- Posts

- 77

- Likes

- 43

maximilian g

·This watch now belongs to my wife, it was her father's watch. He had a car accident and he went through the wind screen which b%ggered it (and him), it was chucked in a drawer 30 years ago,before that he wore it every day so it reminds her of him. She really would like to wear it again but I cant find some of the parts to get it repaired, the most important piece that is missing is the gilt bezel, I have been looking for years in the hope one may come up with no joy? If any one has one or knows where I can get one please let me know.

The watch is a gold plated 168.004 CD case that had no glass, hands, crown and a damaged dial. I

have managed to get a replacement dial that I hope is correct? (in the 2nd photo and the original one in the 3rd ).

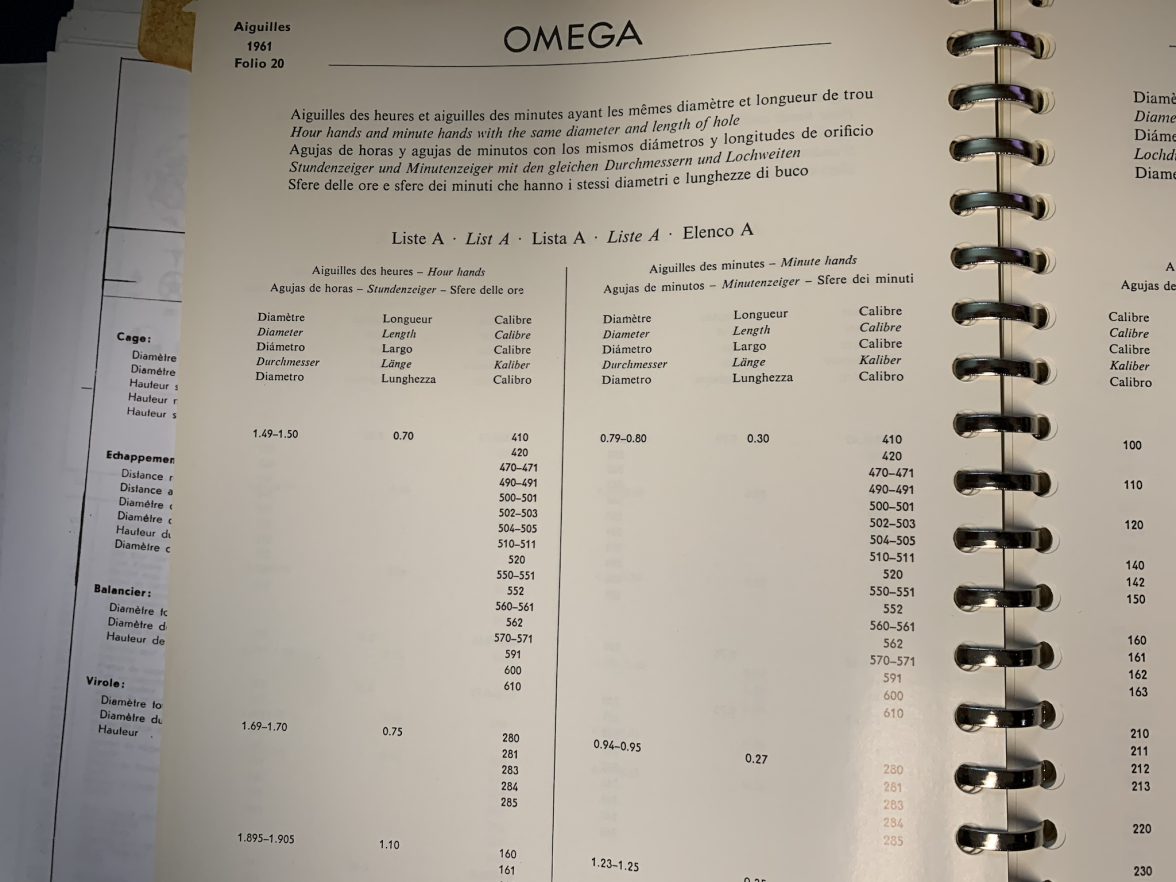

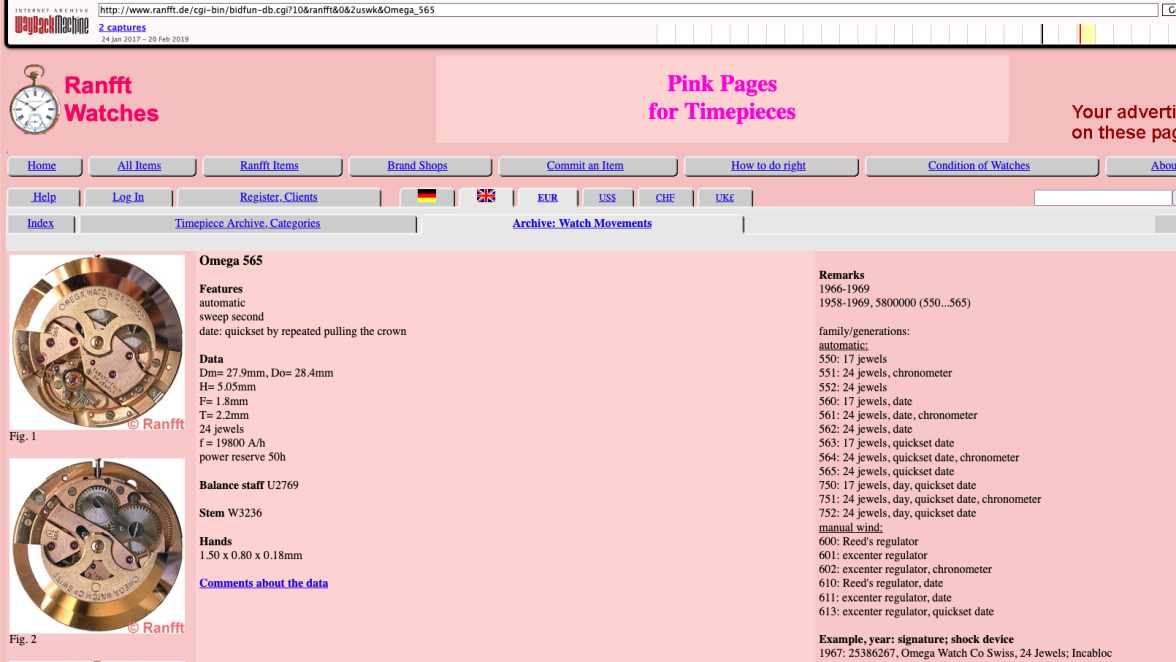

I have a generic glass for it and I have probably 5 sets of dauphine hands that have come from cal 565 movements over the years which I have kept. Would I be able to use these (some of them seem the same as constellation ones)?

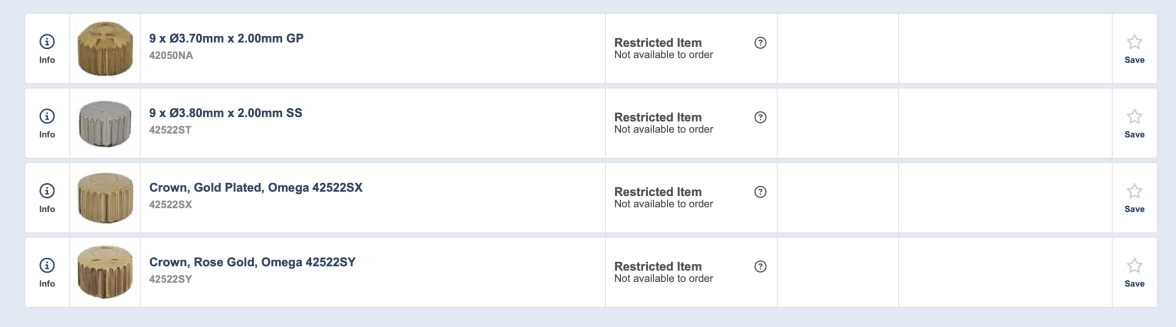

Would someone please let me know what is the correct number and shape of the crown for this model?, it would be a real help thanks.

The movement is a cal 561 and the serial number is 21270508.

I know very little about constellations so any advice would be really appreciated.

My interest with Omegas is sm 300's 165 &166.0024's and 166.0234's.

This is not to re-sale or add to a collection it's a watch that has genuine sentimental value to my wife who just wants her dad's watch to wear. Authenticity is not the most important thing to her, I am just trying to get it up and running for her.

Thanks in advance for any help.