ChrisN

·So, Christmas is coming. I can tell this by the many ads on the TV in early November. Hmmm.

I'm building a watch as one Christmas present for my wife. It's an Omega but in the Watchco style, from parts. She has small wrists and you don't see many of this model from the 60s. It will be a slow reveal and might be interesting as it's not a normal Ladies dress watch. Don't have all the parts in hand yet but, am hoping for later this month (with a little help from a friend).

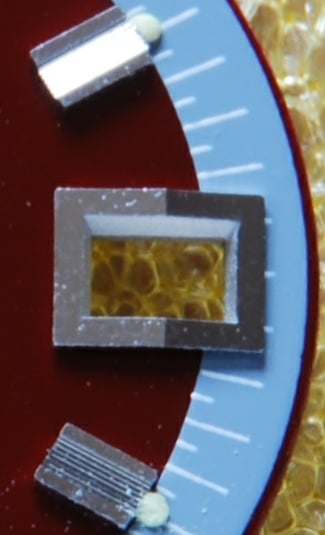

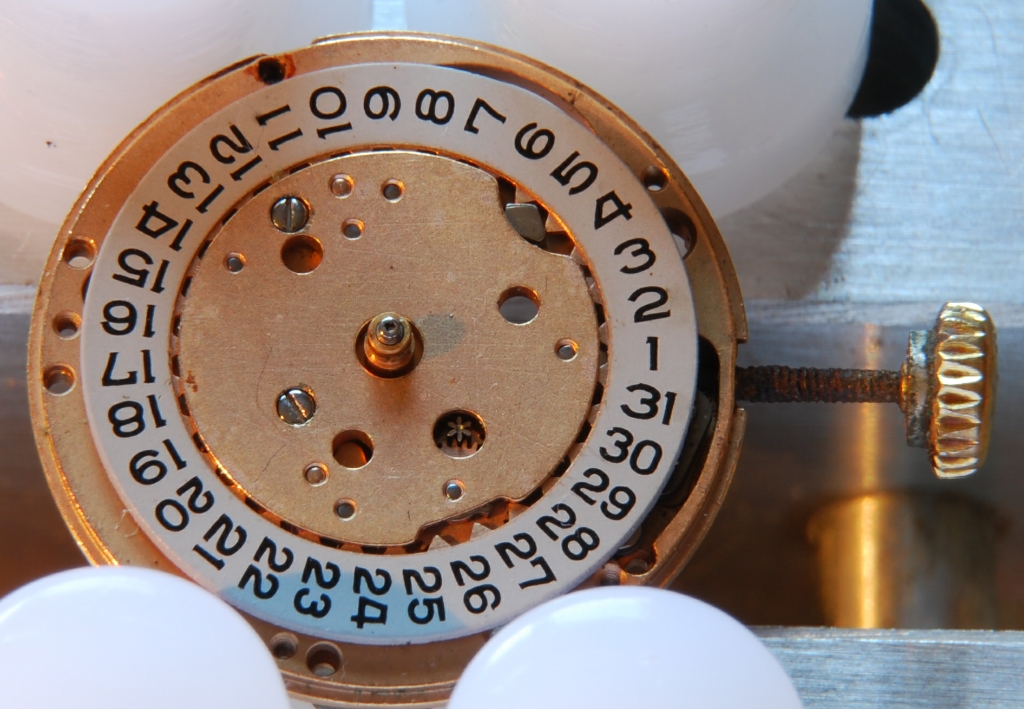

NOS dial from Watchco (partial reveal as don't want to give it away too soon) and we can see it has a date.

It houses a tiny ('tiny' and variations thereof are words I will use a lot), 18 mm diameter, 684 movement although it should really be a 681. I think the main difference is the 684 is an improved version of the 681 running at 3Hz (21600 A/h) rather than 2.75 Hz (19800 A/h). Quite impressive to get an automatic winder, central seconds, date ring and high beat in this miniature movement.

First is to tear down this very dirty/gummed up movement. It's a lot like a 56x in style and functionality but on a 2/3 scale. You can see that by comparing to the pictures in my other thread

http://omegaforums.net/threads/cal-561-a-simple-summary.17131/

so, I put the equivalent figure numbers in [ ]. As before, no attempted discussion of oiling techniques etc.

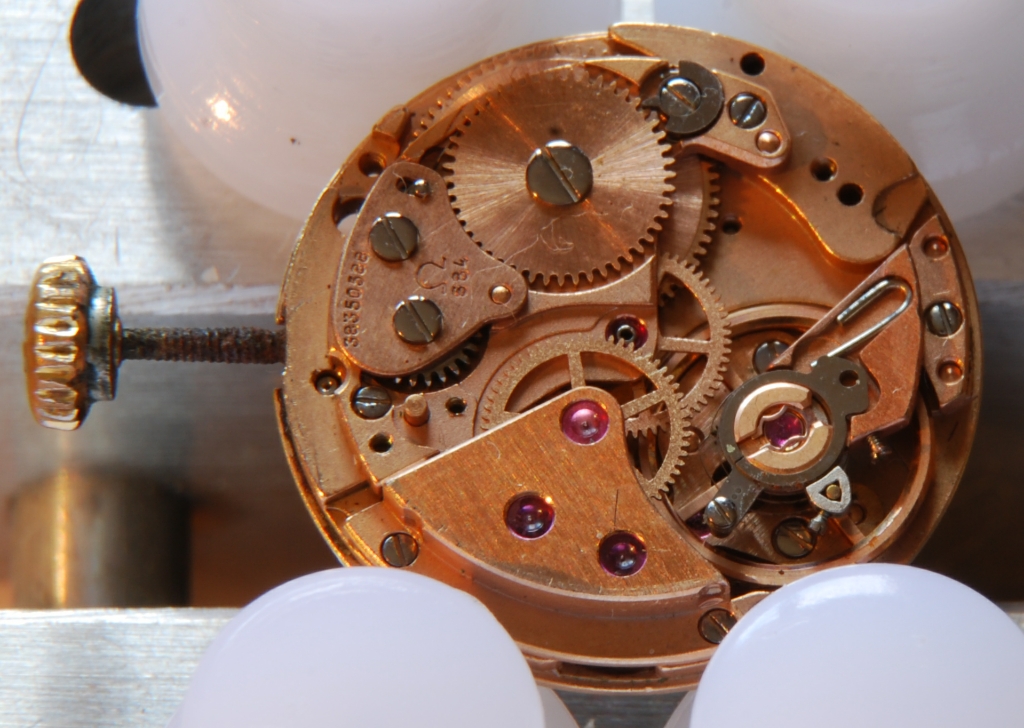

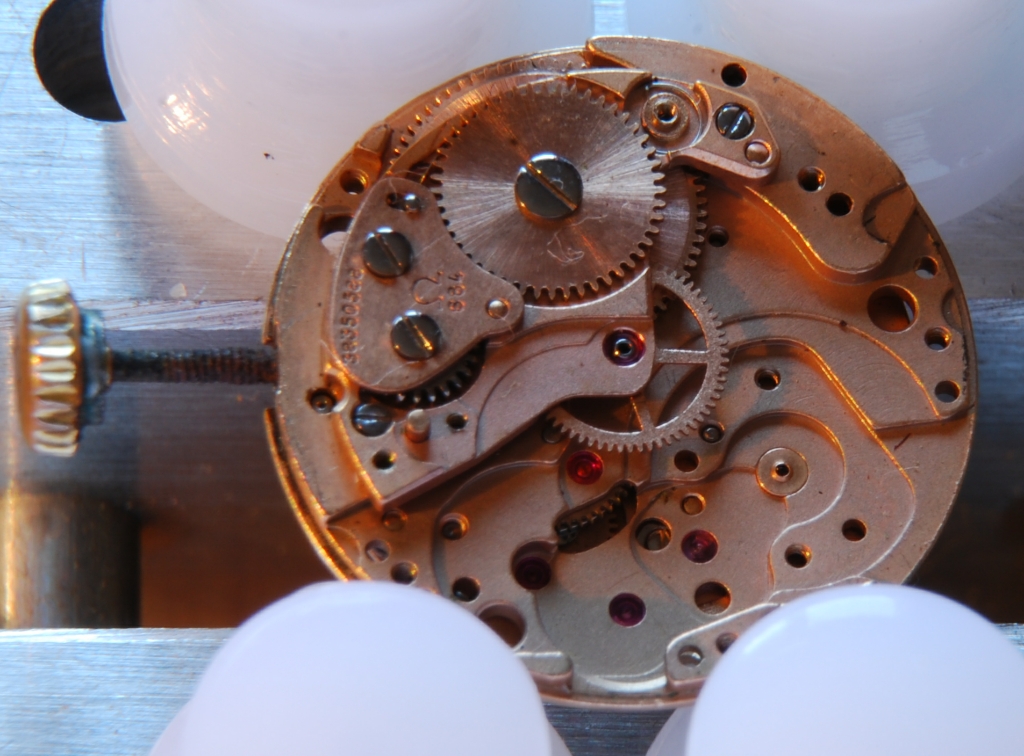

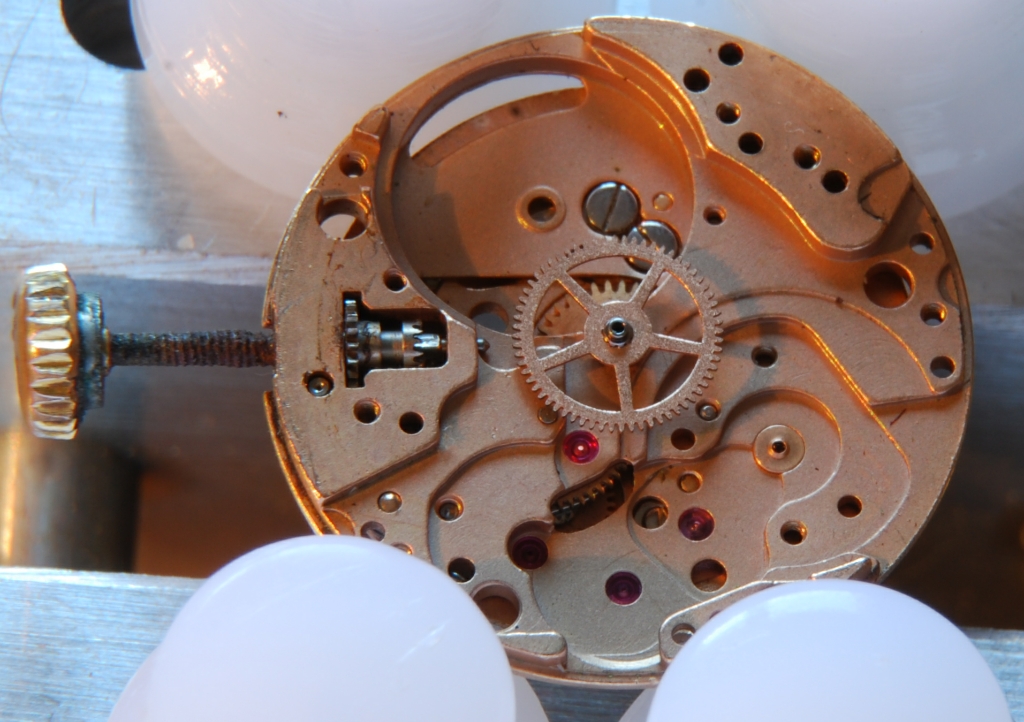

1. Movement from behind [56]. Not as attractive as a 56x. First thing I realised is I don't have a proper holder of this size for the rebuild so, on to Cousins website...

