Hi all,

I think it might make sense to keep you updated, so that if somebody else could profit from my experiences as an absolute newbie starting to work on movements.

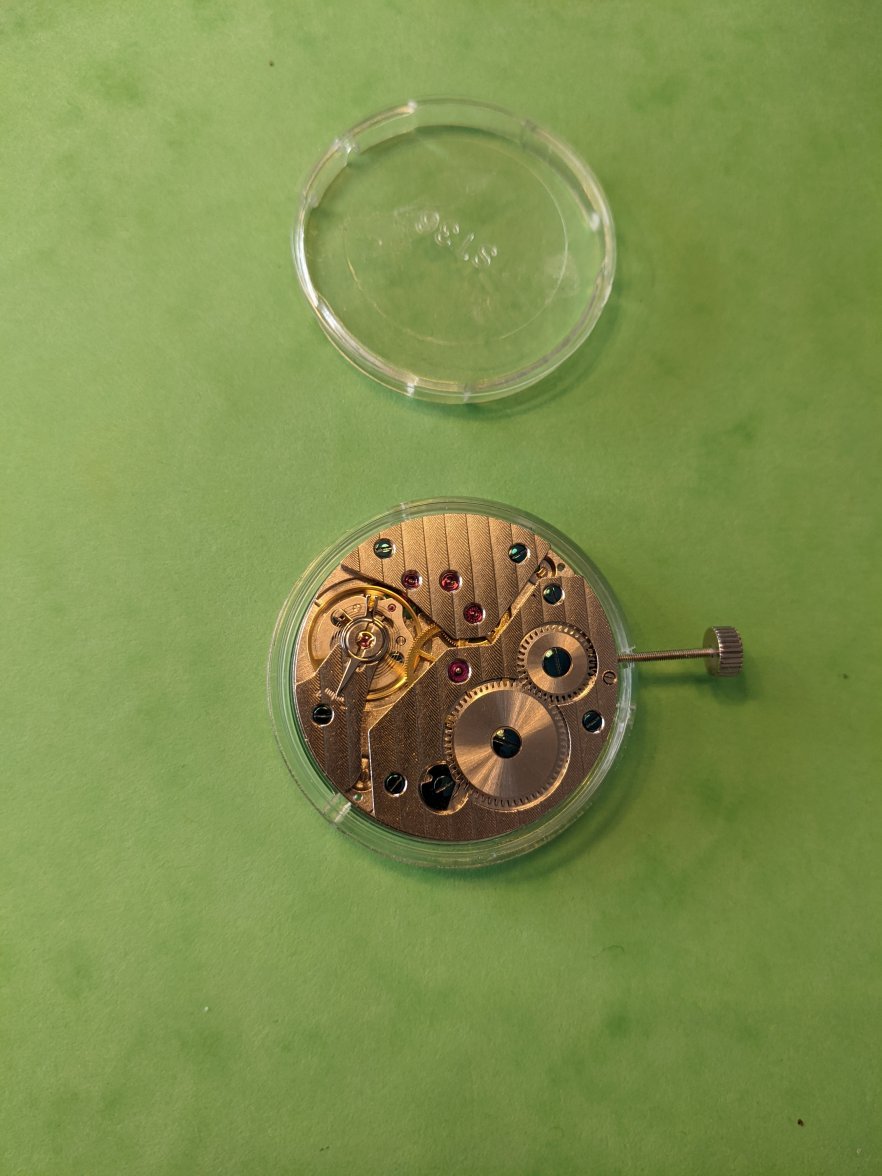

In the mean time the ETA 6498 as well as the screwdivers (Beco) arrived and at first I did not order a loupe as I thought "hey, my eyes are quite good". I am quite happy with the screwdivers, but I will come back to the loupe later.

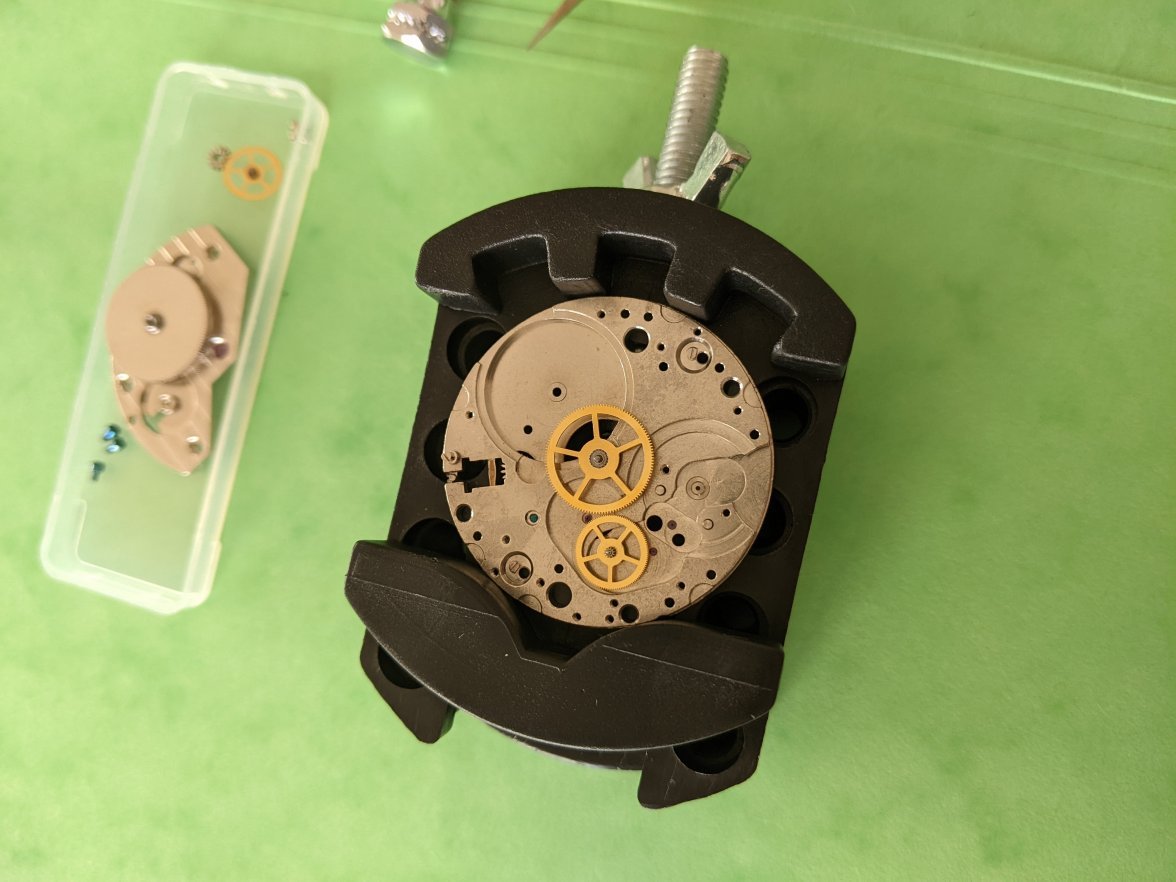

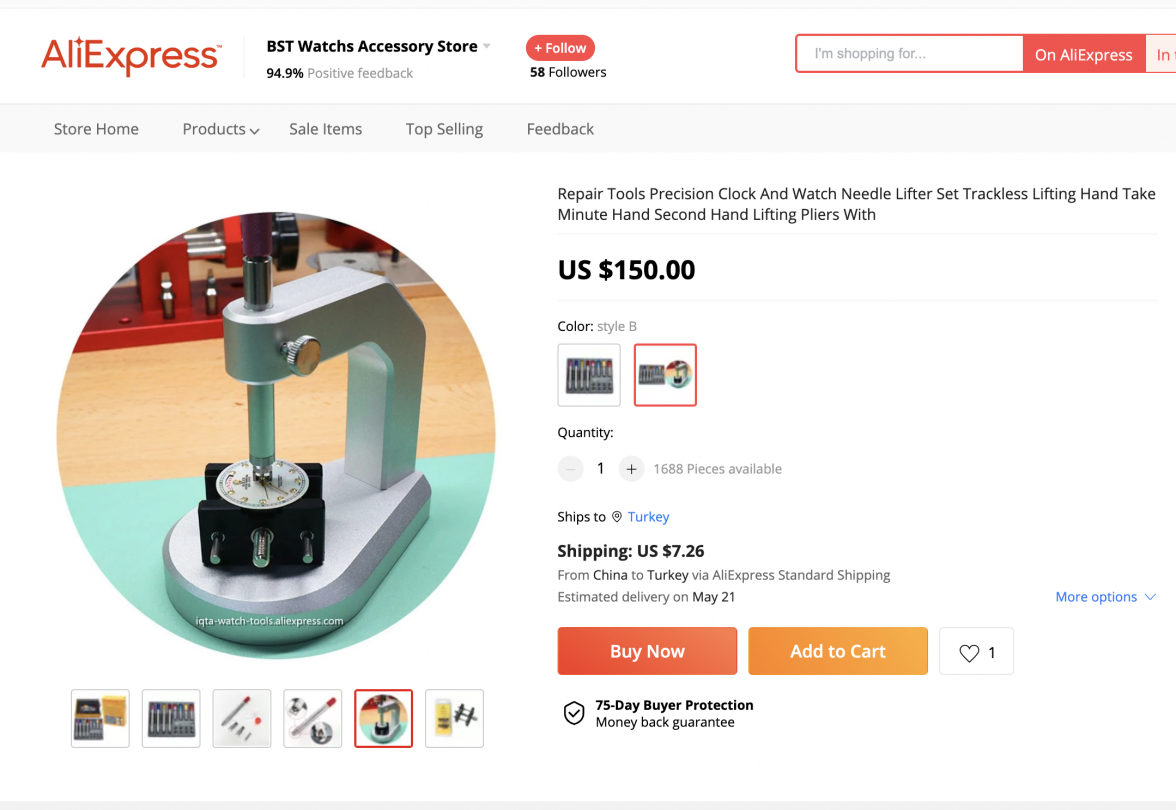

I was able to take the ETA movement apart. However, I could not remove the cannon pinion as I simply don't have the tools for this. The movement holder was part of a cheap toolset I already owned. However it is quite clumsy and the screw can only be operated using both hands. I might want to buy a better one if I would proceed. I am also thinking of buying a proper working mat that does not slip - the green thing I am using right now is just a cardboard folder that is moving the whole time.

Afterwards I managed to put all the different parts together again, and after winding the movement immediately started working.

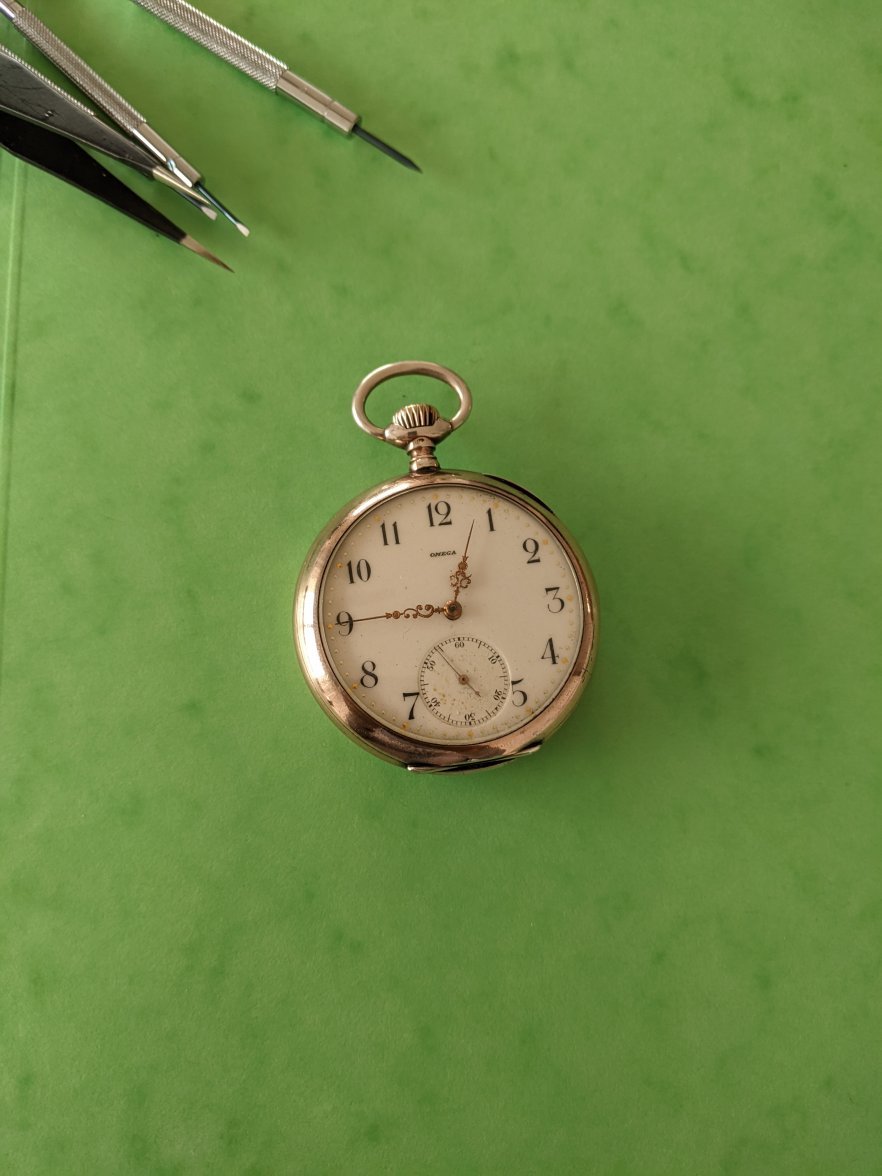

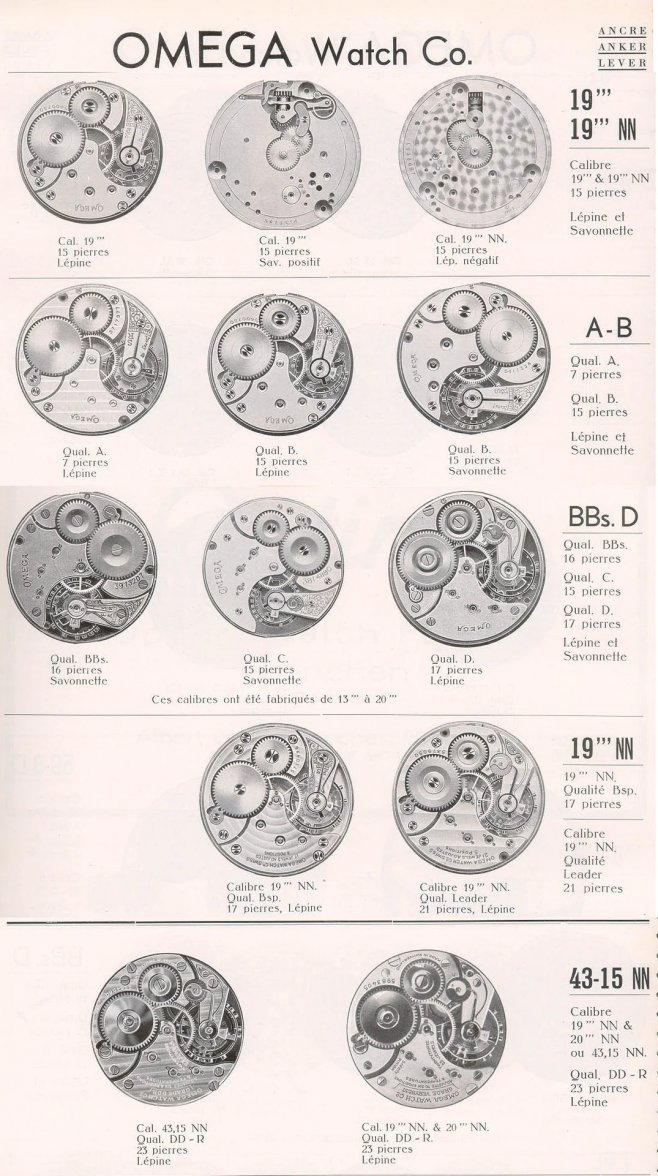

The I thought "Let's carefully have a look onto the old Omega Pocketwatch that I own but is not working"

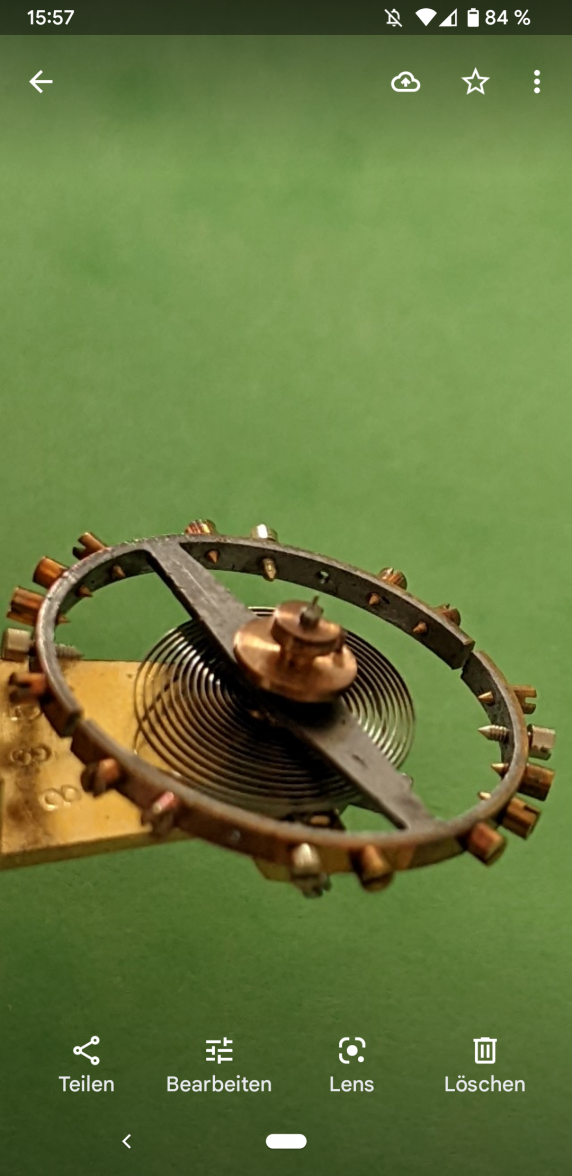

First I unwinded the mainspring to remove the stored energy out of the system before starting to disassemble the movement. It looked quite dirty but right in the beginning you could already see, that the balance wheel was not just moving in a horizontal direction but also vertically. Therefore I assume reason #1 for the non-working state is a broken balance staff. On the bottom side it looked good (see picture), but on the upper part there is not such a "pin" (difficult to see behind the hairspring).

After removing the balance wheel the pallet fork should move from one side to the other upon a gentle touch with the tweezer (and winding the mainspring). This was not the case and the escapement wheel seemed to have a similar defect as the balance wheel. Without a loupe all of the small parts are difficult to see, so I tend to order a loupe too.

To sum it up:

I would like to source a new escapement wheel as well as the balance staff. As I certainly don't have the tools and know-how to change the bance staff, I would like to give this part to a watchmaker.

To find the parts I need to know which caliber the movement is. Is anyone here able to identify the movement?

Let's see if we can revive the watch step by step.

Thank you!