Okay, now finally time to play with parts (and post).

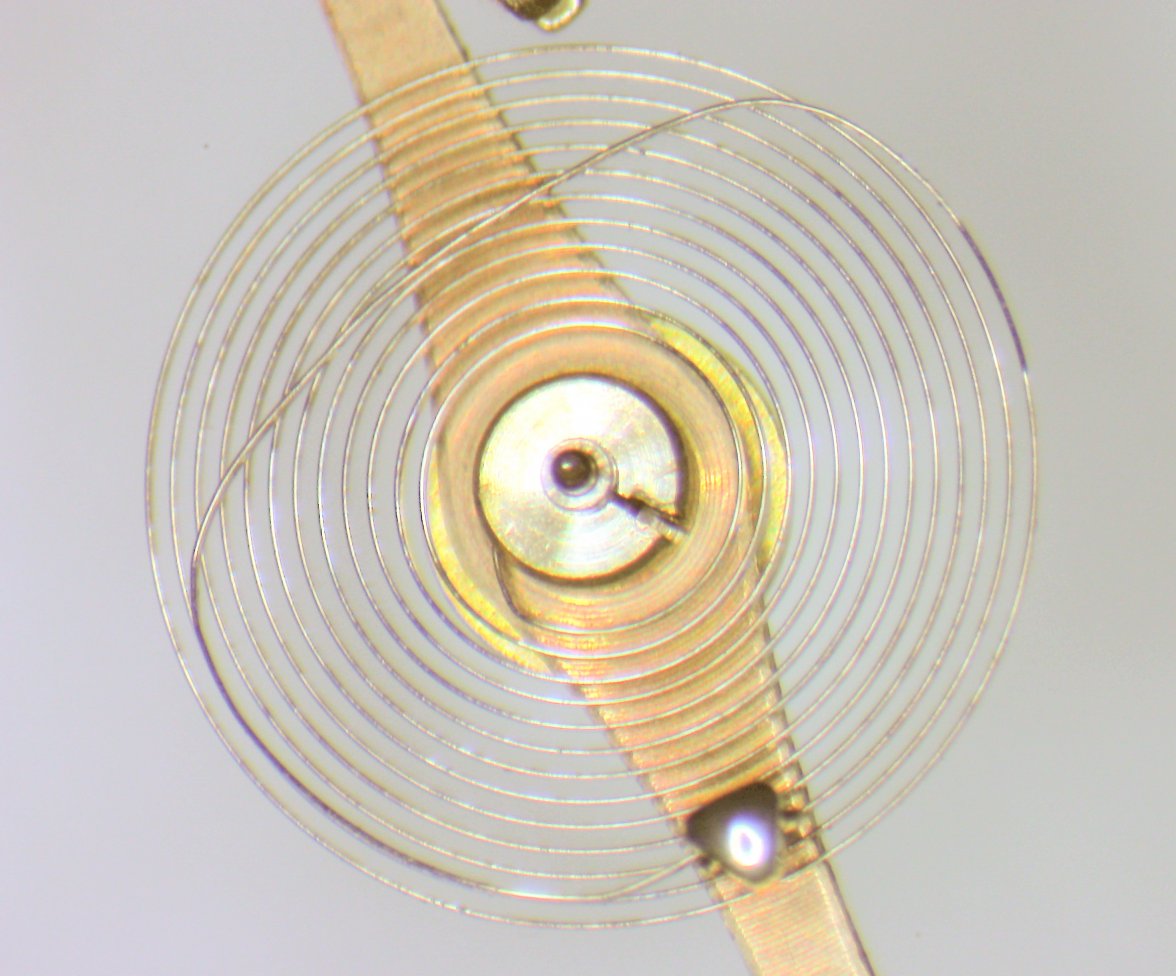

First - here's a look at the hairspring of the NOS balance. This exposure doesn't do it justice - but I think you can kind-of tell how bright and shinny the hairspring is. Looks like it was just made.

HOWEVER - this will not be the hairspring producing my "full-wind" numbers posted here. The reason being, that I had also acquired a used balance (complete) in excellent condition prior to finding the NOS part.

Initially, I thought I would rather install the NOS piece - and that's true. except, the NOS piece seems that it's going to require a little tweaking to install properly - as installing it introduces an out-of-flat condition.

I'm (pretty) sure that is a simple fix - but, since I had the used balance working nicely - and given my reputation as a hairspring murderer - I thought I'd proceed with the used one - and see if it would produce acceptable results.

My "full-wind" numbers for the replacement (used) balance look pretty good to me. Though the amplitude drop in the pendant up position seems strange.

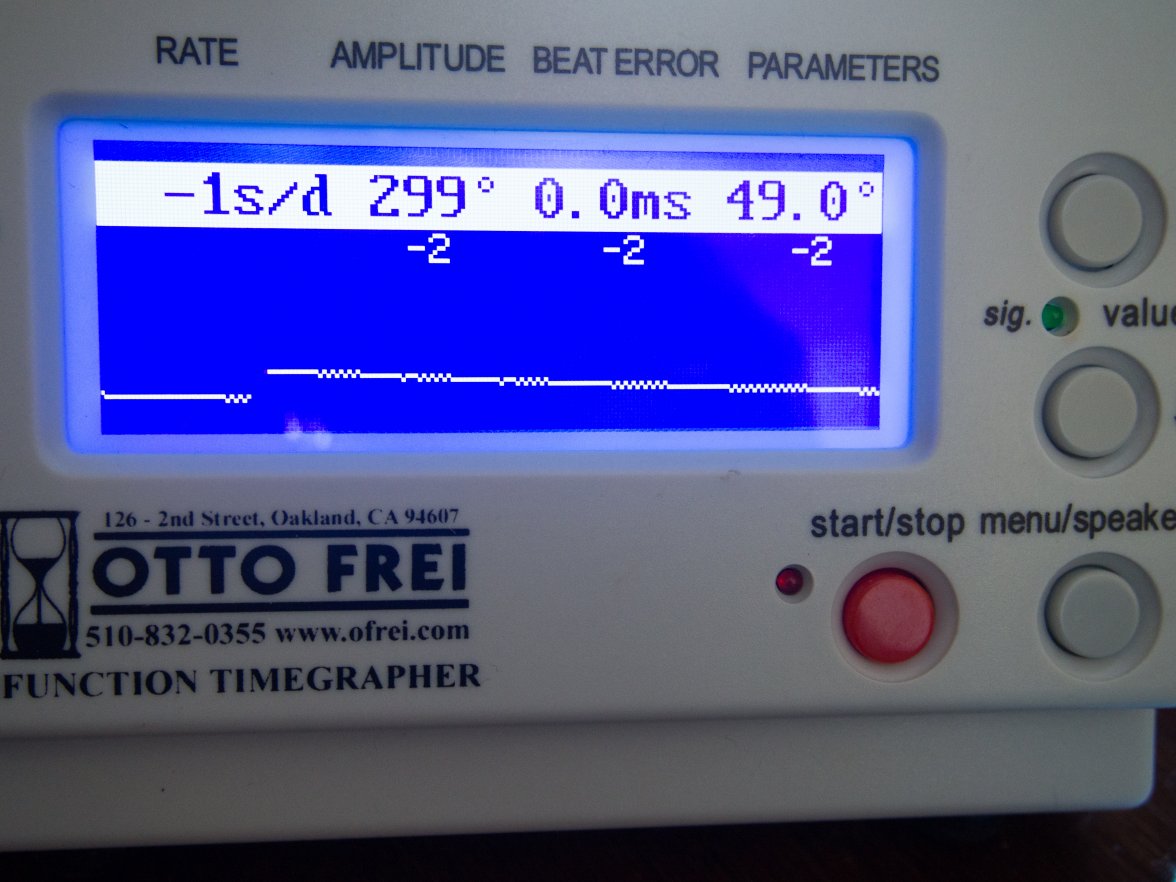

Here is dial up (DU)...

