Firstly, thanks to Al for another comprehensive explanation.

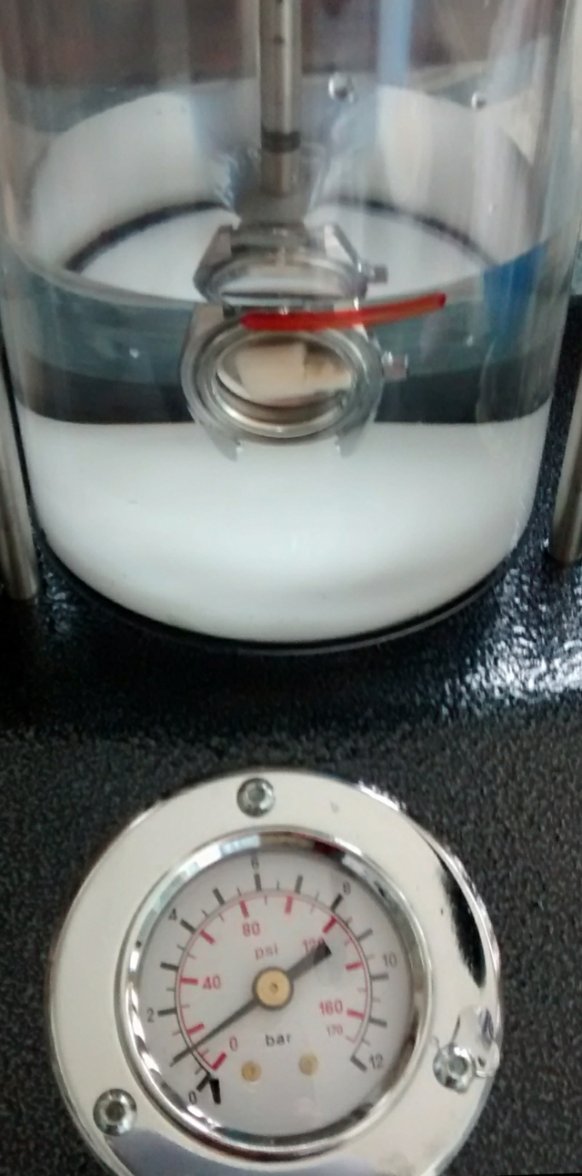

So, pressure test. I'm using a wet tester but someone like Al would use a dry tester. Bit expensive for me. One problem with these is they pressurise the inside of the case and can "blow the bloody crystal off" (paraphrasing Michael Caine). This is the opposite of what happens when you use the watch in water where the pressure is greater on the outside of the watch than the inside so, the crystal is being forced on. There are a couple of ISO standards for these tests but, this will work for me.

The other problem is that it's a pressure vessel and these make me nervous. If they fail, expect to see shards of plastic everywhere. So, quick stress analysis of the plastic wall of my tester:

Cylinder radius = 1.5"

Wall thickness = 0.2"

Max pressure = 180 psi

Hoop stress in the wall is p.r/t = 1350 psi. Allowable for good plastic is about 5000 psi so, Safety factor (or Reserve Factor, RF) is 5000/1350 = 3.70. Even with a significant scratch giving a Stress Concentration of about 2, it still has an RF of 1.85. No problem for me.

Anyway, I'm only working here to 60m with an overpressure of 25% so about 110 psi. (Atmospheric pressure at sea level is 14.7 psi and that increases another 14.7 psi for every 10m of depth).

The crown is not screw in and I'm not willing to risk the movement for a first test so hold the stem with a piece of compressed pith wood. As the pendant internal diameter is 0.055", it only needs to resist a force of 0.25 lb.

Pressure up with the watch in the air pocket and wait so that the pressure in the watch equalises to 110 psi.

Plunge the watch in the water and reduce pressure while looking for bubbles escaping indicating a leak. Here, the watch is still at 110 psi and the water at 15 psi. No leaks so, all good.

{Edit, after Al's comment below: I wrote this as if the watch does leak so, the pressure builds up in the watch. If it does not leak, then the internal pressure stays constant at one atmosphere, 14.7 psi and there are no bubbles}

Picture after test and it lives up to its billing. Note gratuitous water droplets.

😁

Bit more later, coming together nicely now.

Cheers, Chris.