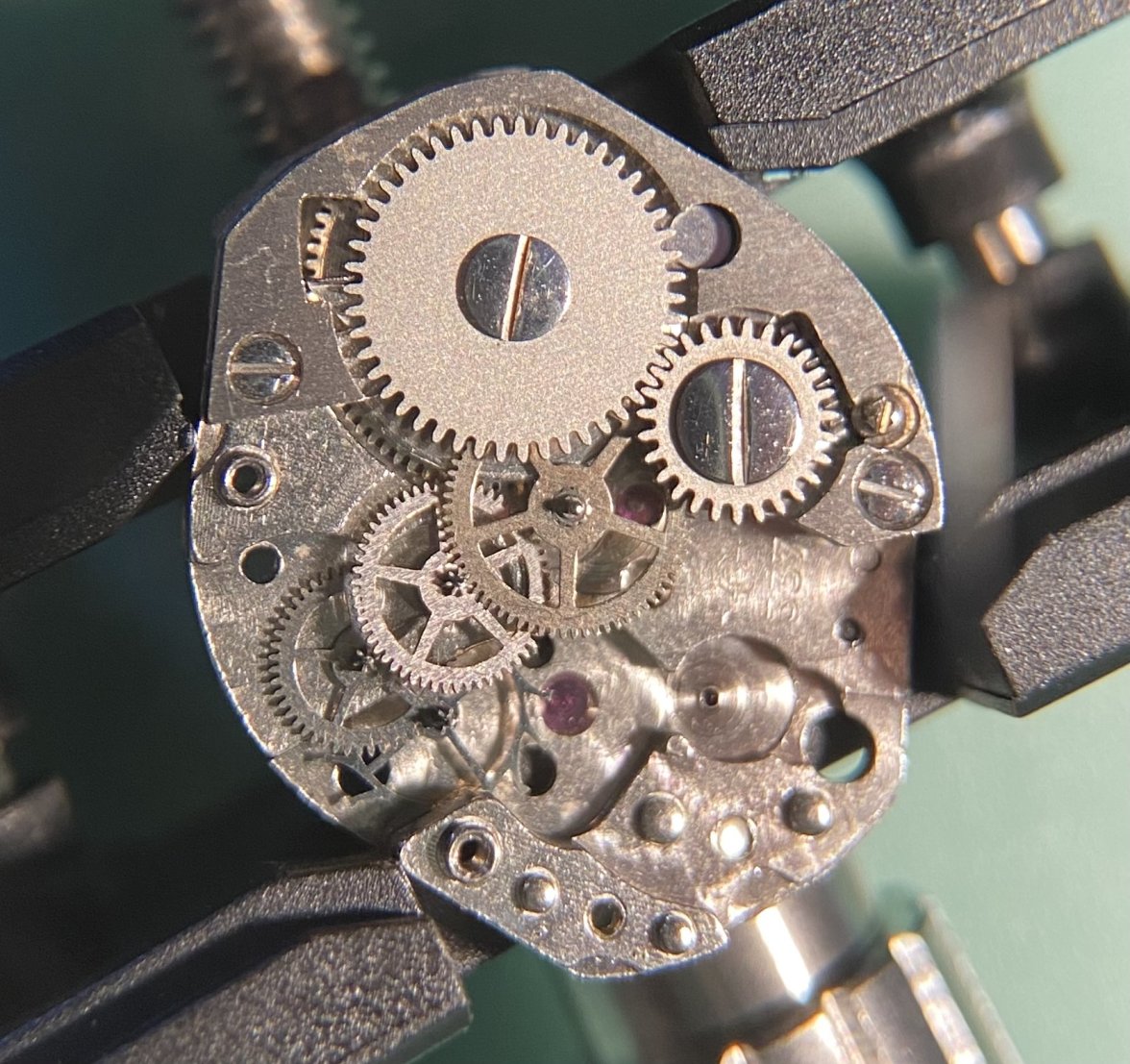

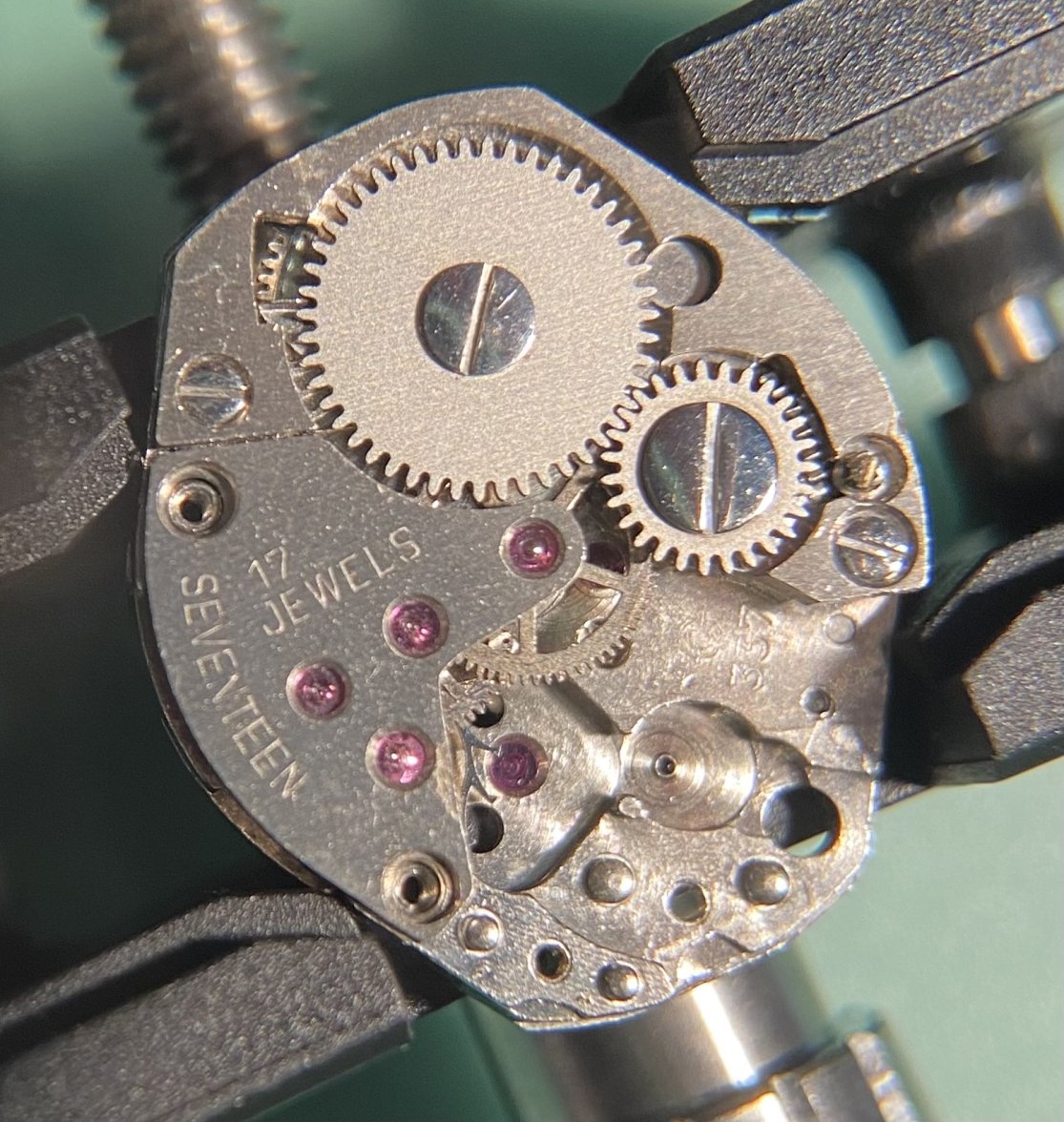

The Zenith is probably the closest to a 'real' watch. The pin levers and roskopff, were used in the lowest grades which got replaced with quarts. These require a different skill set. They were created with automation and mass produced with early robot devices some of which were driven with stacks of cams like the dolls I like and Babbage's 1830s computer. Often they are assembled upside down.

Other times there is a single screw. At Apple we called this the Canada screw. Supposedly there was some Canadian law which required a component to be screwed in and not clipped in. At least the computers were not riveted and spot welding was only done on sub assemblies.

These sorts of products are really not designed for service or repair. There are exceptions like the Bettlach 8800 which can be found in some nice cases with a high grade of finish on the plates. More likely one is likely to find a Baumgartner or Rhonda movement.

Learning to work on such watches, is really a labor of love and frustration. Such watches are not likely to have any collector value. (apart from ones with Mickey or Snoopy on the dial.)

Timex is a world unto itself. Those started as left over WWII era bomb timers. Basically miniaturized alarm clocks. One could learn a lot on those special interest tours.

Personally I do not worry about damaging the watch. In some ways it is harder to damage the mid to high grade stuff than the cheap ones.

I did dump all my Bulova's as I did not have the time to work with them. I did however as I often state keep the AS 1194 watches. I also kept some Helbros and Benrus watches. These use the traditional eubaches. With lots of data sheets and ephemera to detail them. Most use a somewhat standard bridge pattern like the Zenith.

I also recommend complete watches. It always seems that one is getting a deal with a practice movement for a few bucks. Now I am paying the price, as the cases are hard to find empty. Or like the one I got a few weeks ago, the wrong sized and had to be returned.

I did much better with the 20 buck assortment which had a couple of Seikos in it. I was really after the common AS movements.

Over the last year I have not warmed to my pocket watches. They now look like clocks. Pocket watches do lend themselves to the more traditional approach to make new parts like staffs and pivots. I seem to find such projects to be a huge time sink.

Much more stimulating to hit command-R and dash of another missive.