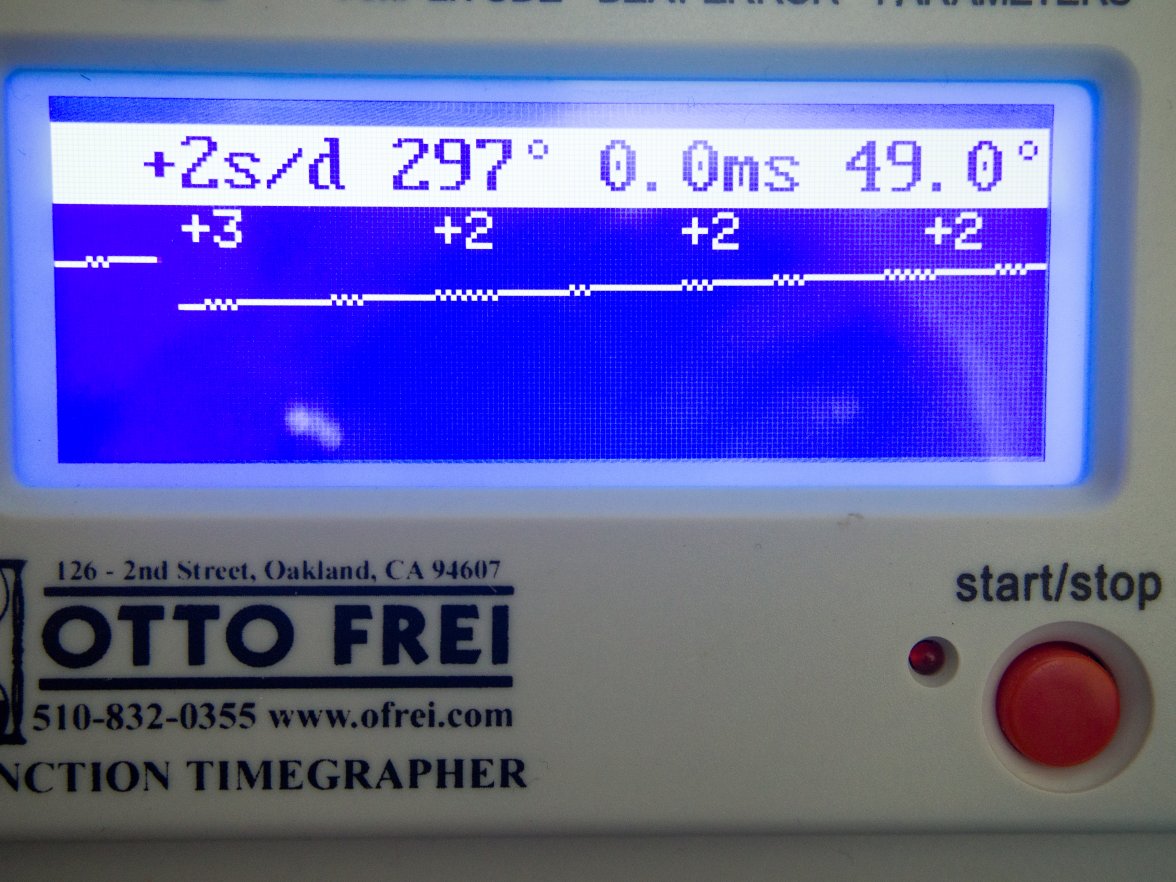

Dial Down (DD)...

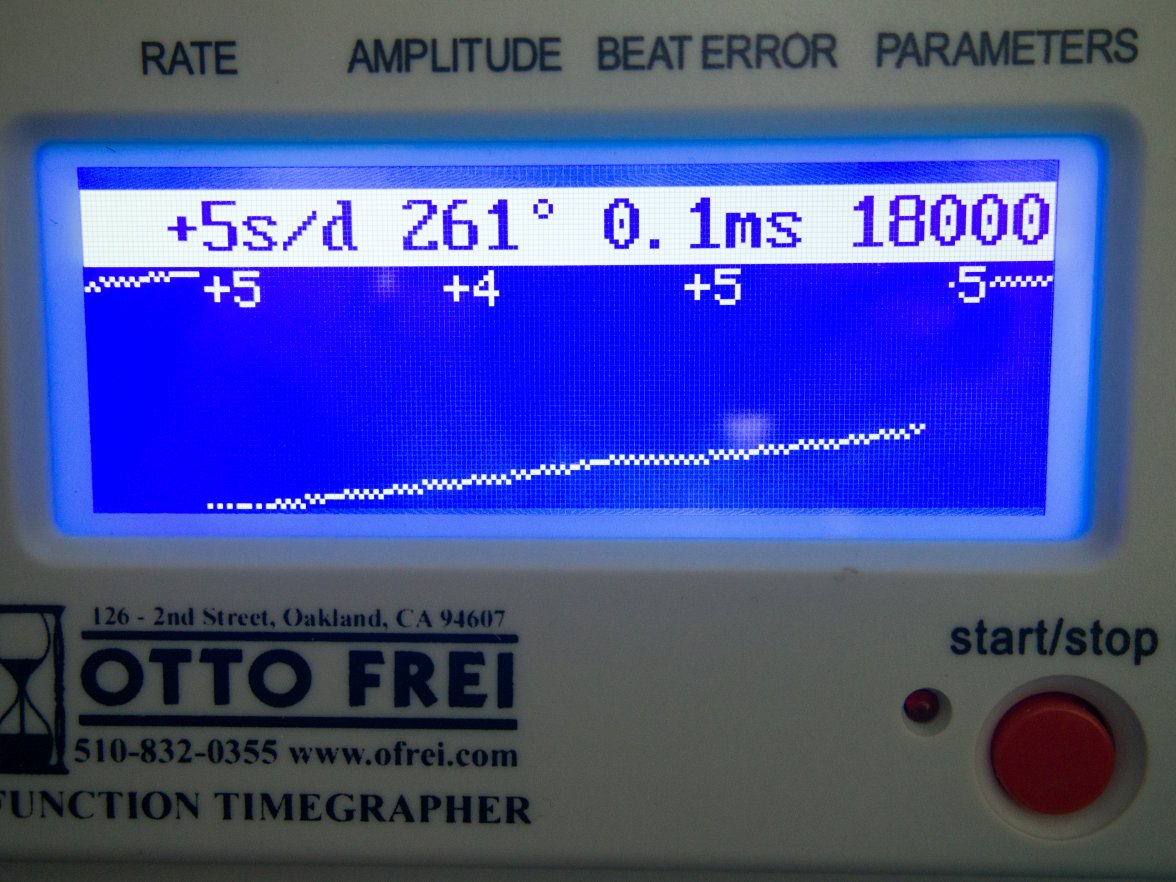

Pendant Right (PR)...

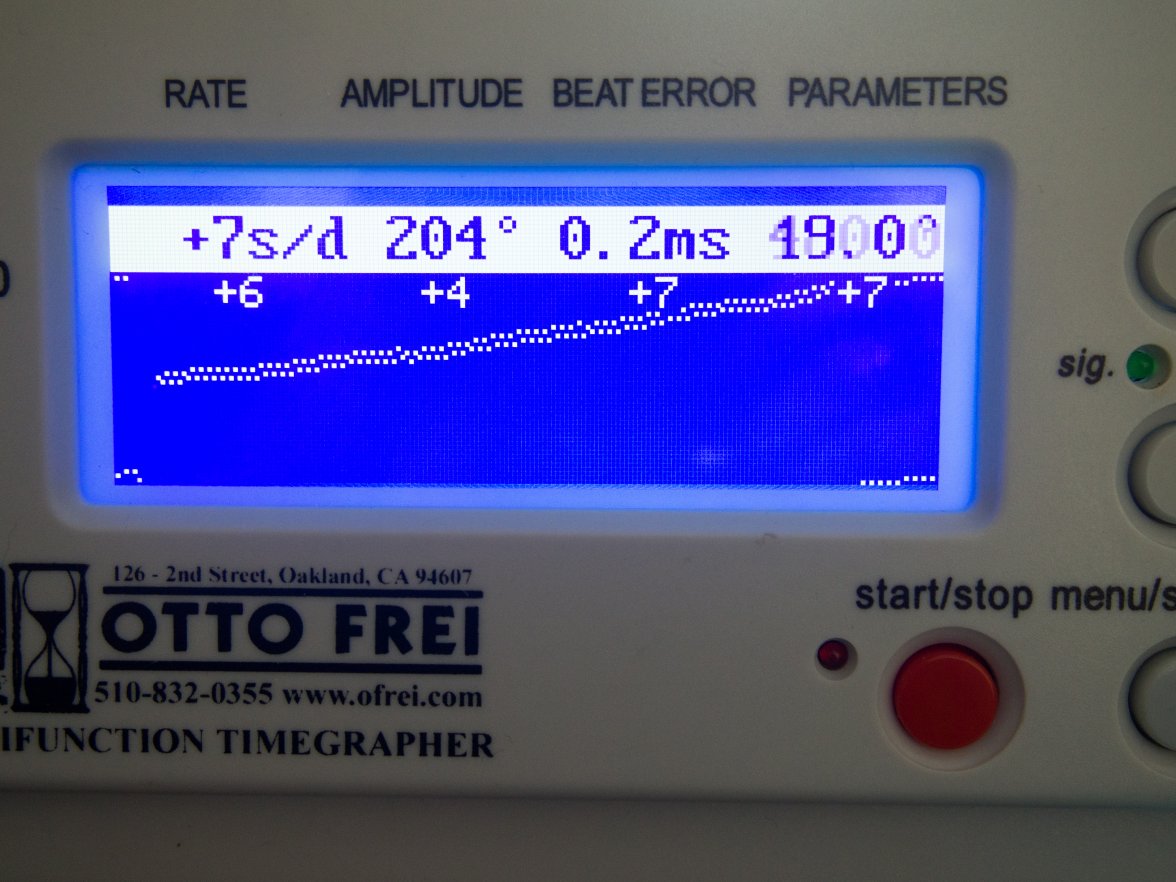

Pendant Up (PU)

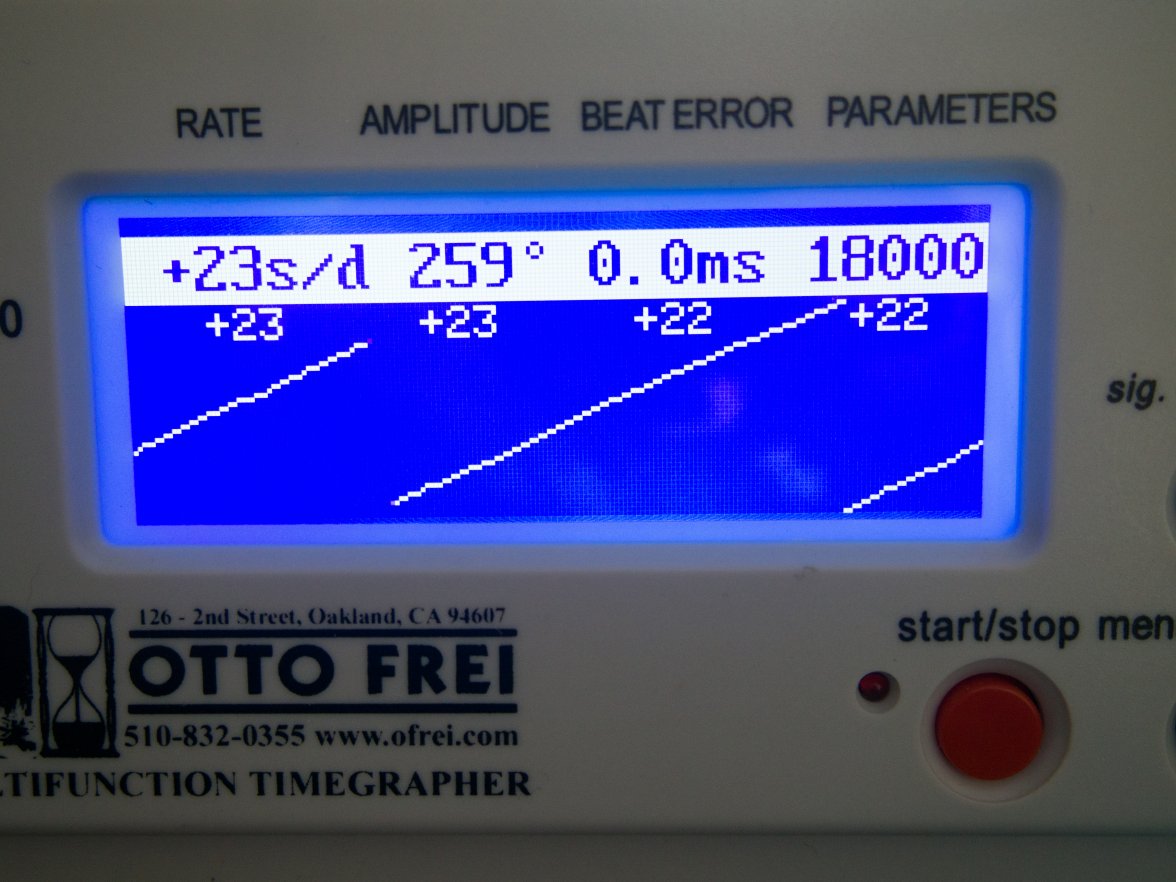

Pendant Left (PL)...

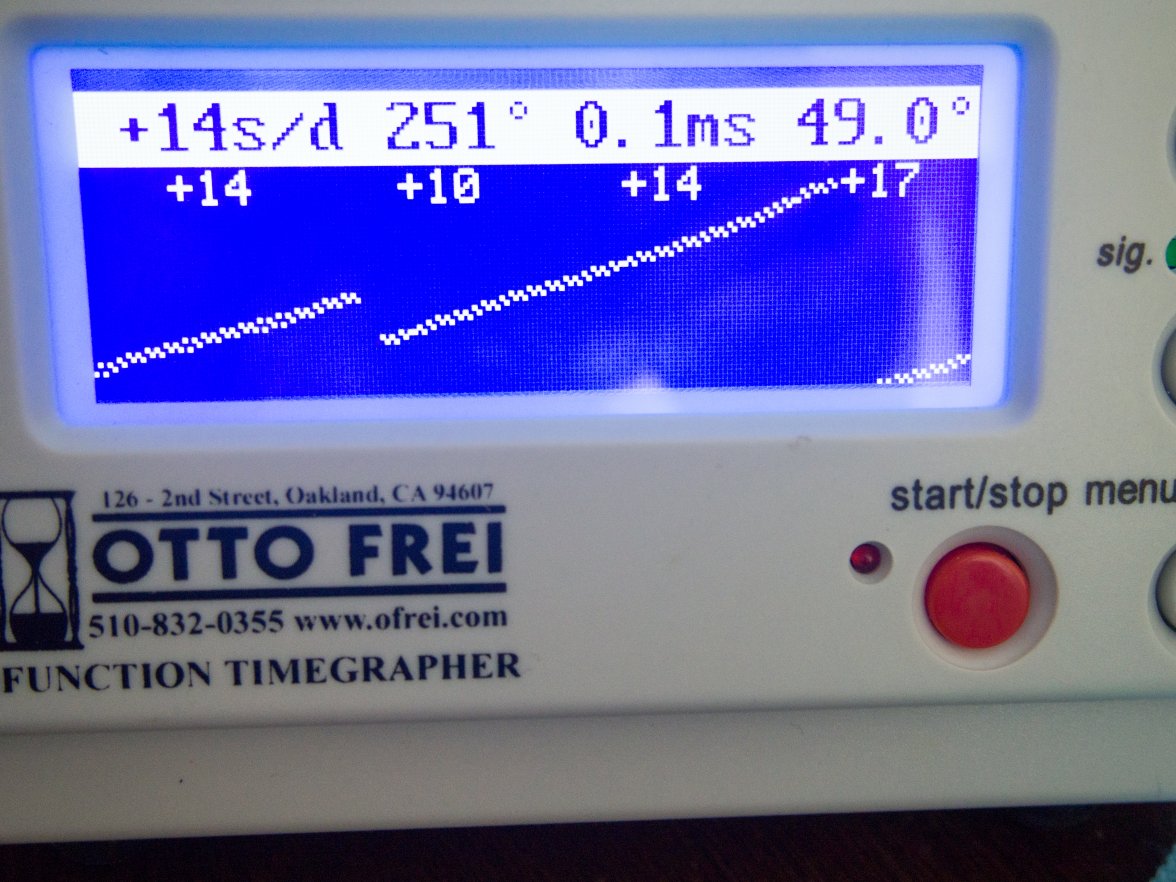

And Pendant Down (PD)...

So - to consolidate in to a table:

[all measurements using 49 deg lift angle]

DU -1 s/d; 299 deg amp; 0.0 ms

DD +2 s/d; 297 deg amp; 0.0 ms

PU +7 s/d; 204 deg amp; 0.2 ms

PD +14 s/d; 251 deg amp; 0.1 ms

PL +23 s/d; 259 deg amp; 0.0 ms

PR +5 s/d; 261 deg amp; 0.1 ms

These numbers were taken about 90 minutes after full-wind.

Should be able to post the 24 hour numbers tomorrow. Will certainly record them - even if I don't have time to post.

-Paul