WARNING, picture heavy!

Alright, I decided to get to my first attempt at actually 'doing good' on this learning experience. I mentioned before I have a pair of pocket watches, 1 that works, 1 that doesn't. I opted to start on the 'non-functional' one first.

I am doing this for three reasons:

1- I am leaving tomorrow for a week-long business trip, so if I forget stuff, I'll feel 'less bad' about taking a broken one making it worse.

2- I think the little more practice using a pocket watch would be nice.

3- The replacement mainspring has yet to arrive (showing up Saturday after I leave!), so any replacement parts that would delay re-assembly can be ordered while I'm gone.

HELP NEEDED:

I figured I'd put together a list of the help I need

😀 Here it is!

-ANY idea what the inscription inside the case back means?

-ANYONE have any idea how to remove the dial? (see side picture with lever near the bottom!)

-Can you confirm the stem is supposed to be 2 parts?

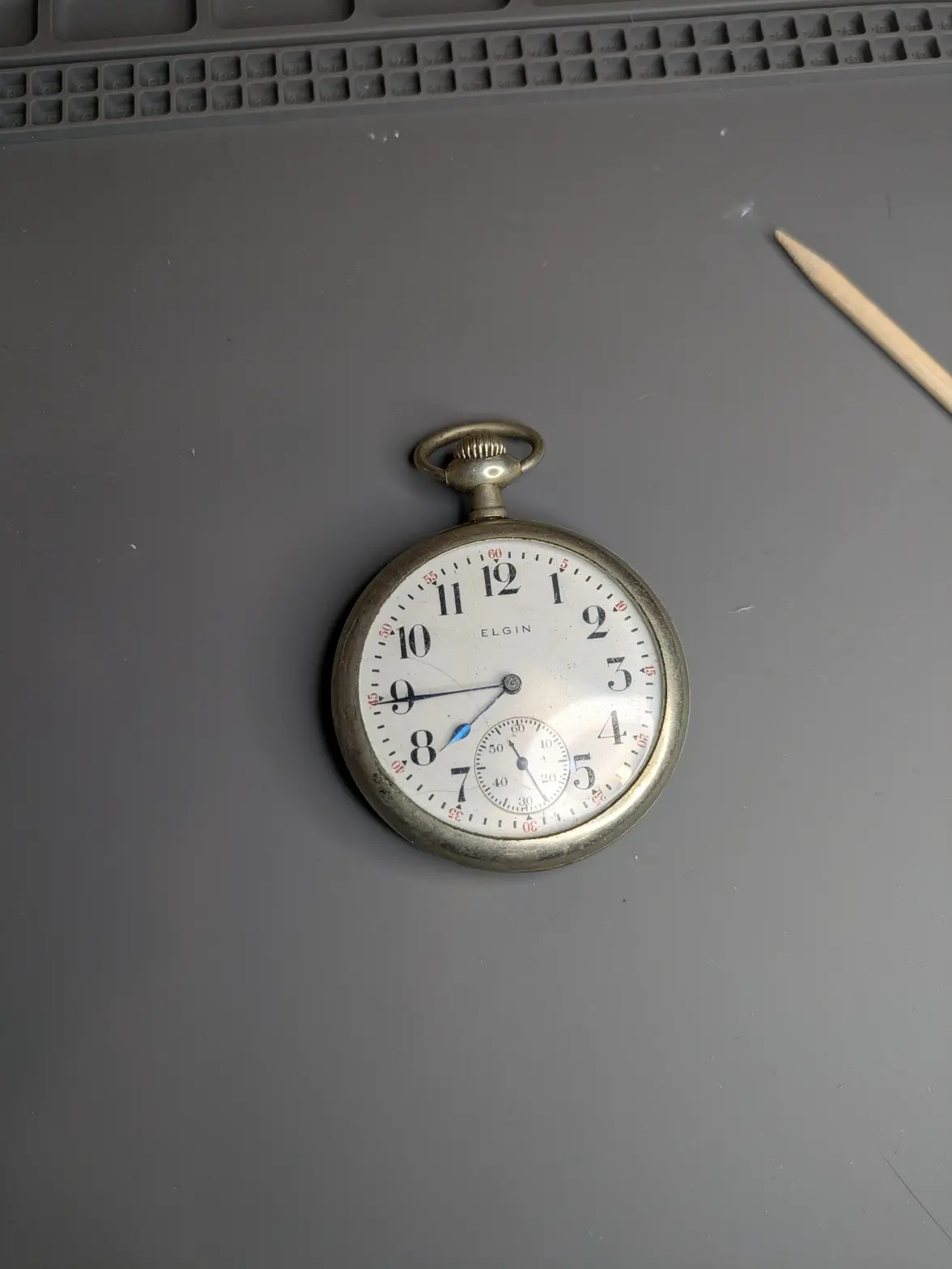

SO, here is the watch itself. A quick function check shows that the crown 'turns' and 'clicks' in 1 direction, and makes no noise in the other direction. I cannot 'pull' it in any way, so there isn't an obvious way how to set it at the point of initial function check. AS far as I can tell it is a silverode cased Elgin 293 movement. I'm only into it < $75 (including the main spring), so hoping I can make it 'nice' enough to be a desk-toy or a gift for a friend. The back is blank, but the hands are nicely blued.

First, the case screws into 3 parts, the crystal, back, and 'main' frame. Here is the movement sans-back. As you can see, there is a bit of surface rust that I'll end up having to/wanting to clean up best I can. The Philadelphia Watch Case Co marking is neat looking, and 'silverode' (which I believe is a nickel alloy). The manual inscription says 12xxx15 Staff J.9.50. I presume that means this was a mark that this was serviced in 1950? No idea what the 12xxx15 means though.

FIRST step I did was to remove what looks like the case screws. These ended up being shockingly long, which is the story of the screws in this movement! It has an interesting bridge design (with a flat-plate as the base instead of raised areas) which necessitates it. At this point, I was expecting it to fall out of the case, but it did not.

SO I carried on. I took off the 'glass' part off the case, and pulled the hands. This happened quite uneventfully. I was scared with how much came off of the seconds hand, and disappointed that the hour hand is a little rippled, but after 110 years, I can't complain too much.

Once I did this, it actually pivoted pretty nicely out of the case by pushing at about 6, and it rolled off the crown. I was a little concerned here at the time, as it seems a little short, but with no obvious way to remove the crown I presume this is the way it is supposed to work. The crown, separated from the movement, actually has a 2nd position that it clicks into. I find myself suspecting that it was 'gunked' into the movement (to be a theme!) and I just needed to hit it with my purse

😀

At this point, i was a little confused. There isn't any real obvious way to remove the dial. It seems to be bonded to some sort of metal plate, and there is no obvious mechanism on the side to remove it. There is one little 'switch' that doesn't actually seem to do anything. Additionally, there are these little copper-looking screws (that don't turn?) that protrude into the plate. You can see one under the balance wheel here, which I've removed:

Here is the balance. it seems healthy enough, though the 'using weights' to set the beat error (particularly as I don't have any spares, AND you have to remove the balance to be able to touch these!) has me praying that this is one I don't have to touch. Also note the bridge is imprinted with the serial number that matches the movement! The balance wheel didn't actually MOVE with air, though spun a little when moved. Now that it is out, I can tell this is because the pivots are FILTHY. It took a bit of prodding to get it to come out of the main plate.

I tried to release the mainspring here, but despite having spun the crown a bunch (and observing it move hte ratchet wheel/click working), there was NOTHING here. Then, I pulled the ratchet wheel, which was uneventful. There IS a bit of scuffing on the movement, but I don't think it has been touching TOO much? I guess I'll see once it is cleaned up better. You can also see more crud on the center wheel pivot here.

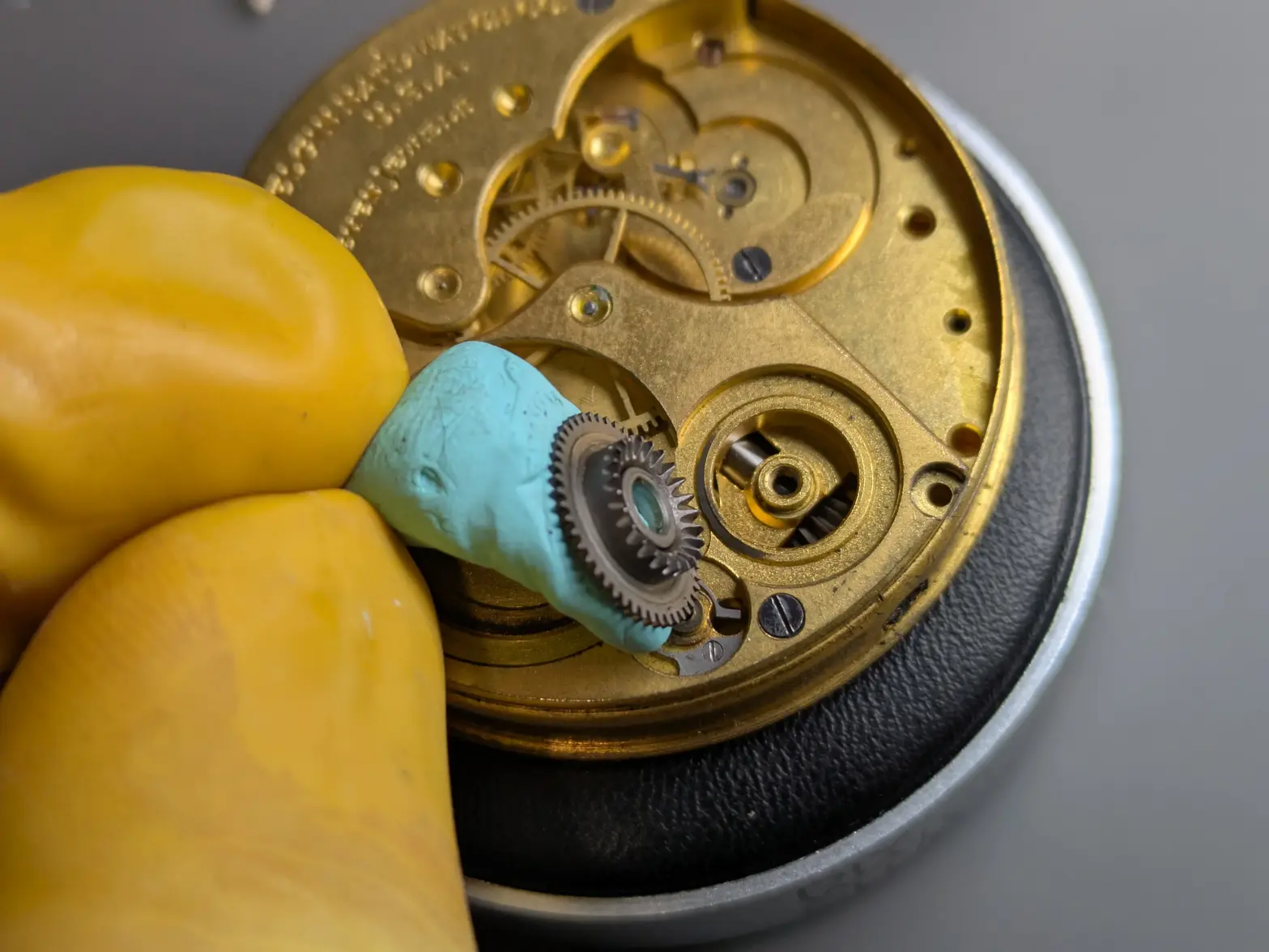

The click came off uneventfully as well, though two things: The spring is an interesting design (though the screw is too small for the screwdrivers I have, so it'll have to come out later). I also noticed that the crown wheel is interesting! it has a really neat looking two-part construction that interacts with the keyless works in a way that seems pretty unique. Note it is two pieces, but the Rodico picked up both together. SEPARATING these was a little bit of work to confirm they were actually two parts (there was a seam but they didn't actually move when lightly prodded), but it fell apart once the gunk was broken free.

The pallet fork bridge was a little stuck, but came out easily enough. it DID come with the pallet fork stuck into the pivot. I used a little bit of wiggling after this picture (actually after I was done!) to remove it. Note again we h ave a matching serial number!

I TRIED to take the mainspring bridge/center wheel bridge out first. I took out the screws, but it was stuck in there pretty good. I didn't really have any way to wedge it out, so opted to take the wheeltrain bridge out first. It ALSO was quite stuck (and wheels stuck to various pivots and required some wiggling to free up). BEFORE I did this I actually confirmed that the wheels actually all spin, and spin each other, which gets me hopeful of the condition here. I took this picture with the wheels put back into place for future reference

😀 Note THIS bridge also has a matching serial number!

At THIS point I was able to wedge the mainspring barrel bridge out of place. It went pretty easy at this point, though was a little gunked down. Just care to make sure I didn't break pivots, and it loosened up well. You can see the interesting construction here, the main plate has some minimal milling work, and a ring around the outside. This picture is also interesting, you can see more of those copper screw-like-things, plus the keyless works. The bridge itself had the same serial number, but on the top side (outer side?) so it all matched. At this point, I was able to give it a quick/light shake and the mainspring barrel popped out.

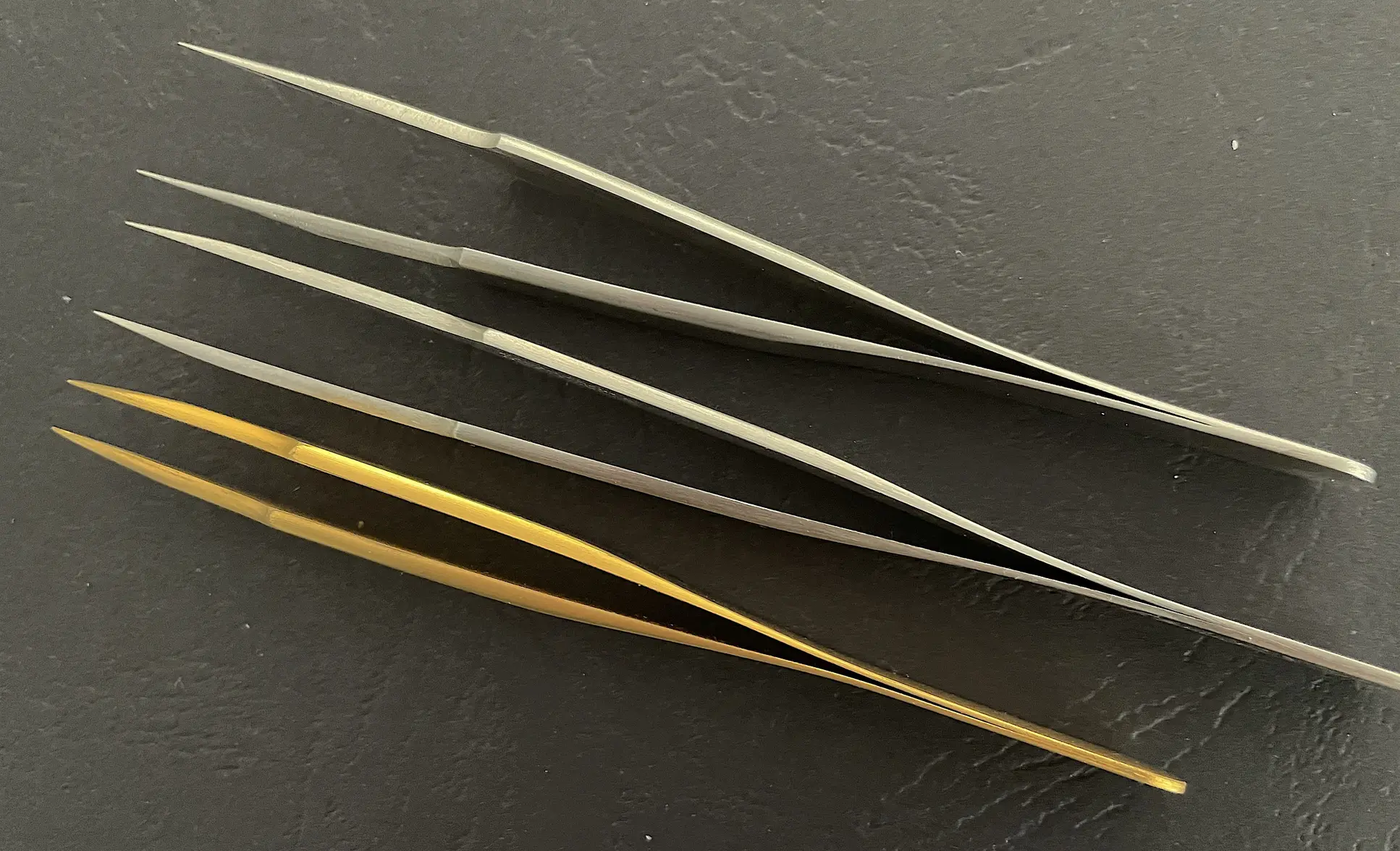

I then opted to try to work on the center wheel. I used my tweezers and some little bit of work, and was able to pop it out. You can see the gear under it (which I presume is either on the cannon pinion), but it popped out with minimal effort.

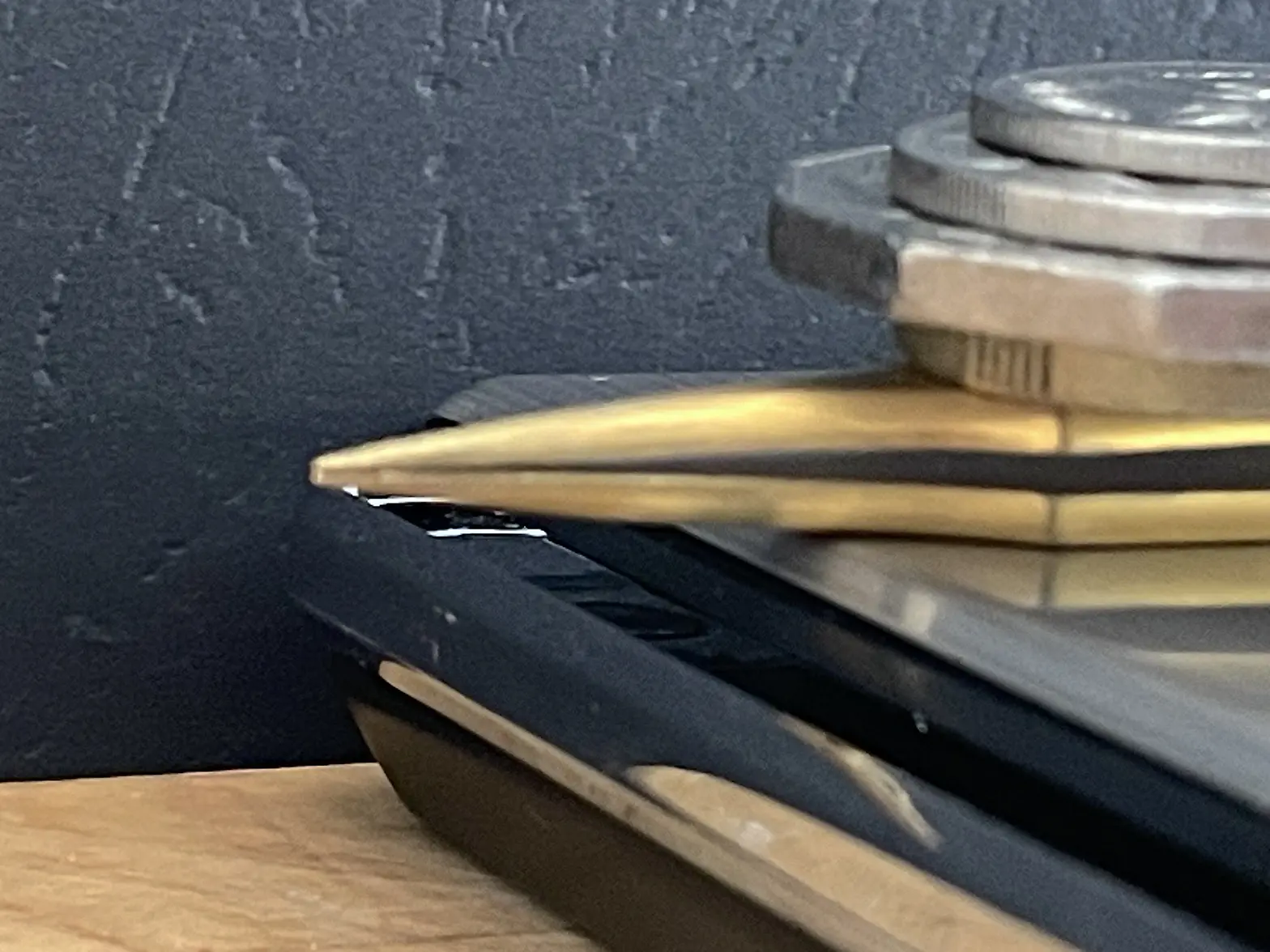

At this point, the keyless works parts were pretty trivial to pop out. I note there is what LOOKS like a second part of the winding stem, but the 'break' between the two looks intentional. Additionally the 'left' side (with the bevel gear) is square broached. I was able to move them and spin them, and see that the wheel on the other side of the movement turns if I push it right, but I have no idea how the two positions work here.

The screw holding down the lever part here came off uneventfully, as did the part itself. The other part (the round one) was a little 'stuck', and seemed to move the other side. I was a little afraid it was a single piece, but couldn't figure out how that would work, so I hit it with Rodico. Once off, it became pretty clear how it works/interacts with the other side (see it flipped over in the 2nd image):

I went back to looking at the dial, but have no idea. I see this little switch on the side (which can be moved 'down' or 'up' in this direction, and I can see where it pivots from the other side, but it is completely unclear what it does. It doesn't seem to loosen the dial in the least.

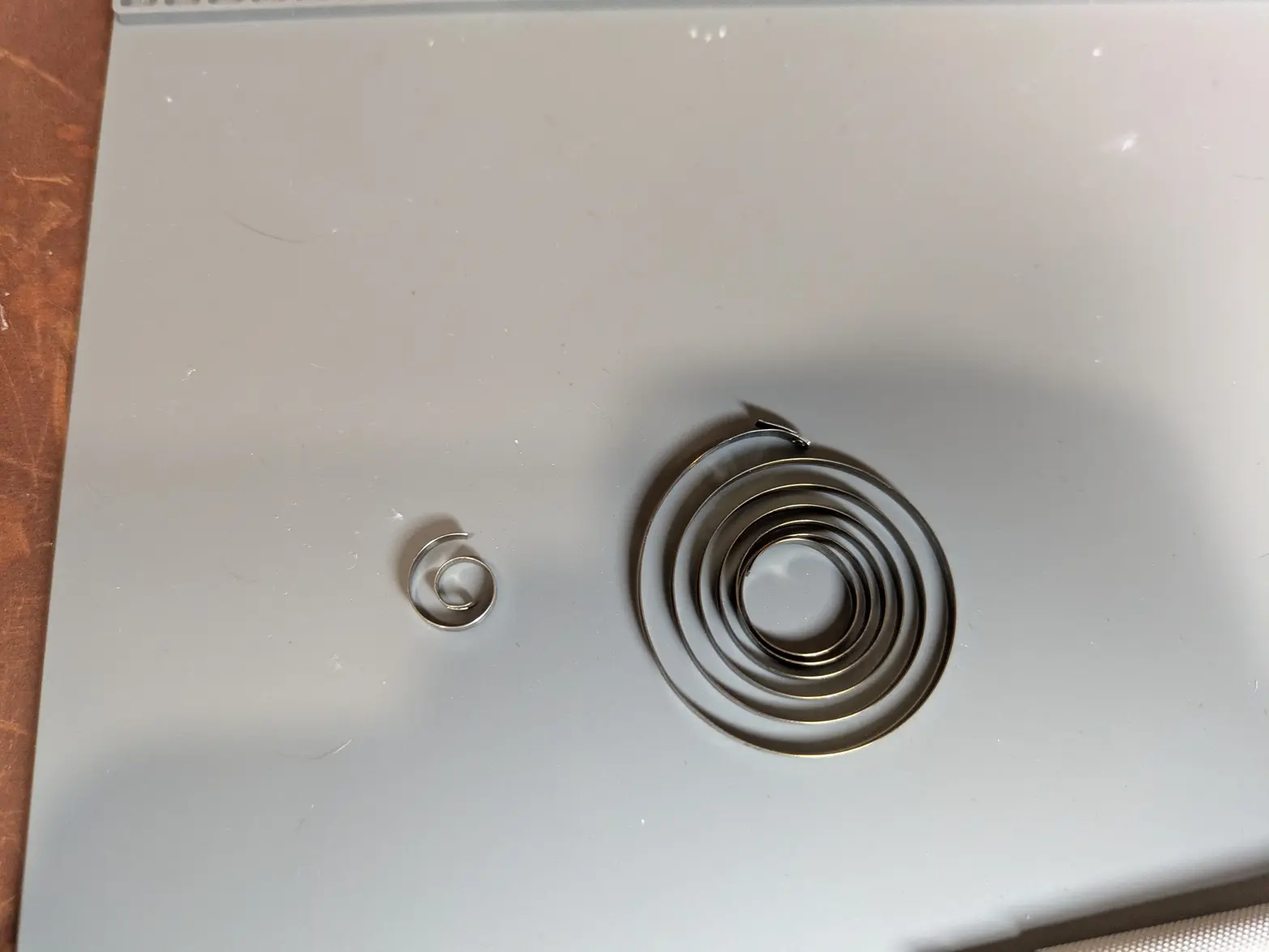

At this point, I decided to open the mainspring barrel. HERE it became perfectly clear why this watch doesn't run (in addition to the gunk). the mainspring is clearly broken in two! Fortunately I ordered a replacement. It LOOKS to be the right one for this 293 movement (as advertised, and it looks like that movement?).

SO, that is it for today! I'm going to toss the case into the ultrasonic and try to get it cleaned up a little. I might use some polywatch on the crystal to clean it up a touch, and some cape cod cloths to make it look a little shinier, but thats about it.

Thanks for making it this far, I hope you enjoyed my progress!