ninman

·So, I really love the FOIS. It's a great watch. The finishing is fantastic, and it's got the vintage look and proportions that I love. I know some people don't like the colour of the lume, but I'm ok with it.

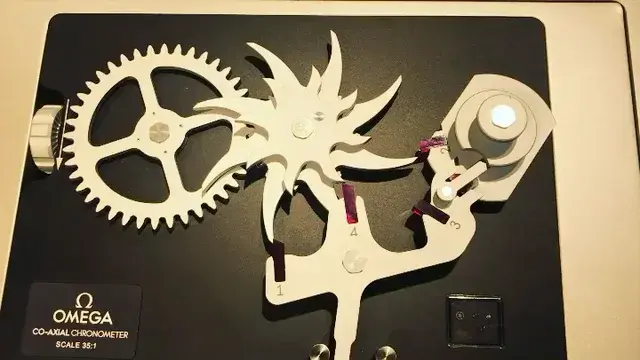

However, one thing that's always bothered me about modern Speedmasters is that they use the new co-axial escapement. I understand it's meant to be more advanced than the traditional Swiss lever escapement, but for some reason I think changing the escapement on the Speedmaster is a little bit like changing it to an automatic.

Basically, in my mind, the Speedmaster should be a manual winding chronograph with a fairly simple, yet robust, movement. That includes the Swiss lever escapement.

Obviously, ultimately, it doesn't really make any difference what kind of movement it uses because a mechanical watch is effectively outdated technology anyway, and has been since the invention of quartz.

I think what kind of bothers me about it is that from a servicing point of view, you essentially have to send the watch back to Omega because watchmakers need specific training on coaxial escapements, and it kind of gives me similar vibes to newer computers, phones, laptops etc, where everything's kind of put together in a way that makes simple repair difficult, and it can even hurt reliability.

I might not be articulating myself very well, but I'd just feel a bit more comfortable if they used the Swiss lever escapement in the Speedmaster.

What do you think?

However, one thing that's always bothered me about modern Speedmasters is that they use the new co-axial escapement. I understand it's meant to be more advanced than the traditional Swiss lever escapement, but for some reason I think changing the escapement on the Speedmaster is a little bit like changing it to an automatic.

Basically, in my mind, the Speedmaster should be a manual winding chronograph with a fairly simple, yet robust, movement. That includes the Swiss lever escapement.

Obviously, ultimately, it doesn't really make any difference what kind of movement it uses because a mechanical watch is effectively outdated technology anyway, and has been since the invention of quartz.

I think what kind of bothers me about it is that from a servicing point of view, you essentially have to send the watch back to Omega because watchmakers need specific training on coaxial escapements, and it kind of gives me similar vibes to newer computers, phones, laptops etc, where everything's kind of put together in a way that makes simple repair difficult, and it can even hurt reliability.

I might not be articulating myself very well, but I'd just feel a bit more comfortable if they used the Swiss lever escapement in the Speedmaster.

What do you think?