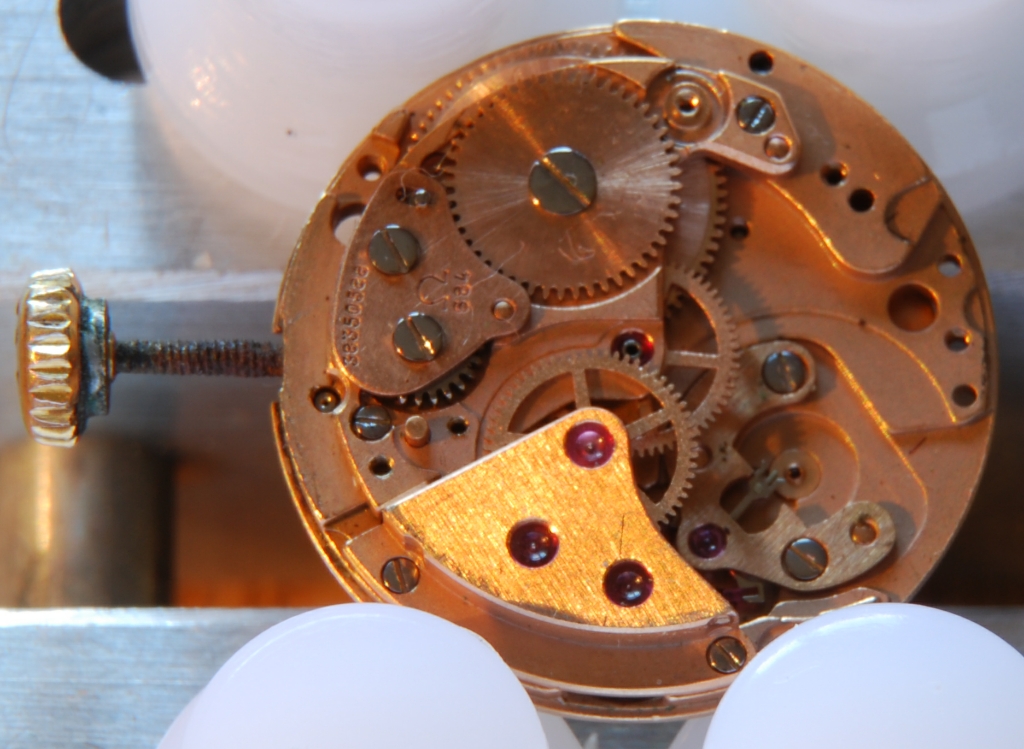

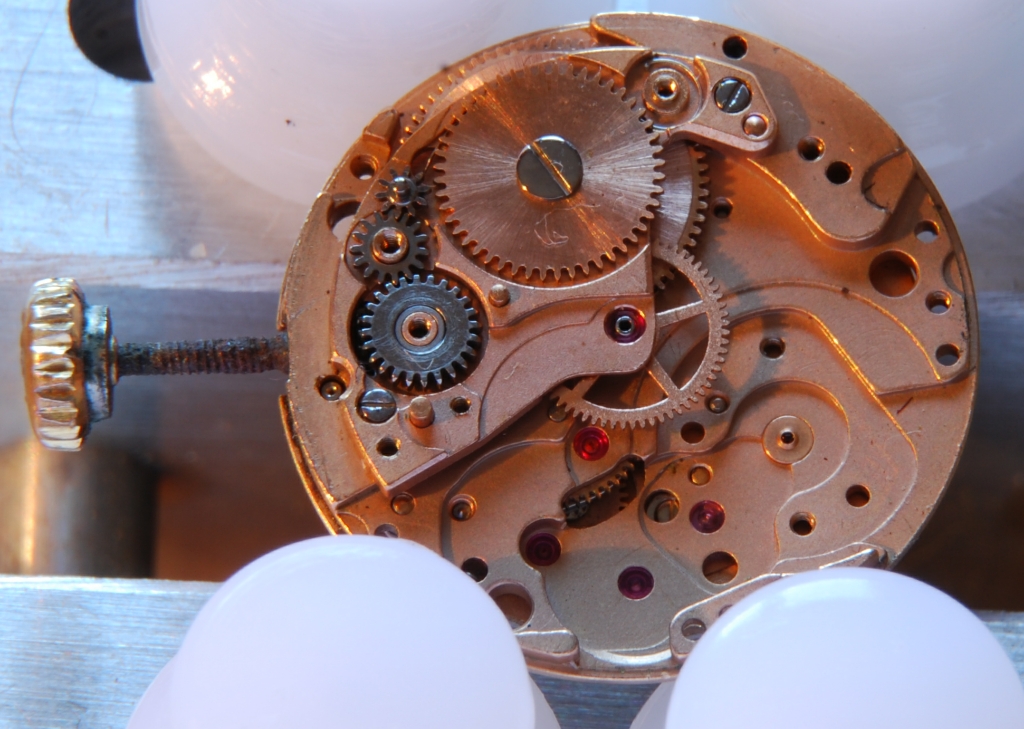

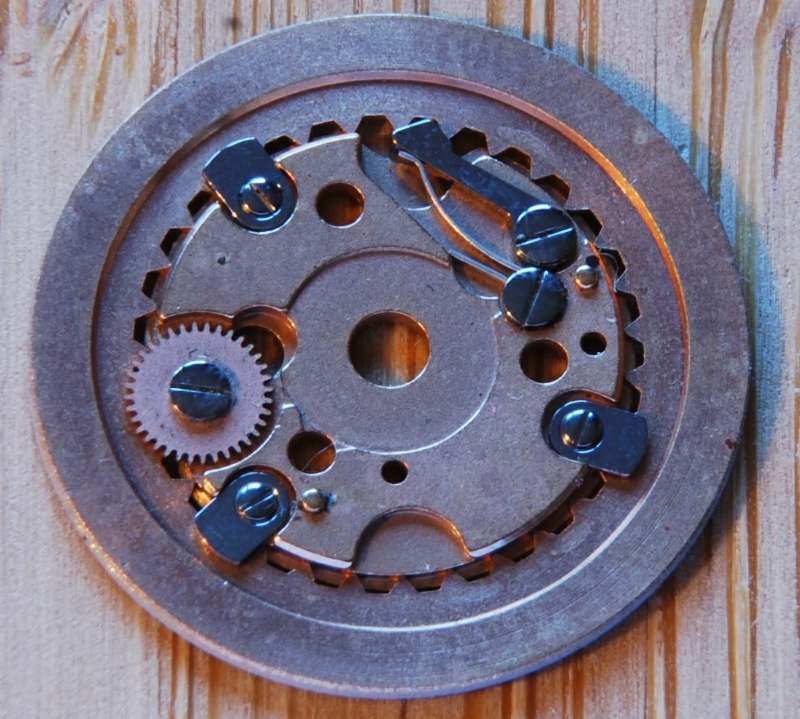

2. Auto bridge and mechanism removed [36] from which I realise there is no seconds pinion and spring [35] so back to Cousinsuk again. Lucky I got this movement for virtually nothing.

3. Let the movement down and removed the balance assembly [33] and it's shown next to a spare 565 balance to emphasise its tininess.

