On My Bench - Elgin 12S Pocket Watch

Canuck

·Pivot size? O/d of the chaton?

JimInOz

··Melbourne AustraliaPivot measures 0.24mm, not sure about the diameter yet.

It looks like it's a rubbed in setting (upper one is screwed in a chaton). I haven't done a rubbed in jewel before. Can they just be pressed out or does the burr have to be cut away.

And can I re-seat the jewel with a Seitz jewelling tool.

Pics of the setting.

Top of plate:

From underneath:

It looks like it's a rubbed in setting (upper one is screwed in a chaton). I haven't done a rubbed in jewel before. Can they just be pressed out or does the burr have to be cut away.

And can I re-seat the jewel with a Seitz jewelling tool.

Pics of the setting.

Top of plate:

From underneath:

JimInOz

··Melbourne AustraliaCanuck

·I have an incomplete assortment of replacement Elgin jewels in settings. After you send me the o/d, I’ll check to see if I have what you need. There are special seating tools for adjusting the chaton so it can accommodate a replacement jewel. The Seitz tool should have conical stumps that can be used to close the chaton on the new jewel. Assuming of course that you locate a jewel that is a close fit. I’ll get back to you. Replacing the jewel in the pallet cock would be the right way to do the job. But it is pretty much up to you to decide if a replacement jewel will improve performance or preserve the pivot on the pallet arbor.

JimInOz

··Melbourne AustraliaI have an incomplete assortment of replacement Elgin jewels in settings. After you send me the o/d, I’ll check to see if I have what you need. There are special seating tools for adjusting the chaton so it can accommodate a replacement jewel. The Seitz tool should have conical stumps that can be used to close the chaton on the new jewel. Assuming of course that you locate a jewel that is a close fit. I’ll get back to you. Replacing the jewel in the pallet cock would be the right way to do the job. But it is pretty much up to you to decide if a replacement jewel will improve performance or preserve the pivot on the pallet arbor.

Thanks for that. I should get a chance to take the jewel out today, will let you know how it goes.

JimInOz

··Melbourne AustraliaJimInOz

··Melbourne AustraliaArcher

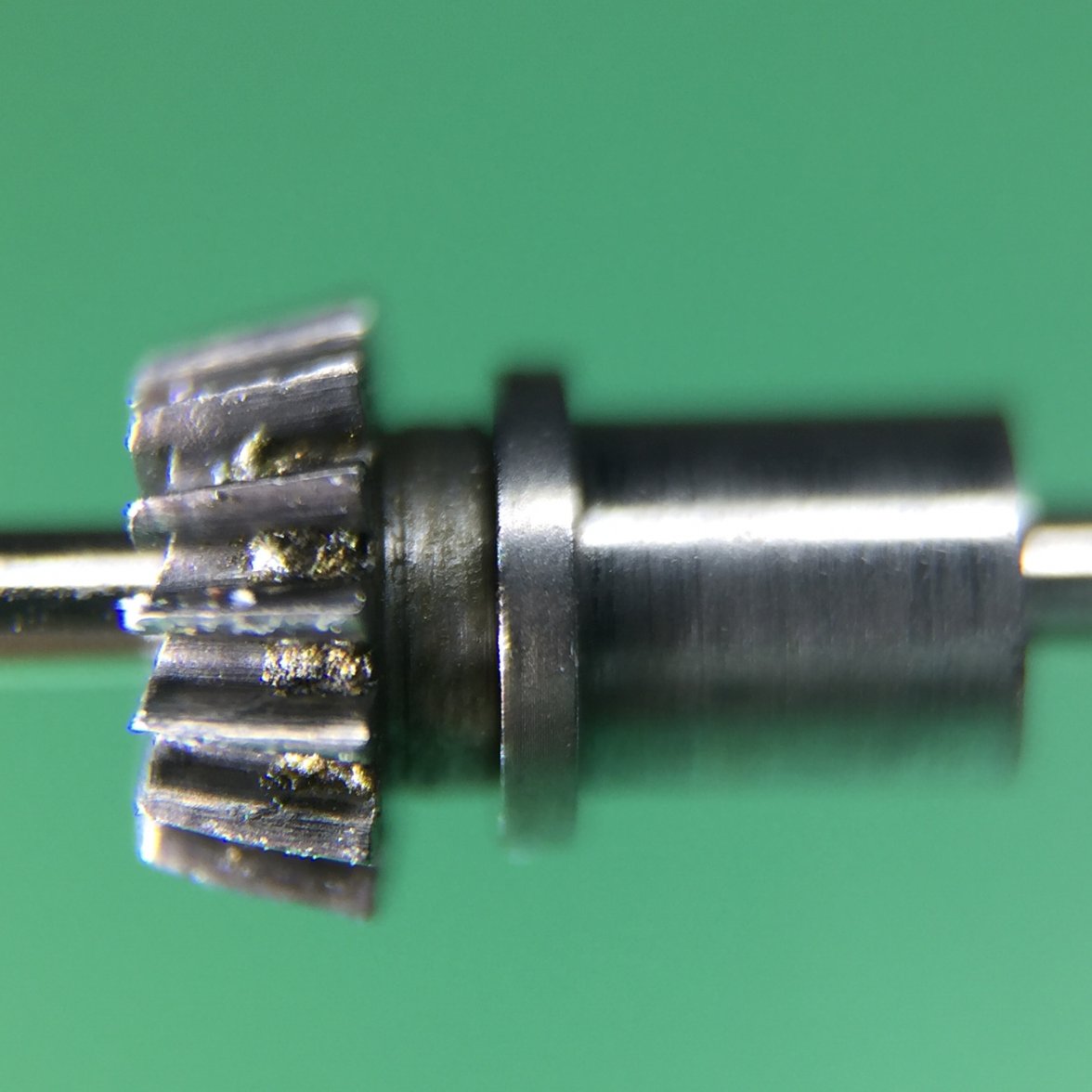

··Omega Qualified WatchmakerAnother good reason to inspect parts before cleaning. This crown wheel shows signs of bad engagement with the winding pinion, so off on another parts search.

If there's bad engagement, there's a reason for that, so you also need to determine what that is and resolve it. If you don't, the new parts will soon look like the old parts...

Swissmister

·From my own nightmares searching for parts for 100 ish yr old pocket watches, I feel for you. I was simply unable to find parts for a few over the last several years, and in the case of jewels with cracks and even wear as you show on the crown wheel, I was left to clean, lub, and put those imperfect parts back in. The watches will often run consistently unless there are multiple cracked jewels in the train. If the balance jewels are cracked, well, I try my best to find replacements. My pocket watches very rarely get wound or carried, so it's not important that they keep great time, and the worn parts will likely get very little future wear. At least that's how I rationalize it. I like seeing them run. Good work and keep it up.

X5Mita

·That is seriously cool! Beautiful!

yande

·Yes, thanks for an enlightening insight Jim et al. The trials and tribulations....

JimInOz

··Melbourne AustraliaYes, thanks for an enlightening insight Jim et al. The trials and tribulations....

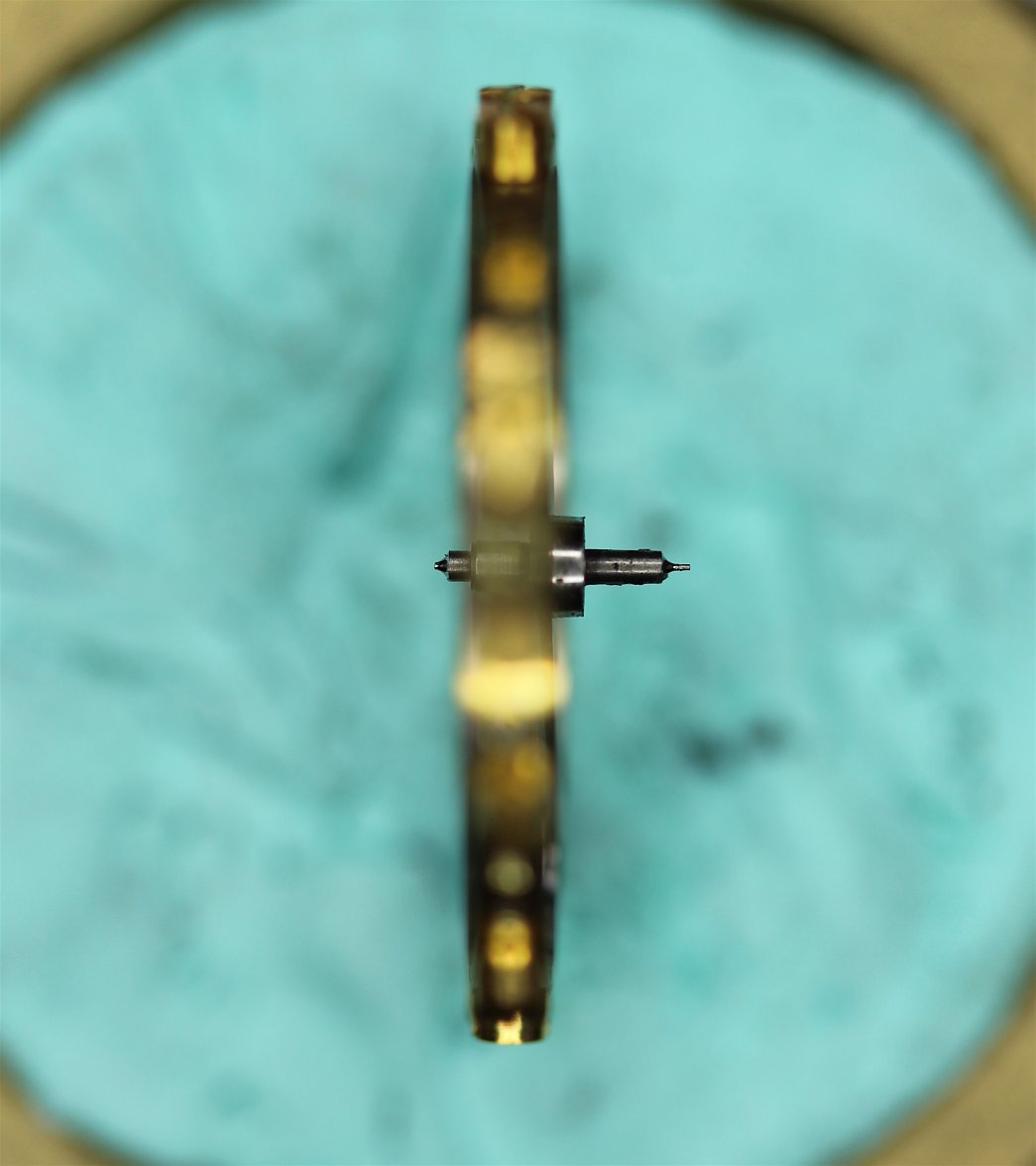

........continue. After sourcing a spare movement (a couple of parts were OK) and a donor watch (totally different movement despite the description) I had everything ready to go, but couldn't get any amplitude and the end shake was incredible, despite the balance staff looking OK after cleaning. Have a look here:

As you can see, things are not right. The jewels look OK, but when I screw down the balance cock, it seizes, so there is something badly wrong with the current balance staff.

This could have been a replacement balance staff, but a look at it confirms the reality. 🙁

Oh well, onward and upward as the saying goes.

Back to the search for a correct balance staff.

EDIT: I don't think this is the problem, the staff may be OK, see next post.

Edited:

JimInOz

··Melbourne AustraliaI think I've found the problem, and I'm kicking myself I didn't check for it prior to cleaning/re-assembly.

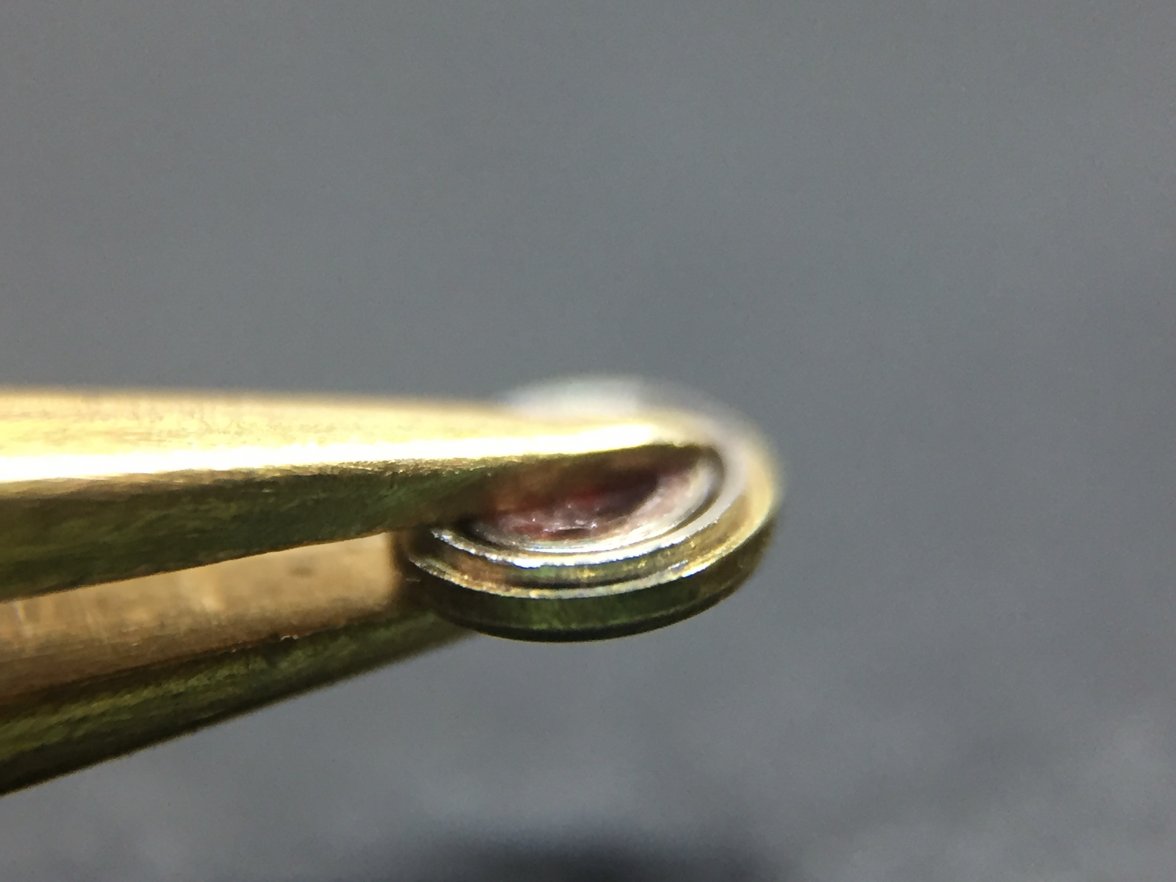

I took the balance assembly apart and found that the jewel in the balance cock is loose and had tilted in the cock.

I removed the jewel (which is OK) and re-fitted it with my jewelling tool, however I can still move the jewel even when it's fully seated.

So, any tips on how to retain the jewel (as in both keep it and secure it)?

My engineer side thinks a retaining compound, and I'm unwilling to stake it with a centre punch as I've seen in some old watches and clocks so I'm open to suggestions from the mentors @Archer @Canuck @ChrisN and anyone else who can help me with this little dilemma.

Cheers

Jim

I took the balance assembly apart and found that the jewel in the balance cock is loose and had tilted in the cock.

I removed the jewel (which is OK) and re-fitted it with my jewelling tool, however I can still move the jewel even when it's fully seated.

So, any tips on how to retain the jewel (as in both keep it and secure it)?

My engineer side thinks a retaining compound, and I'm unwilling to stake it with a centre punch as I've seen in some old watches and clocks so I'm open to suggestions from the mentors @Archer @Canuck @ChrisN and anyone else who can help me with this little dilemma.

Cheers

Jim

Archer

··Omega Qualified WatchmakerSo the staff was okay after cleaning but is now obviously broken. You think this happened because the jewel setting was crooked?

Is this the original jewel setting that came in this watch, or a replacement?

Is this the original jewel setting that came in this watch, or a replacement?

airansun

·Fascinating. To me, one of the best threads in months!

I think I understand now why my bank vault of railroad grade pocket watches, bought at auctions in the 80’s, haven’t increased in value. (In current dollars, most have decreased in value.) Considering how beautiful these watches are, the reality documented here makes me very sad. I had no idea. Shame on me.

Thank you all!

I think I understand now why my bank vault of railroad grade pocket watches, bought at auctions in the 80’s, haven’t increased in value. (In current dollars, most have decreased in value.) Considering how beautiful these watches are, the reality documented here makes me very sad. I had no idea. Shame on me.

Thank you all!

JimInOz

··Melbourne AustraliaSo the staff was okay after cleaning but is now obviously broken. You think this happened because the jewel setting was crooked?

No, the staff is OK, the binding occurred when screwing down the balance (extremely gently) and the crooked jewel touched the shoulder (I think).

Is this the original jewel setting that came in this watch, or a replacement?

"Original" in as much as this is what the watch came to me with, but there are obvious signs of previous work, so who knows.

Sorry Al, should have made it clearer. The original staff is OK, the problem is the loose jewel (in the original cock).

The broken staff I showed (when I thought it was a staff problem) was from the donor movement where I sourced some parts.

I may have a look today to see if the cock or the jewel from the donor can be used to rectify the loose jewel problem.

Failing that, can the jewel hole be upset to hold the jewel, or can the jewel be bonded (shellac?)

Archer

··Omega Qualified WatchmakerHopefully the donor has a jewel that will work and stay seated. One of the problems with these old US pocket watches in particular is that a lot of them have not been repaired well over the years (understatement alert!). So who knows if the loose jewel is the original one or not.

You can either try to find a jewel that fits better, which I'm guessing might not be as easy in Australia as it is in North America, and it's not really easy here to be honest. If you are able to find jewels they often come all mixed up, and require hand sorting to figure out what you have.

So I would put the solution of using adhesive down as "not ideal" but possibly the only way out for you in this situation. Of course people sometimes make new chatons to fit, but I don't know if you have a lathe or not. If modifications are required, it's typically better to modify the part rather than what the part goes into, so in this case modifying the jewel rather than the balance cock, because then if you do find the right jewel it can be replaced.

Not sure this helped, but hopefully it did!

Cheers, Al

You can either try to find a jewel that fits better, which I'm guessing might not be as easy in Australia as it is in North America, and it's not really easy here to be honest. If you are able to find jewels they often come all mixed up, and require hand sorting to figure out what you have.

So I would put the solution of using adhesive down as "not ideal" but possibly the only way out for you in this situation. Of course people sometimes make new chatons to fit, but I don't know if you have a lathe or not. If modifications are required, it's typically better to modify the part rather than what the part goes into, so in this case modifying the jewel rather than the balance cock, because then if you do find the right jewel it can be replaced.

Not sure this helped, but hopefully it did!

Cheers, Al

JimInOz

··Melbourne AustraliaThanks again Al. I appreciate the comment about "being repaired". I've also found the quality and finish on some of the American pocket watches to be of varying standards of quality and finish, although I'm probably more used to later Swiss movements.

Ideally I would remove the old jewel from the chaton and turn up a new one on my lathe. However, my lathe, and my skills, are probably not up to the task, although finding the correct gauge of brass from hobby/model maker shops isn't that hard.

I agree with you about keeping everything as original as possible, and in this case I've kept the balance original and used a jewel from the donor movement as it was in better condition than the original. Unfortunately it exhibited the same loose fit, so I could either stake it in with a pin punch 😲😲😲, or try retaining it in a more sympathetic manner.

So, here we go:

After cleaning the jewel and the balance cock again I set the jewel gently, mounted it so I could view it under the microscope and then applied bearing retainer with a Bergeon fine oiler and allowed it to wick in to the circumference of the chaton.

I'll give it a full 24 hours to cure although Im sure it won't take that long to harden.

Finished jewel looks much better than it did before.

Ideally I would remove the old jewel from the chaton and turn up a new one on my lathe. However, my lathe, and my skills, are probably not up to the task, although finding the correct gauge of brass from hobby/model maker shops isn't that hard.

I agree with you about keeping everything as original as possible, and in this case I've kept the balance original and used a jewel from the donor movement as it was in better condition than the original. Unfortunately it exhibited the same loose fit, so I could either stake it in with a pin punch 😲😲😲, or try retaining it in a more sympathetic manner.

So, here we go:

After cleaning the jewel and the balance cock again I set the jewel gently, mounted it so I could view it under the microscope and then applied bearing retainer with a Bergeon fine oiler and allowed it to wick in to the circumference of the chaton.

I'll give it a full 24 hours to cure although Im sure it won't take that long to harden.

Finished jewel looks much better than it did before.

JimInOz

··Melbourne AustraliaWell, we're getting close to the end of the line. After adjusting for beat error about six times, which requires disassembly of the balance assembly, unless you have the sneaky little tools to do it on a balance tack, I got it to the stage where I could time it and then case it.

Although the Timegrapher readings are a bit erratic (and I expected that) it's keeping reasonable time for what it is.

Here's a shot of it in its natural position, and showing good results (yes, I know, 52º is wrong!). 😁

but over the long run, it will keep reasonable time, is properly lubricated, has a good mainspring and now winds correctly, so we will see how it settles in over the next day or two.

Although the Timegrapher readings are a bit erratic (and I expected that) it's keeping reasonable time for what it is.

Here's a shot of it in its natural position, and showing good results (yes, I know, 52º is wrong!). 😁

but over the long run, it will keep reasonable time, is properly lubricated, has a good mainspring and now winds correctly, so we will see how it settles in over the next day or two.

Similar threads

- Posts

- 19

- Views

- 3K