Anthony Lane

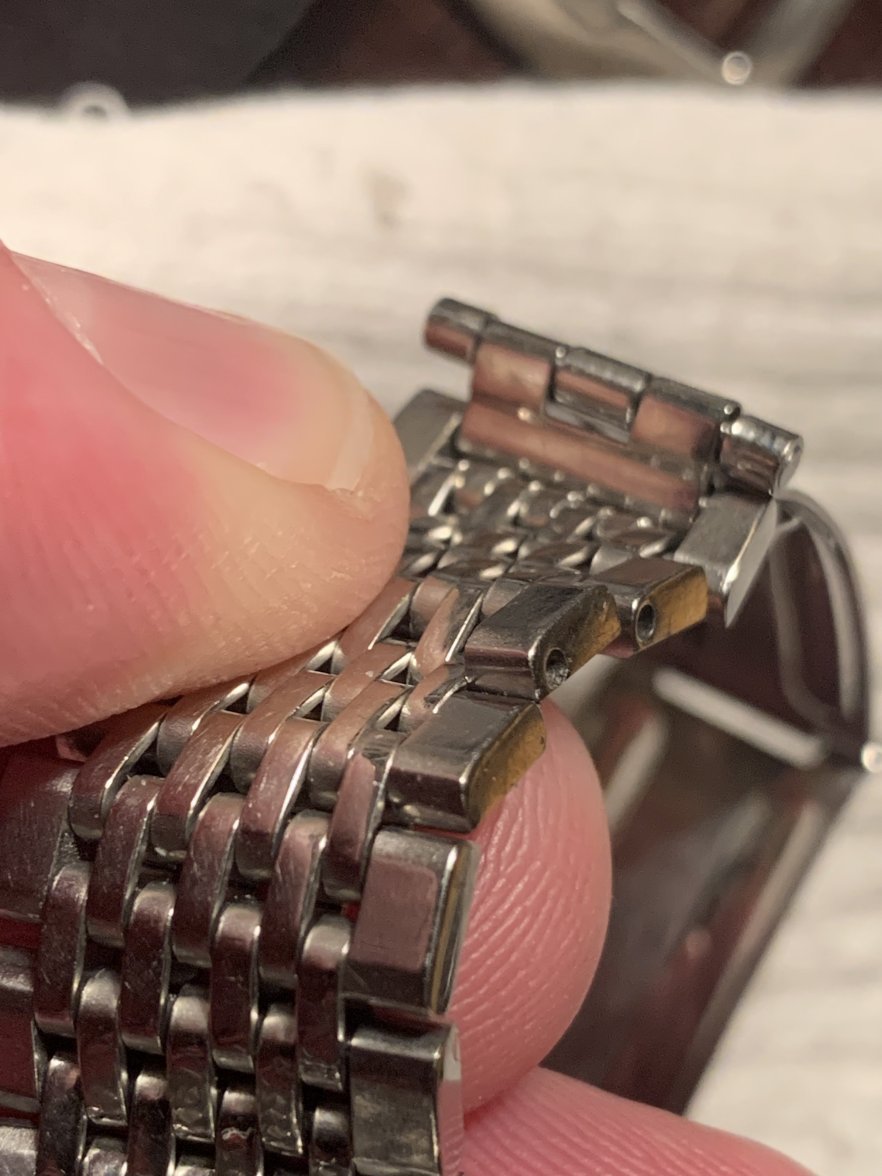

·I have this bracelet here with a couple of removable links. These are not the split or friction pins that pushes out uni-directionally. They are spring loaded and can push in 2-3mm, but nothing happens. I assume they have to be pushed in a certain depth and then behave like a spring bar, however I can’t figure it out.

Any help would be appreciated. Furthermore, the clasp is horribly off center, can I remove links from the long end and add them to the short side? There are no removable links on the short side.

Any help would be appreciated. Furthermore, the clasp is horribly off center, can I remove links from the long end and add them to the short side? There are no removable links on the short side.

Edited: