JimInOz

··Melbourne AustraliaOnward.

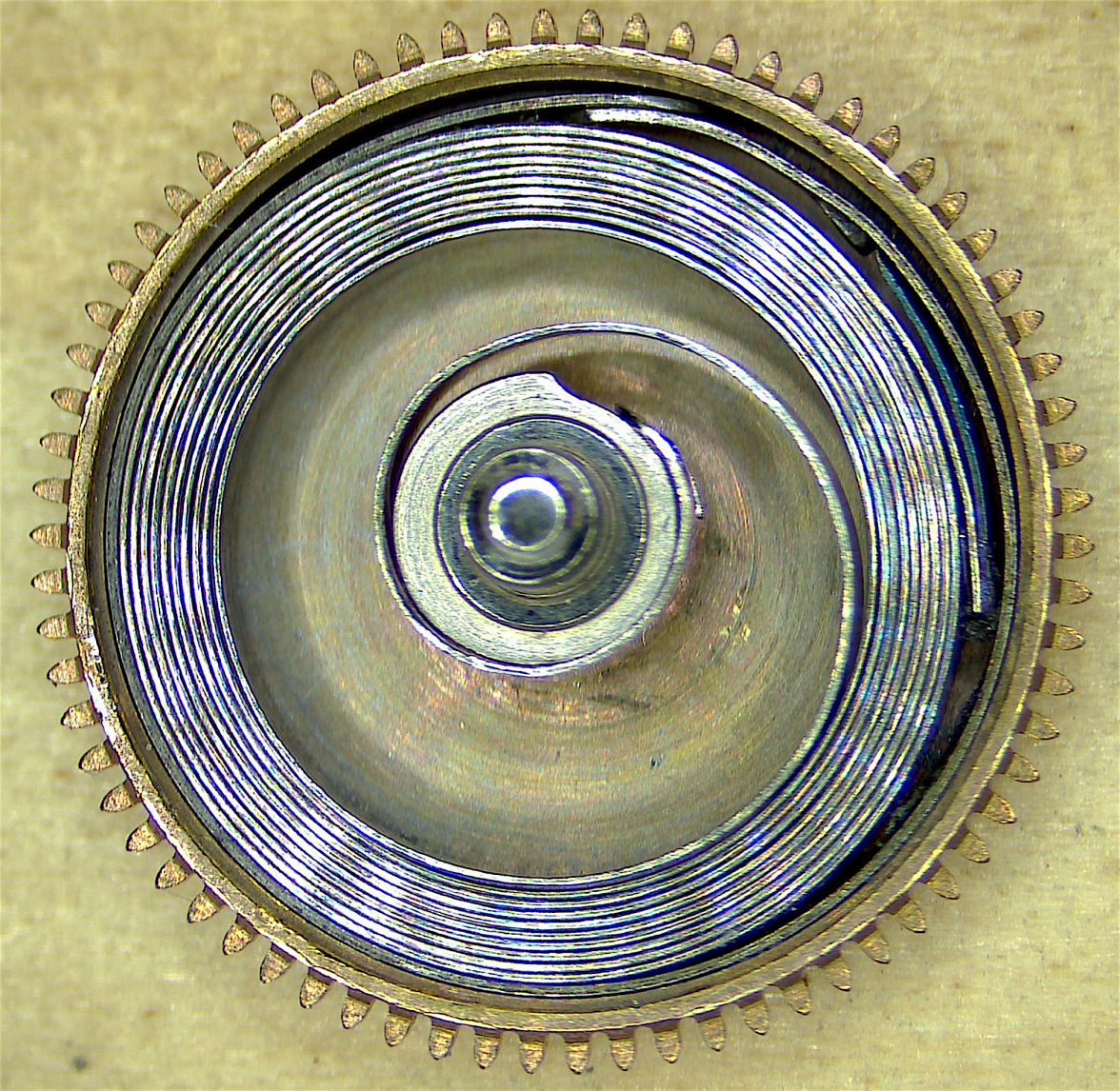

Step 1. Firstly, the rotor was stripped and checked for wear and then the gouge was smoothed out and the rotor parts cleaned.

Then it was re-assembled.

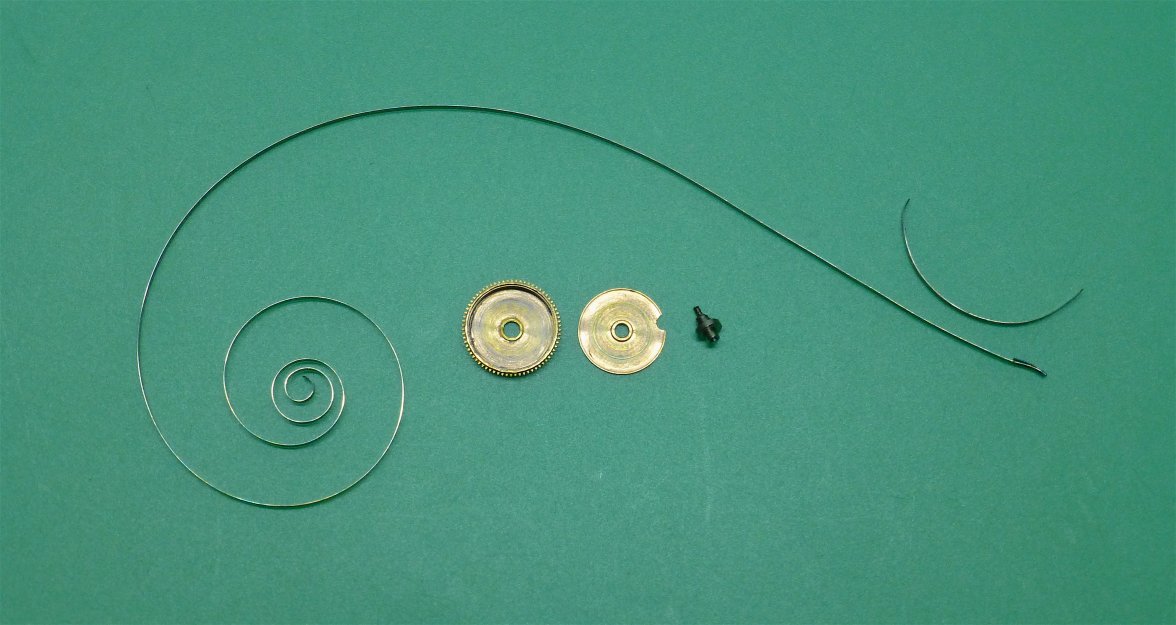

The reverser wheels and bits were removed from the auto bridge and cleaned.

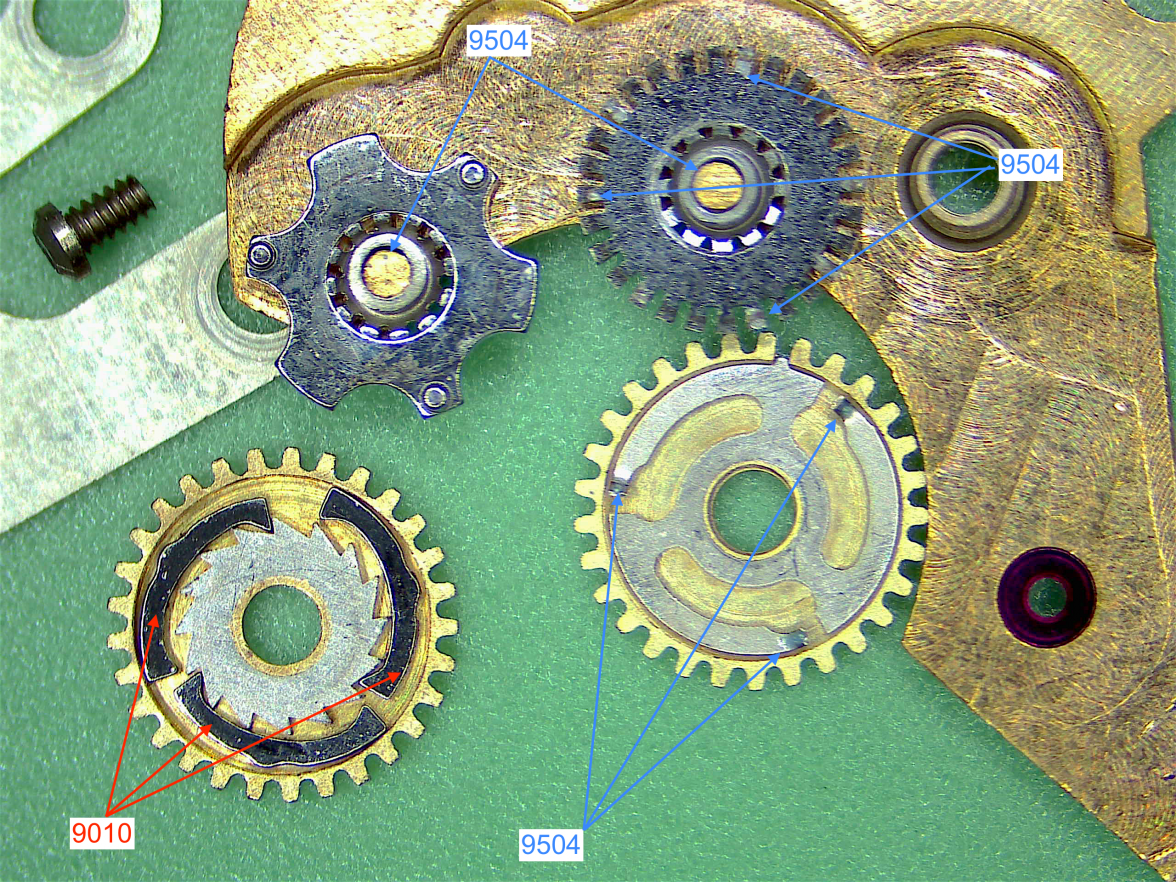

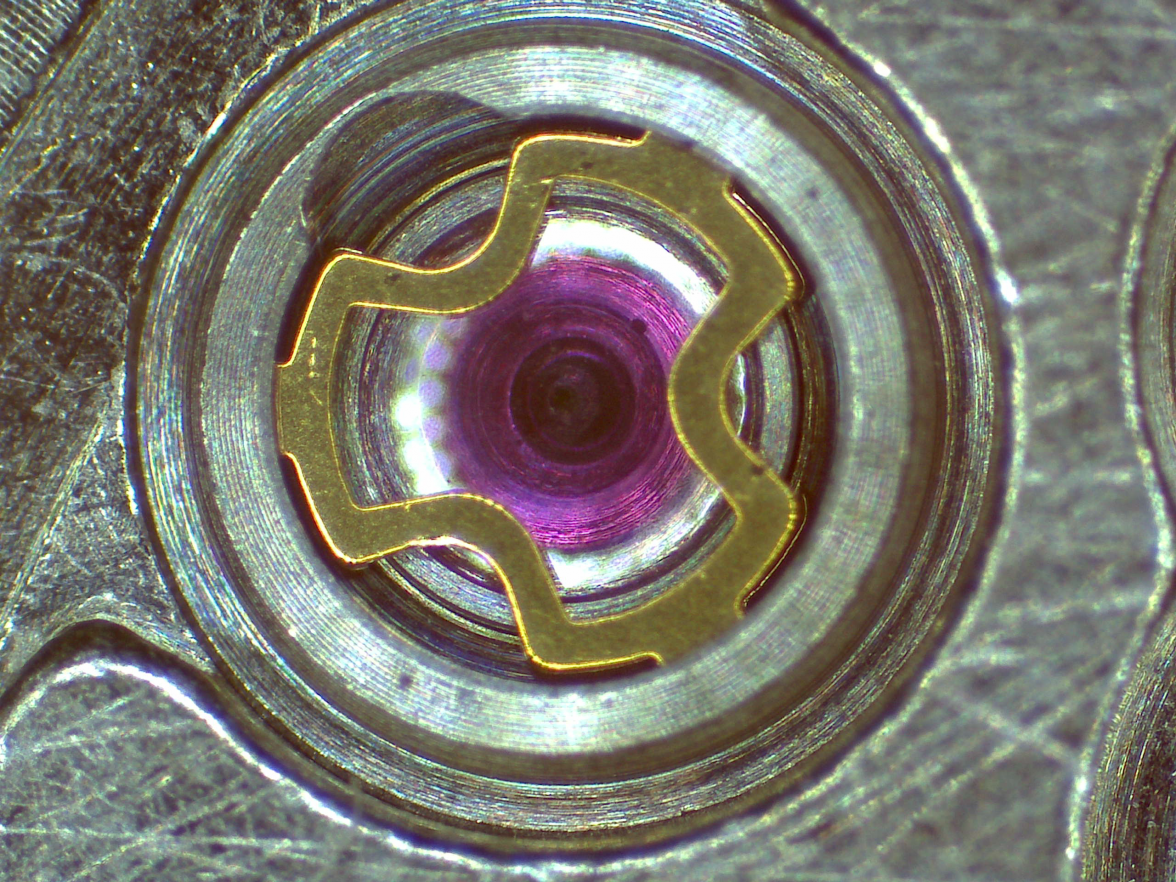

As you can see, there are two styles of reverser wheel. Why? No idea, but I wish it was two of the tri-spring ones.

Lubricating was an experiment, mainly for the three little pawl fingers. I used a pegwood stick just damp with Moebius 9010 and wiped the inside of the barrel, then I wiped the oil onto a sheet of glass and put the fingers in the oil (turning to coat all over). Then I transferred the fingers to a sheet of watch paper to get rid of excess oil, a bit like cooking fish fingers, but much harder!

My cooked fingers were then installed in the barrel and the pivot posts on the bridge given a film of Moebius 9504 and the tri-spring reverser was also treated with a tiny amount of 9504.

Reverser system was fitted to the bridge and that's where the fun began. As explained previously, the rotor can only be installed with the bridge off the movement. I lubricated the rotor pin and installed it and the rotor pinion and the rotor to the bridge.

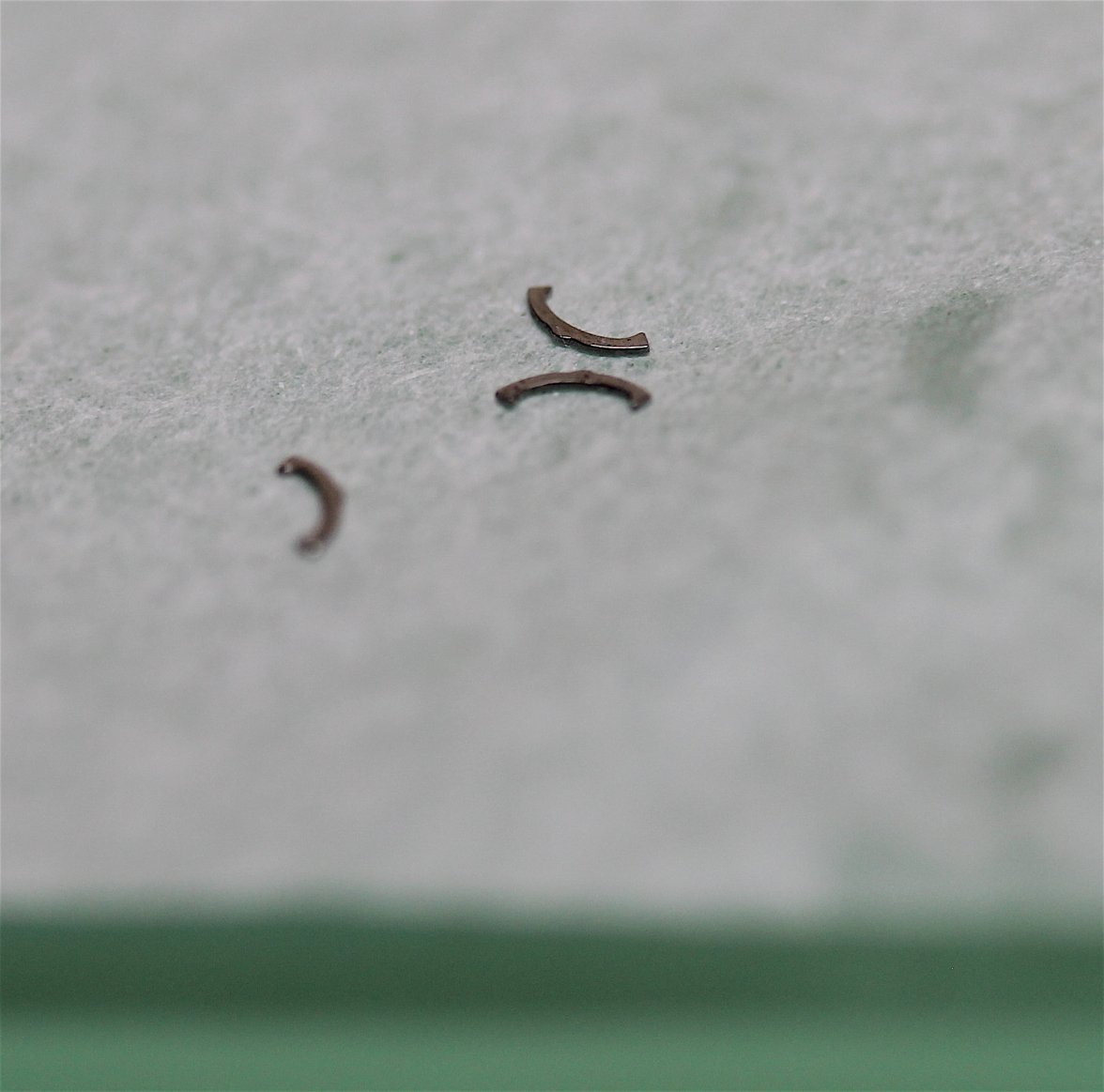

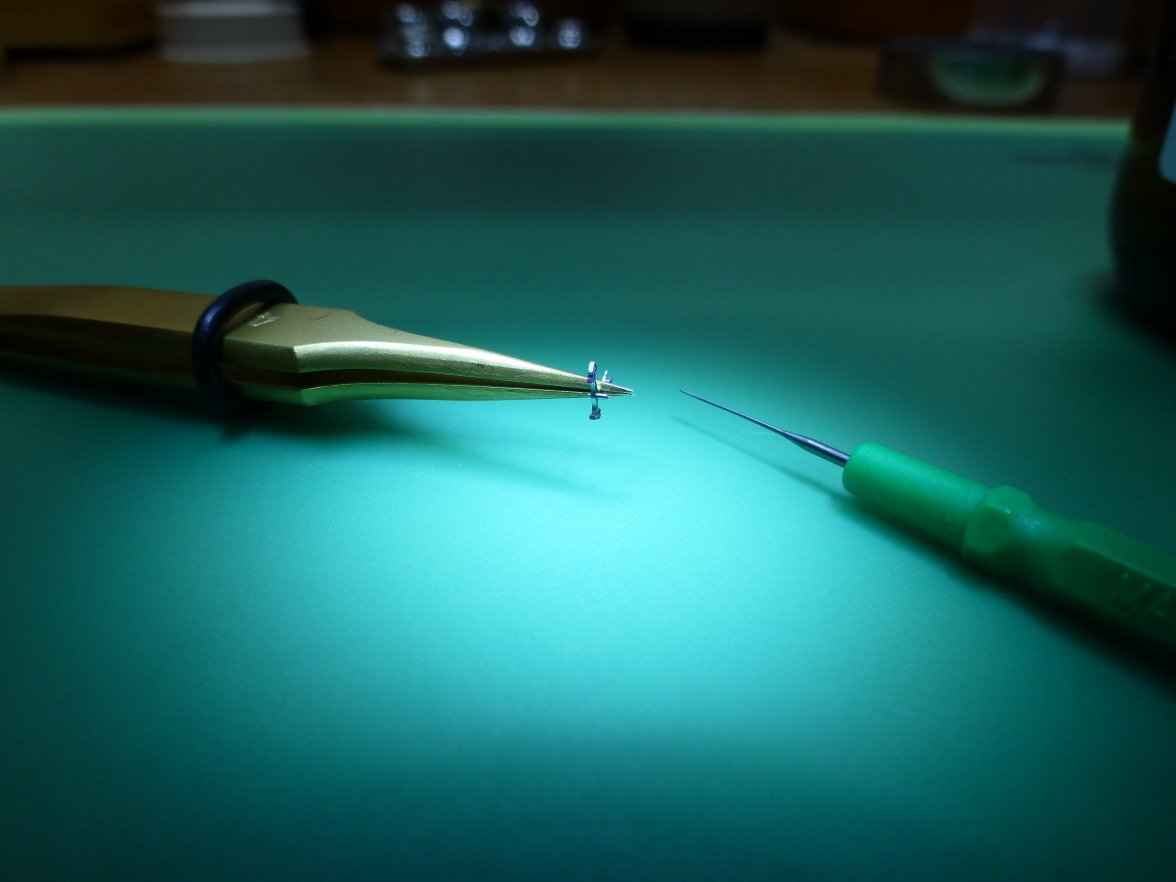

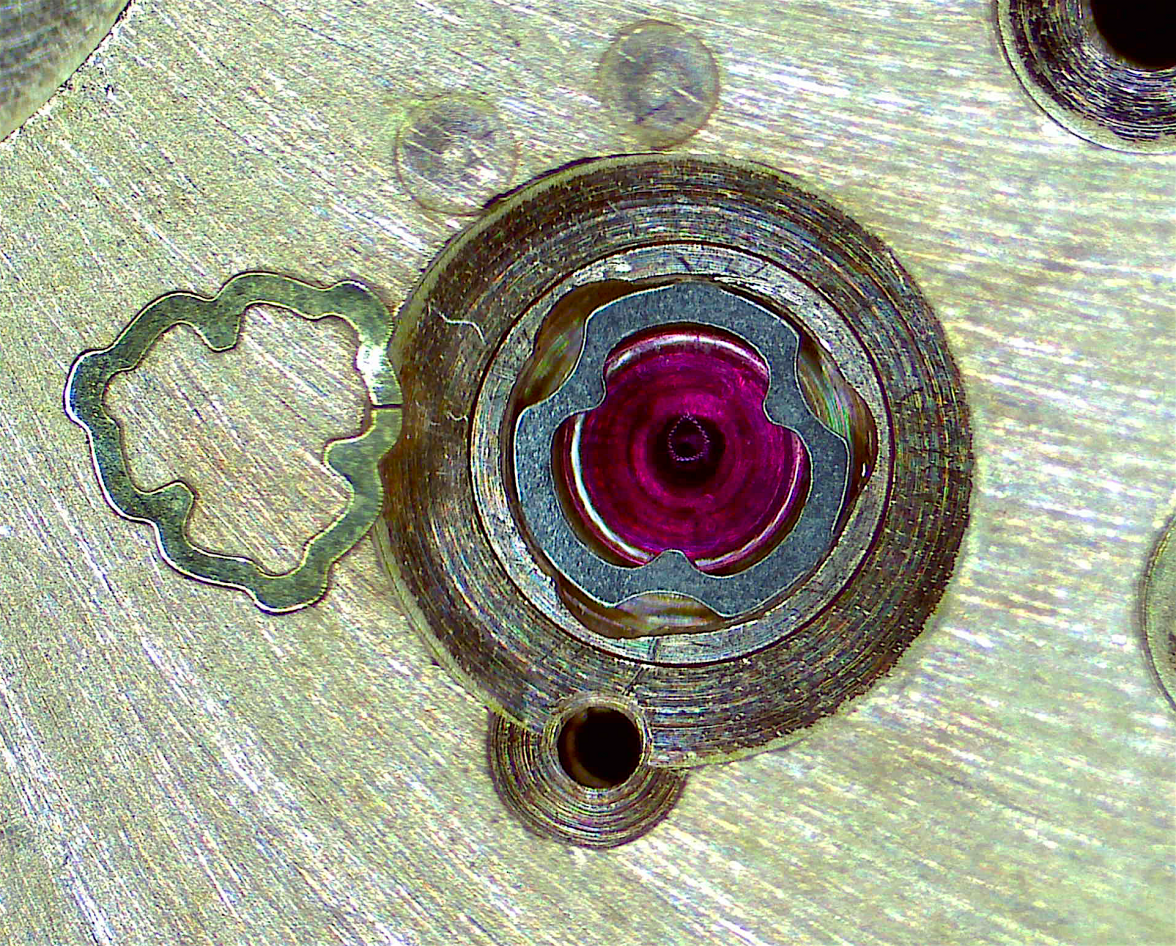

Then, squeezing the rotor pin/rotor/bridge between the fingers of my left hand, I used my right hand to pick up my tweezers, pick up the tiny cross clip that hold the rotor on the pin and position it over the pin. Next I had to swap tweezers for a specially shaped bamboo stick, all the while keeping the rotor parts together and not disturbing the precariously poised cross clip. The bamboo stick was then pushed onto the clip to seat it. It god a bit interesting when the finger of my glove started to wrinkle under pressure and get in the way of the clip, but thankfully it popped into place and didn't ping off into the ether!

I say thankfully, because if you lose one and need another you need to find one first, and then hold your breath when you pay $75 for a used one. 😲 Again, that's if you can find any, so I'm happy the little bugger is where it should be.

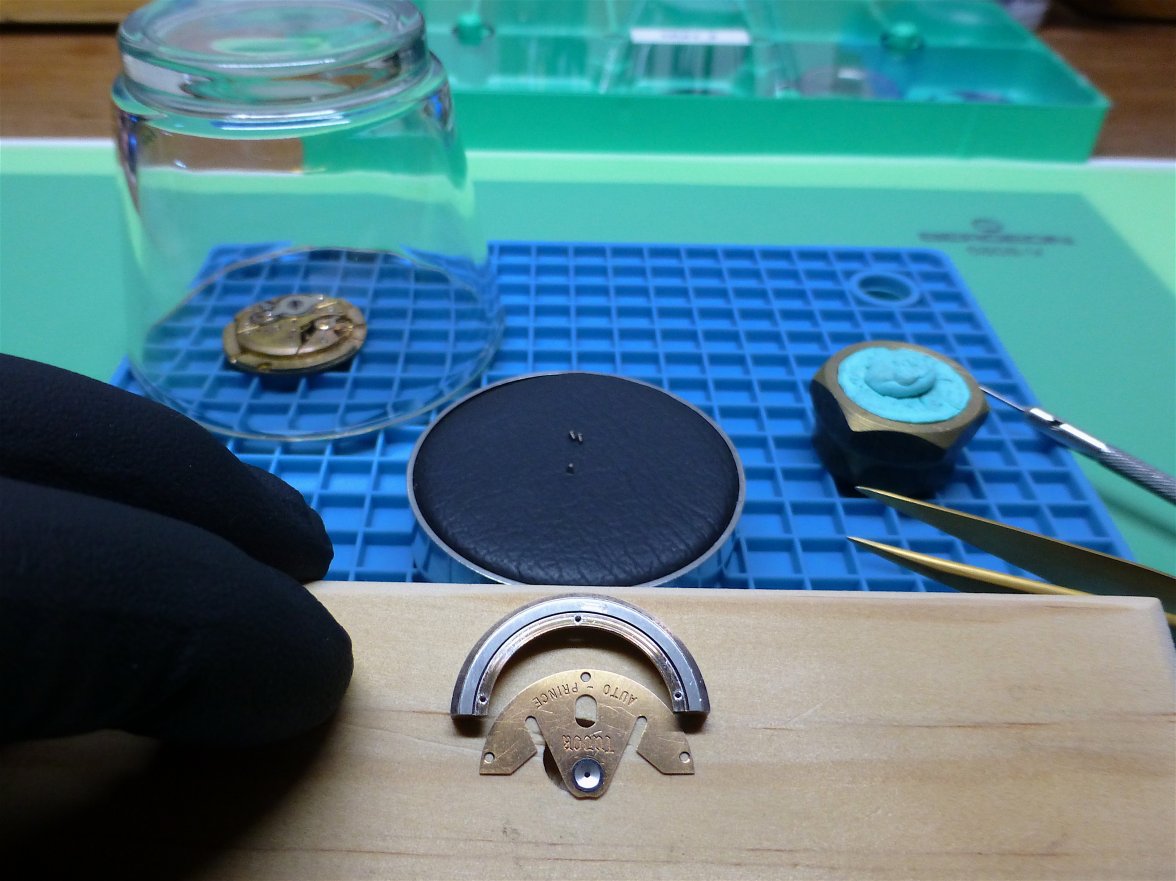

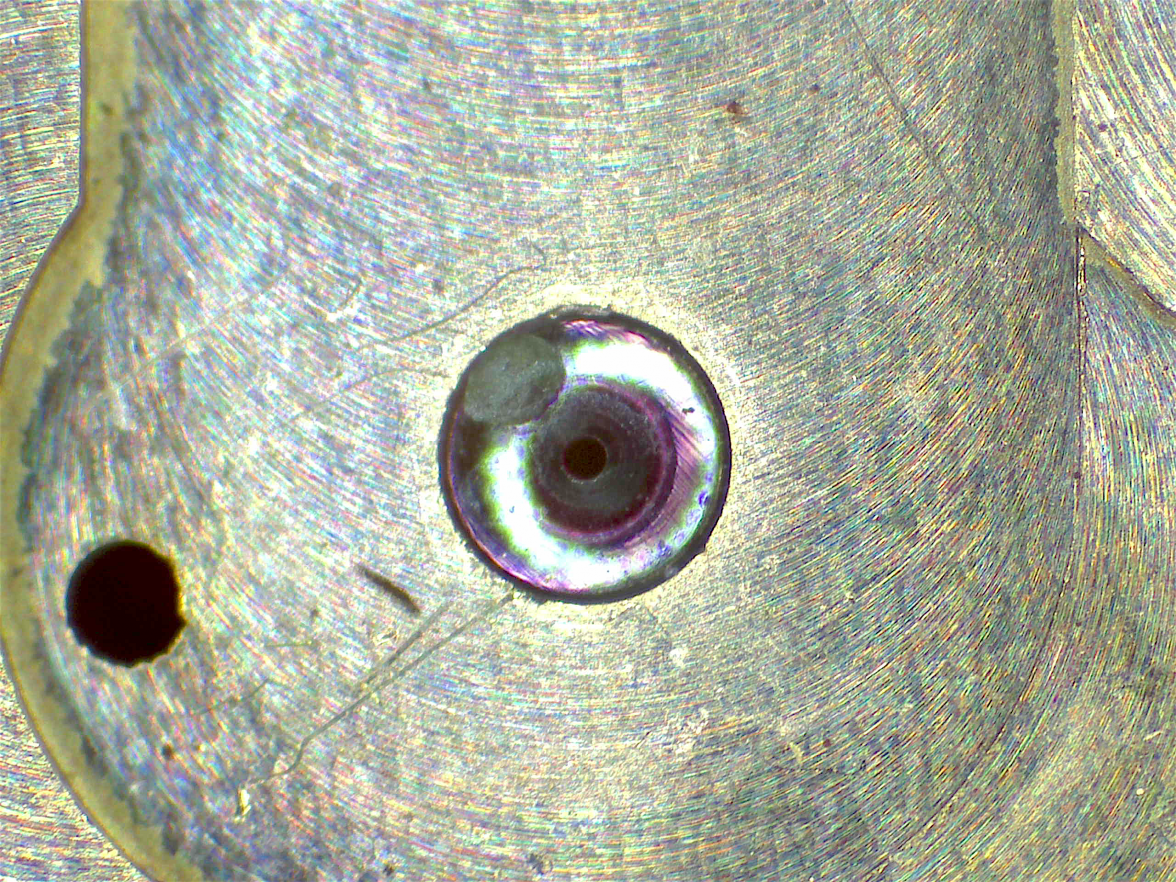

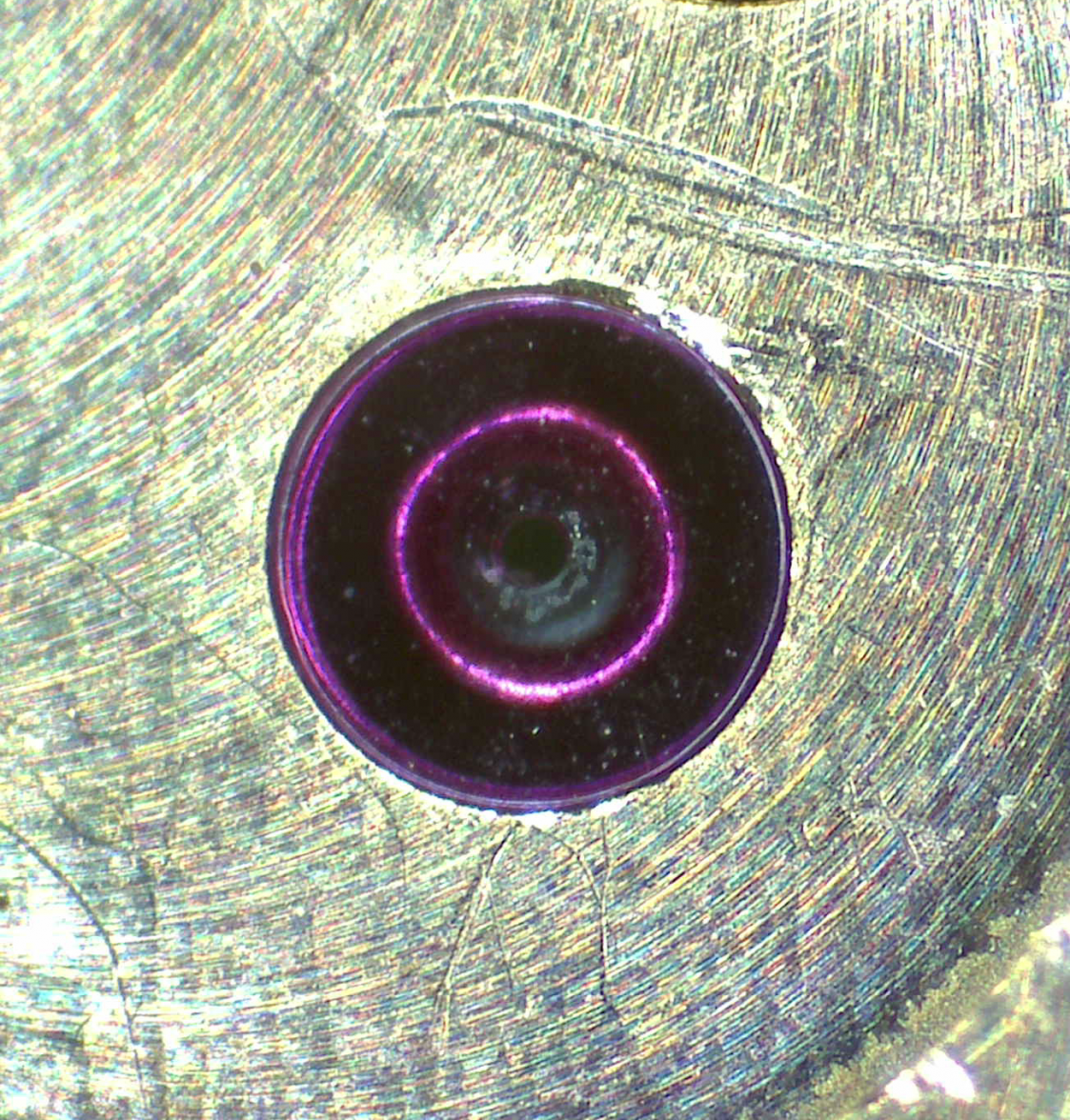

Here we see the underside of the rotor/bridge assembly showing the cumbersome inelegant design.

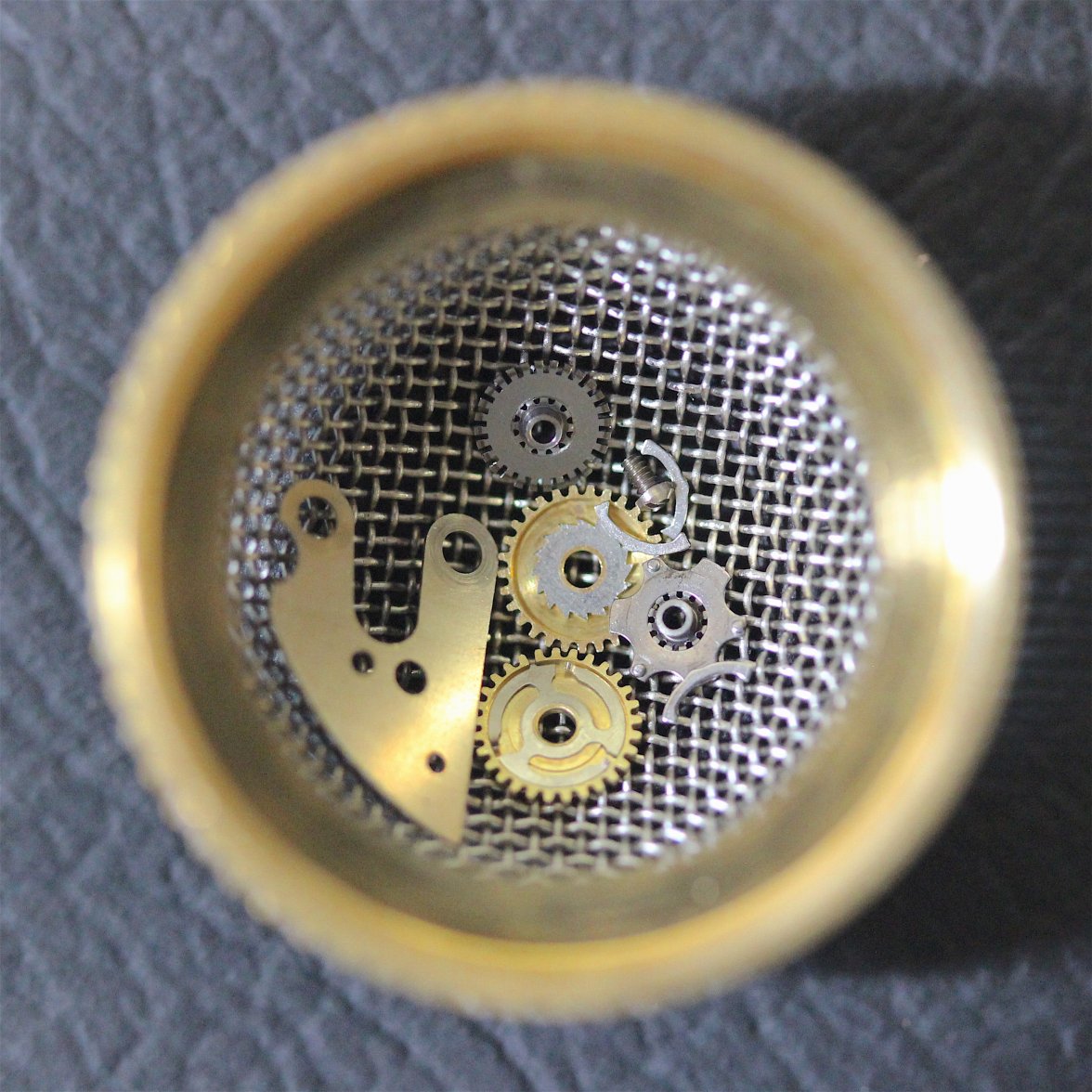

And here's a shot of the complete assembly, upper side, showing the equally clumsy example of watch design.

Did I mention that the little cross clip in the centre will cost $75 (if you can find one).

Well that's the autowind assembly wrapped up and put away.

I wonder what interesting features the base caliber holds in store?

😒

We shall see.

Step 1. Firstly, the rotor was stripped and checked for wear and then the gouge was smoothed out and the rotor parts cleaned.

Then it was re-assembled.

The reverser wheels and bits were removed from the auto bridge and cleaned.

As you can see, there are two styles of reverser wheel. Why? No idea, but I wish it was two of the tri-spring ones.

Lubricating was an experiment, mainly for the three little pawl fingers. I used a pegwood stick just damp with Moebius 9010 and wiped the inside of the barrel, then I wiped the oil onto a sheet of glass and put the fingers in the oil (turning to coat all over). Then I transferred the fingers to a sheet of watch paper to get rid of excess oil, a bit like cooking fish fingers, but much harder!

My cooked fingers were then installed in the barrel and the pivot posts on the bridge given a film of Moebius 9504 and the tri-spring reverser was also treated with a tiny amount of 9504.

Reverser system was fitted to the bridge and that's where the fun began. As explained previously, the rotor can only be installed with the bridge off the movement. I lubricated the rotor pin and installed it and the rotor pinion and the rotor to the bridge.

Then, squeezing the rotor pin/rotor/bridge between the fingers of my left hand, I used my right hand to pick up my tweezers, pick up the tiny cross clip that hold the rotor on the pin and position it over the pin. Next I had to swap tweezers for a specially shaped bamboo stick, all the while keeping the rotor parts together and not disturbing the precariously poised cross clip. The bamboo stick was then pushed onto the clip to seat it. It god a bit interesting when the finger of my glove started to wrinkle under pressure and get in the way of the clip, but thankfully it popped into place and didn't ping off into the ether!

I say thankfully, because if you lose one and need another you need to find one first, and then hold your breath when you pay $75 for a used one. 😲 Again, that's if you can find any, so I'm happy the little bugger is where it should be.

Here we see the underside of the rotor/bridge assembly showing the cumbersome inelegant design.

And here's a shot of the complete assembly, upper side, showing the equally clumsy example of watch design.

Did I mention that the little cross clip in the centre will cost $75 (if you can find one).

Well that's the autowind assembly wrapped up and put away.

I wonder what interesting features the base caliber holds in store?

😒

We shall see.