samweldspoorly

·Thanks guys! I dont think will become a better welder even with the best equipment and fabrication tools. Sorta like how it doesnt matter if I am using a Bergeon case back back remover tool or a cheap Chinese knock off, imma still scratch that case back. 😉

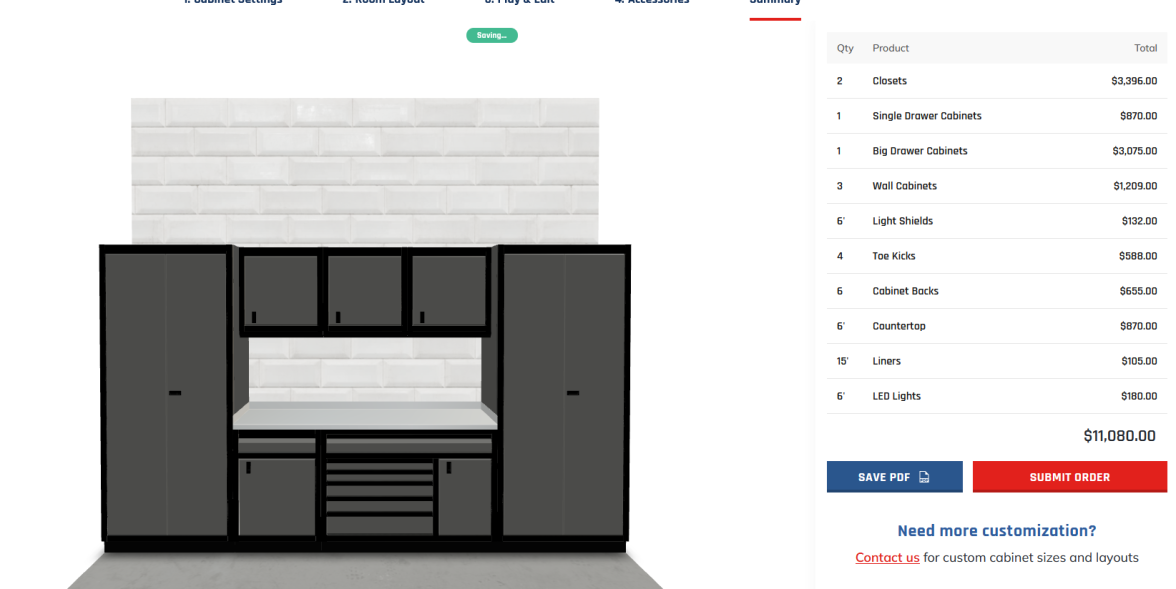

Doors have shown up, cabinnets are getting installed, some painting is happening. Finnaly got my garage doors installed on jackshafts. garage doors are 16x8 and 9x8. Have quotes out right now for a 2-post and 4-post car lift. Also trying to source a Acorn platens 5x5' table for the garage.

Doors have shown up, cabinnets are getting installed, some painting is happening. Finnaly got my garage doors installed on jackshafts. garage doors are 16x8 and 9x8. Have quotes out right now for a 2-post and 4-post car lift. Also trying to source a Acorn platens 5x5' table for the garage.