I've managed to go through the 20 or so pages of this thread and compared your thoughts with my own...

Speaking only for myself; when the 321 made its debut roughly one year ago, I wanted to see the 321 placed in a SS case... (and) I wanted to "SEE" it... literally . Enter the 321 Ed White - Omega has essentially delivered what I asked for

(and I suspect, many others as well).

I never took the time to consider how it should be packaged - as a Speedmaster Pro or a Speedmaster, if it absolutely had to have a DON or applied logo, etc. No, I just asked to "see" a 321 in SS... .

Looking back, maybe I should have made a very detailed list for Omega (lol

😜).

All-in-all, I think they put together a pretty nice package for us (or me...). Granted, the decision to go with sapphire was baffling... and I would have preferred white lume although this was not much of a surprise given the overall trend with tributes / re-creations.

Aaand then there's the price. Who wouldn't have like to see it much lower. But, in the words of The Irishmen's Russel Bufalino,

"...it is what it is."

So yeah... I'm in for one

...I felt Omega did right with the display back, as there is no NASA association and the back would have been bare. Hippocampus would have been a great choice, but I'm afraid Omega is all about showing off the movement on the reissue 321 models...

I really like everything about this, except would prefer a standard 1960's pre-moon hippocampus on the back. No real point in a display back on a standard copper plated manual wind 321. A regular back would allow the watch to wear slimmer and incorporate the antimagnetic shield feature.

I'm delighted that it comes with a display back. While I understand quite a few members feel that a correct "tribute" to the Ed White reference should follow through with the appropriate inscribed solid caseback, the real star of this show is the movement!

If Omega were to release an Ed White tribute that was 1-1 but had an 1861 movement, I suppose the same group would lament it not having a 321. At least, until they noted the price tag...

😁

The introduction of the 321 reminds me of what often happens in the car and motorcycle industries. A manufacturer introduces a concept vehicle and the reaction is overwhelming, the public says they will run down to the dealer and buy one if they would really make the vehicle. So it is greenlighted and upon release to the marketplace it flops. All of a sudden people aren't interested, 'too expensive, too many compromises made, just not interested any more'. The 321 really is an answer to a question very few people were asking. Just how many customers are out there for a watch containing a very old movement design? A few, obviously, but the reaction from many who have been pining for this watch have been mixed. Some don't like the sapphire crystal, or clear back, most don't like the price. So what is Omega's reason for this watch? Obviously they think it will make money for them, but I wonder if they vastly overestimated the demand. We will find out going forward, but this is a very expensive product in a very competitive market.

...It's not a question of will they sell the first years production.. That will go to enthusiasts. It's who will they sell the year after and the year after to.. They make a huge gamble by making the price point this high but not making it an LE...

I sincerely doubt Omega has / had any intentions of mass-producing the 321. That job belongs to the 3861. My guess is that the 321 will make an appearance whenever warranted and at most, one reference per year. As with any "limited" release, there will always be mixed reactions. What was the last reference, if any, that received unanimous approval from the community...? I doubt even the last Snoopy managed that...

🤔

As the number of views of this topic reaches the price of the new 321 chronograph in Euros, I wonder if, within 2 months time, we'll have a similar topic on a modern day Speedmaster with 321 movement looking like the 105.012 or 145.012 ... celebrating 50 years Apollo 13...

Yes, this is my guess also. Then the $15k would be more accepted by the masses. Of course this one will be quite a bit higher...

...What if Omega will run this model only for 2 years, in

anticipation or preparation of the forthcoming release of the real 321 moonwatch revival 105.102 reference probably later

or in the middle of the year...

I'm convinced the Apollo XIII will be powered by the 3861. With a solid caseback. As I noted above, I don't believe Omega intends to release the 321 in that many references.

What I find more and more crazy as time goes by is how every lemming on the internet throws 'faux tina' in when they diss a watch (like this).

So... I'm one of those lemmings. I've been one ever since Panerai released their first reference with "aged" patina back in ...2013? My argument is two-fold. First off, I don't need my watched pre-aged for me, thank you very much. Not even if said watch is a throwback to the Radium / Tritium era. Having said that, I did note your thread on

tritium's actual color. Ok, I'll accept your claim. Which brings me to my second argument... one of pure aesthetics and the speedmaster is the perfect candidate for the discussion. The Speedmaster's black, white and steel. Monochromatic bliss

(or grayscale, if you prefer).

🥰 Why go mess that up with color, one that ranges from slightly off-white to near-brown just to represent tritium

(aged or otherwise). Tropical dials - I don't really need that either. If you twist my arm, I'll take faded dials / bezels but if the dial was originally black, then it should be faded again, using grayscale. But back on topic... I did add the 2014 SM300MC "tribute" to my collection, despite the aged lume and I will make the exception once again... . This time at least I can use your "original tritium color" to justify it...

😁👍

2,000 units at $15,000 (rounded up) is $30 million. I don't know what Omega's margins are--who does?

I'm in agreement with any & everybody that raised an eyebrow over the price & Omega's pricing strategy. My only theory

(aside from Omega now playing "that" game) is Omega already did the math of the number of 321s to be produced annually vs. the initial cost to set up the tooling and whatnot. FWIW, Fred Mandelbaum has suggested something to this extent as well on the #SpeedyTuesday FB Group.

Amazed at all the folks giving Omega an interest free loan for an indeterminate period of time...

I agree. I'm not al all pleased with this concept - particularly if there is no date in sight. I certainly want to be the one earning the interest in the interim... !

Let's look at what Omega says the time should be for servicing an old Cal. 321 watch for some perspective... the expected time frame for a full service would be 7 hours and 30 minutes. This is broken down as 5 hours and 38 minutes for the movement service, and 1 hour and 52 minutes for install the dial, hands, and final casing (which seems generous to me). Now this isn't for assembling a new watch from parts,. but for taking an old beat up watch, completely disassembling it, cleaning the movement parts, replacing case parts, replacing worn movement parts, assembly and timing of the movement (may include finding faults that have to be dealt with), and then final assembly and casing... [new 321 assembly] ...I would expect at least one completed watch per day from any competent watchmaker assembling, these, and it wouldn't surprise me if they could get 2 done in a day pretty easily, not having to fight with all the issues that people like me deal with when we get one of these old watches in...

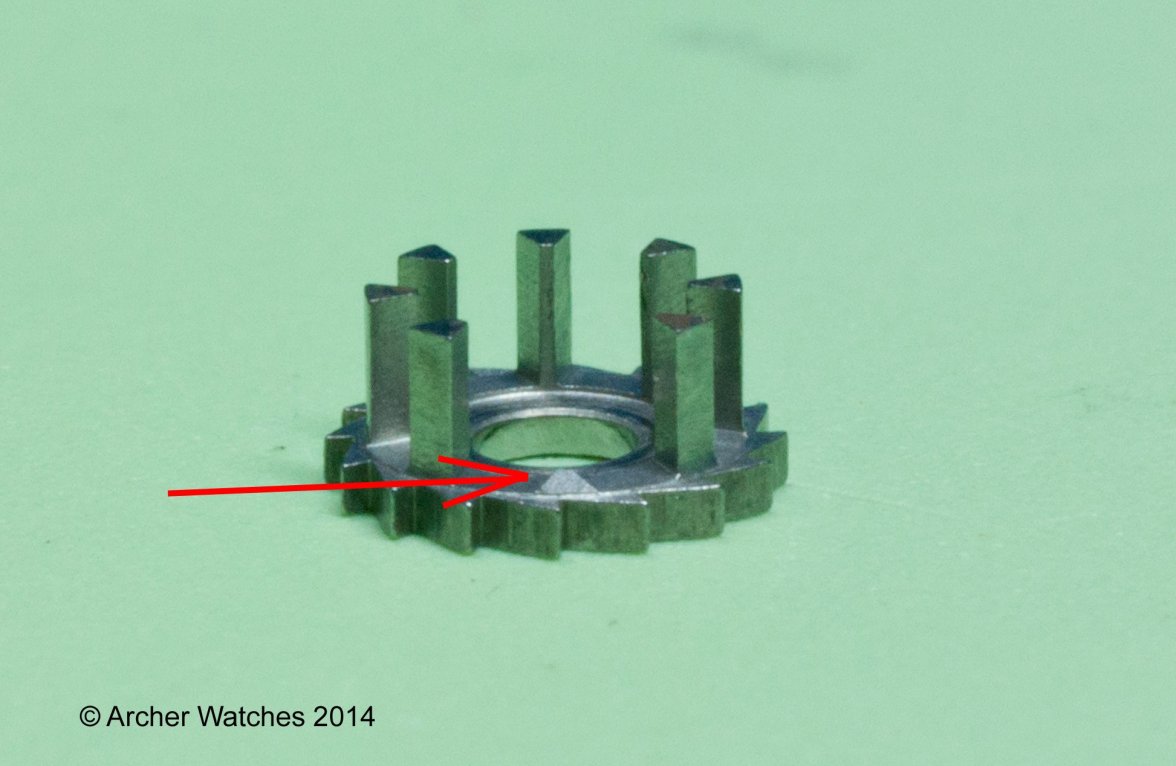

...So if I look at the claims he makes comparing the 321 column wheel design to the 1861/1861 cam design ... Easier to assemble - when I install the column wheel I place it on the bridge and insert a screw, then tighten the screw. For a cam I place the lower half on the post, then the upper half on the post, and the insert and tighten a screw. The cam requires an extra step since it has two parts. ... Easier to service - the only thing left is lubrication, and yes the column wheel may take a whole 15 seconds more to apply lube to than a cam does, but in the end the column wheel itself, and the parts needed to actuate it, are no more complicated to assemble than the cam system is. Let's expand on the differences a bit... Column wheels break - this is from a 321 [see org. post for photo] I can't show you a photo of a broken cam, because I've never seen a cam break... A claim often heard is that column wheels have a "nicer" or less firm pusher feel, and that is certainly true. However for the purposes of timing an event, the column wheel is "mushy" and in my view, less precise in terms of when the chronograph actually starts and stops. The cam has a much crisper snap to it that happens very quickly. The preference for a column wheel is mostly from either a purely aesthetic point of view, or because people read on blogs and forums that it is "traditional" and somehow better. In reality, I don't think it's any better at doing to job than a cam is - they are both just very simple on/off switches.

Well that settles it; the new 321 movement is a

pure emotional investment, no more, no less. Al, thanks for your input and candor -

invaluable! 👍