- Posts

- 26

- Likes

- 55

Bayrat

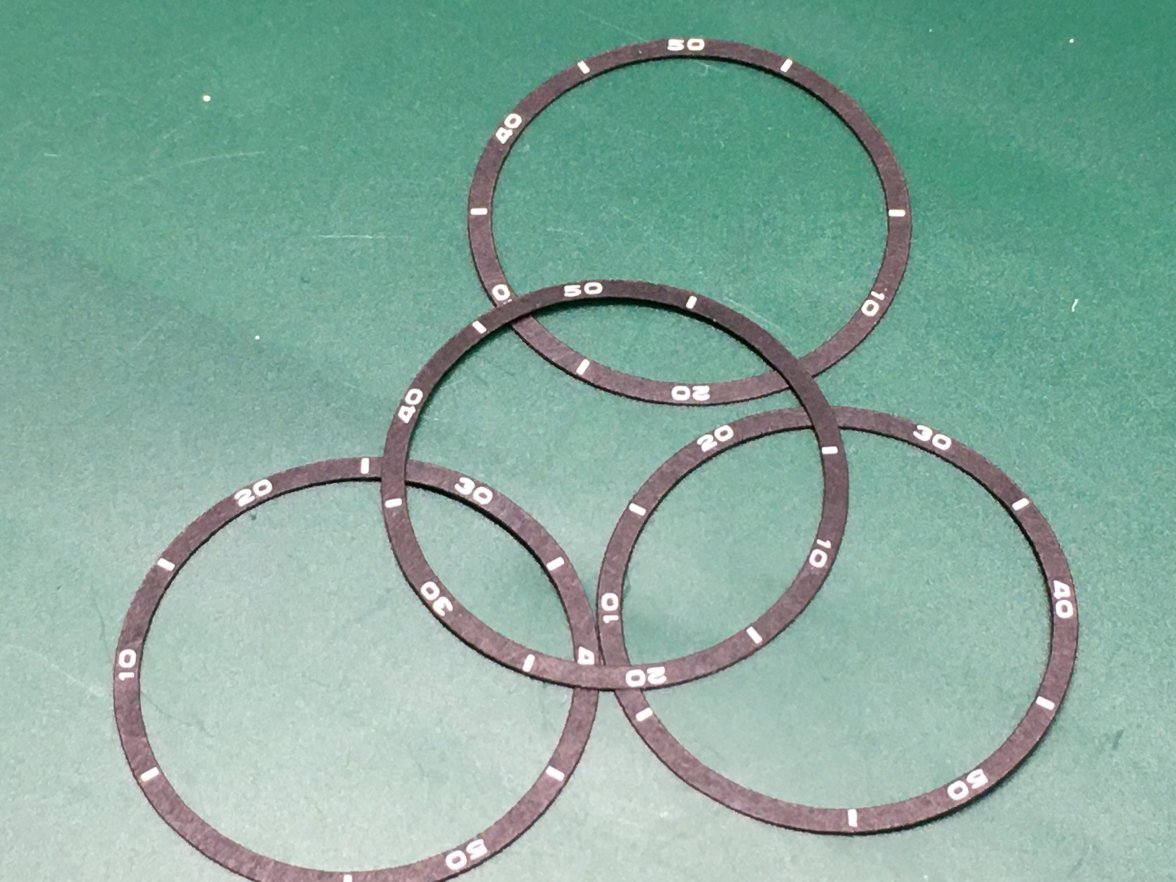

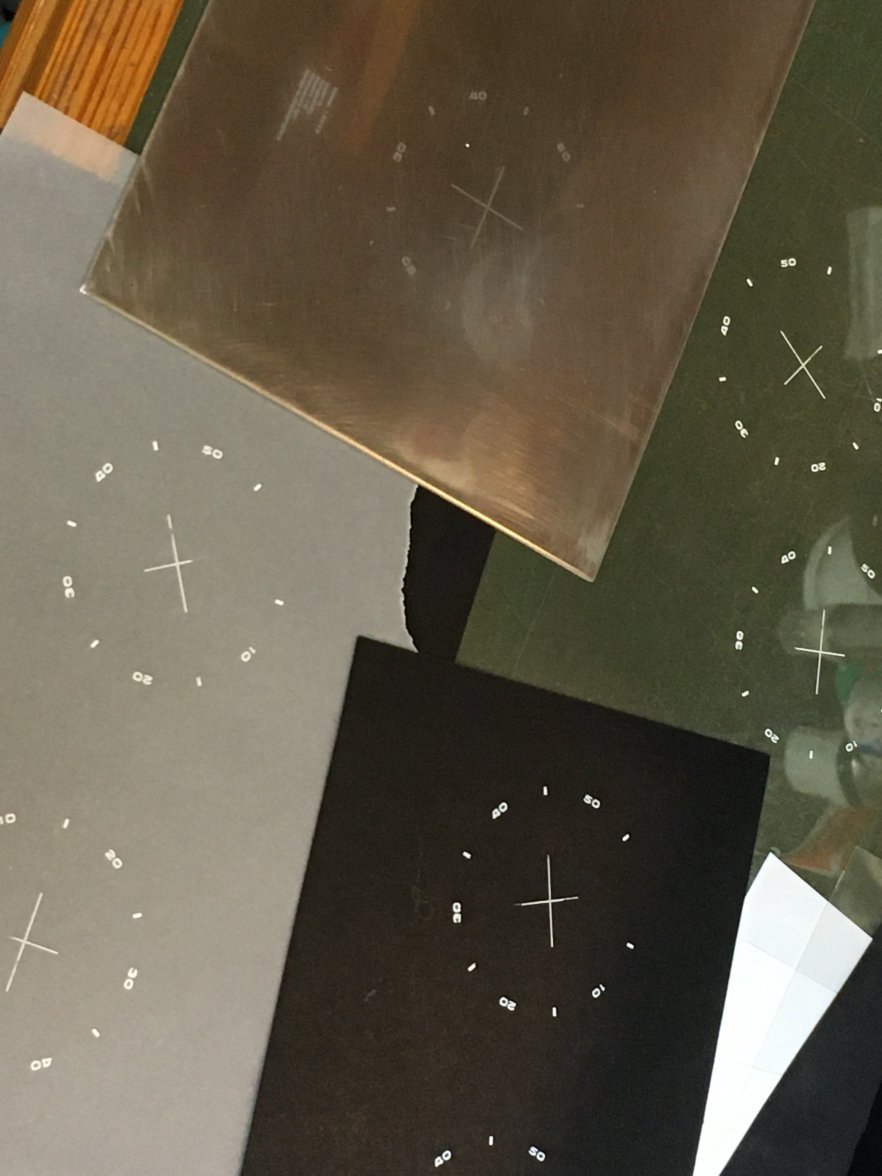

·That insert looks awesome!

Will that insert fit a 165.014 1962 Seamaster? I'll roll the dice on any prototype you got!

Mcgyver - you are a true MacGyver! The definition of a "MacGyver Type" is “To assemble or repair something by ingenious improvisation, using everyday items that would not usually be used for the purpose” LOL…I think you’re there!

Will that insert fit a 165.014 1962 Seamaster? I'll roll the dice on any prototype you got!

Mcgyver - you are a true MacGyver! The definition of a "MacGyver Type" is “To assemble or repair something by ingenious improvisation, using everyday items that would not usually be used for the purpose” LOL…I think you’re there!

Edited: