ExpiredWatchdog

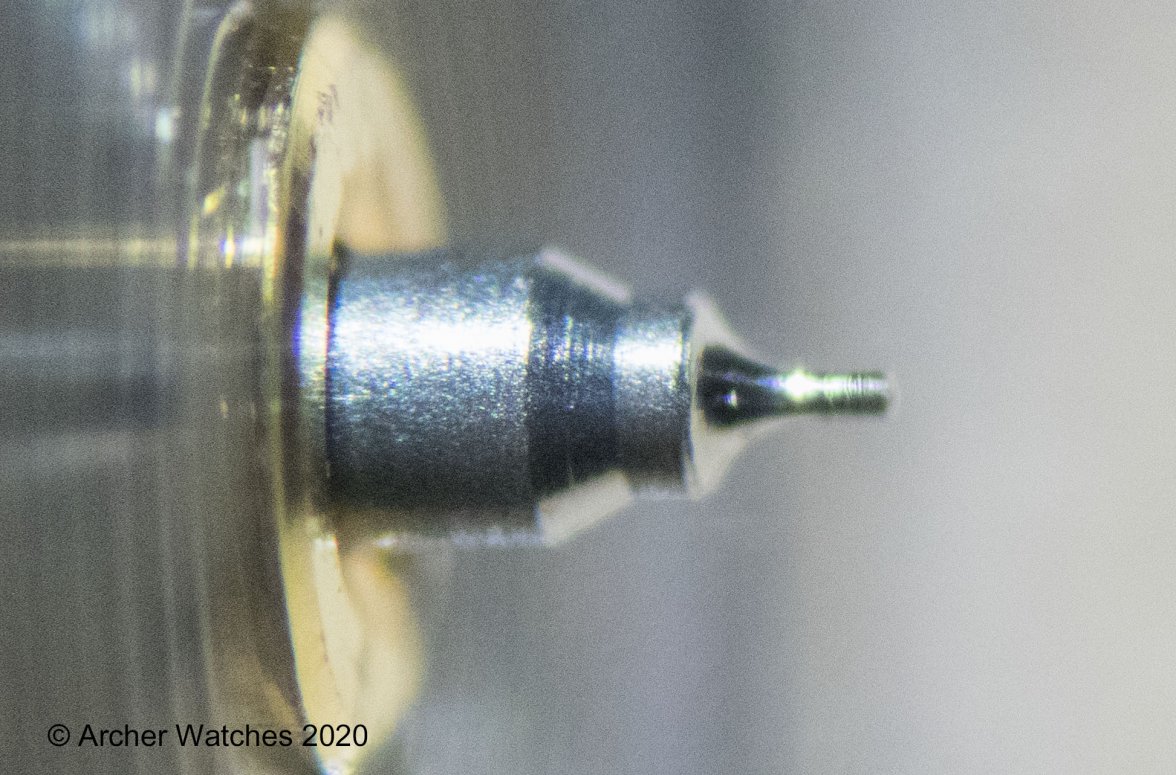

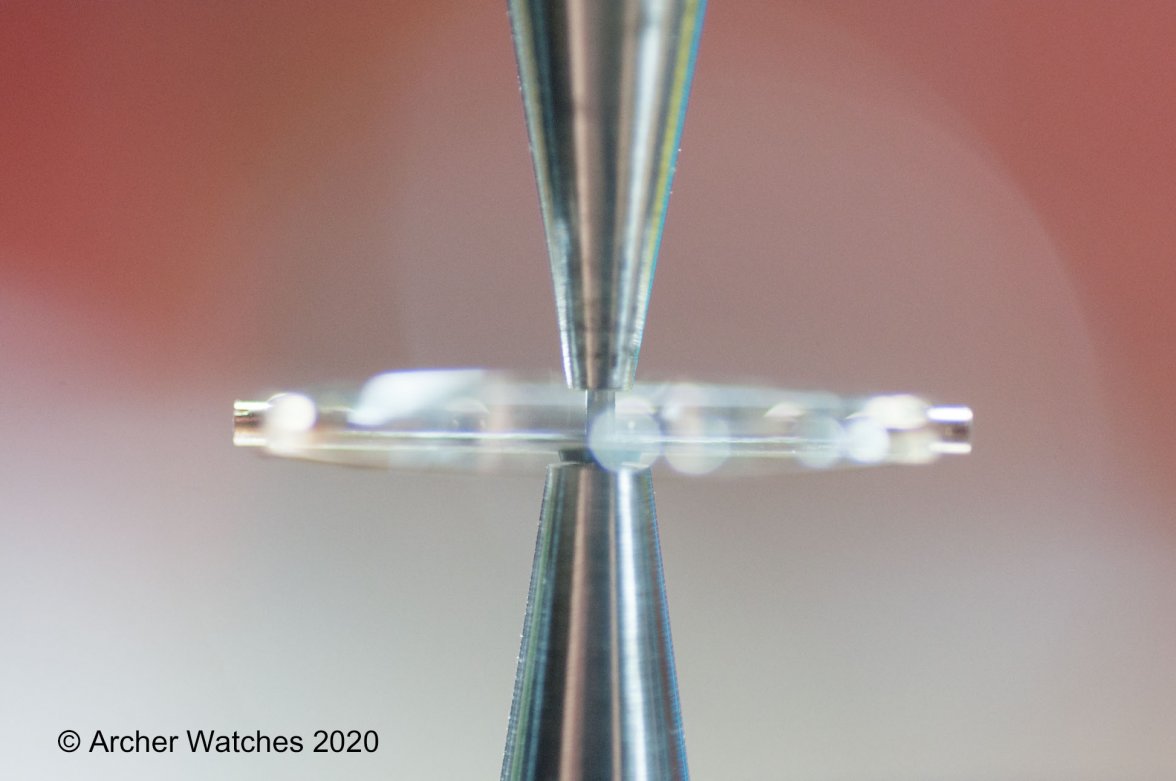

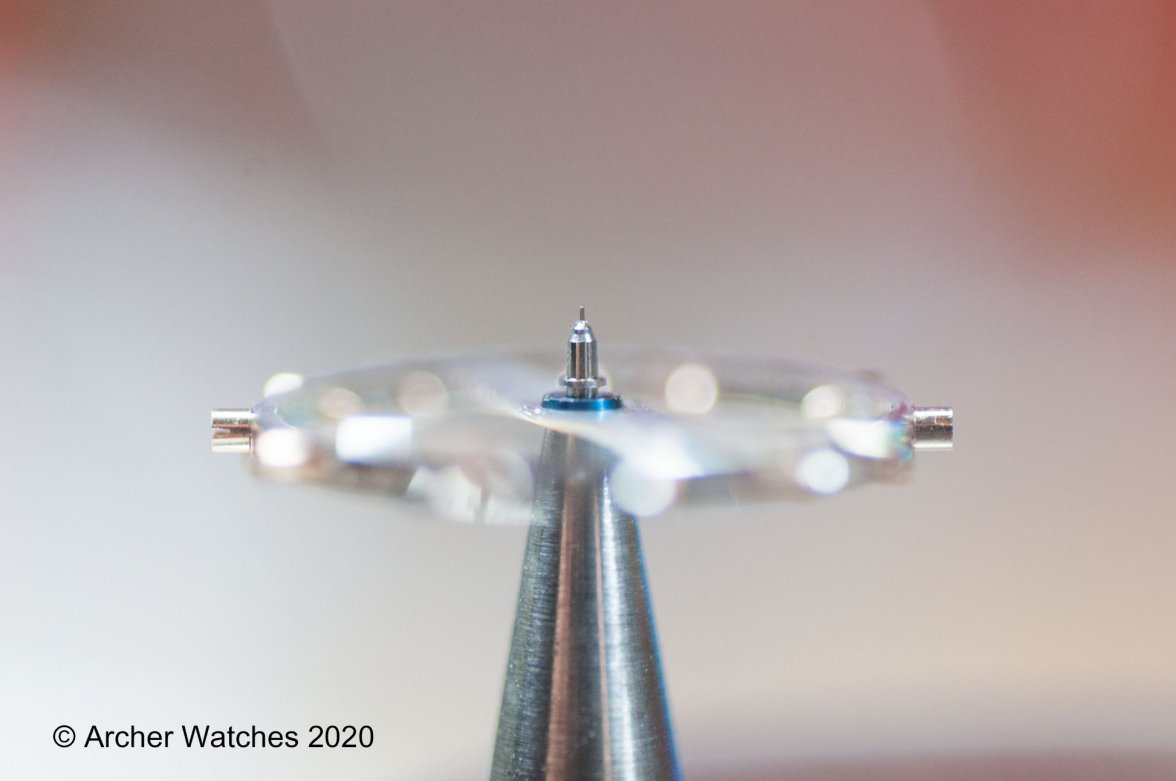

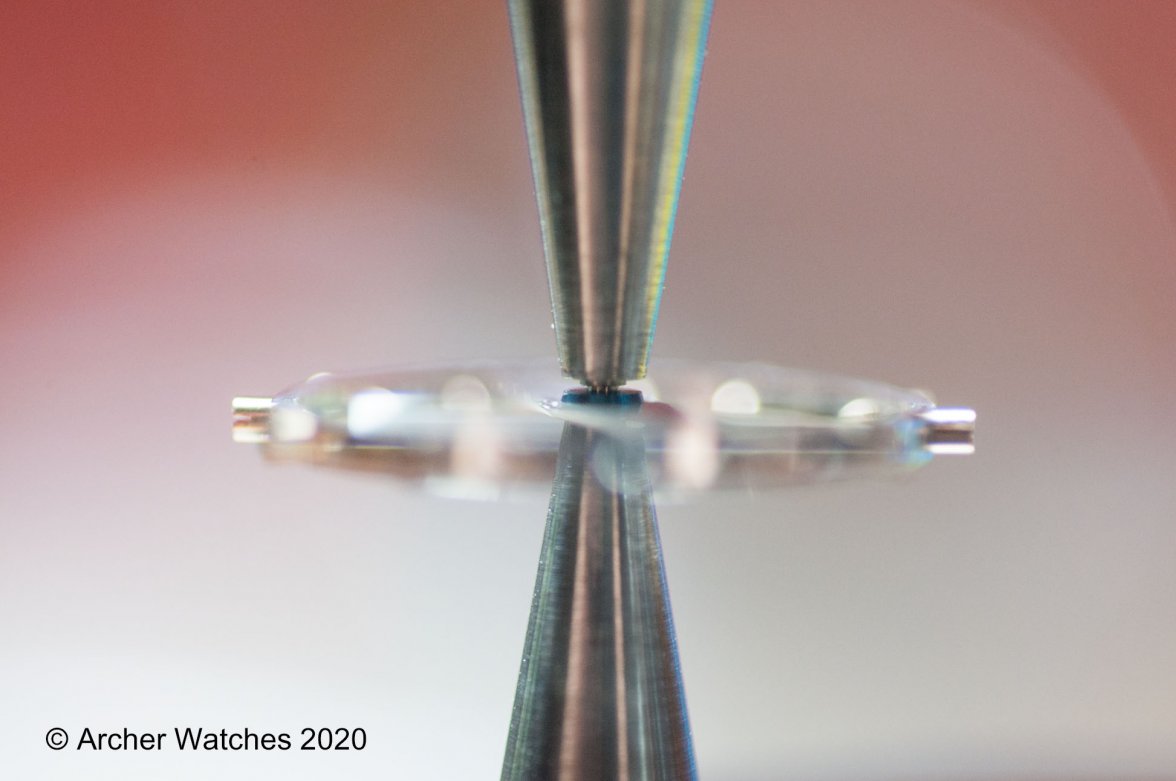

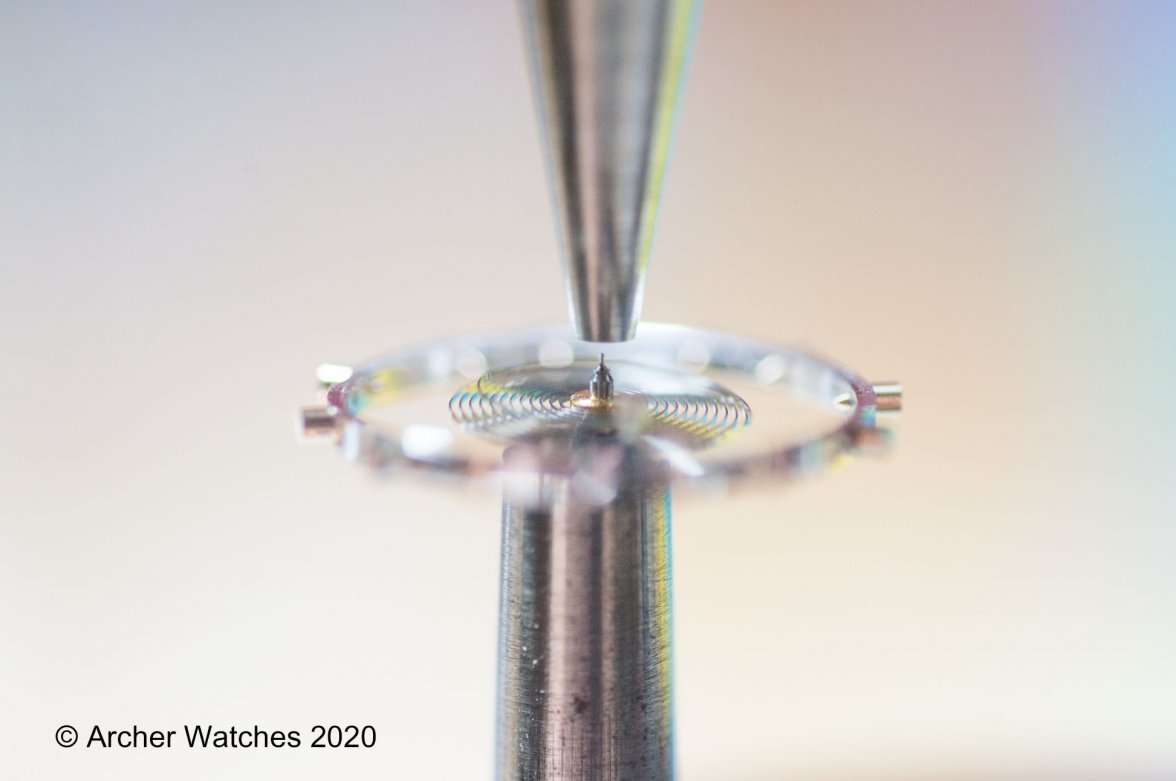

·Thanks for taking the time to answer. I deduced the need to keep the wheel phasing as close to original as possible for the reasons you mention. I find it interesting that you use the stud as a reference; I would have thought it would be the most unreliable choice due to the possibility of the spring changing shape when removing or reinstalling. But I suppose a good watchmaker doesn't have that problem. The larger radius gives you more sensitivity in measurement.

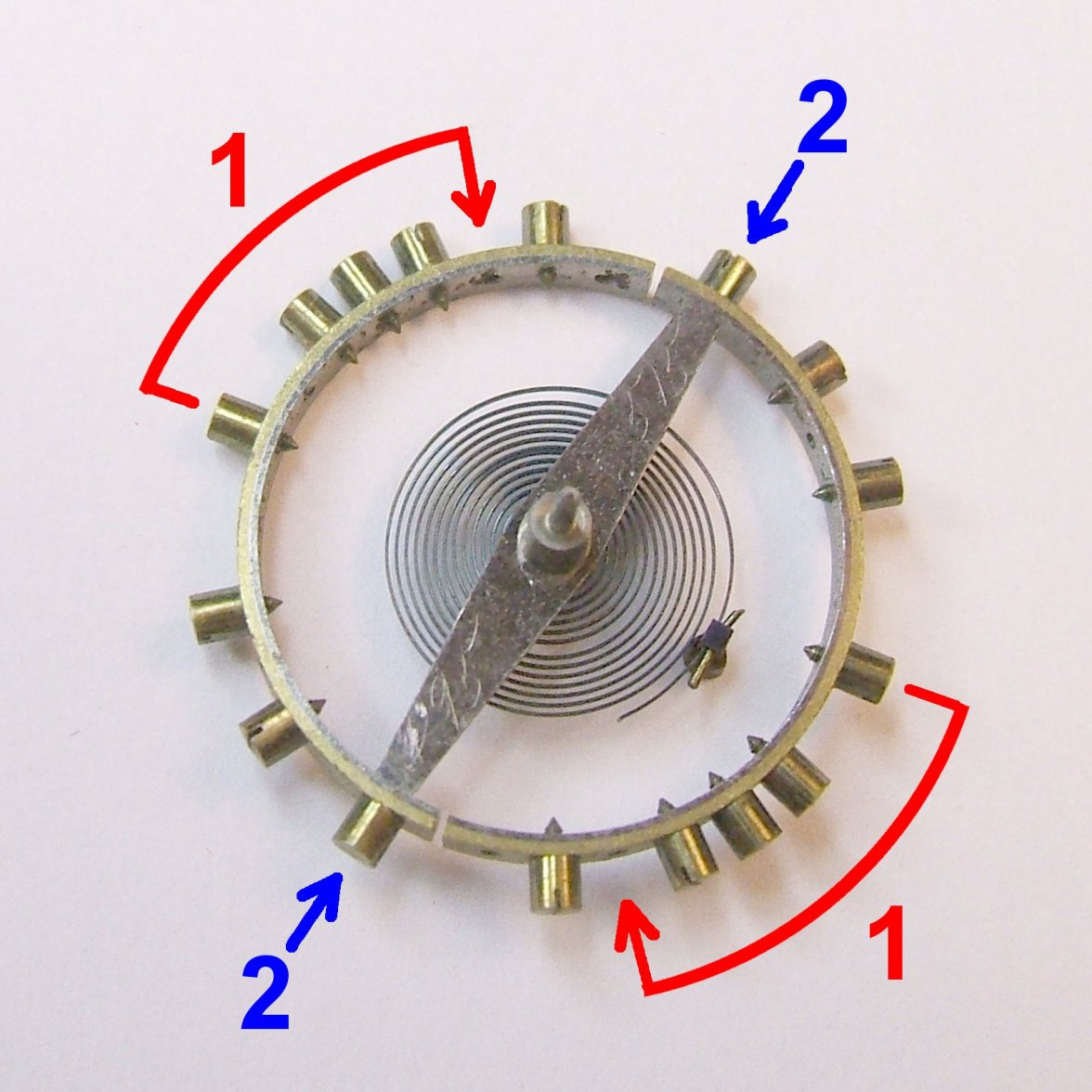

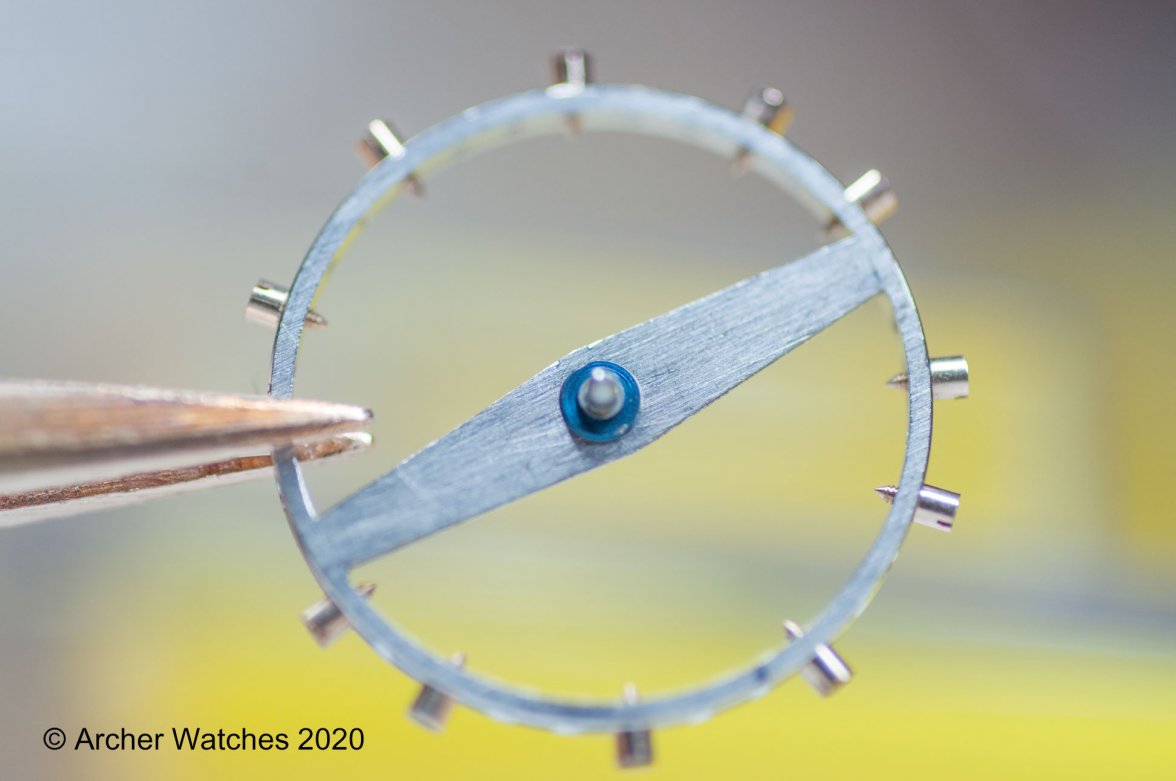

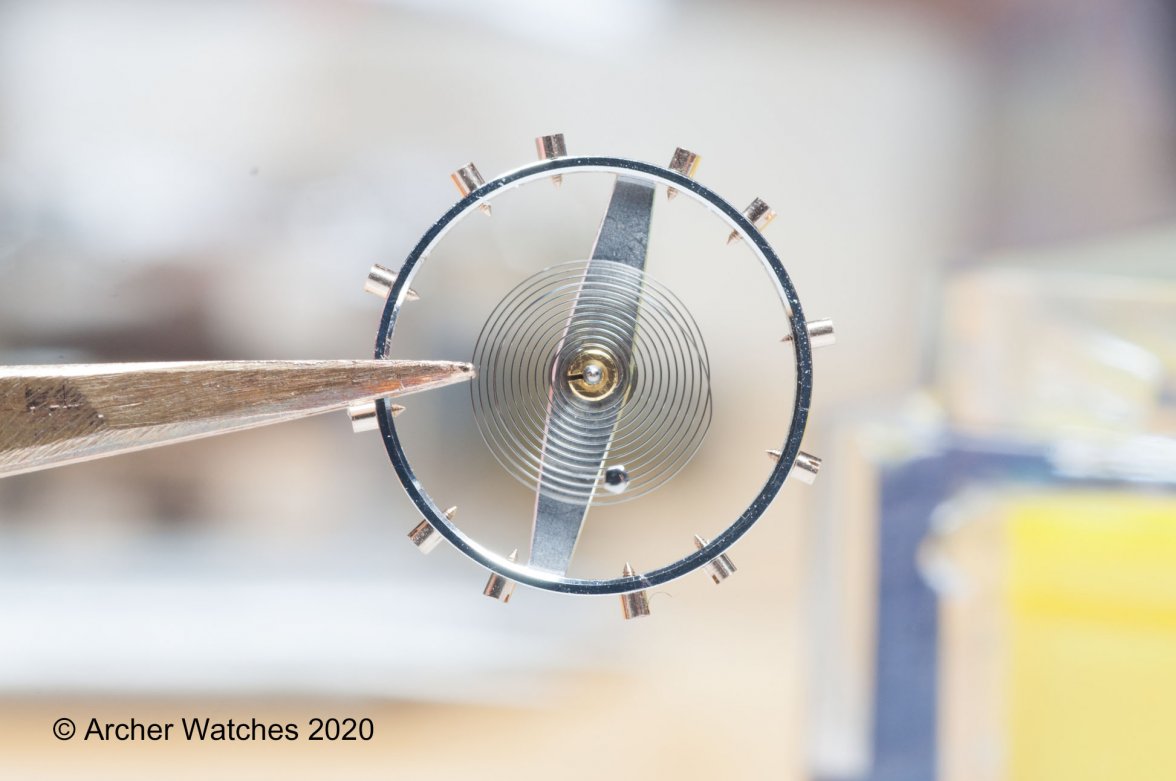

Another question if you don't mind, you chose to put timing washers on opposite sides.Since the balance wheel has timing screws, it's a split bi-metal design, isn't it? What's the best location to put timing washers on to minimize the temperature variance? My guess is halfway between the fixed and floating ends of the rim segments as it's the place that's least likely to move upon temperature differences.

Another question if you don't mind, you chose to put timing washers on opposite sides.Since the balance wheel has timing screws, it's a split bi-metal design, isn't it? What's the best location to put timing washers on to minimize the temperature variance? My guess is halfway between the fixed and floating ends of the rim segments as it's the place that's least likely to move upon temperature differences.

Edited: