Davidt

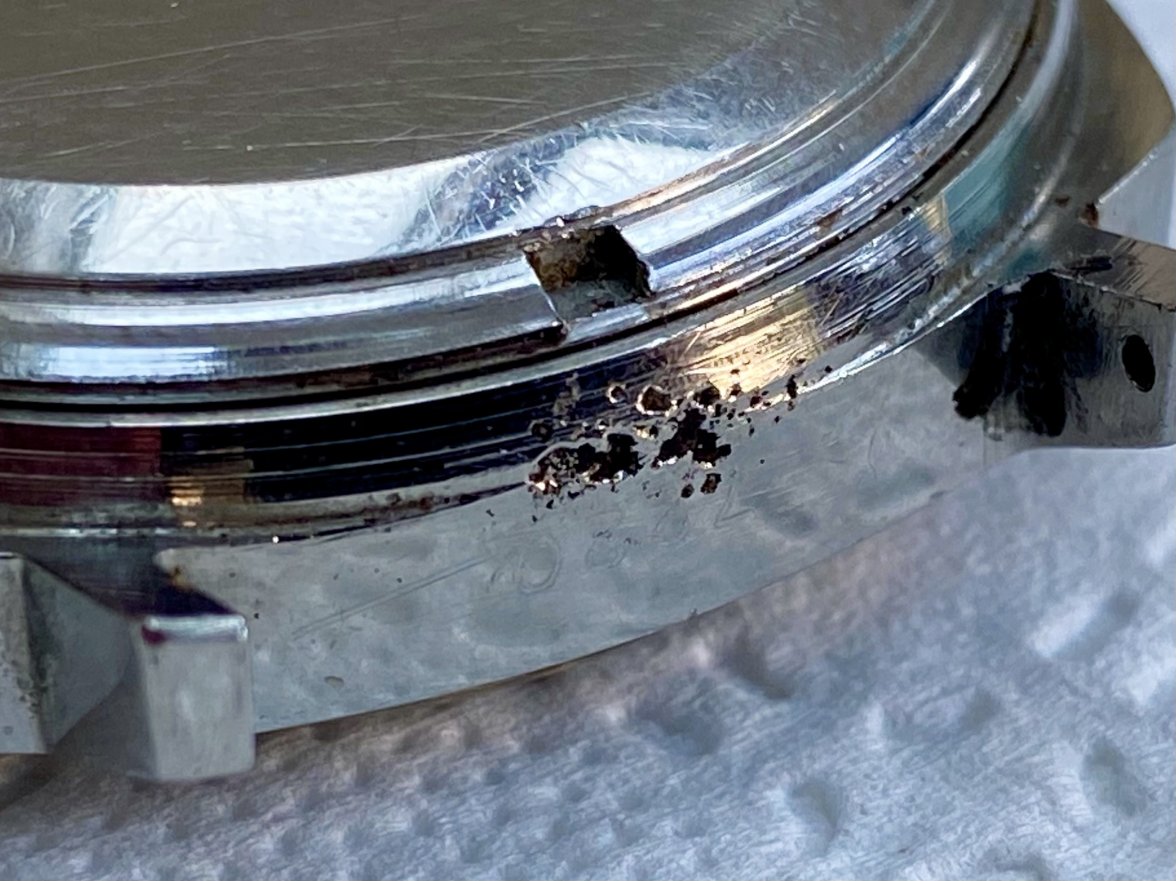

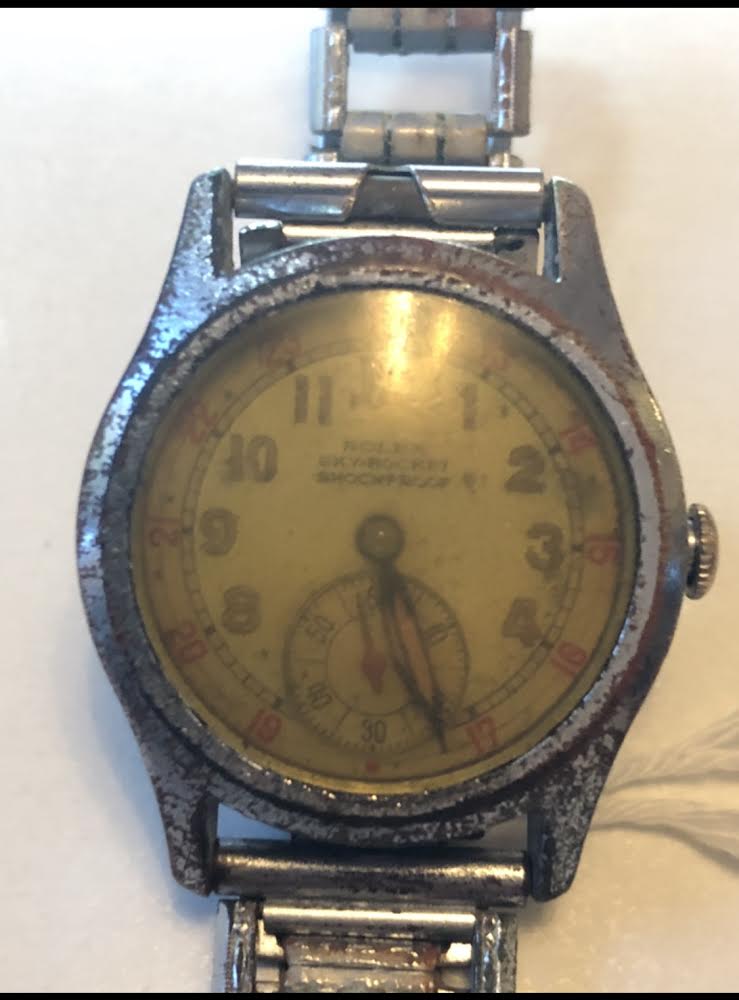

·A recent acquisition has some unfortunate pitting between the lugs. I was aware of this before purchase and as the dial combo is so wonderful I’m happy to accept it. However, I would like to stop it spreading.

My first thought was having it laser welded but I’ve been advised that laser welding doesn’t work very well with pitting so that’s not an option.

What’s the best way of stopping this from causing further deterioration in the comings years?

Is it possible to remove the actual oxidised parts (using either chemicals or abrasion) to get back to good metal, without compromising the overall case finish and the serial no?

My first thought was having it laser welded but I’ve been advised that laser welding doesn’t work very well with pitting so that’s not an option.

What’s the best way of stopping this from causing further deterioration in the comings years?

Is it possible to remove the actual oxidised parts (using either chemicals or abrasion) to get back to good metal, without compromising the overall case finish and the serial no?