Elsewhere there’s been posted the original NASA “Statement of Specifications” for the wristwatches to be used by NASA astronauts, which did in fact give treatment to the issue of having a “shatterproof” crystal.

While the specifications do not use the word “plexi” (etc.), I think it reasonable to assume that “shatterproof” had straightforward colloquial meaning amongst the engineers that wrote the Statement of Specifications.

Still today it looks like the materials selections prerogatives for both NASA and ISS deal with the topic in a rather pragmatic way: avoid frangible materials when you can, and when you can’t minimize risk.

In all, it seems that the “Statement of Specifications” specifically contemplated a crystal that was “shatterproof,” which meant on this metric the Speedmaster qualified at all (compared to possible competitors that used sapphire at the time). Engineers are far too specific to specify “plexi” if the quality they actually desire is more fundamental, being open to whatever material may satisfy the more fundamental requirement of being “shatterproof.”

These pragmatic materials selections for avoiding frangible materials can still be seen being discussed at length today for the various types of frangible materials used in craft or on ISS

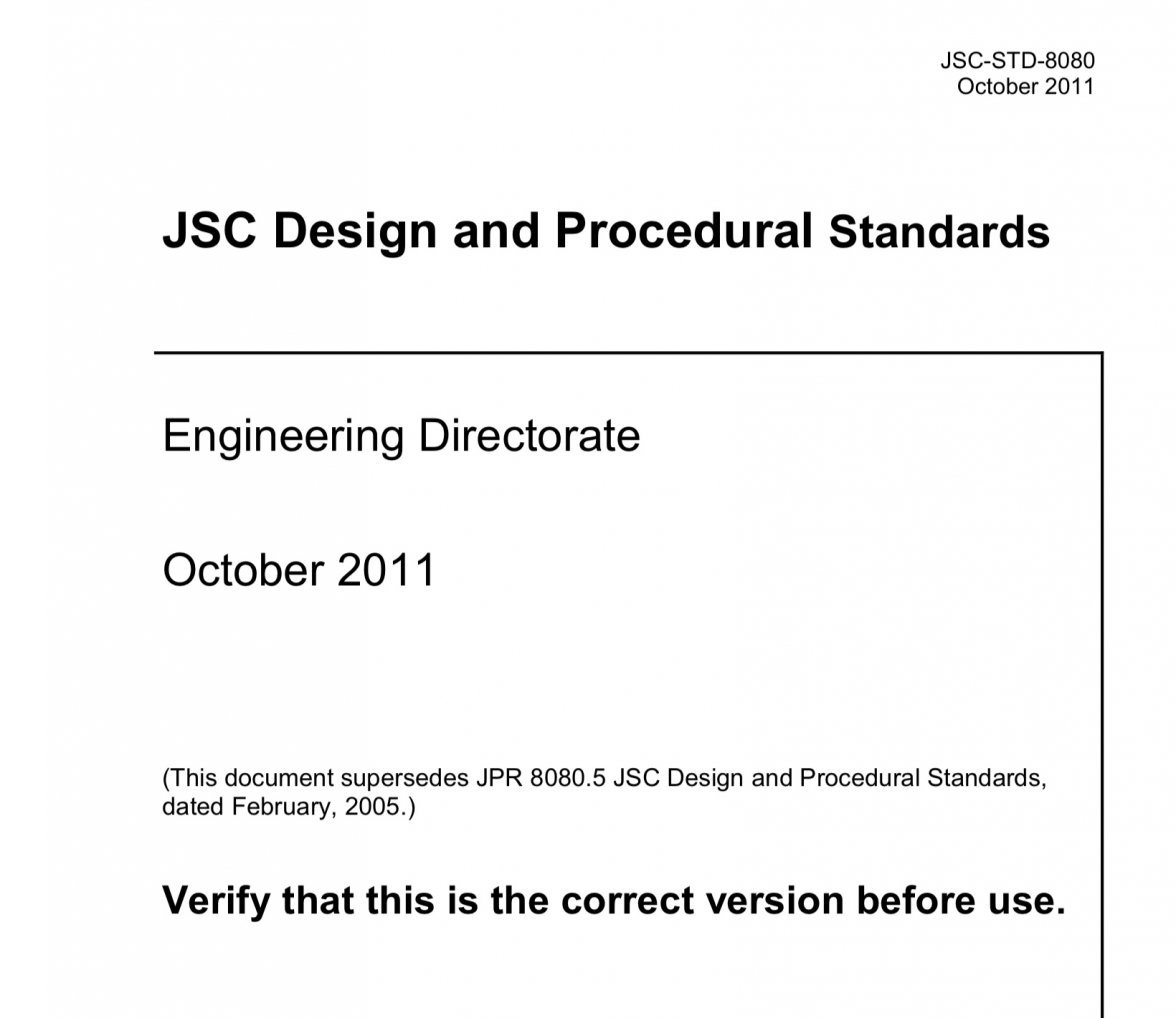

From NASA, a white paper:

SAFELY CONTAINING FRANGIBLE MATERIALS USED IN SPACE FLIGHT EQUIPMENT

From ISS:

ISS Safety Requirements Document section titled “Shatterable Materials”

“SHATTERABLE MATERIALS

Shatterable materials are unique physical agents. A shatterable material is any material that can fracture under a load or impact and produce fragments that are potentially hazardous to the crew and/or vehicle. Common shatterable materials on the ISS include glass, ceramics, LCD monitors, certain metallic alloys, optical equipment, and any other frangible materials that can fracture and produce fragments. Shatterable material requirements are addressed based on preventing release of fragments (Section 4.7.2.5.2.1, Shatterable Material Release) and based on protecting optical glass from fracture (Section 4.7.2.5.2.2, Optical Glass Protection).

This section addresses potential IVA release of shatterable materials. Shatterable materials that do not fit into the requirements below should meet structural requirements as addressed in Section 4.2, Structures.

SHATTERABLE MATERIALS RELEASE

End items with shatterable materials shall prevent the release of fragments larger than

50 micrometers (μm) into the ISS habitable volume.

Rationale

This requirement encompasses shatterable materials that are located in or may be introduced into the pressurized habitable environment. It is established to protect the crew from physiological hazards and/or to protect the environment and VV/ISS equipment from hazards resulting from contamination.

Additional rationale for this requirement can be found in Appendix D.4.7.2.5.2.1.

4.7.2.5.2.1.1 VERIFICATION– SHATTERABLE MATERIALS RELEASE

Verification is considered successful when one of the following is completed: A or B

A. The end item design is shown to fully and permanently contain the shatterable

material, based on both of the following.

1. The contained covering is identified and proven effective in preventing

shatterable material release. (A or T)

2. Review of the end item design and review of the as-built hardware shows containment of the shatterable material. (I)

B. When containment is not practical, the following are provided:

1. For non-operational phases (launch or when hardware is not operational),

both of the following are provided: (1 and 2)

a. The contained covering is identified and proven effective in preventing shatterable material release. (A or T)

b. Review of the end item design and review of the as-built hardware shows containment of the shatterable material. (I)

2. For the operational phase, the following is provided:

a. Inspection of procedures shows that operational controls are in place to inspect for breakage prior to removing the protective covering, restoring the protective cover when not in use, and identification of any limitations in the use of the end item that prevent damage to the shatterable material.”

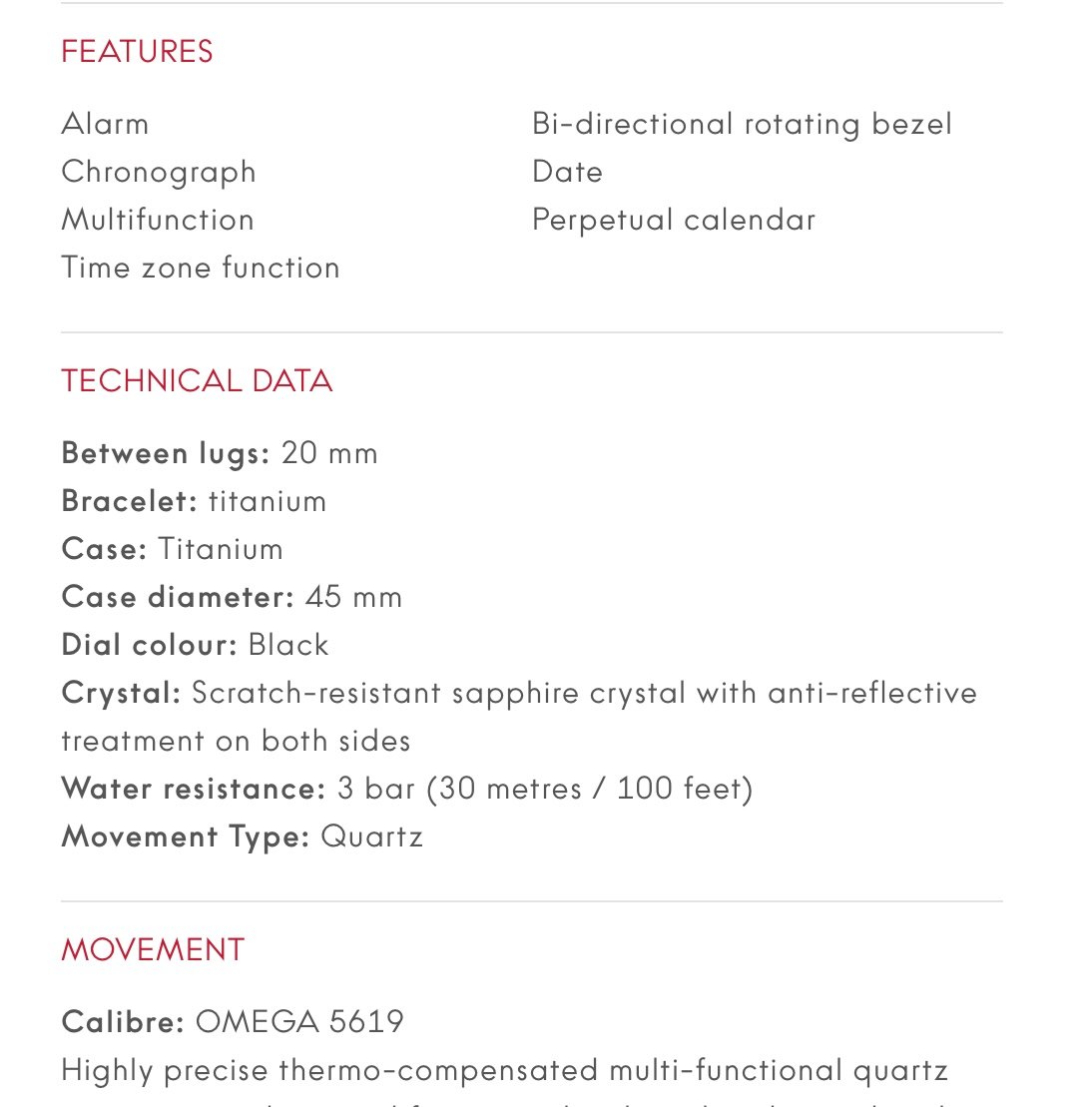

![IMG_20190320_0028085[9464].jpg IMG_20190320_0028085[9464].jpg](https://omegaforums.net/data/attachments/729/729614-9f38fefdd9c1837cf134fed7f6c2a67f.jpg?hash=nzj-_dnBg3)