On My Bench - Smiths De Luxe

size11s

·jaguar11

·Another enjoyable addition of your series!!!

CPRwatch

·What a great thread & lovely to see someone taking the time & effort to put in the hard work for us to enjoy .And I’ve got to add my Smiths De luxe I picked up last Saturday , it’s a lovely watch but a bit too small for me . So the lovely Mrs CPRwatch is doing the wrist modelling on the first picture

SmithSJ

·JimInOz

··Melbourne AustraliaBack to the workbench.

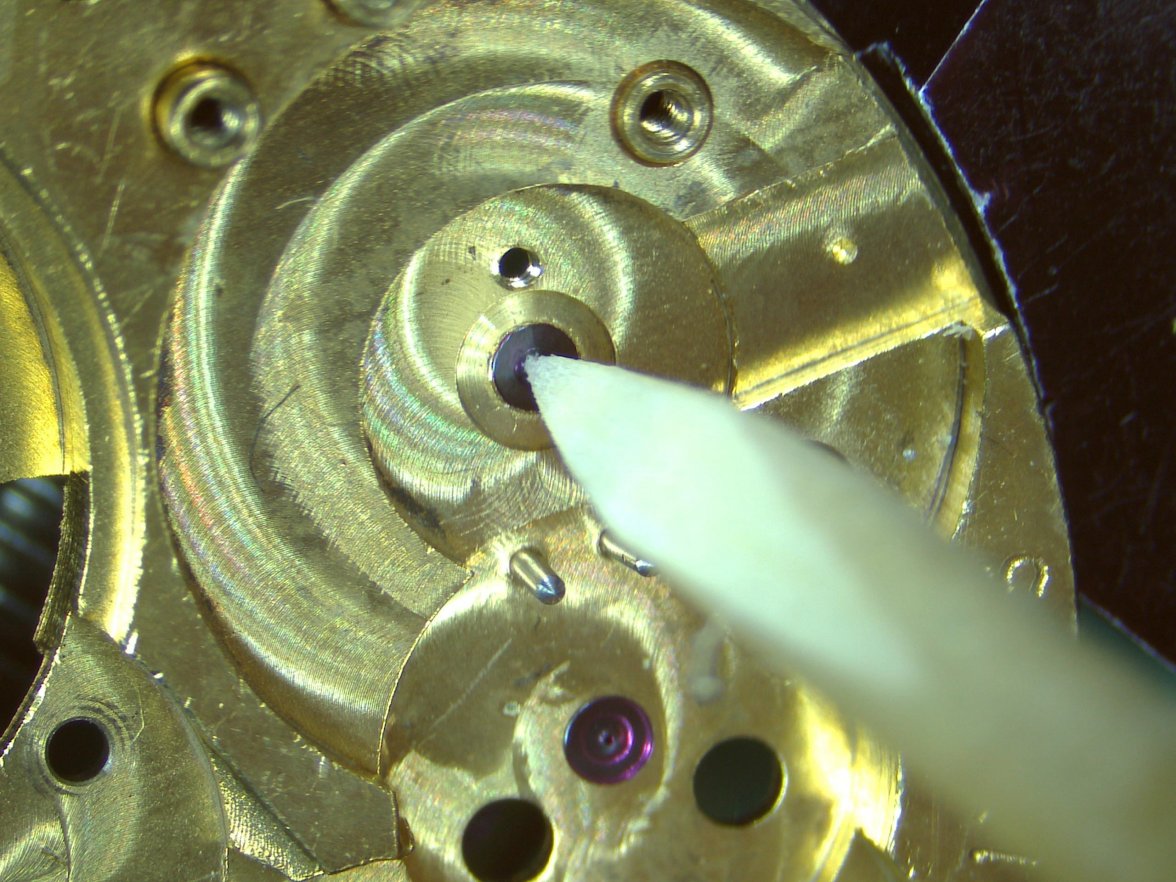

Everything looked OK (for what it was) so I set about pegging the jewels to remove dried oil/grease.

Then I got ready to put everything into the watch cleaner. But first I had to take some photos for reference. As this was my first Smiths, I needed a record of where the screw went, so.....

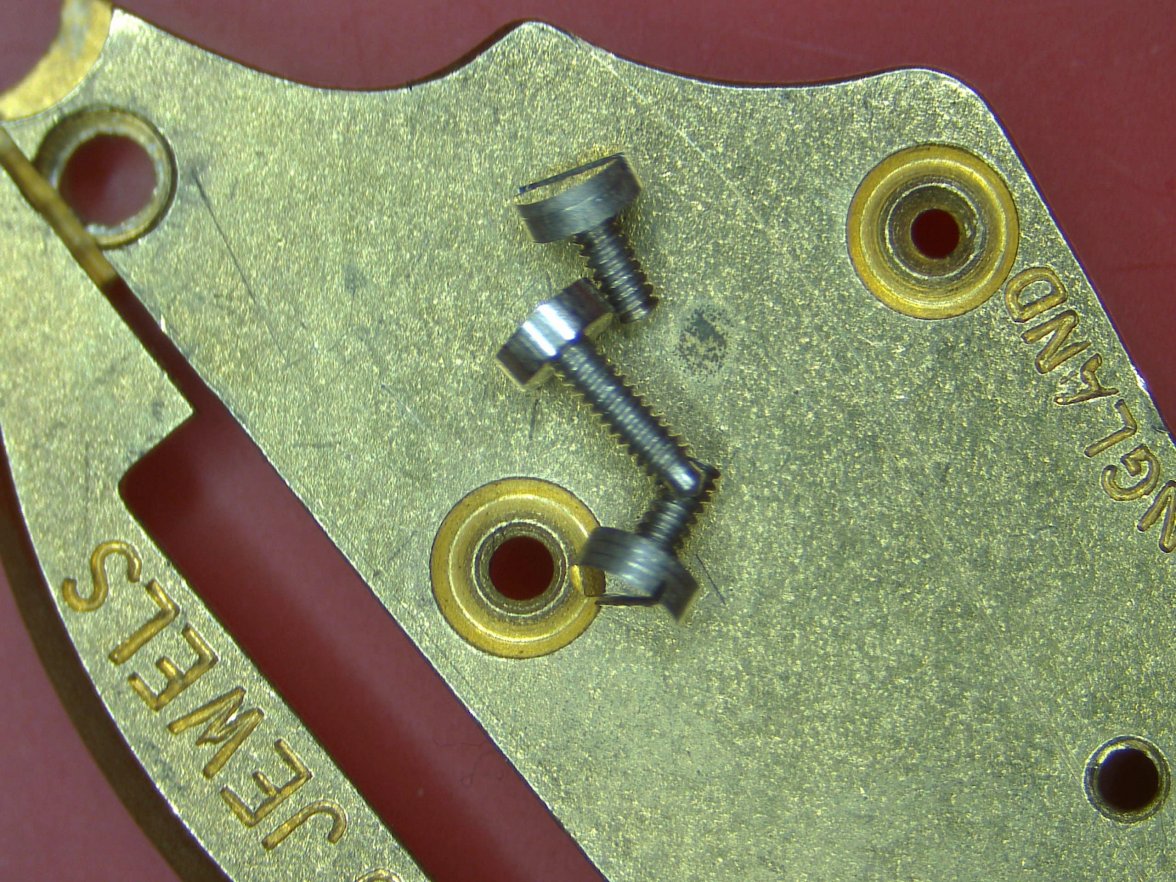

Casing screws, well, one is and one is a ring in.

Barrel bridge. I wondered why there were two short screws. Turns out that it shares the tube with another screw from the other side of the plate so has to be shorter.

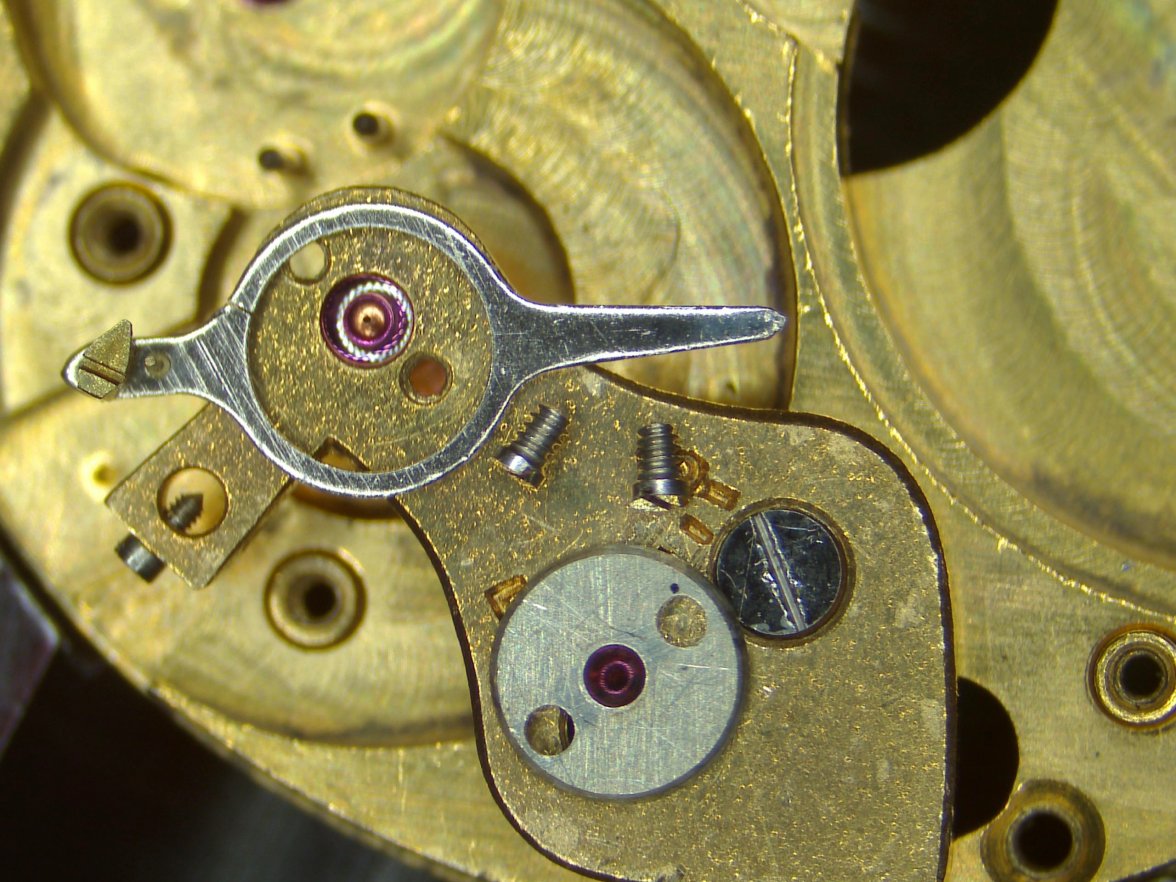

and this is the setting spring/bridge with one of the screws sharing a tube as noted above.

The pallet cock screws

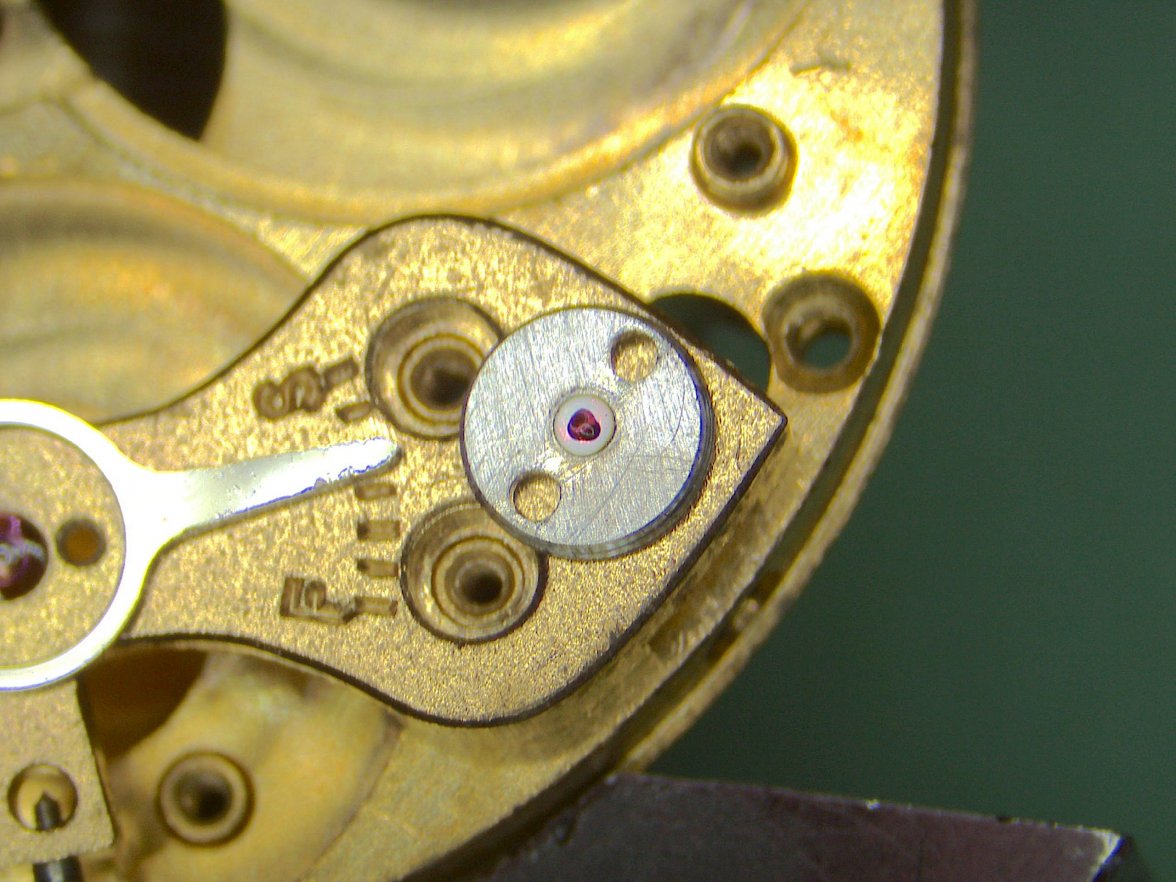

and the regulator/cap jewel screws

Now that I had a record, it all went into the cleaning machine.

(Sorry, forgot to take photos 😬)

Everything looked OK (for what it was) so I set about pegging the jewels to remove dried oil/grease.

Then I got ready to put everything into the watch cleaner. But first I had to take some photos for reference. As this was my first Smiths, I needed a record of where the screw went, so.....

Casing screws, well, one is and one is a ring in.

Barrel bridge. I wondered why there were two short screws. Turns out that it shares the tube with another screw from the other side of the plate so has to be shorter.

and this is the setting spring/bridge with one of the screws sharing a tube as noted above.

The pallet cock screws

and the regulator/cap jewel screws

Now that I had a record, it all went into the cleaning machine.

(Sorry, forgot to take photos 😬)

JimInOz

··Melbourne AustraliaWith everything shiny sparkly, the first thing I wanted to do was make sure the balance was good for rotation/endshake etc.

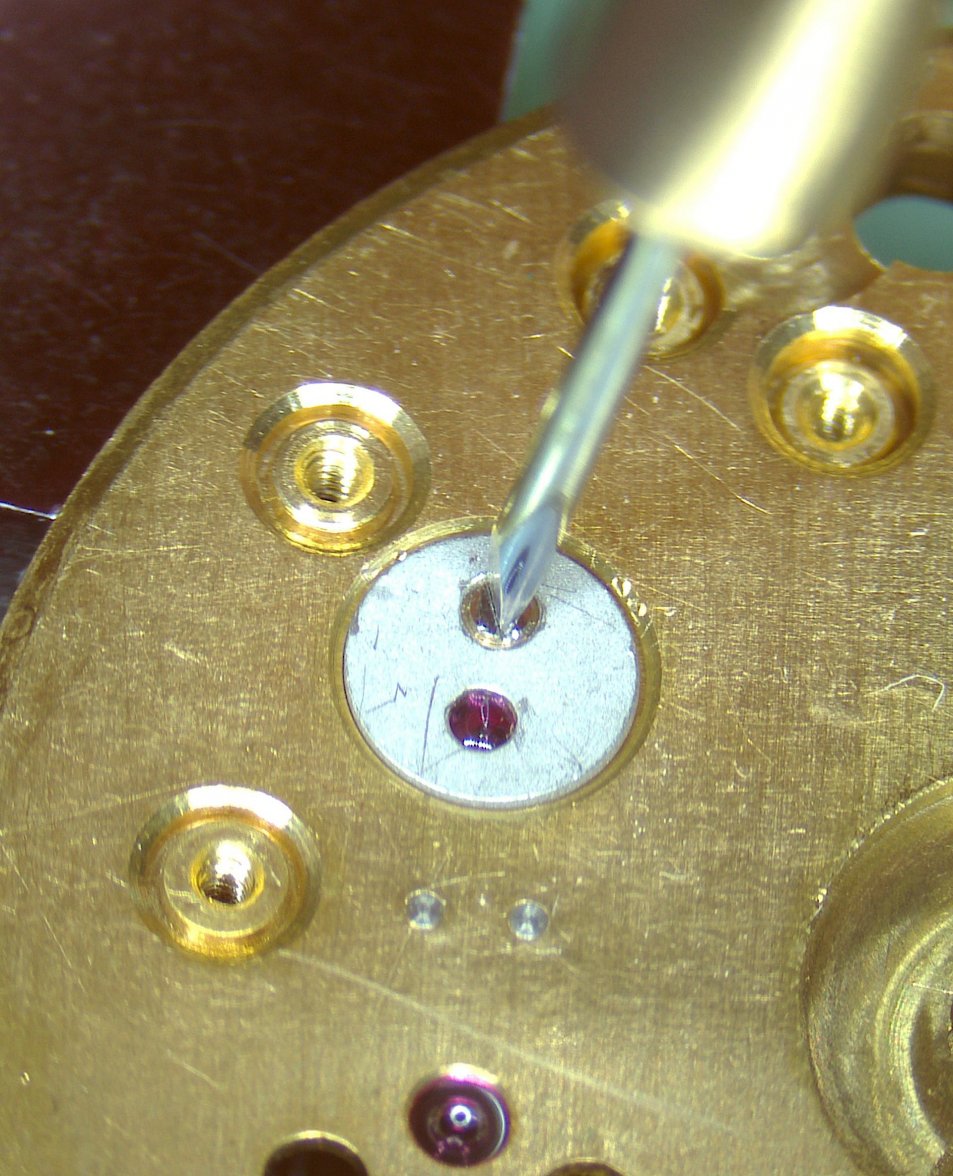

That required oiling and installing the bottom cap jewel. The experts here will notice I used the wrong screw, so I had to remove it and use the correct one.

The top cap jewel was oiled and installed with the regulator so that the balance assembly could be installed.

With the balance cock complete the balance assembly went on and I did a test fit by installing the whole thing on the plate and giving the balance wheel a few puffs of air to get it moving.

It all checked out nicely, good end shake and the balance took an acceptably long time to stop oscillating.

Then it was all removed and back on to the balance tack while the movement parts started to come together.

Sorry, it was so intensive working on a brand new movement with some unusual kinks and no parts lists or tech guides I forgot to take pics, another pants down for me.

That required oiling and installing the bottom cap jewel. The experts here will notice I used the wrong screw, so I had to remove it and use the correct one.

The top cap jewel was oiled and installed with the regulator so that the balance assembly could be installed.

With the balance cock complete the balance assembly went on and I did a test fit by installing the whole thing on the plate and giving the balance wheel a few puffs of air to get it moving.

It all checked out nicely, good end shake and the balance took an acceptably long time to stop oscillating.

Then it was all removed and back on to the balance tack while the movement parts started to come together.

Sorry, it was so intensive working on a brand new movement with some unusual kinks and no parts lists or tech guides I forgot to take pics, another pants down for me.

JimInOz

··Melbourne AustraliaOops! I'm a dickhead, the pics are on my phone.

😬

As soon as it's charged, regular scheduled programming will resume.

😬

As soon as it's charged, regular scheduled programming will resume.

wilderbeast

·What a fantastic thread, @JimInOz! Fascinated by this, owning an A361, A454 and 6B myself. Great little watches, from God's own town of Cheltenham:

SmithSJ

·Nice A454!

SmithSJ

·and thanks again to JiminOz for a great post …

JimInOz

··Melbourne AustraliaBack to normal.

All parts nice and clean.

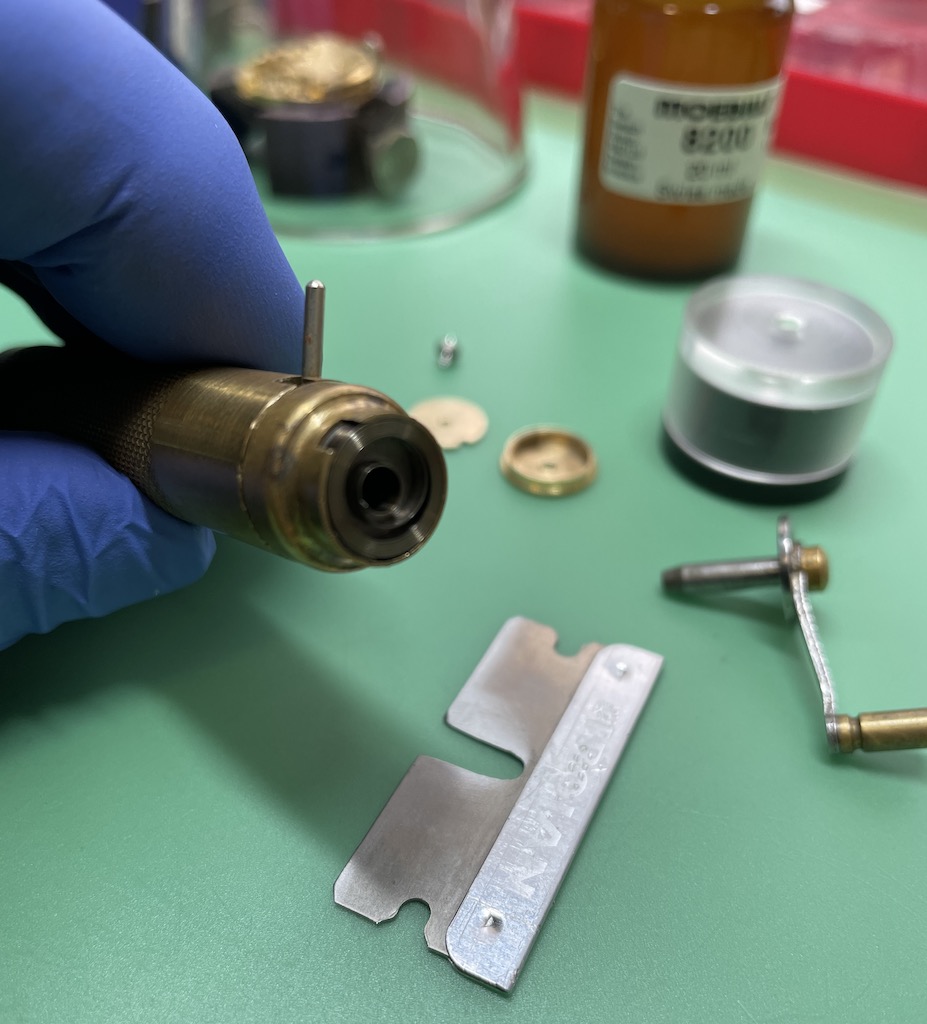

First thing to do is re-assemble the mainspring/barrel, therefore we lubricate the mainspring with a cotton pad with a drop of Moebius 8200.

and the mainspring is drawn through the pad a couple of times.

Then the mainspring is wound

And pressed into the barrel.

the arbor is lubricated and fitted and all put together, and that's the mainspring/barrel done.

All parts nice and clean.

First thing to do is re-assemble the mainspring/barrel, therefore we lubricate the mainspring with a cotton pad with a drop of Moebius 8200.

and the mainspring is drawn through the pad a couple of times.

Then the mainspring is wound

And pressed into the barrel.

the arbor is lubricated and fitted and all put together, and that's the mainspring/barrel done.

JimInOz

··Melbourne AustraliaStarting to re-assemble the movement. I've got no guides so just flying blind. I start on the dial side and put all of the winding/setting parts in place and do a check to see that it works as advertised.

All well, so I turn to the train side, this one has something different. A hidden crown wheel. The crown wheel is the thing that transmits winding movement from the stem to the ratchet wheel on the barrel, thus winding the mainspring.

The hidden crown wheel on the Smiths has a number of parts on the underside of the barrel bridge.

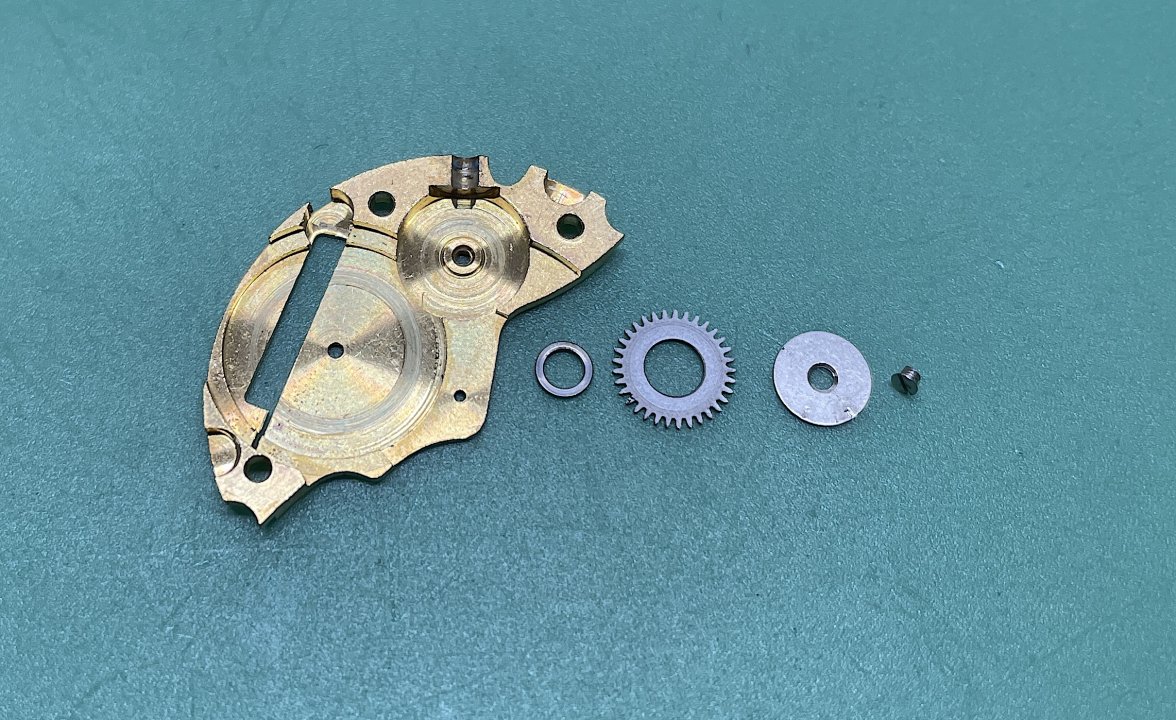

From L to R, Barrel Bridge, bearing ring, crown wheel, crown wheel plate, retaining screw.

Once lubricated, it's all put together ready to fit to the plate.

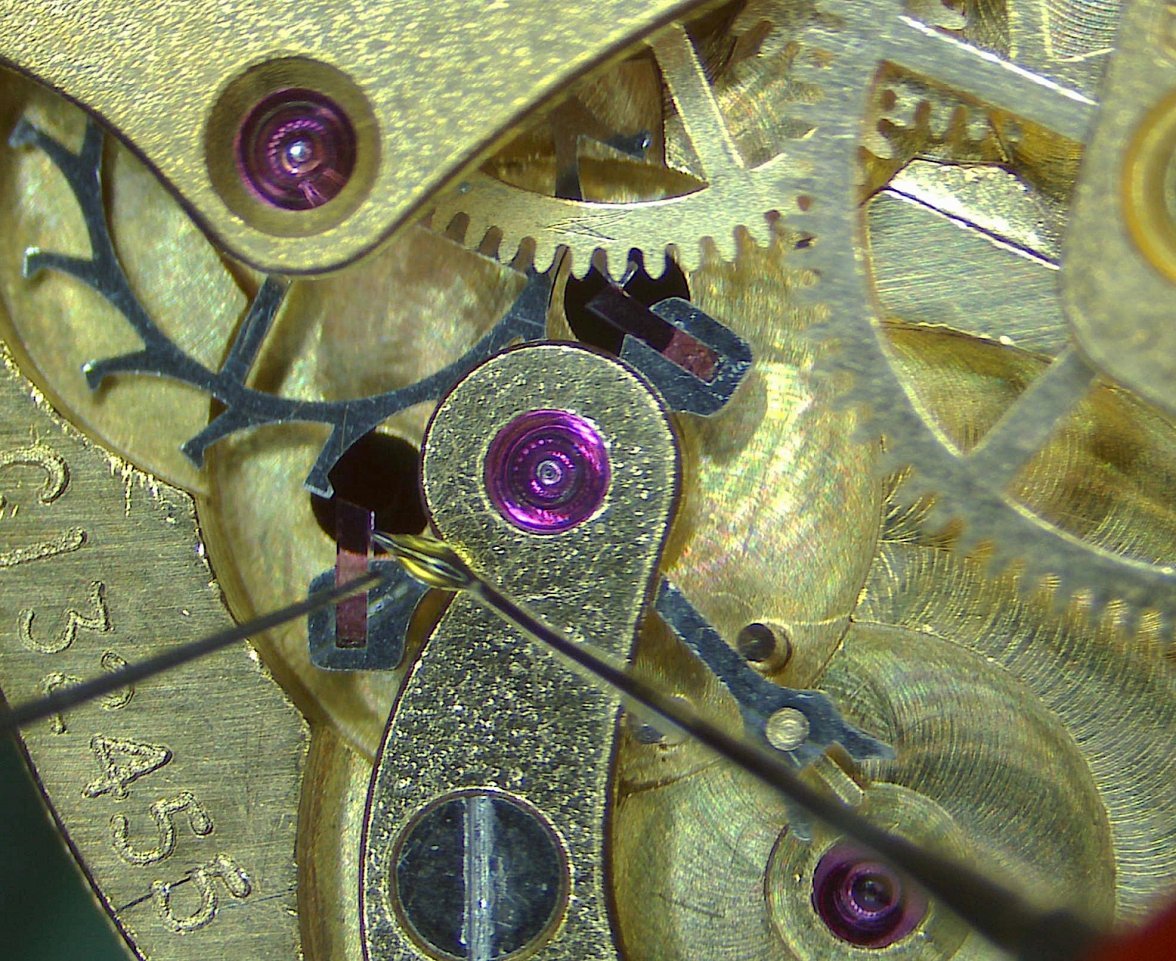

The power train parts are fitted and given a quick wobble of the centre wheel to see that they are all meshing properly.

I couldn't figure out why there was no movement! Can anybody spot the problem?

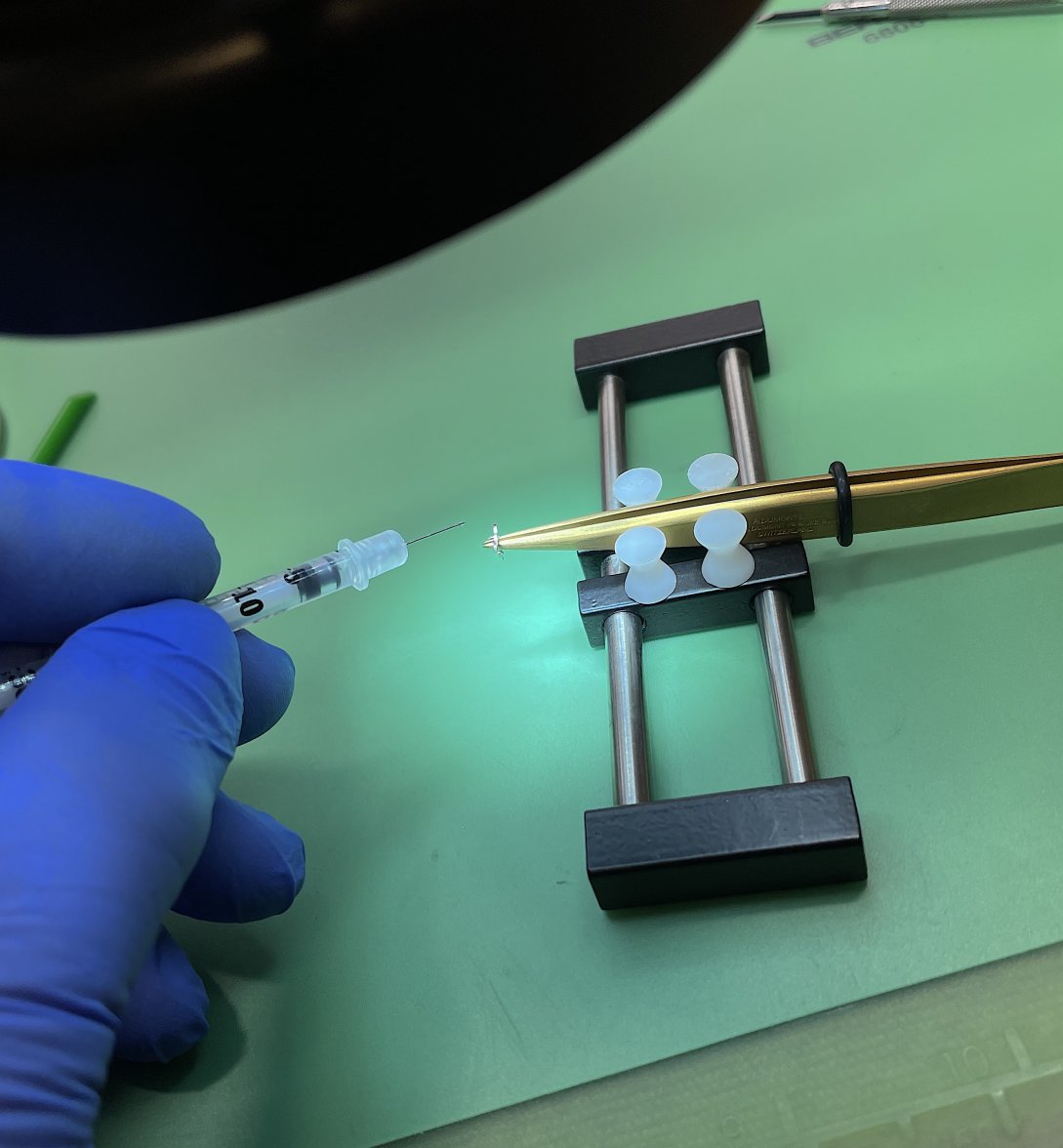

With that sorted after a "Doh!" moment I just had to fit the pallet and the balance, but first I used a micro syringe to apply a tiny drop of epilame to the pallet stones.

and while we're talking about epilame, here's a pic from when I did the cap jewels for the balance. The bottle has a small basket in the neck and parts are put in the basket, the red top screwed on and the bottle inverted for 43 seconds, then turned back upright and the parts removed from the basket and allowed to dry with some assistance from a puffer.

All well, so I turn to the train side, this one has something different. A hidden crown wheel. The crown wheel is the thing that transmits winding movement from the stem to the ratchet wheel on the barrel, thus winding the mainspring.

The hidden crown wheel on the Smiths has a number of parts on the underside of the barrel bridge.

From L to R, Barrel Bridge, bearing ring, crown wheel, crown wheel plate, retaining screw.

Once lubricated, it's all put together ready to fit to the plate.

The power train parts are fitted and given a quick wobble of the centre wheel to see that they are all meshing properly.

I couldn't figure out why there was no movement! Can anybody spot the problem?

With that sorted after a "Doh!" moment I just had to fit the pallet and the balance, but first I used a micro syringe to apply a tiny drop of epilame to the pallet stones.

and while we're talking about epilame, here's a pic from when I did the cap jewels for the balance. The bottle has a small basket in the neck and parts are put in the basket, the red top screwed on and the bottle inverted for 43 seconds, then turned back upright and the parts removed from the basket and allowed to dry with some assistance from a puffer.

JimInOz

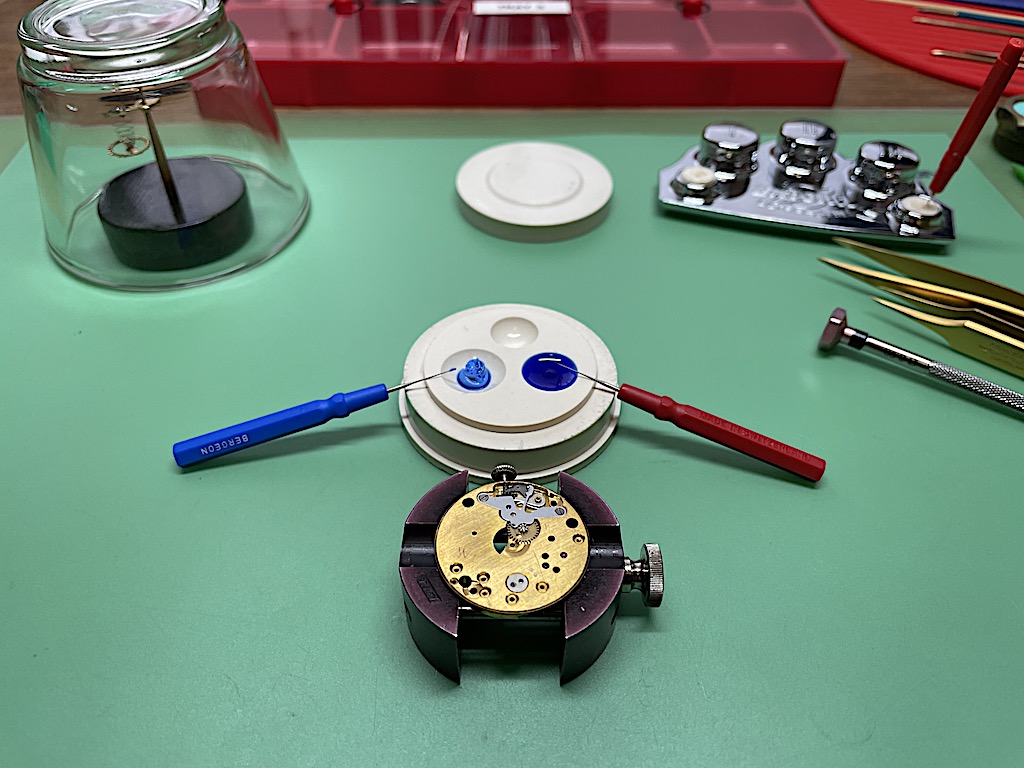

··Melbourne AustraliaNow that I had the pallet installed, I could oil the pallets stones. I use two oilers, one to hold a drop of oil (the one on the left with enough oil to do fifty watches!) and the small one on the right to pick off a tiny drop of Moebius 9415 (actually a grease) and apply it to the pallet faces that contact the escape wheel teeth. The pallet is then cycled for five teeth of the escape wheel and the process is repeated twice more. When the watch is run, the grease will distribute itself evenly on the impacting parts and if done properly, won't splash around the movement.

Sorry about the pics, I was a second out taking it.

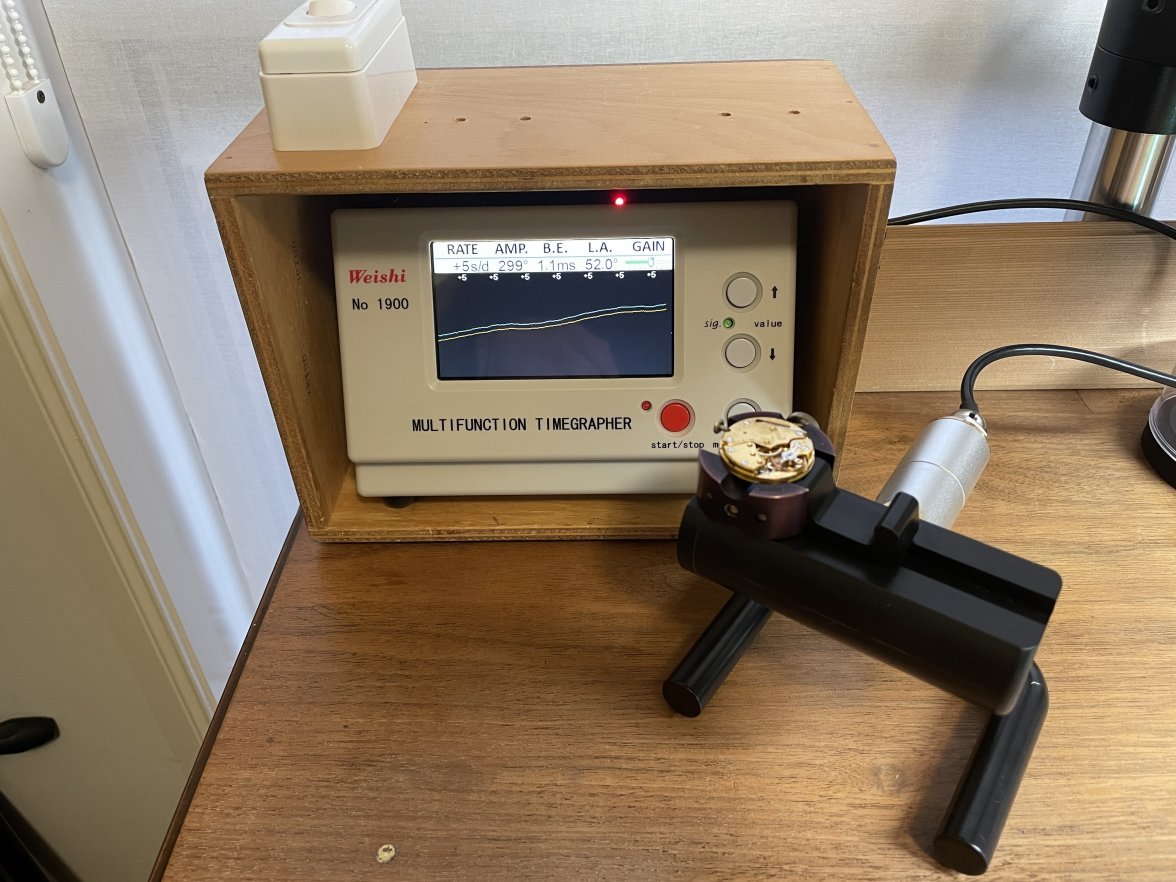

That done, it was just a matter of fitting the balance and giving it a wind. After an hour to let it settle, it was on to the Timegrapher.

With the lift angle set to 47º (thanks @ChrisN) it didn't look too bad, except for the huge beat error.

If this movement had a moveable stud, fixing the beat error would be a rather simple task, but in this case, the balance assembly has to be taken apart and the hairspring/collar rotated on the balance staff. Not too hard on a pocket watch, but a real test of my skills with a balance this small.

Oh well, we shall see how it goes.

Sorry about the pics, I was a second out taking it.

That done, it was just a matter of fitting the balance and giving it a wind. After an hour to let it settle, it was on to the Timegrapher.

With the lift angle set to 47º (thanks @ChrisN) it didn't look too bad, except for the huge beat error.

If this movement had a moveable stud, fixing the beat error would be a rather simple task, but in this case, the balance assembly has to be taken apart and the hairspring/collar rotated on the balance staff. Not too hard on a pocket watch, but a real test of my skills with a balance this small.

Oh well, we shall see how it goes.

JimInOz

··Melbourne AustraliaJimInOz

··Melbourne Australia😡

That was fun. All apart and adjusted and while putting it back in the balance cock slipped of the tweezers and pulled the balance out of the movement with it, stretching the hairspring in the process.

So two more episodes of this.

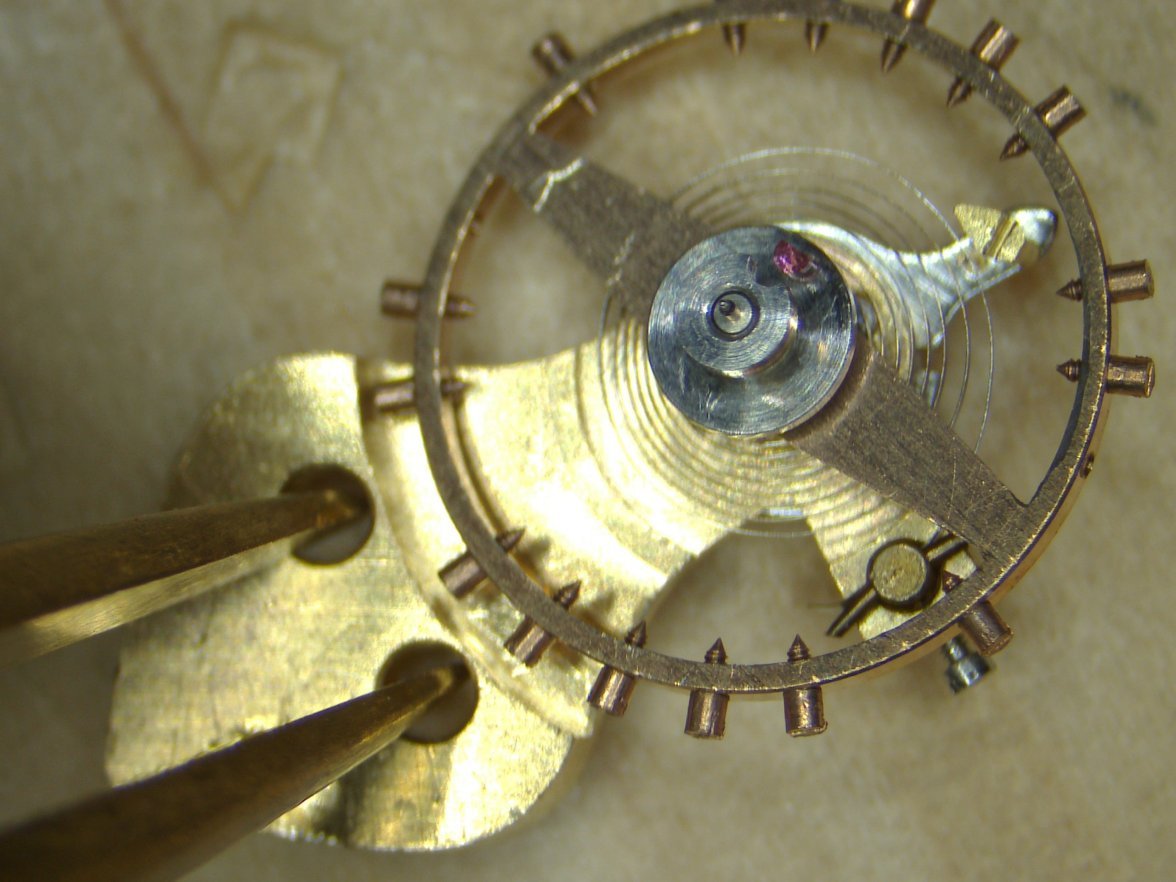

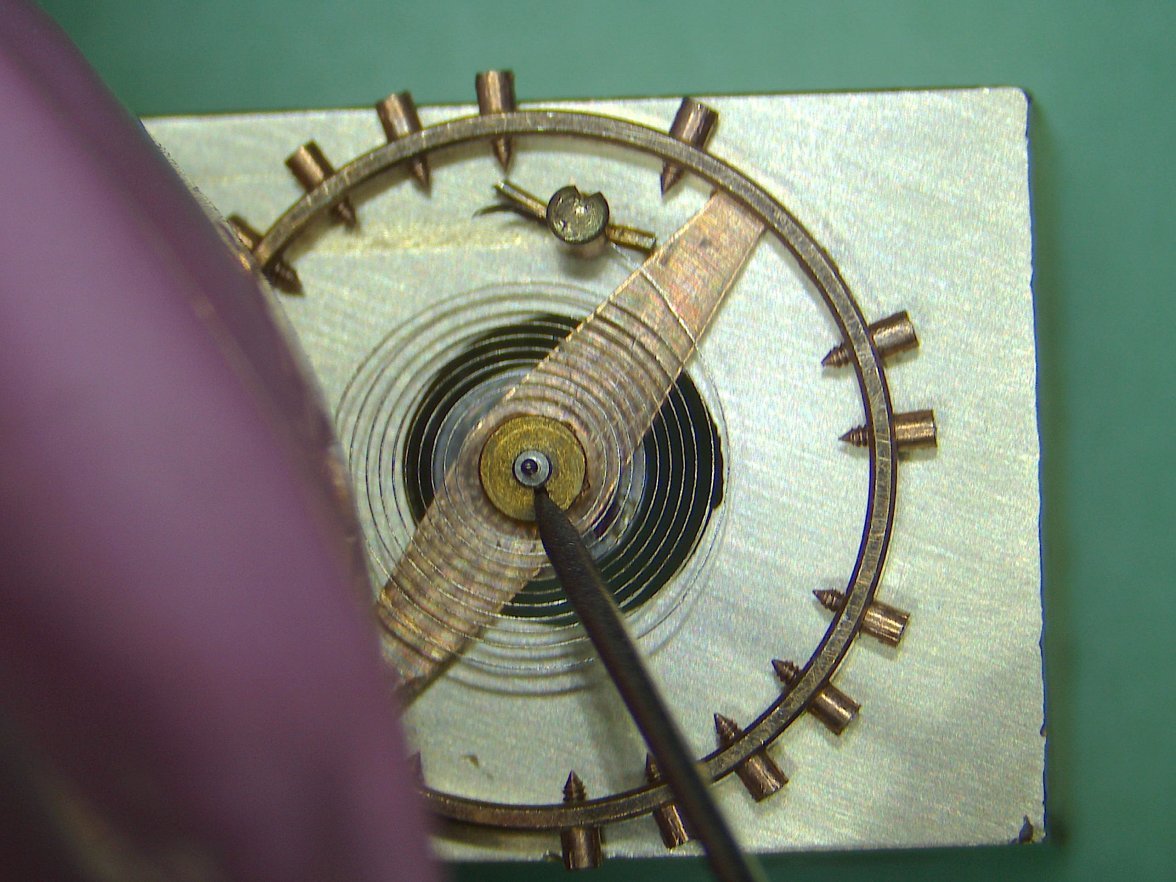

Balance removed and laid on a soft surface so I could undo the stud screw (silver one) and turn the boot so I could lift the balance wheel/hairspring off the cock.

Then the balance wheel was inverted on a brass block and a shaped pivot wire is used to rotate the collet. This moves the position of the stud in relation to the impulse jewel, and when it's back on the movement, hopefully the impulse jewel will be closer to a theoretical centre where beat error does not exist.

Note that the hole the balance wheel is sitting in is 4mm diameter.

After getting it back together, things started looking OK again. Beat error is much lower and I could go all day trying to get it better so I'm happy with this.

Another trick question. What is wrong with this picture?

😉

That was fun. All apart and adjusted and while putting it back in the balance cock slipped of the tweezers and pulled the balance out of the movement with it, stretching the hairspring in the process.

So two more episodes of this.

Balance removed and laid on a soft surface so I could undo the stud screw (silver one) and turn the boot so I could lift the balance wheel/hairspring off the cock.

Then the balance wheel was inverted on a brass block and a shaped pivot wire is used to rotate the collet. This moves the position of the stud in relation to the impulse jewel, and when it's back on the movement, hopefully the impulse jewel will be closer to a theoretical centre where beat error does not exist.

Note that the hole the balance wheel is sitting in is 4mm diameter.

After getting it back together, things started looking OK again. Beat error is much lower and I could go all day trying to get it better so I'm happy with this.

Another trick question. What is wrong with this picture?

😉

JimInOz

··Melbourne AustraliaTime to attend to the case.

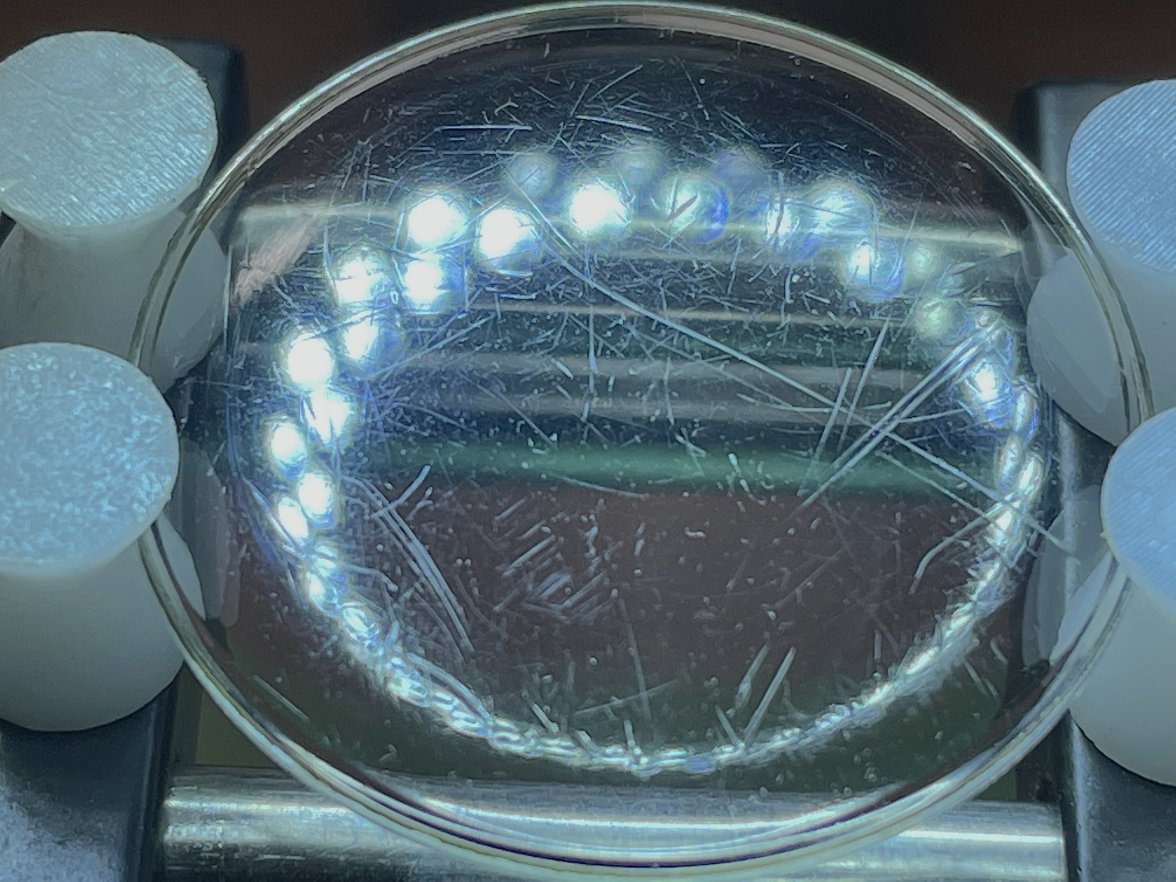

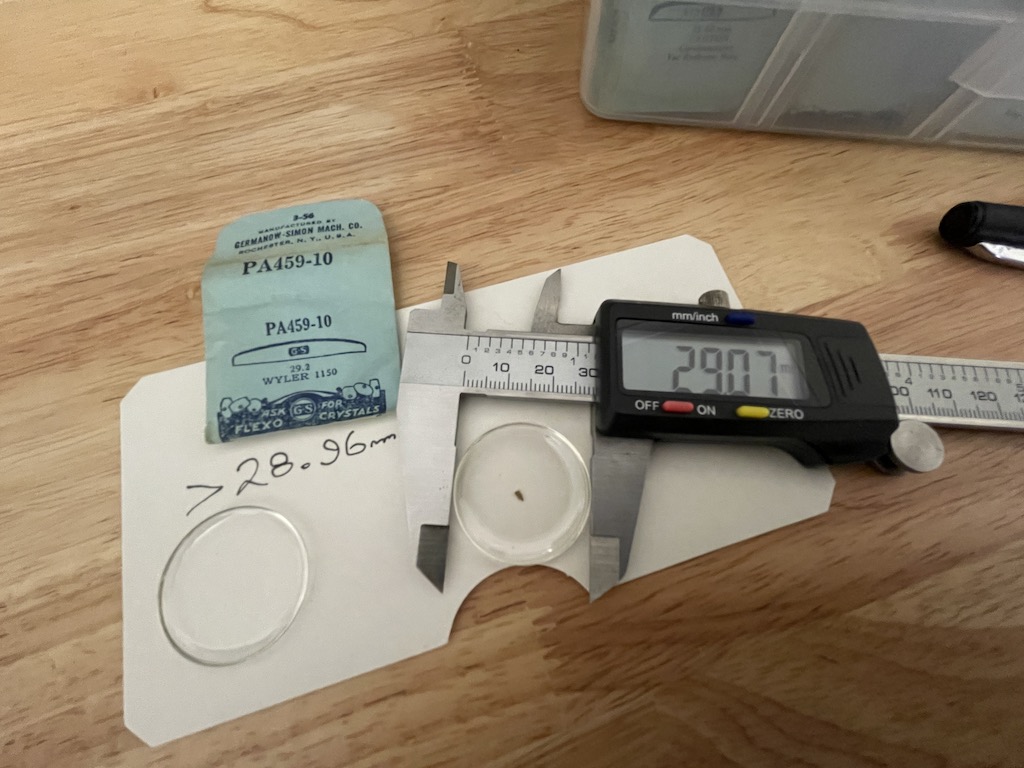

The crystal that came with the watch had a habit of falling out. It was also in pretty poor condition, not just from scratches, but also signs of material degradation (where the structure of the polymer bonds are breaking down).

So where do you find a crystal for an uncommon (in Australia) vintage watch.

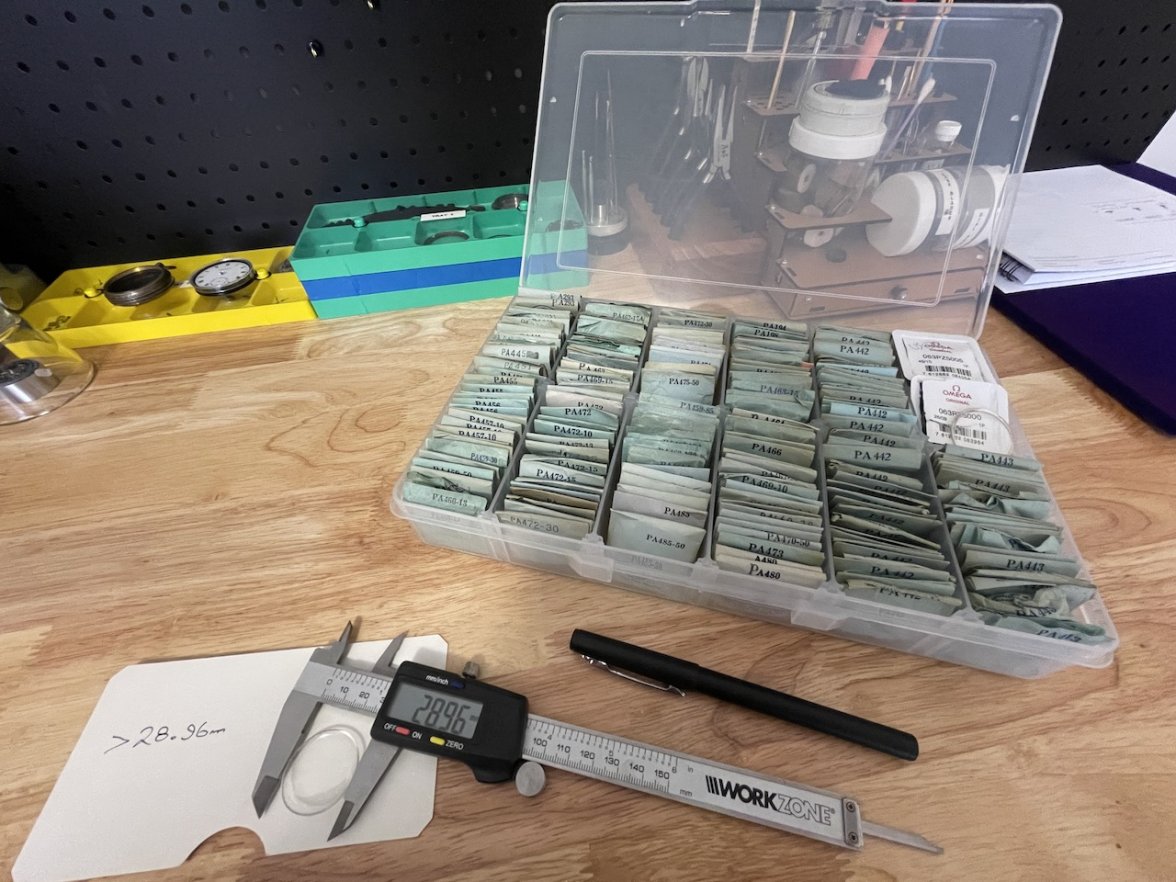

Well, you go to your secret crystal stash!

Then, after noting the size of the dud crystal, you start searching for something a few tenths of a millimetre larger.

Luckily I found one after less than ten minutes of searching. It was meant for a 1950s Wyler, but I think it will do the job.

Woo Hoo!

Next step was to do a final measurement check on the bezel and the crystal, and then press the crystal into the bezel.

Result?

We now have a nice "NOS" secure crystal in its bezel.

Have to go now, Sunday evening here and we've got "Pork Ribs'n'Rice'n'Broccolini" for dinner. Yum!

The crystal that came with the watch had a habit of falling out. It was also in pretty poor condition, not just from scratches, but also signs of material degradation (where the structure of the polymer bonds are breaking down).

So where do you find a crystal for an uncommon (in Australia) vintage watch.

Well, you go to your secret crystal stash!

Then, after noting the size of the dud crystal, you start searching for something a few tenths of a millimetre larger.

Luckily I found one after less than ten minutes of searching. It was meant for a 1950s Wyler, but I think it will do the job.

Woo Hoo!

Next step was to do a final measurement check on the bezel and the crystal, and then press the crystal into the bezel.

Result?

We now have a nice "NOS" secure crystal in its bezel.

Have to go now, Sunday evening here and we've got "Pork Ribs'n'Rice'n'Broccolini" for dinner. Yum!