JimInOz

··Melbourne AustraliaSo now that the Zenith crowd and fans of watches using famous Caliber 11 have just had the WIS equivalent of an apoplexy, let me continue.

A nice 6139-6002 recently arrived and as advised by the owner, it was dead, not working, defunct etc etc.

As this was a known, I didn't bother trying to start it, just straight into photos.

A rather nice bezel, aged crystal and reasonable case shape when seen from the front.

The caseback is pretty normal, and the information tels us that this watch dates to August 1971, so about 48 years and 6 months old.

First thing was to get the caseback off. Nothing very interesting there.

So let's have a quick look inside.

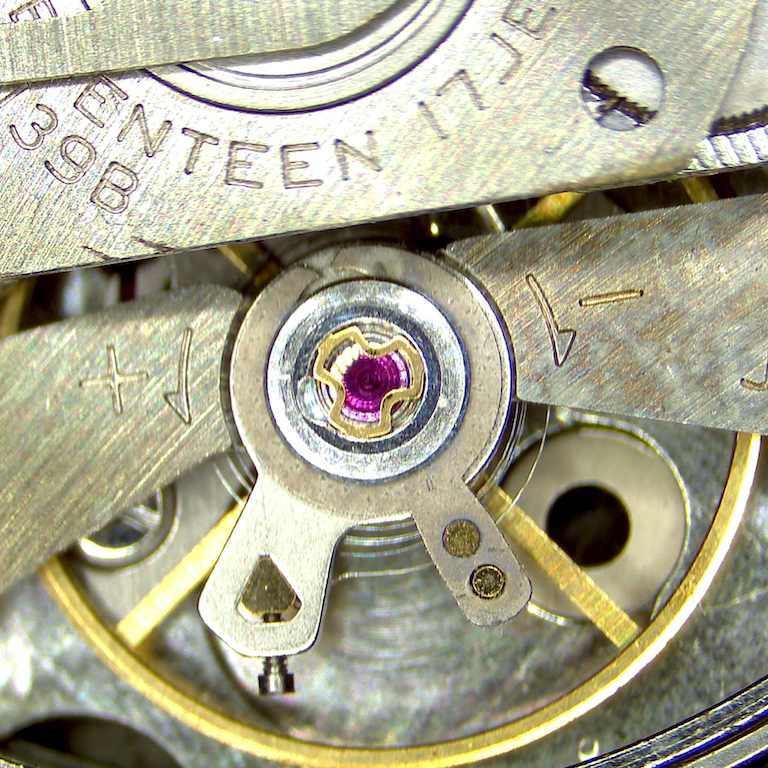

The upper half of the movement looks OK, shows a little rubbing on the bridge but not too serious.

The lower section is much the same, not too bad but the visible jewels are very dry and there's lots of "stuff" around the movement.

