Horlogerie

·Your very welcome Chris.

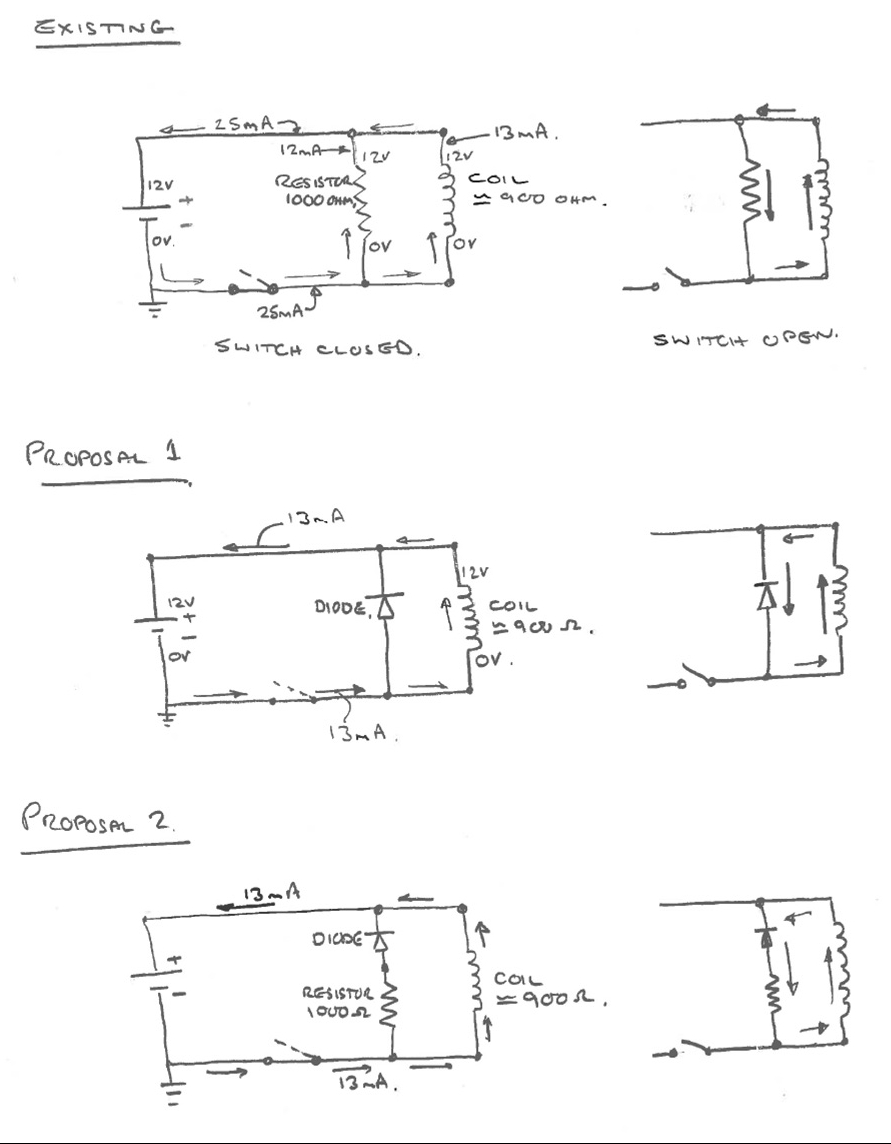

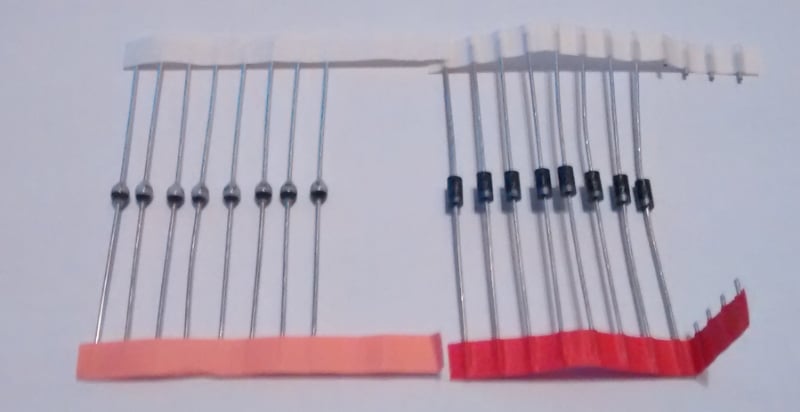

The diode is used on all relays in aircraft and it does a great job of preventing the collapsing reverse magnetic field from the coil sparking across the contact gap and causing pitting/wear, or feeding back in the circuit, installing a diode should help in your application.

vinn2, the diode should work in any application with a coil/electromagnet field that collapses and discharges it's voltage back into the circuit or across a set of points.

The diode is used on all relays in aircraft and it does a great job of preventing the collapsing reverse magnetic field from the coil sparking across the contact gap and causing pitting/wear, or feeding back in the circuit, installing a diode should help in your application.

vinn2, the diode should work in any application with a coil/electromagnet field that collapses and discharges it's voltage back into the circuit or across a set of points.

Edited: