JimInOz

··Melbourne AustraliaHi Jim,

I see you have bought the Fleurier 350 manual winding spring. Before you install it, please measure the old spring you removed, as I think you may have the wrong spring.

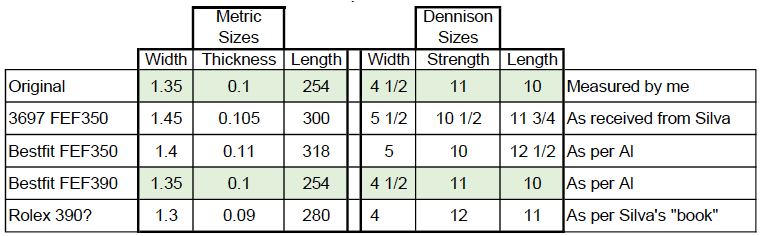

Looking in by Bestfit book, the FEF 350 calls for a slightly different spring than the spring you have. Your is a 5 1/2 X 10 1/2 X 11 3/4 Dennison, while Bestfit calls for a 5 X 10 X 12 1/2. Those differences aside, the FEF 390 calls for a different spring completely - a 4 1/2 X 11 X 10.

Just want to be sure you have the right spring before you try to install it, because once you do there's no chance of sending it back.

Cheers, Al

Thanks Al, I'll measure everything and cross ref to the chart to see what I took out.

I'll also get back to the seller who advertised it as fit for a Tudor Cal 390.

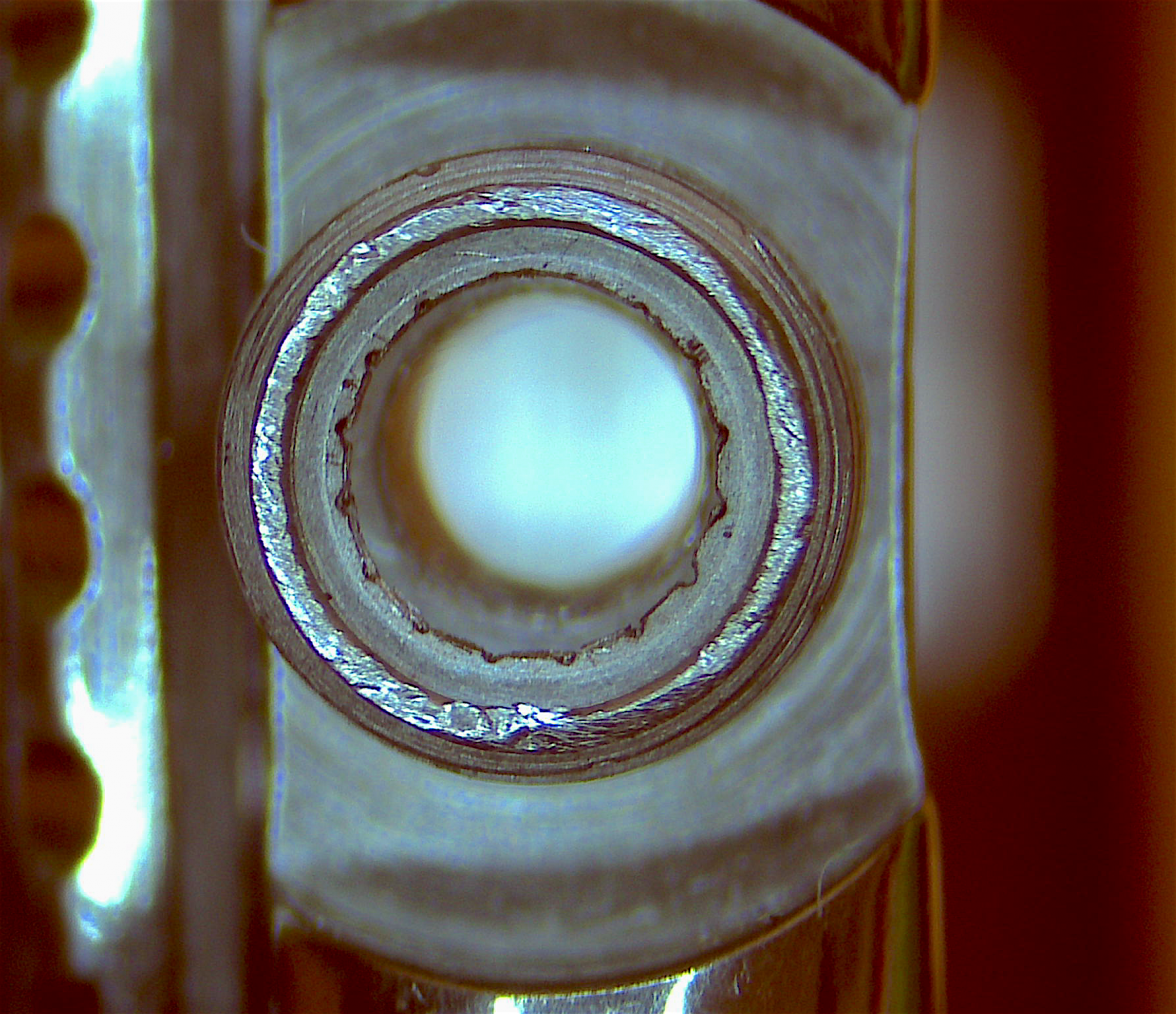

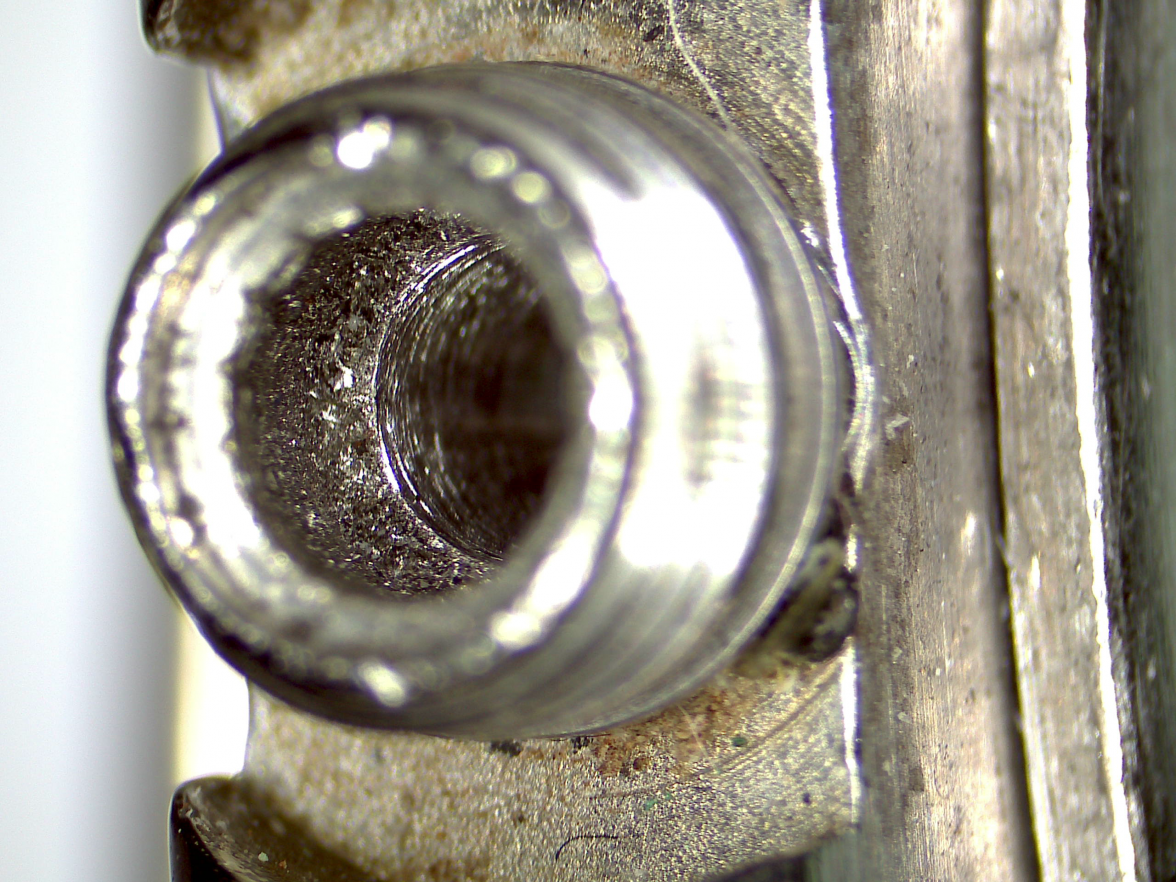

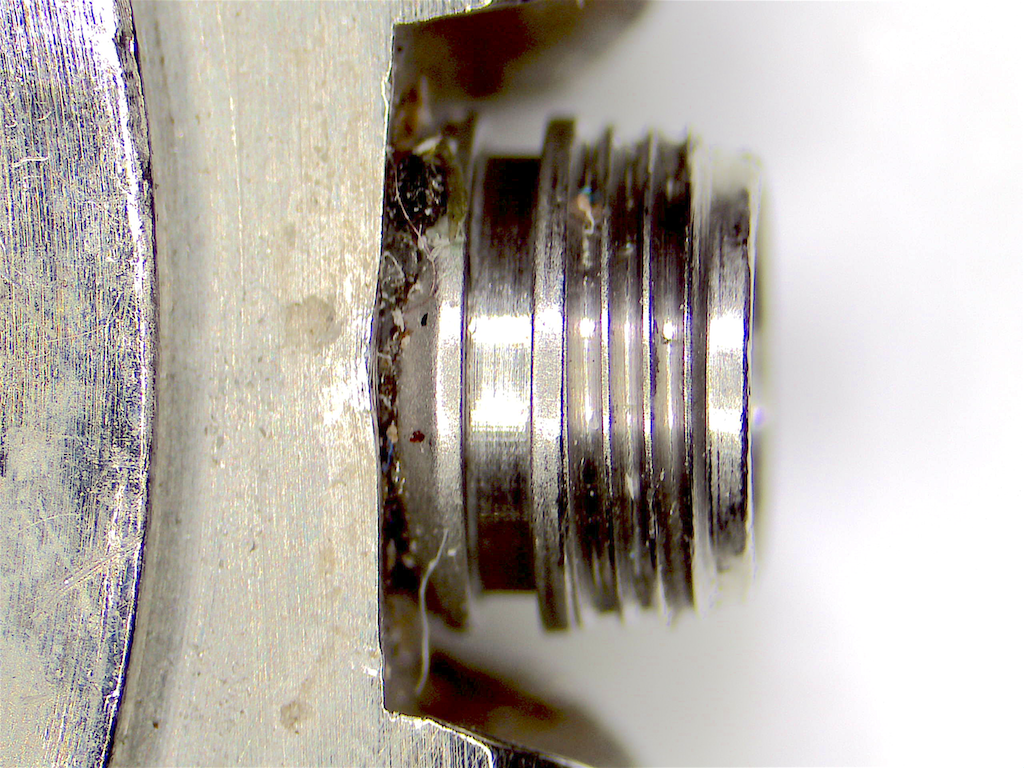

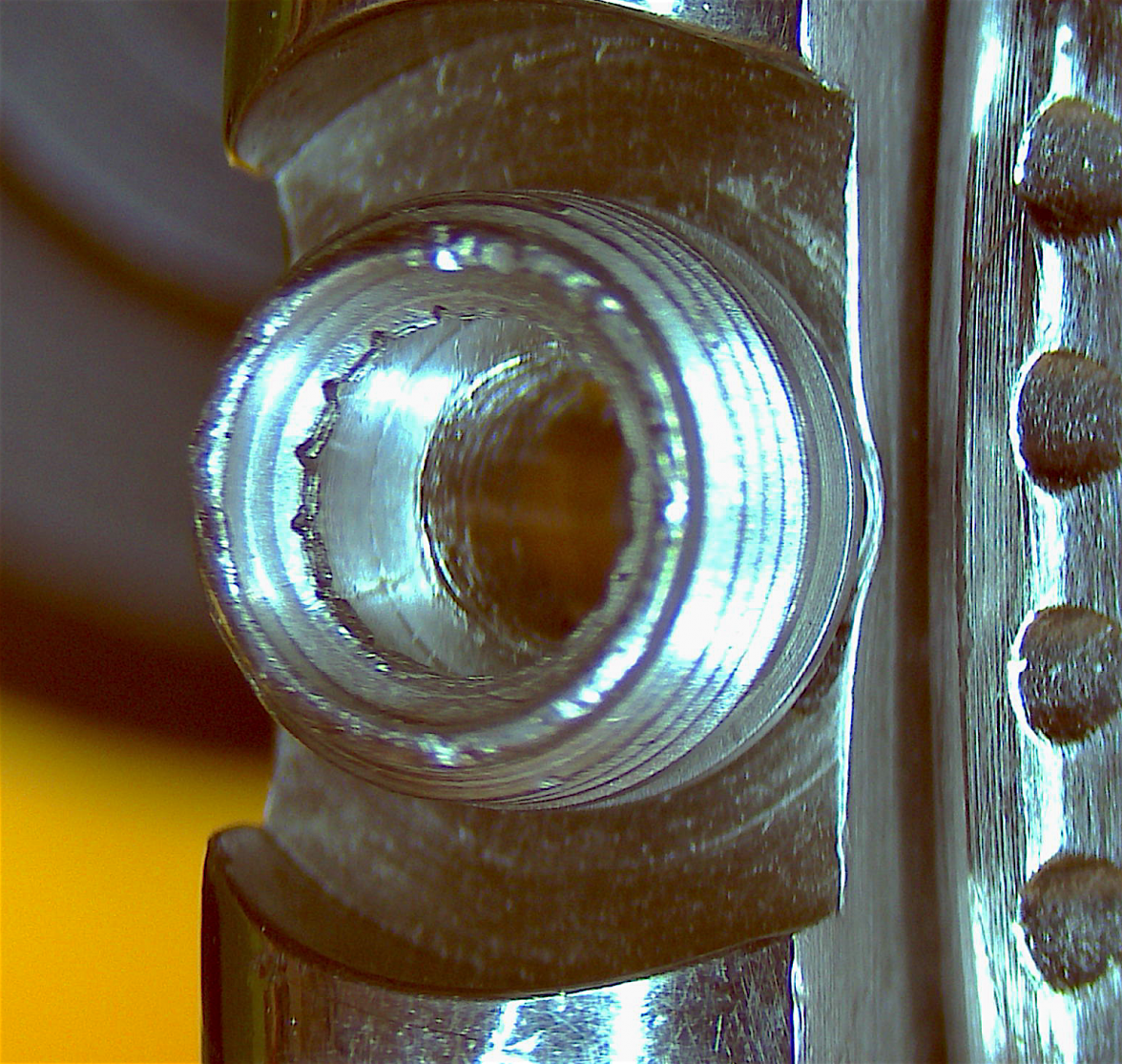

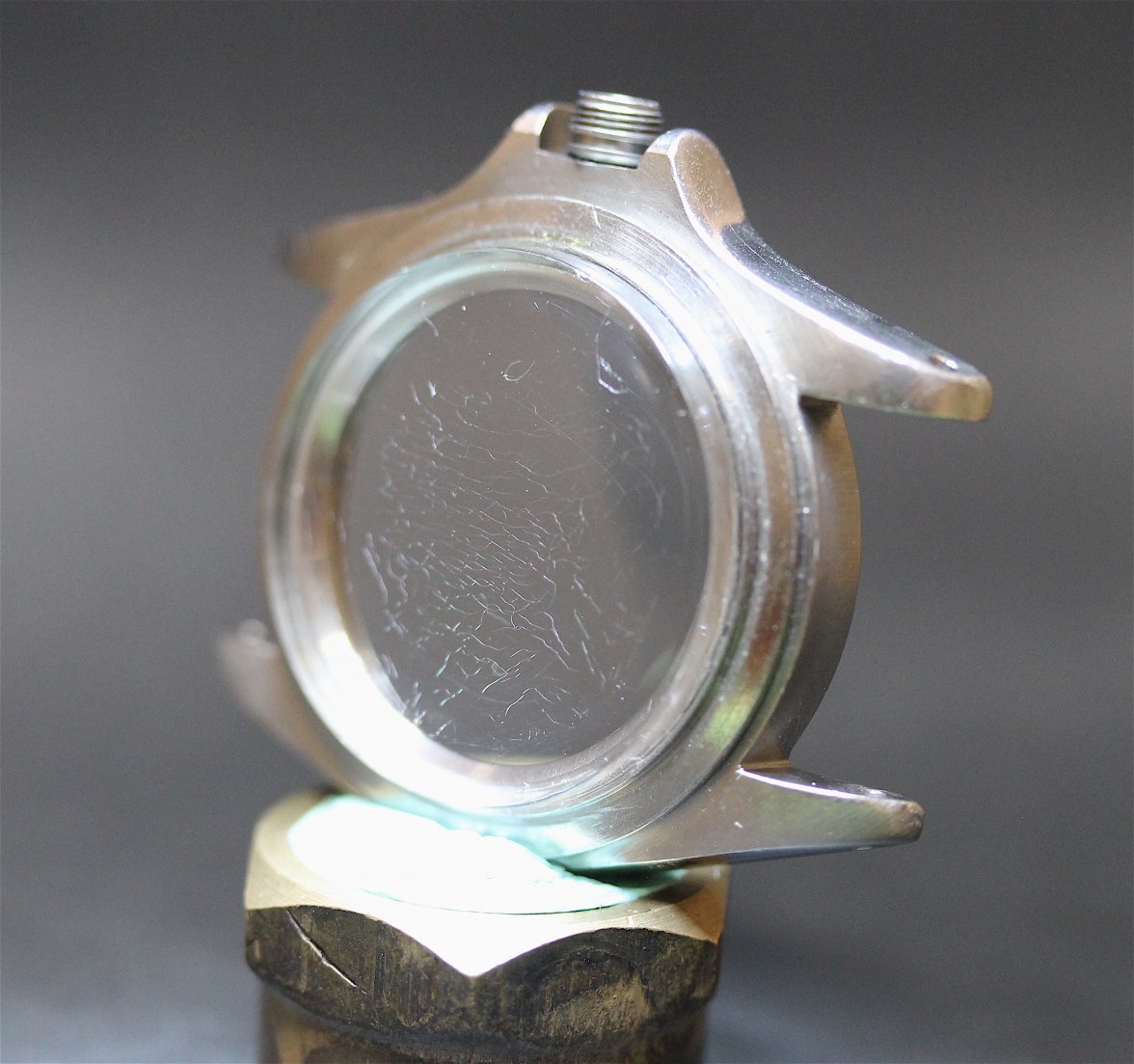

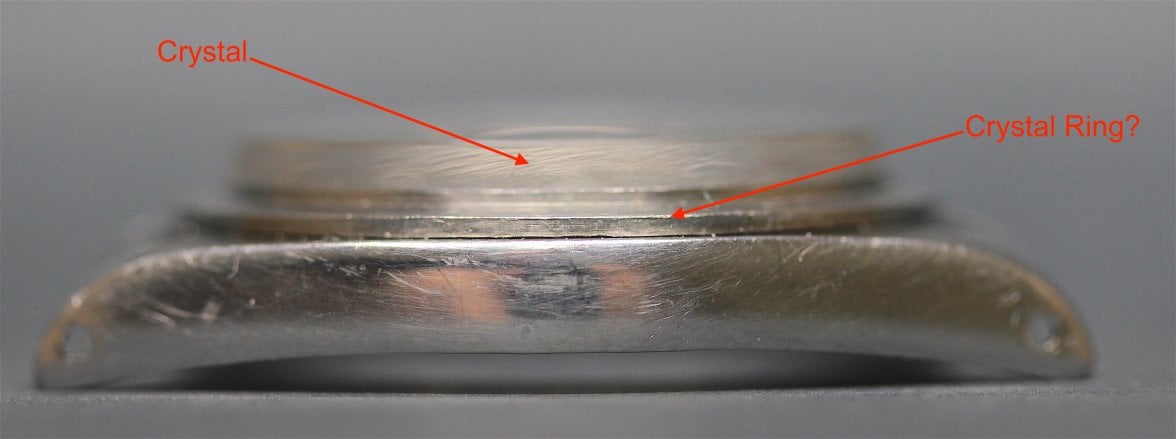

@JimInOz I've seen the same type of image/photo technique in other people's photos (some weren't watchmakers or anything like that) and I would really like to recreate it as I'm liking it so much.

Don't know if you've already done this but could you please share how you take such photos ? For example how come you manage to light up the watches/movements withot getting that annoying light reflexion into the metal ? I imagine you use diffused light ?

Cheers!

I mostly try to use natural daylight and get the best results on cloudy days. If I can't get enough natural light, I have a light ring on my camera setup.