- Posts

- 16

- Likes

- 8

AlanTexas

·Swatch/Omega/Tissot as a group are very secretive about the various ways silicon is used in their watches. Silly, as any watchmaker can take a watch apart and see the silicon components.

Instead of being secretive, Swatch should do what Patek does: brag endlessly about advanced movements that require far less service yet are far more reliable.

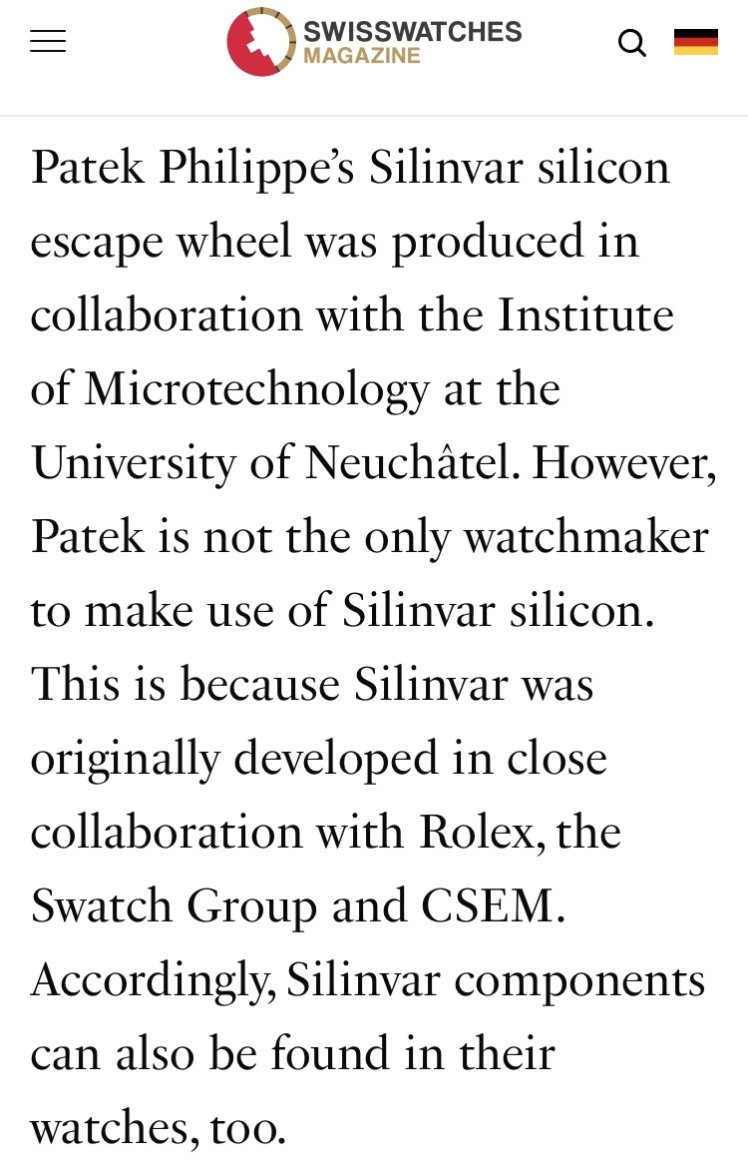

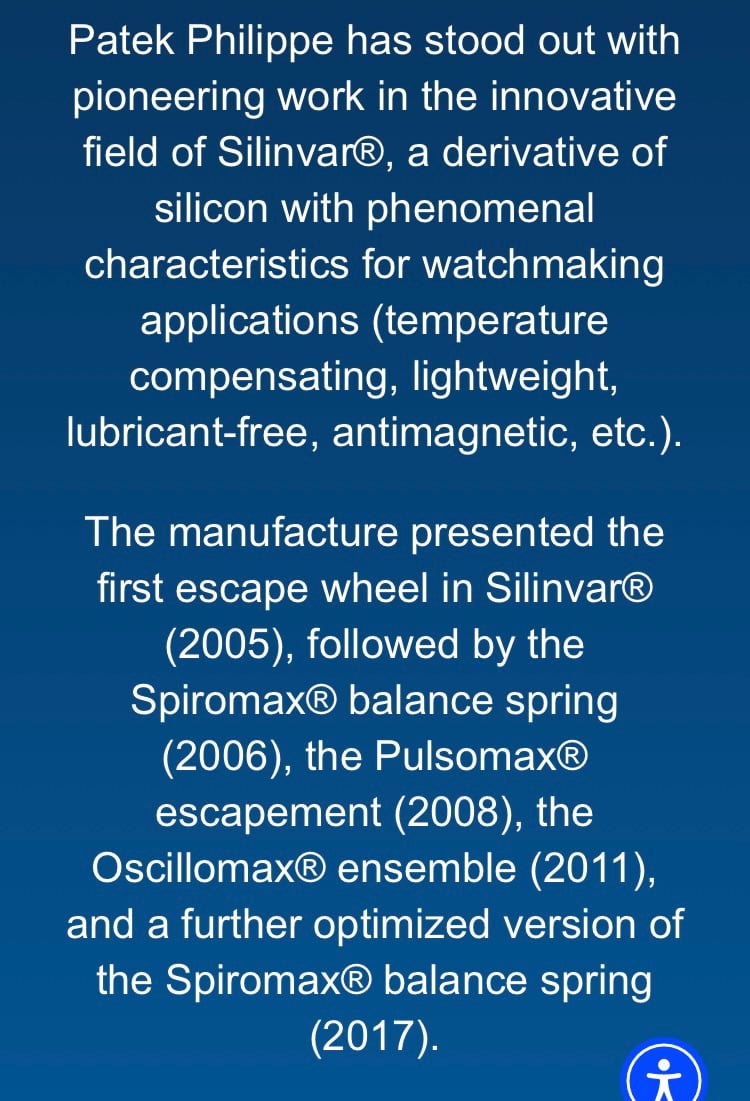

Google for "WatchTime Anti-Magnetic or Bust" for information about the partnership between Patek, Omega and Rolex that controls key patents on the use of silicon in watches. Patek brags about it endlessly on their website.

The evidence is clear that silicon is the "magic" behind the Powermatic movement. The Powermatic upgraded an ETA movement with a 40 hour reserve into one with an 80 hour reserve by replacing an heavy, high friction, high wear steel and ruby escapement with a low weight, zero friction, zero wear, zero lubrication silicon escapement.

Silicone (which people think of as a plastic) is constantly confused with SILICON, a natural substance that is much harder than steel.

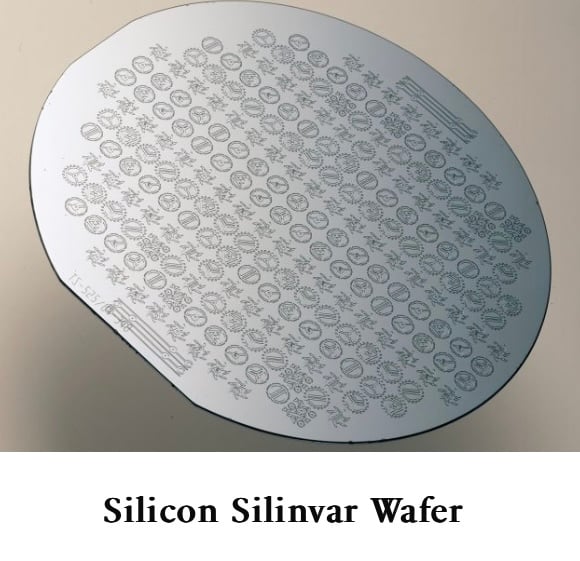

A plastic escapement would wear rapidly and fail very quickly. The cost of a silicon escape wheel and pallet fork when a factory churns out 500,000 units per year is likely about a DIME each (not counting the hundreds of millions of dollars Patek, Rolex and Swatch have invested to get silicon components into mass production).

If a plastic escapements were possible cost just a penny, Swatch would be saving a few pennies per watch but spending millions of dollars in warranty repairs every year.

Instead of being secretive, Swatch should do what Patek does: brag endlessly about advanced movements that require far less service yet are far more reliable.

Google for "WatchTime Anti-Magnetic or Bust" for information about the partnership between Patek, Omega and Rolex that controls key patents on the use of silicon in watches. Patek brags about it endlessly on their website.

The evidence is clear that silicon is the "magic" behind the Powermatic movement. The Powermatic upgraded an ETA movement with a 40 hour reserve into one with an 80 hour reserve by replacing an heavy, high friction, high wear steel and ruby escapement with a low weight, zero friction, zero wear, zero lubrication silicon escapement.

Silicone (which people think of as a plastic) is constantly confused with SILICON, a natural substance that is much harder than steel.

A plastic escapement would wear rapidly and fail very quickly. The cost of a silicon escape wheel and pallet fork when a factory churns out 500,000 units per year is likely about a DIME each (not counting the hundreds of millions of dollars Patek, Rolex and Swatch have invested to get silicon components into mass production).

If a plastic escapements were possible cost just a penny, Swatch would be saving a few pennies per watch but spending millions of dollars in warranty repairs every year.