Archer

··Omega Qualified WatchmakerAl, can I ask you what tool you use to remove hairsprings from the balance?

Balance spring removal levers of course. 😀

http://www.jewelerssupplies.com/product9562.html

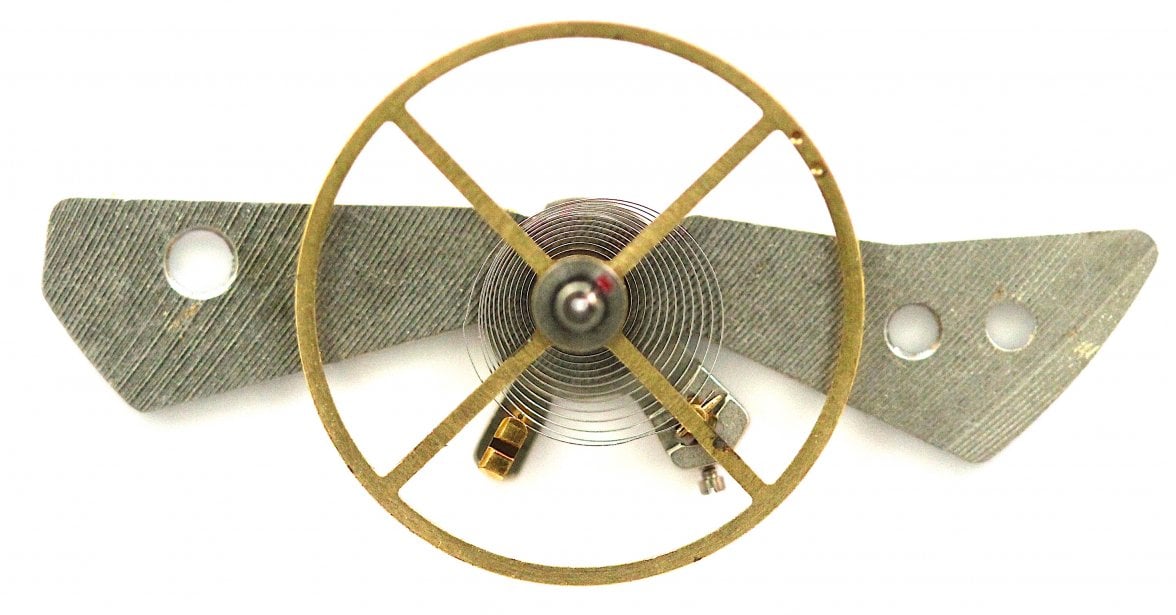

These are a different shape than hand levers are, but use the same principle. Are you using the screwdriver as a lever (hopefully not pushing it under the collet and twisting!), or are you inserting it into the slot of the collet? I suspect you are only dealing with pinned collets that have a gap in them, so just be aware that opening up the collet this way too many times can lead to a collet that is loose on the staff. So for those who may not know what I mean, this is a traditional pinned collet on this balance:

Note that I took this photo for another reason that you can see as balance screw snapped as I was unscrewing it to add a timing washer while dynamic poising...getting the remainder of the broken balance screw out was 😡

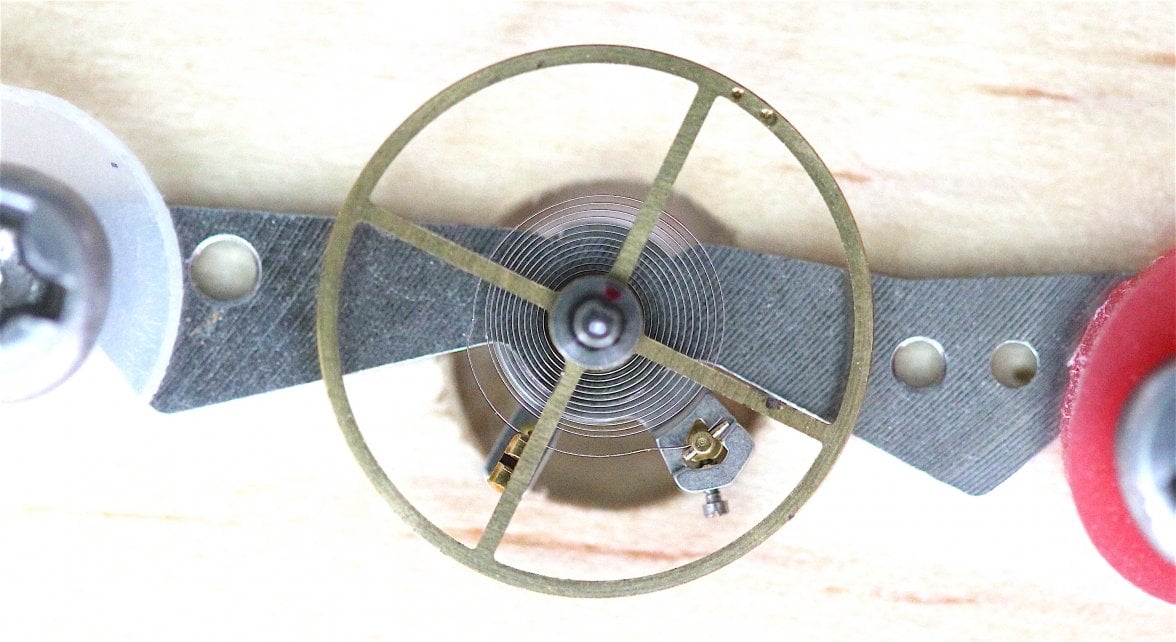

So on this one the collet is a brass ring with a slot cut in it and a hole drilled for a small taper pin that pins the balance spring to the collet, and the collet is then a friction fit on the balance staff. Using that slot to open up the collet to remove it from the staff can be problematic, and really using a screwdriver as a lever could also cause problems if you are not careful. Here is an older Rolex balance where the collet in more in focus:

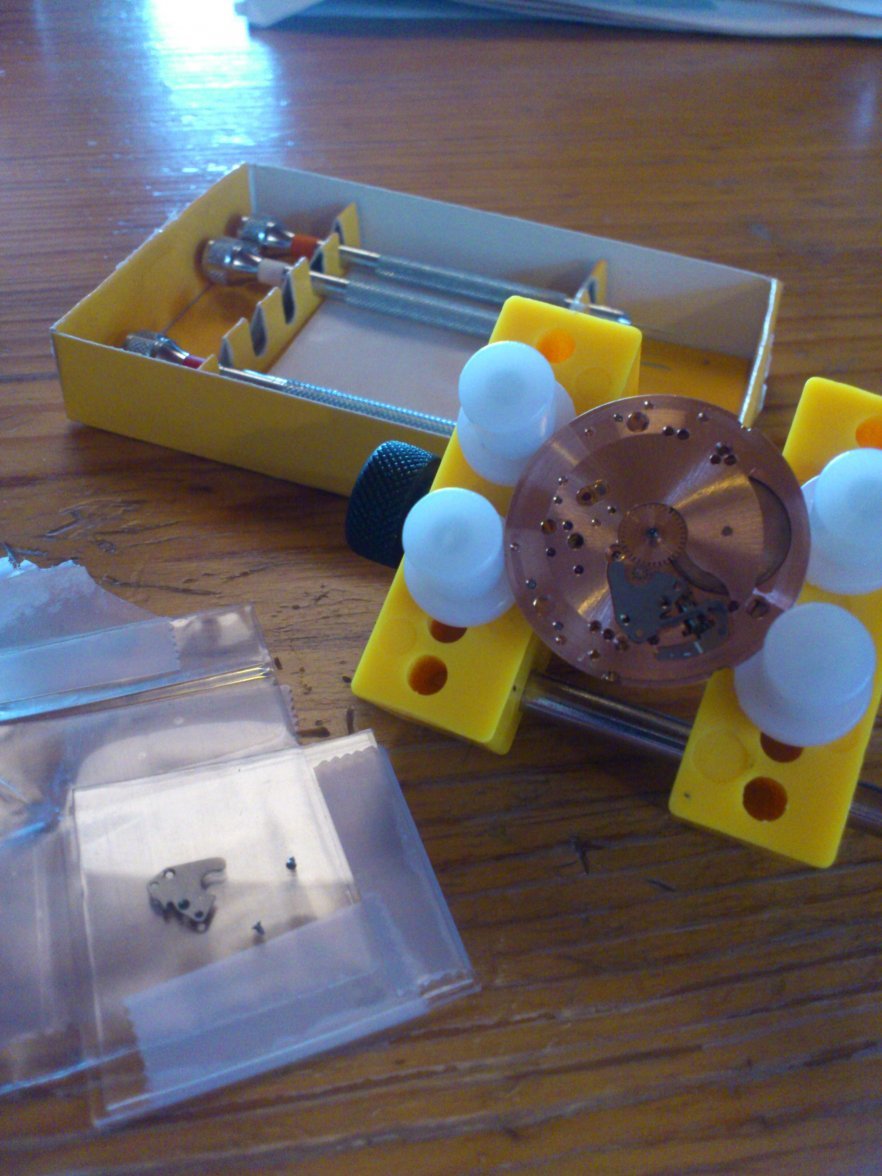

I actually can't recall what this balance spring assembly is from, but this assembly is actually made up of the collet, pin at the collet, the spring, the stud, and the pin at the stud, so 5 different parts:

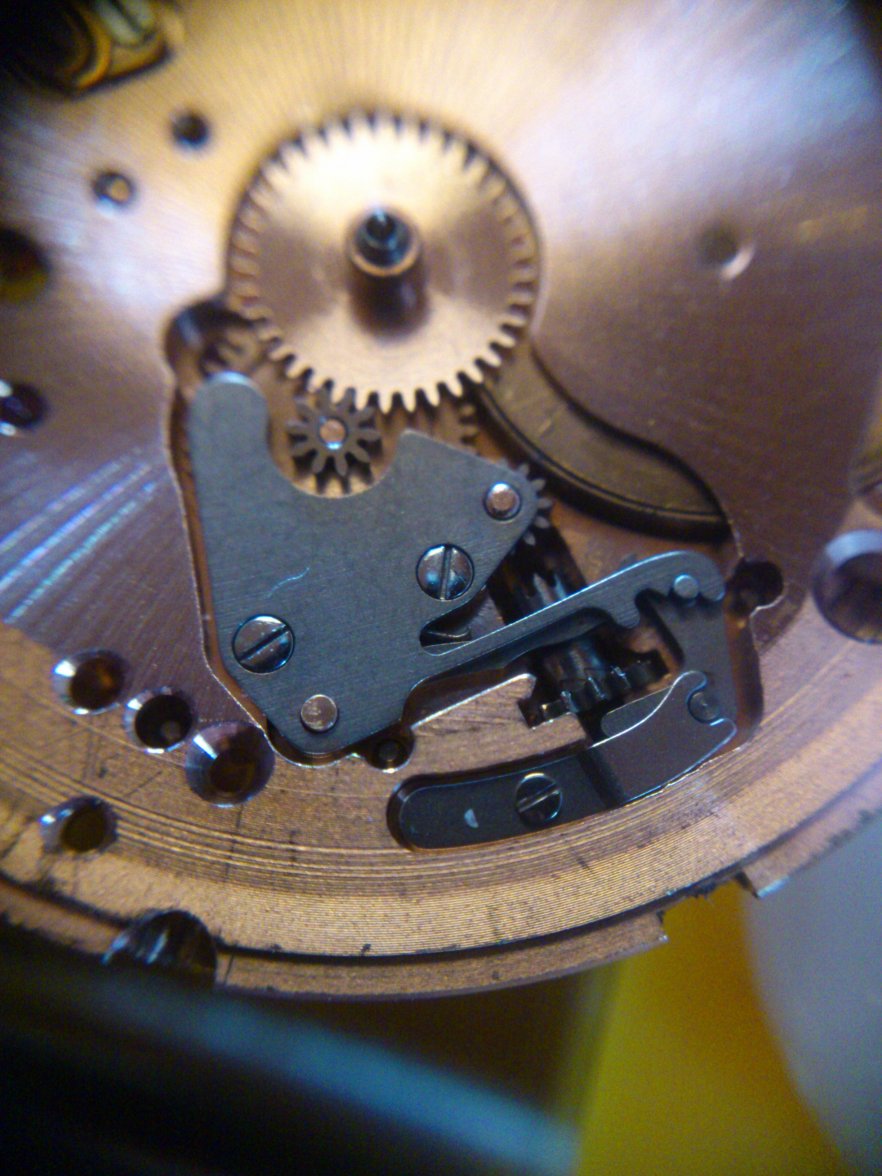

Of course many modern watches don't have this kind of round collet with a slot, so there's no slot to stick a screwdriver in, and trying to lever it off with a screwdriver won't go well. This is a modern balance "ETA based" and as you can see the collet is a completely different animal - oddly shaped and the balance spring is welded to the collet, not pinned:

On the stud end it's glued into the stud, not pinned or welded. These tend to fit very tightly on the staff, so levers are the best way to remove them and it takes some force to do so...they come off with a bit of a snap...

Hope this helps.

Cheers, Al