sheepdoll

·Is this the right Alum? How is one supposed to use it. I have an old scrap movement with a busted bridge and rusted screw. The Alum does next to nothing other than to clean away the old rust. I let it sit over the weekend. All the water did was evaporate and leave the white stuff behind.

I went back to the screw extractor. Spending most of the day making a screw shaped pin for it. Grinding hardening and tempering a length of drill rod.

I then broke the set screw in the extractor tool.

I had some metric screws that fit.

The bridge screw is really hard.

I actually enjoyed making the extractor pin. Been planning to do this for months. Today was the fist free day I have had since late October. I first tried the new tool without hardening the drill rod (which was sort of hard to start with.) The bridge screw simply sheared off the tip. I re ground it then heated the rod to red hot and quenched it. The tip shattered. I then heated the tip again to red hot. Held red hot tip against the stuck screw to see if that would help. (I am concerned about the pallet fork if applying direct heat)

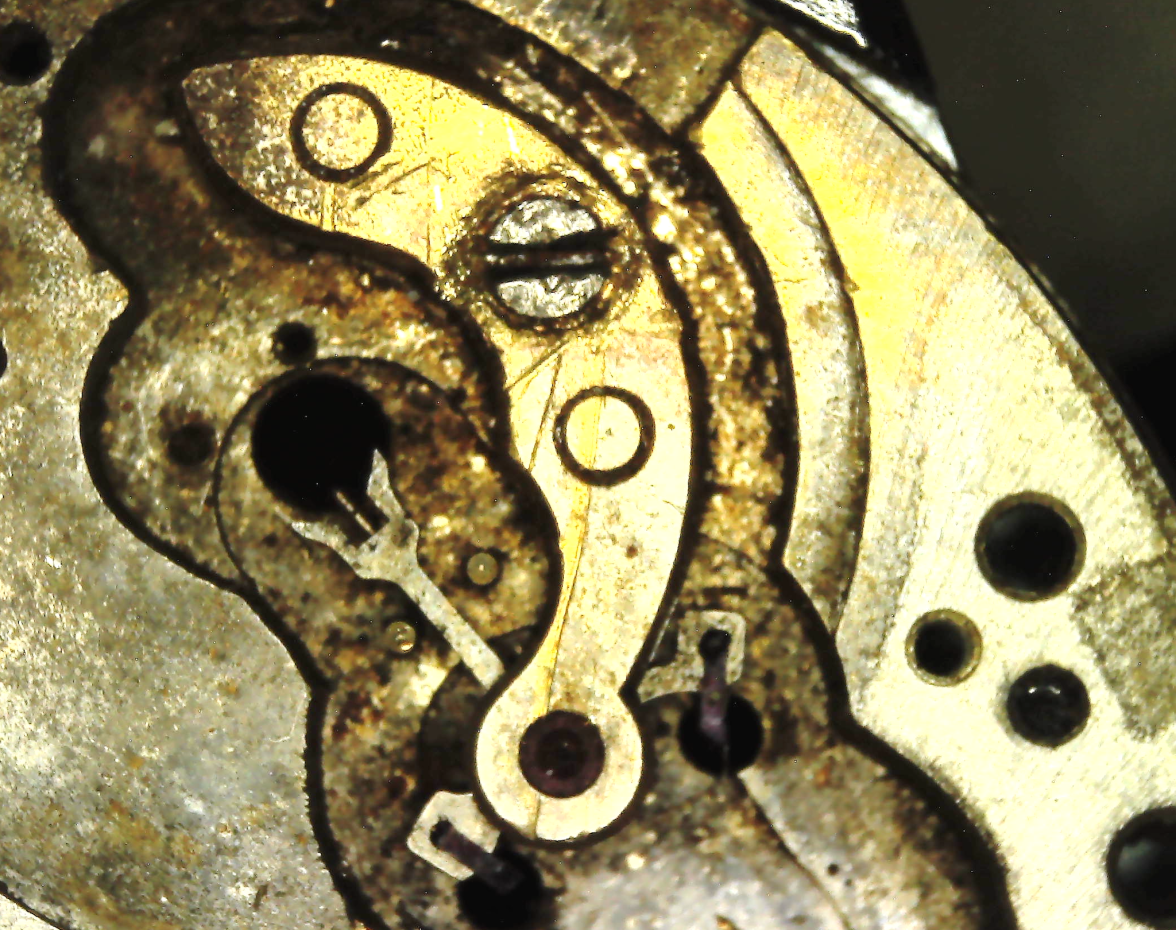

Reground the tip as shown, hardened it then tempered it to the amberish color & polished it.

This is when the set screw broke as I was torquing it with the back of an exacto knife in the slot.

I think this method would have worked with a normally tightened bridge screw. The bridge screw seems to be micro welded in place. Or friction welded chemically bonded or something.

Penetrating oil has sat on this for months, refreshed every now and then. That loosened the other screws. Not this one.