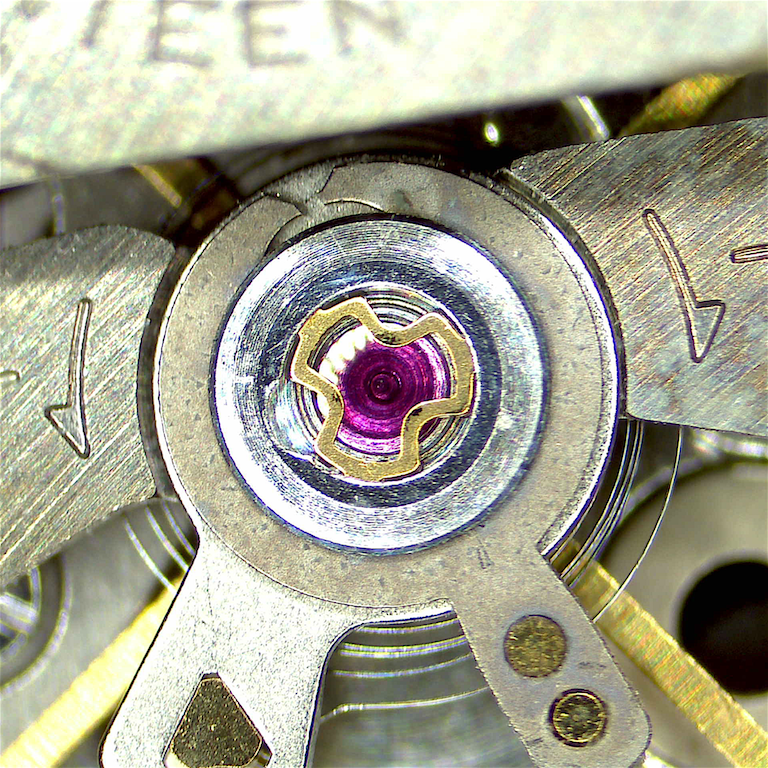

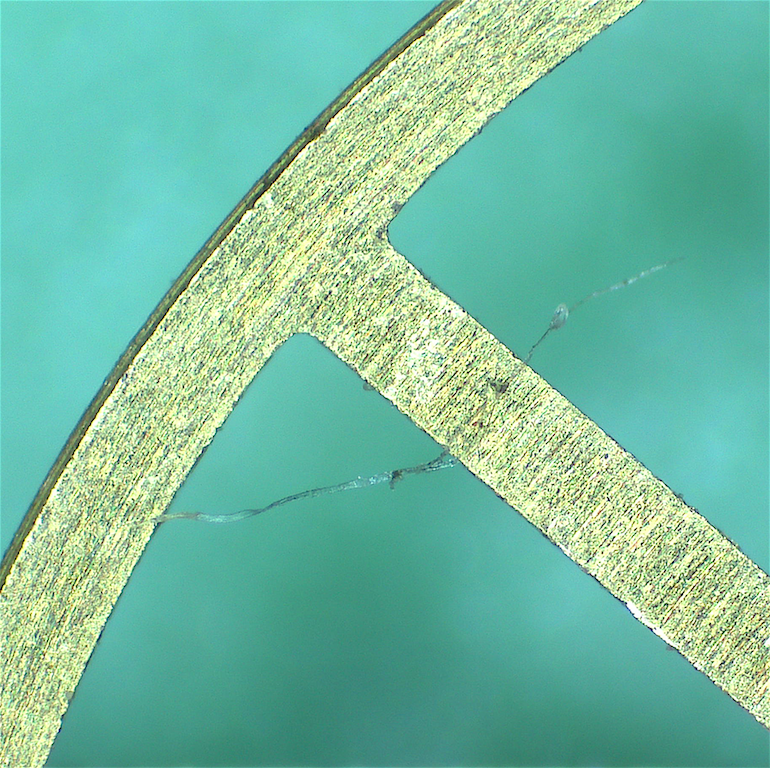

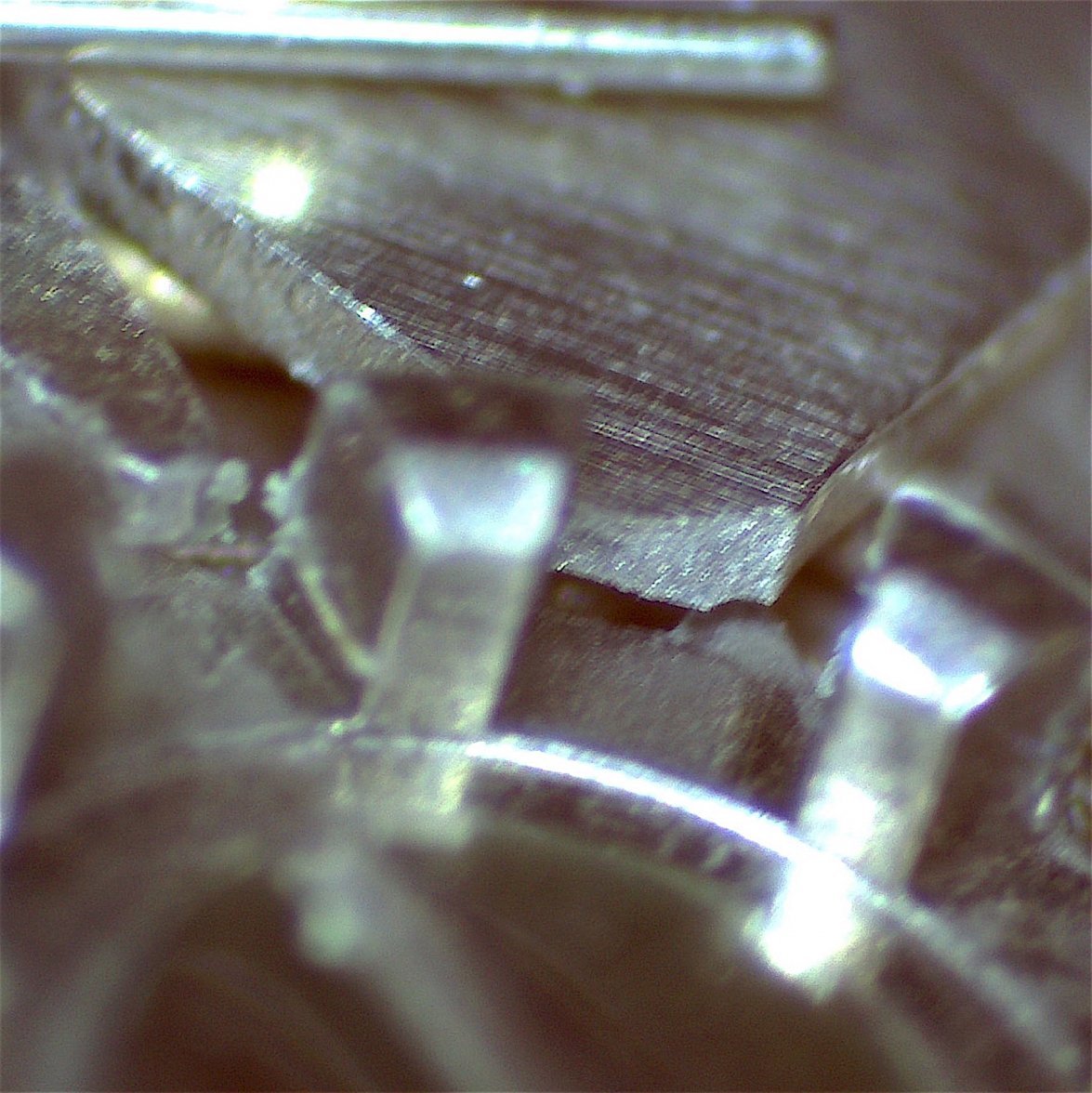

A closer look at the hairspring shows some coil binding. Oil? Magnetism? Or something else?

A closer look and not much more is visible.............

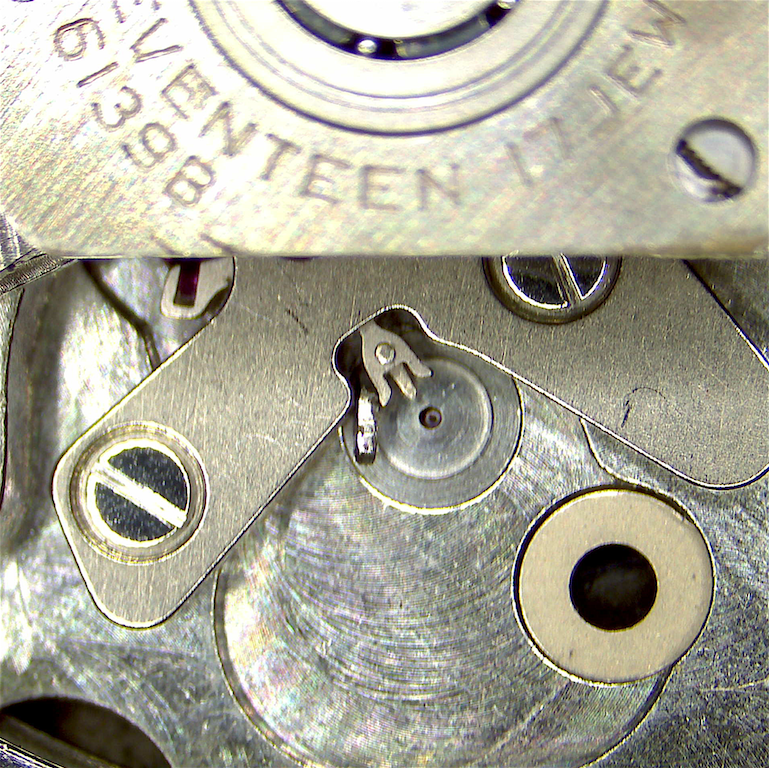

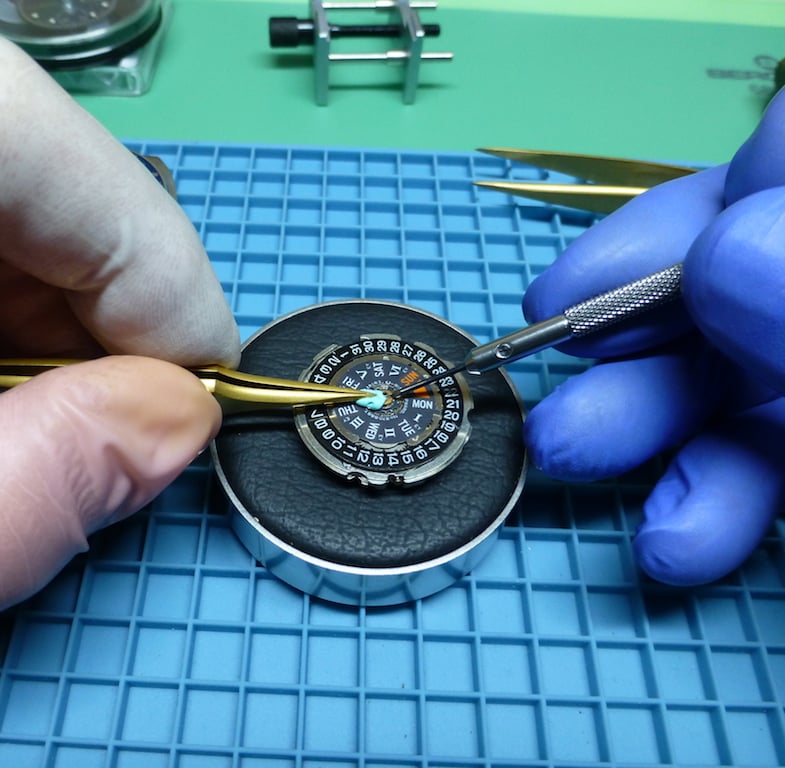

.............so I'll remove the balance assembly as it's easy to do while the movement is still in the case.

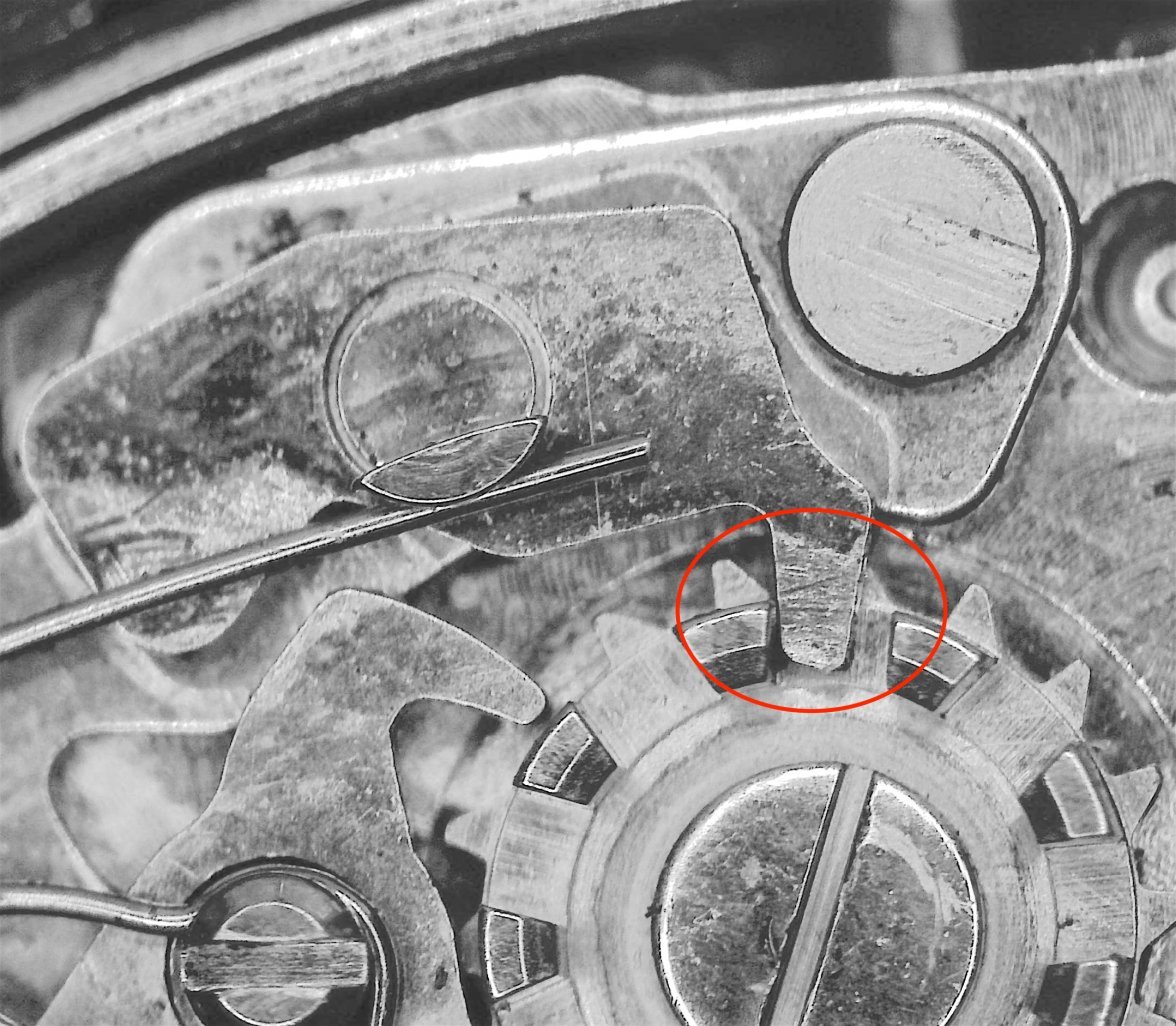

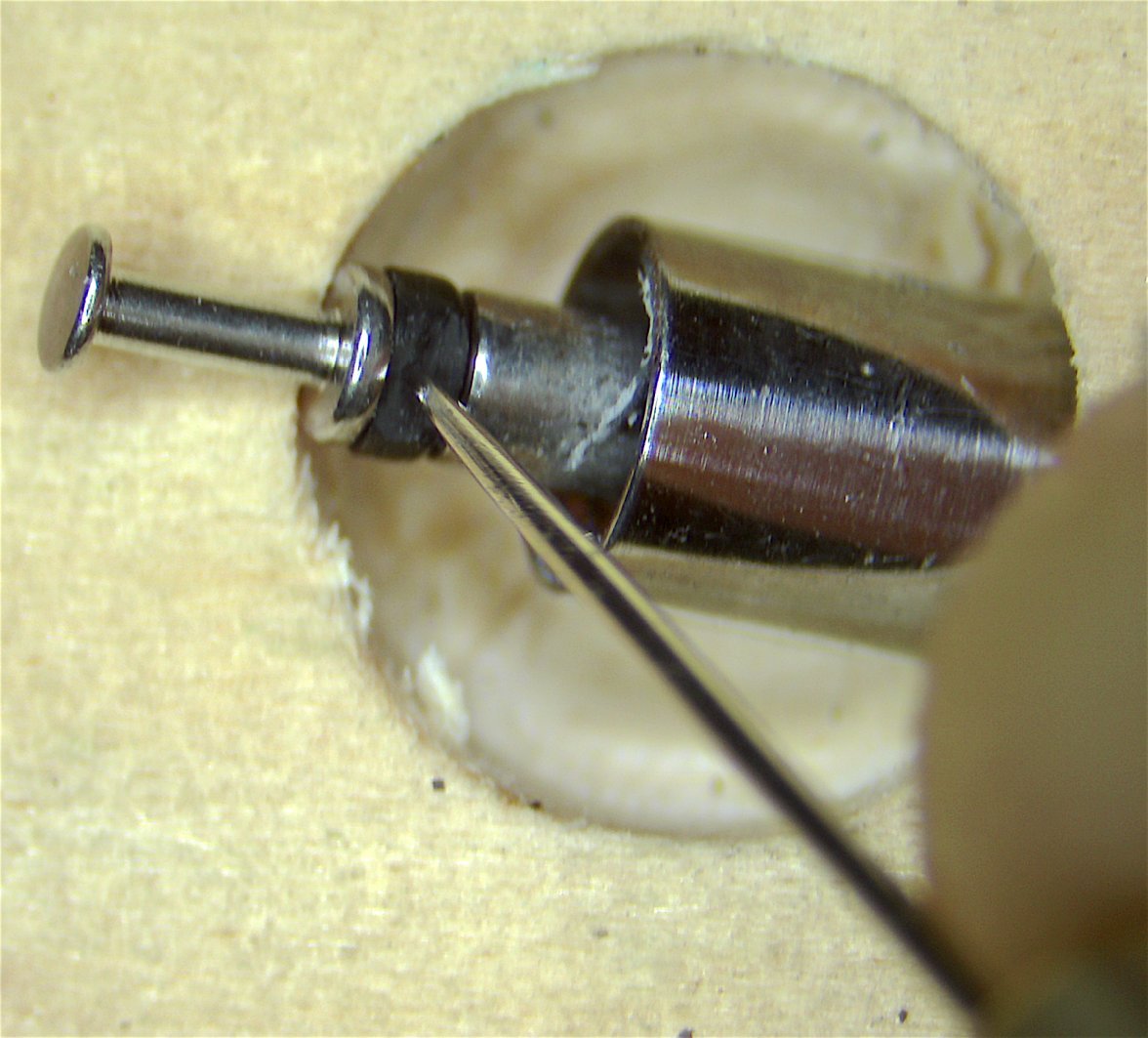

With the balance removed, the problem is obvious.

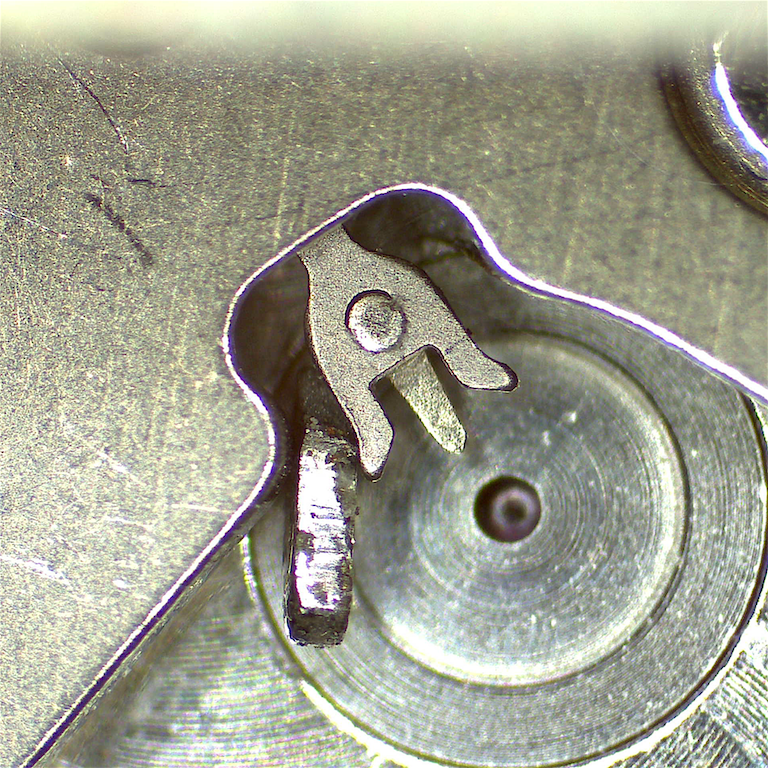

Can't see it? It's the lump of metal blocking the pallet lever.

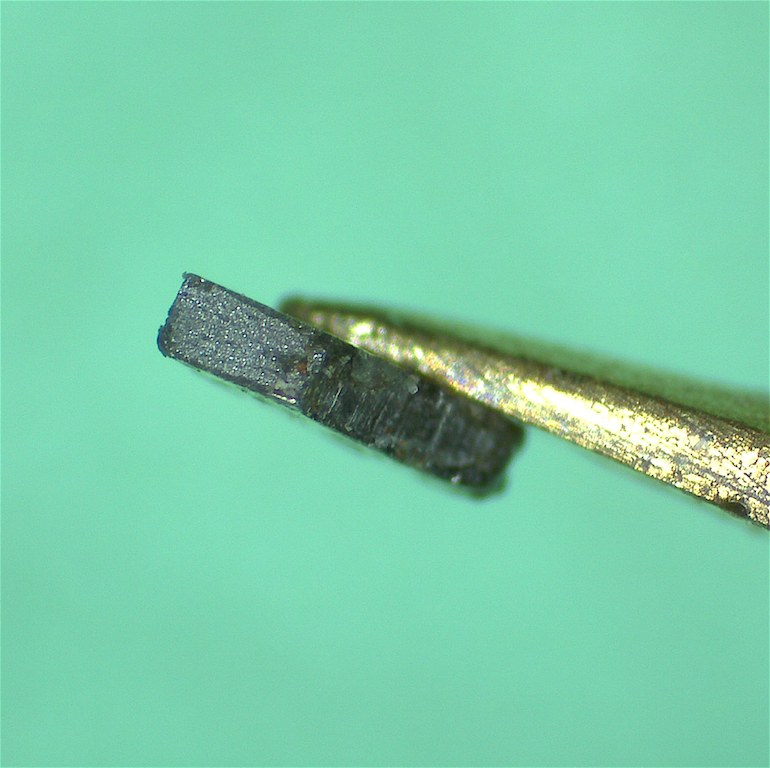

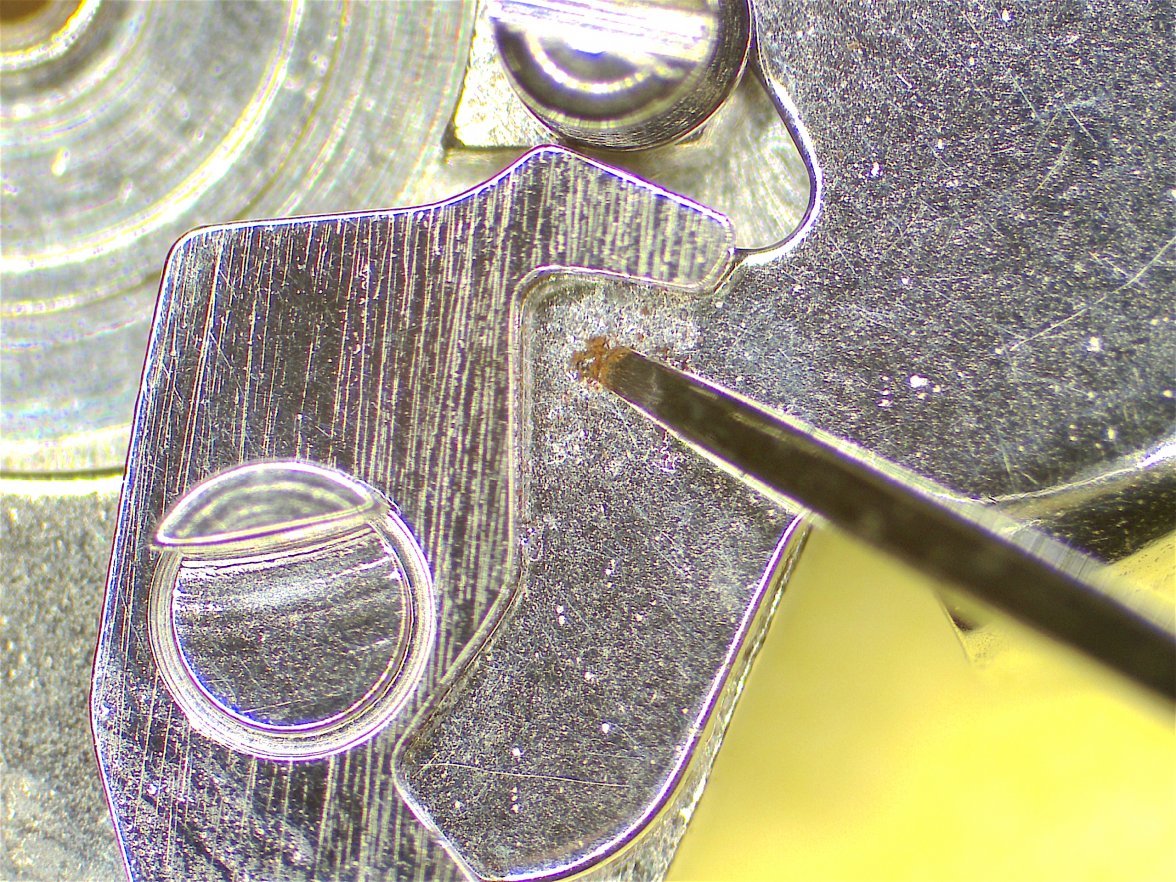

With my fine tweezers it's removed and bagged as "evidence".

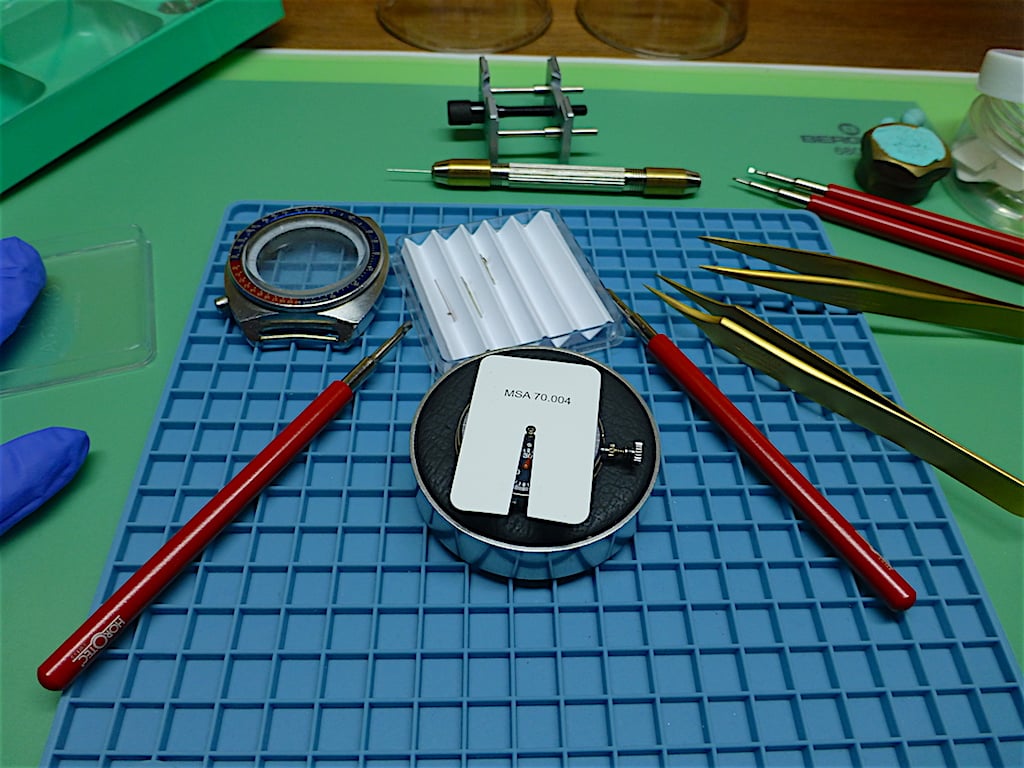

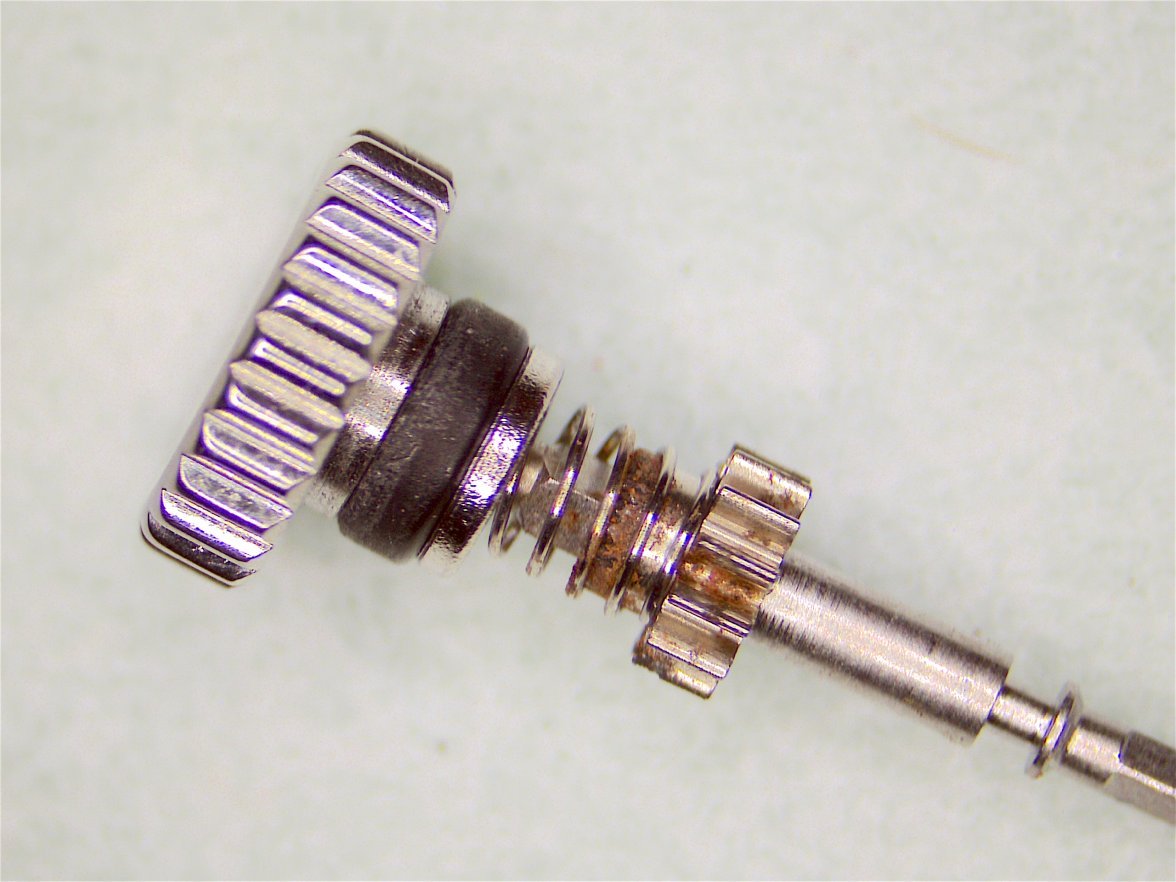

Now it's time to do some detective work.

A nice 6139-6002 recently arrived and as advised by the owner, it was dead, not working, defunct etc etc.

As this was a known, I didn't bother trying to start it, just straight into photos.

A rather nice bezel, aged crystal and reasonable case shape when seen from the front.

The caseback is pretty normal, and the information tels us that this watch dates to August 1971, so about 48 years and 6 months old.

First thing was to get the caseback off. Nothing very interesting there.

So let's have a quick look inside.

The upper half of the movement looks OK, shows a little rubbing on the bridge but not too serious.

The lower section is much the same, not too bad but the visible jewels are very dry and there's lots of "stuff" around the movement.

A closer look at the hairspring shows some coil binding. Oil? Magnetism? Or something else?

A closer look and not much more is visible.............

.............so I'll remove the balance assembly as it's easy to do while the movement is still in the case.

With the balance removed, the problem is obvious.

Can't see it? It's the lump of metal blocking the pallet lever.

With my fine tweezers it's removed and bagged as "evidence".

Now it's time to do some detective work.