Please help identify and maybe find Omega cal 351 replacement parts

drgary

·Thanks, Don. I've sent an email to the president of the Portland, OR chapter. Before that, another member posting on this thread recommended a watchmaker he has used in New Mexico, Gregory Mogle, and I'm in email conversation with him. He may well work out. He was recommended by another member too, who had several watches serviced by him. Here's that post.

https://omegaforums.net/threads/wat...intage-omegas-and-others.102227/#post-1335043

Edited:

drgary

·As a follow-up, I've had the best possible experience working with watchmaker Greg Mogle. He has a WOSTEP, CW21 certification.

From the moment he received my watch, Greg sent me detailed pictures, showing me what he was finding that needed repair or replacement. He gave me the option to go even further and have new bearings installed, showing me the start of wear on one part, but there was no pressure. Since I won't wear this watch daily (although I'm tempted), I chose to forgo the bearings. He was meticulous in setting it for accuracy and wore it for a week to make sure the repair was holding up. He warrants his work for a year and wants me to keep me posted on how it's performing. My Omega is holding excellent time, it runs through the night, and the feeling of winding it is much smoother than before. It retains its vintage look. I couldn't be happier.

I can highly recommend Greg. His fee is $150 to inspect, $300 a day if he proceeds, when the inspection fee is waived. The inspection involves "a full tear-down and inspection of all parts and load-bearing surfaces." He writes that a "normal" service takes a day, although some work may require more time. With parts, labor and shipping I paid $570. I can post contact information if that is allowed on this forum. Please let me know. Until then, please send me a private message for his contact information.

From the moment he received my watch, Greg sent me detailed pictures, showing me what he was finding that needed repair or replacement. He gave me the option to go even further and have new bearings installed, showing me the start of wear on one part, but there was no pressure. Since I won't wear this watch daily (although I'm tempted), I chose to forgo the bearings. He was meticulous in setting it for accuracy and wore it for a week to make sure the repair was holding up. He warrants his work for a year and wants me to keep me posted on how it's performing. My Omega is holding excellent time, it runs through the night, and the feeling of winding it is much smoother than before. It retains its vintage look. I couldn't be happier.

I can highly recommend Greg. His fee is $150 to inspect, $300 a day if he proceeds, when the inspection fee is waived. The inspection involves "a full tear-down and inspection of all parts and load-bearing surfaces." He writes that a "normal" service takes a day, although some work may require more time. With parts, labor and shipping I paid $570. I can post contact information if that is allowed on this forum. Please let me know. Until then, please send me a private message for his contact information.

Edited:

GMOG

·Thank you drgary for the positive endorsement! It was a real treat working with you on this project. I look forward to the next one.

If anyone else is interested in my services please feel free to send me a message. I specialize in vintage wrist and pocket watches, and am happy to advise folks about proper care of and service for their watches.

Cheers!

-

Greg

If anyone else is interested in my services please feel free to send me a message. I specialize in vintage wrist and pocket watches, and am happy to advise folks about proper care of and service for their watches.

Cheers!

-

Greg

Edited:

GMOG

·I'll add that drgary's caliber 351's main challenge was from an incorrect part that was swapped over from an earlier caliber (342 - 344, I believe), in this case the bridge that covers the automatic mechanism. The 351 - 355 calibers look almost identical the those earlier calibers, and while some parts in the automatic works appear the same they are different. In the 351 - 355 movements Omega simplified the design, replacing two bridges that sandwich together with one piece. Someone used the earlier top bridge (Bestfit # 1268 or 1281) which is thinner than the correct part (Bestfit # 1299), and employed a "creative" approach to try to make it work. I'm surprised drgary's watch held together as long as it did after this swap was done. I'm glad that I had the correct parts for his watch in my stash of old movements.

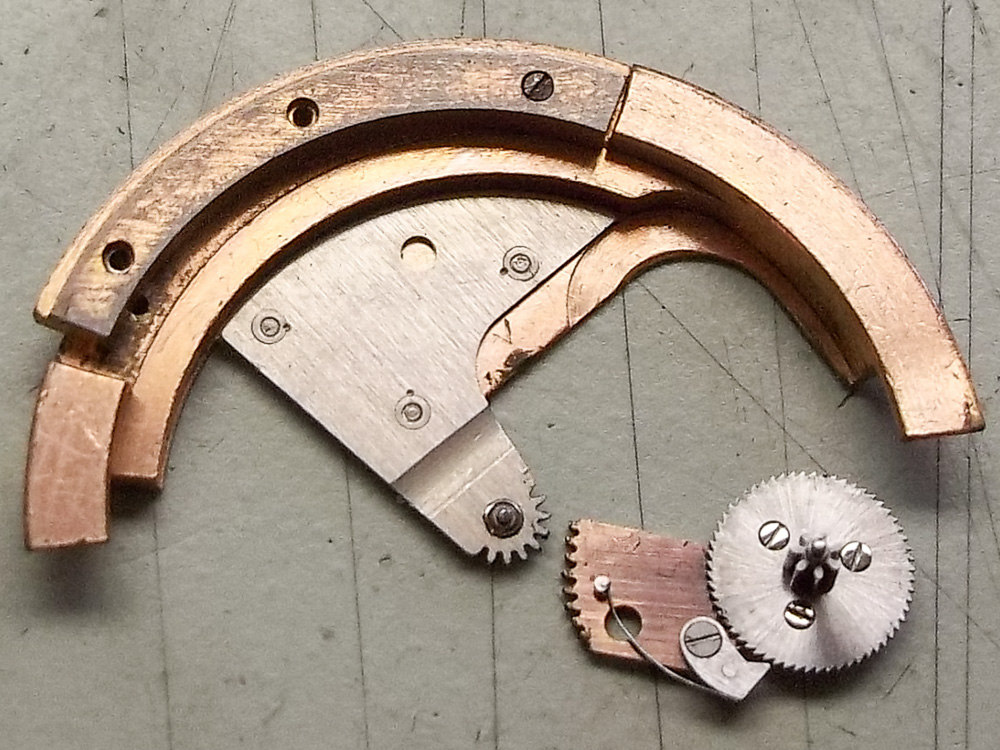

The photo below shows the difference between the two bridges. The thinner, earlier part that was swapped into drgary's movement is on the left. It was squeezing down on the oscillating weight's axle and also on the pawl bearing's arbor. When the bridge screws came loose the teeth on the pawl bearing's rack were deformed badly:

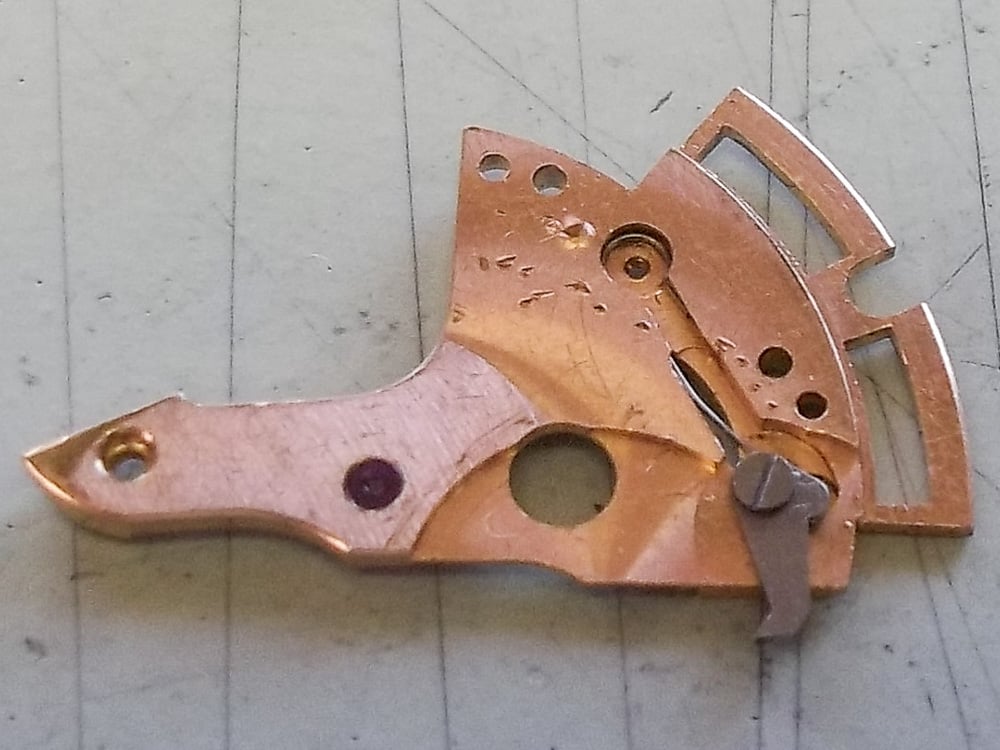

Here are the damaged teeth on the pawl bearing. You can also see here that the oscillating weight was missing two of the three screws that hold the weight mass to the weight assembly:

And here is what someone did to try to space that thinner, incorrect bridge out to make things "fit":

Cheers!

-

Greg

The photo below shows the difference between the two bridges. The thinner, earlier part that was swapped into drgary's movement is on the left. It was squeezing down on the oscillating weight's axle and also on the pawl bearing's arbor. When the bridge screws came loose the teeth on the pawl bearing's rack were deformed badly:

Here are the damaged teeth on the pawl bearing. You can also see here that the oscillating weight was missing two of the three screws that hold the weight mass to the weight assembly:

And here is what someone did to try to space that thinner, incorrect bridge out to make things "fit":

Cheers!

-

Greg

drgary

·As I said ... my Omega was in good hands! Greg was showing me these photos and more as he was estimating my repair.