I tried heating the Alum over a 7W Christmas bulb (from a glass display that gets quite warm) Used a shot glass to heat water and the alum so the alum would dissolve. The old Atlas jar lid is where I do my application.

The drop just sits there on the test movement. (Hesitant to try it on the screw itself as again I am concerned with the pallet fork.)

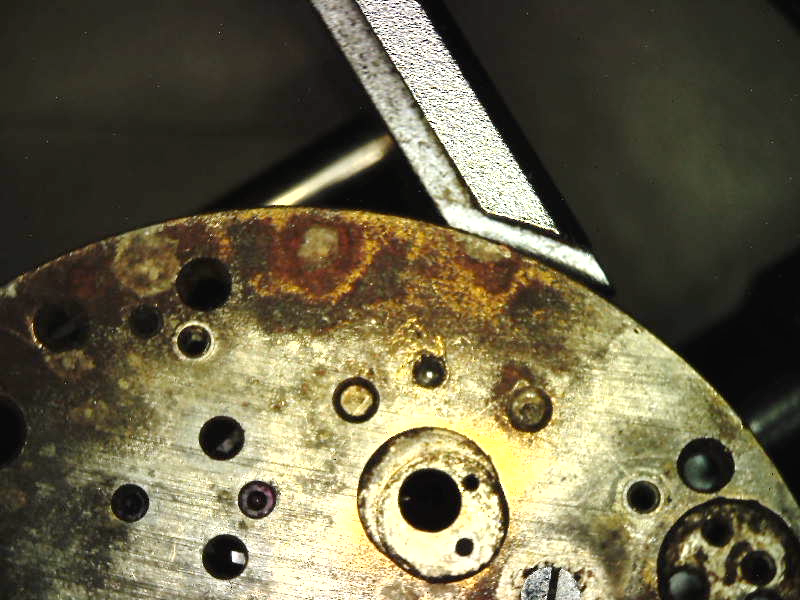

I suppose I could attempt drilling The bridge out. The bridge is toast now that I got the new one, still seems drastic. I could also bend it like the old scrap movement to release the fork. Then get more aggressive with the Alum water. The eccentrics are still in place, so I can not dip the whole plate unless I remove them, which I may have to do to clean them.

One more microscope photograph. Showing the back side of the plate and how the extractor polished the end of the screw. I did attempt to put a drop of Alum water on this side. No effect.

I really want to get this screw out so I can (get the broken off screws out.) then start playing with all the replacement parts I have purchased over the last few months.

Side note. My micro torch sprung a leak. spraying butane and freezing the side as it leaked out. I got out the mapp gas torch which worked better anyway.

I did hold a can of compressed air upside down to see if freezing the screw made a difference. This is one stubborn screw.

I have had this movement 25 or 30 years. I got it because I got a bunch of booklets on how to repair chronographs. Wish I could remember how much I paid for it. Might have been part of a box of chronographs. I doubt I paid more than 30USD. I think I am 2 or 300 into it. Including my now broken screw extracting tool. This is the watch that keeps on giving.