Dan S

·I assume you have a 321 with a damaged hairspring and, to me, you have a few options:

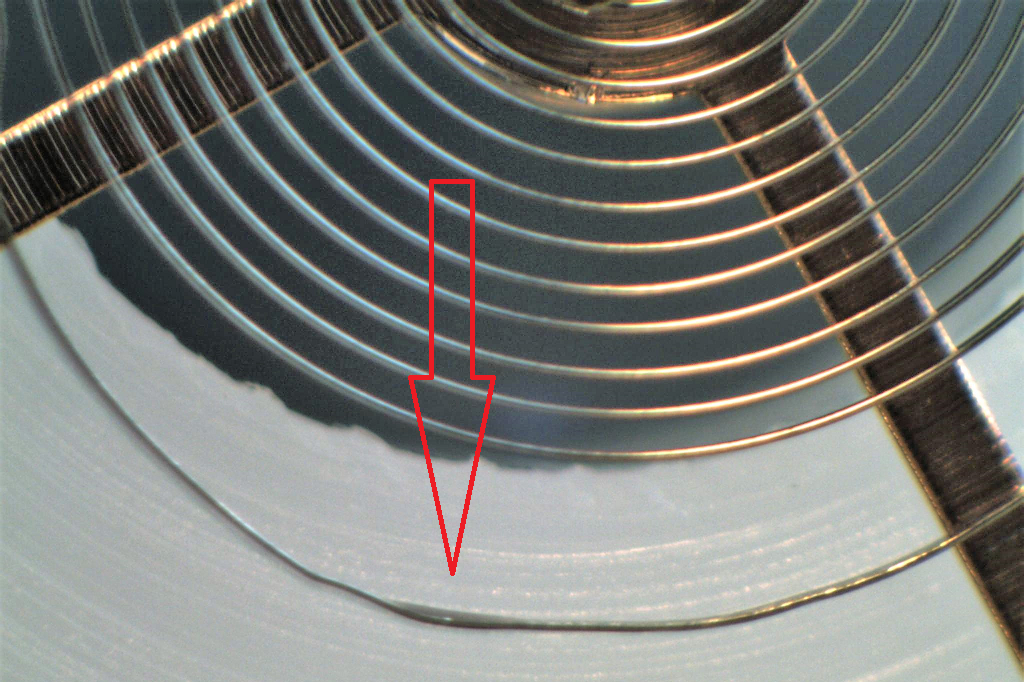

It would have to be very badly damaged to not be recoverable so, start here. In general, it can be re-shaped but, I'd say, only 10-20% of watchmakers will have the desire and ability to do this.

I can still buy a 320 (321) complete balance which includes the hairspring but, there are not many out there. I'd assume your watchmaker has contacts for finding such parts as well. By the way, not all these 321 balances are the same so, there is a risk that anything bought is not totally suitable.

Send it to Omega as I find it hard to believe they are not keeping some parts back for internal use. I could be wrong, though.

If there really is no other way, then you buy a flat hairspring and form the overcoil at the bench. You're down to 5-10% of watchmakers now and it will be expensive. You can still buy steel hairspring blanks in a huge range of stiffness values for about $1 each, although calculating the stiffness you need is not simple at all, and that's the easy part...

We don't write a watch off just because of hairspring damage and, as @Larry S says, most other parts can be resolved as well so,why not just buy what you want and wear it. I have a classic car and the value has leapt by about a factor of 5 in the last ten years, which has pushed all the original parts prices up in a similar manner - I couldn't afford the car now but, that's not going to change the fact that I drive it as I want to. If not, it's not worth having. At least in a watch, the movement should be protected by the case so with regular servicing, you shouldn't get too many surprises.

Cheers, Chris

Great post. This has been my impression and experience, but it's good to hear from the watchmaker's perspective. Life it too short to worry about future hypotheticals. Enjoy the watches that you love while you can.