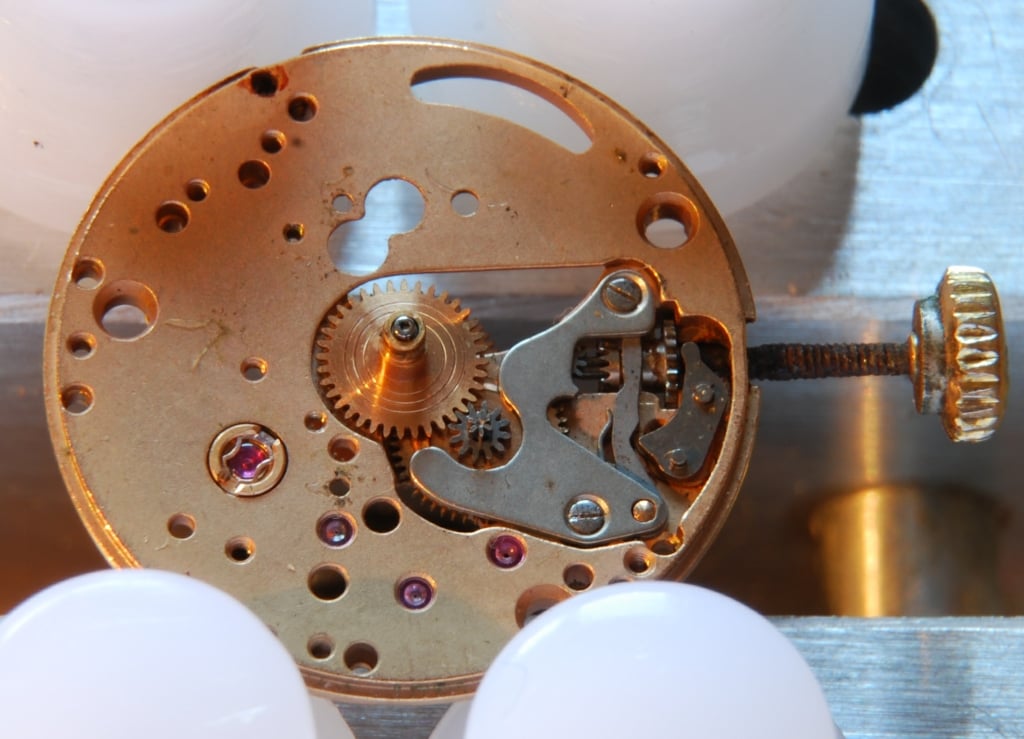

4. Movement without click and balance [40]. Am not looking forward to oiling the minute fork pallet stones.

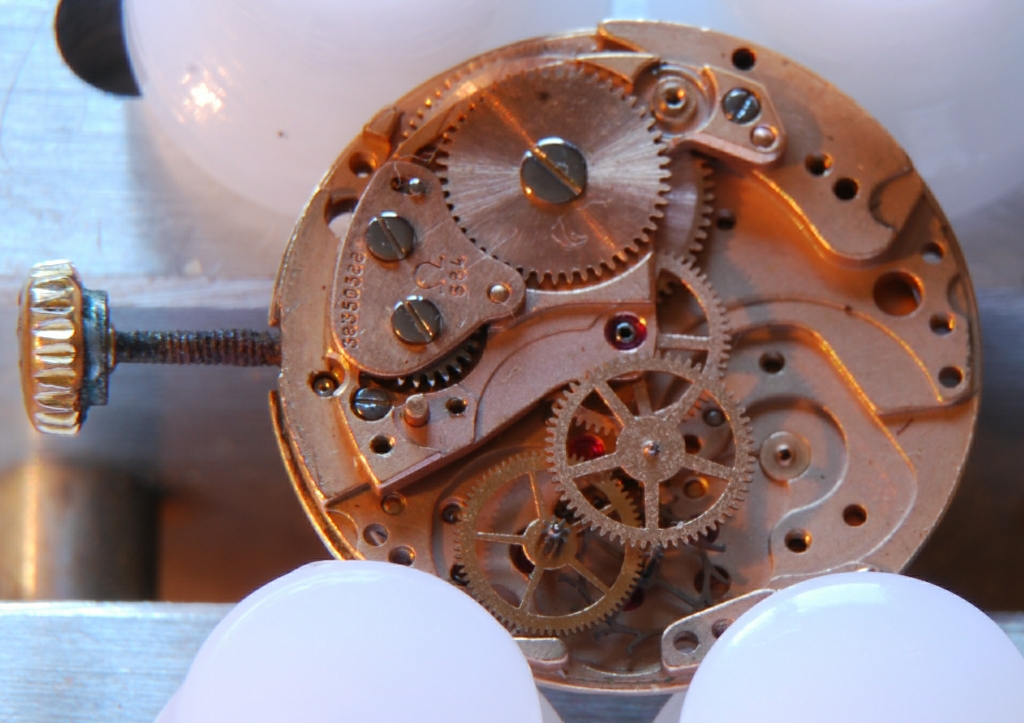

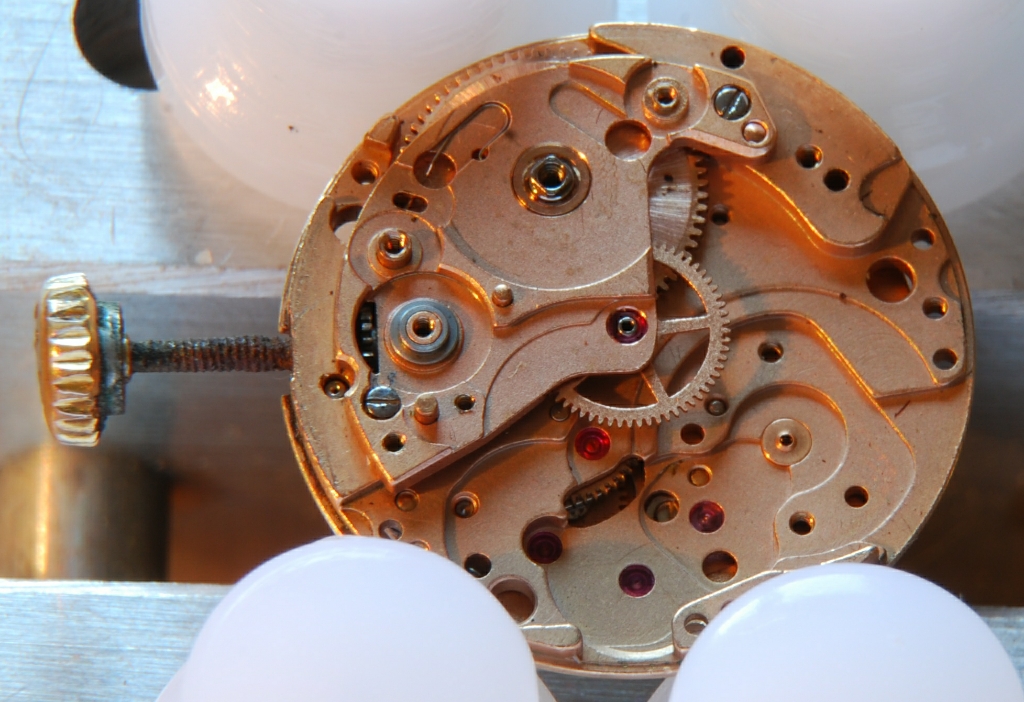

5. Fork bridge, fork and train bridge removed [28]. Shows 2nd, 3rd, 4th and escape wheels Nothing unusual here.

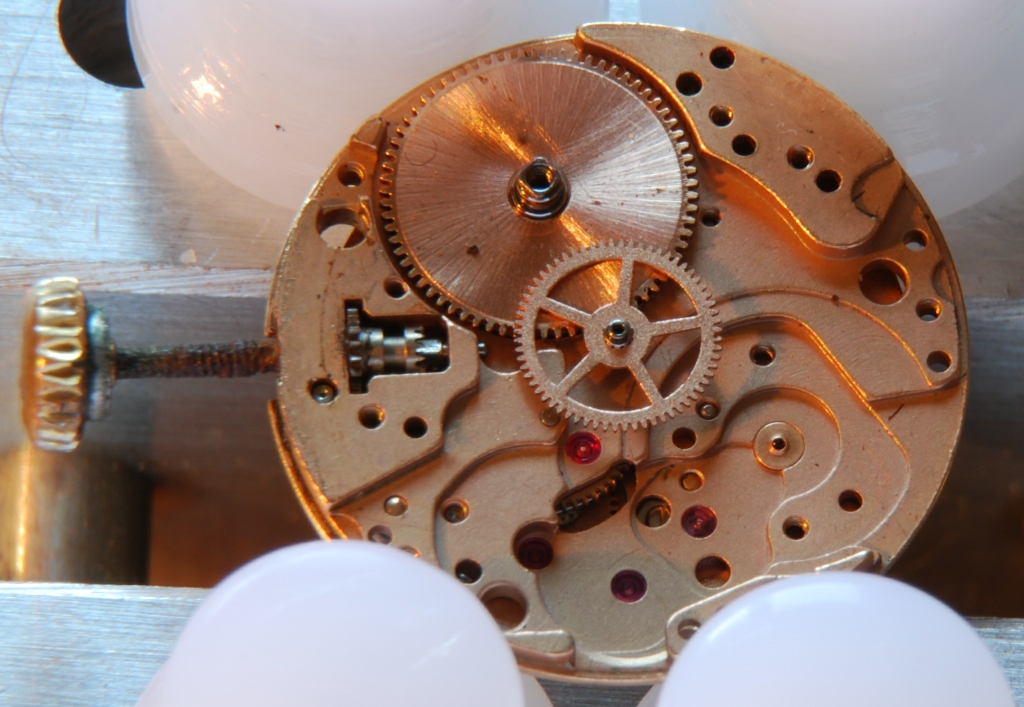

6. The train wheels removed [15]. Note the little plate with 684 on has a slotted hole at the top.

7. That plate removed and the reason for the slot is clear. When the crown is turned the big wheel keeps on turning (paraphrased from Lynyrd Skynyrd) as do the next two. When the crown rotates clockwise, the tiny upper gear is driven across the slot to the right and meshes with the ratchet wheel that will turn the spring arbor and wind the spring. When the crown turns anticlockwise, it stays to the left of the slot (as shown) and just freewheels. This is done in a different and more robust way in the 56x series [14].

8. Those three gears removed and equivalent slot shown in the barrel bridge.

9. Ratchet wheel removed and then click spring [12]. There is another wire spring at the top that presses on the little gear from above and keeps it to the left of it's slot as a default position.

10. Barrel bridge removed [6].

11. Barrel with cover removed [3] to see the spring. Next to a spare 565 barrel to show how tiny it is. After writing tiny again, one Frank Zappa song is now on repeat in my head.

12. Barrel removed and just second/centre wheel left on this side. The two screws under the barrel are not in the mainplate, it is just cut away to allow a space for the heads.

More movement, then dial, hands, case, bracelet to come.

Cheers, Chris

I'm building a watch as one Christmas present for my wife. It's an Omega but in the Watchco style, from parts. She has small wrists and you don't see many of this model from the 60s. It will be a slow reveal and might be interesting as it's not a normal Ladies dress watch. Don't have all the parts in hand yet but, am hoping for later this month (with a little help from a friend).

NOS dial from Watchco (partial reveal as don't want to give it away too soon) and we can see it has a date.

It houses a tiny ('tiny' and variations thereof are words I will use a lot), 18 mm diameter, 684 movement although it should really be a 681. I think the main difference is the 684 is an improved version of the 681 running at 3Hz (21600 A/h) rather than 2.75 Hz (19800 A/h). Quite impressive to get an automatic winder, central seconds, date ring and high beat in this miniature movement.

First is to tear down this very dirty/gummed up movement. It's a lot like a 56x in style and functionality but on a 2/3 scale. You can see that by comparing to the pictures in my other thread

http://omegaforums.net/threads/cal-561-a-simple-summary.17131/

so, I put the equivalent figure numbers in [ ]. As before, no attempted discussion of oiling techniques etc.

1. Movement from behind [56]. Not as attractive as a 56x. First thing I realised is I don't have a proper holder of this size for the rebuild so, on to Cousins website...

2. Auto bridge and mechanism removed [36] from which I realise there is no seconds pinion and spring [35] so back to Cousinsuk again. Lucky I got this movement for virtually nothing.

3. Let the movement down and removed the balance assembly [33] and it's shown next to a spare 565 balance to emphasise its tininess.

4. Movement without click and balance [40]. Am not looking forward to oiling the minute fork pallet stones.

5. Fork bridge, fork and train bridge removed [28]. Shows 2nd, 3rd, 4th and escape wheels Nothing unusual here.

6. The train wheels removed [15]. Note the little plate with 684 on has a slotted hole at the top.

7. That plate removed and the reason for the slot is clear. When the crown is turned the big wheel keeps on turning (paraphrased from Lynyrd Skynyrd) as do the next two. When the crown rotates clockwise, the tiny upper gear is driven across the slot to the right and meshes with the ratchet wheel that will turn the spring arbor and wind the spring. When the crown turns anticlockwise, it stays to the left of the slot (as shown) and just freewheels. This is done in a different and more robust way in the 56x series [14].

8. Those three gears removed and equivalent slot shown in the barrel bridge.

9. Ratchet wheel removed and then click spring [12]. There is another wire spring at the top that presses on the little gear from above and keeps it to the left of it's slot as a default position.

10. Barrel bridge removed [6].

11. Barrel with cover removed [3] to see the spring. Next to a spare 565 barrel to show how tiny it is. After writing tiny again, one Frank Zappa song is now on repeat in my head.

12. Barrel removed and just second/centre wheel left on this side. The two screws under the barrel are not in the mainplate, it is just cut away to allow a space for the heads.

More movement, then dial, hands, case, bracelet to come.

Cheers, Chris