Thanks.

He mentions the hammer as the lone example of a part that requires fitting. This is true that hammers require fitting, so yes he is correct. The fact is you can't buy a new hammer for a 321 from Omega, because the part is discontinued, so if you are buying a spare it has likely already been fitted. Thankfully I've not had to replace one on a 321 as I imagine they are not cheap.

The claim though that this was "solved" by the introduction of the 861, is strange.

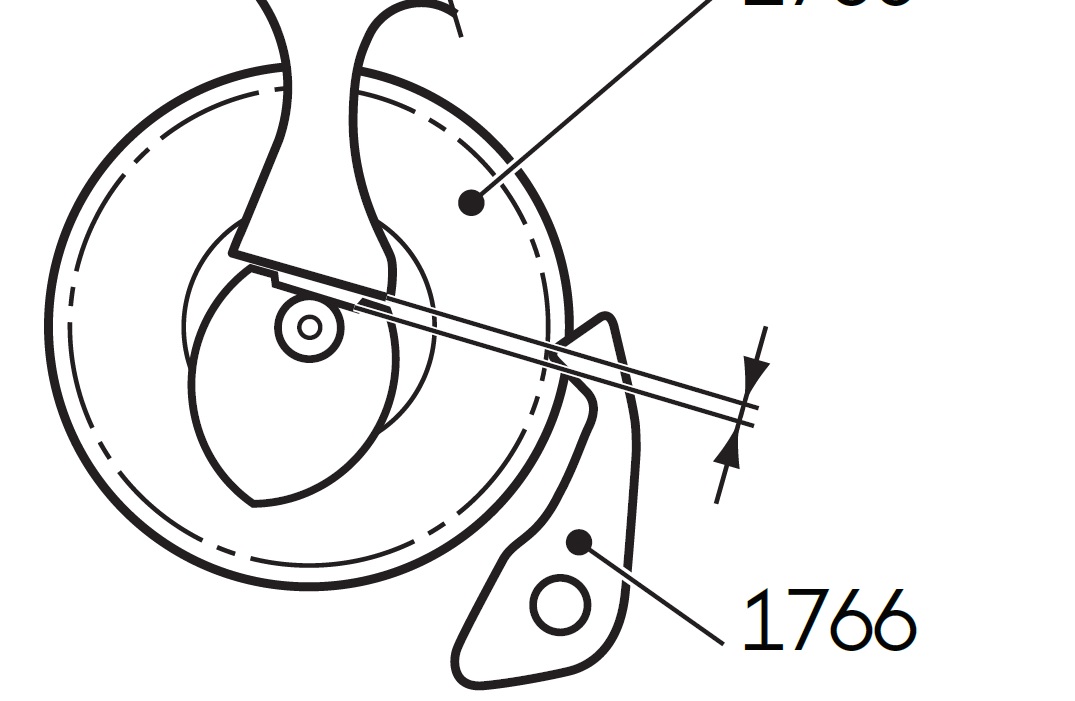

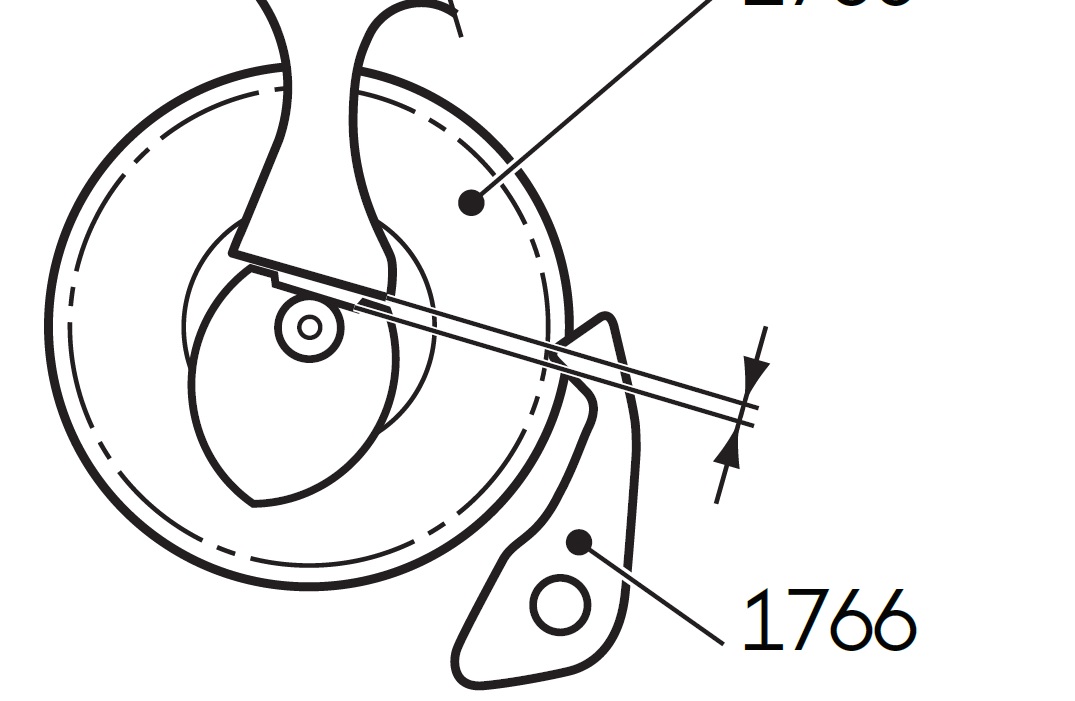

Let's look at the description of the hammer for the 861 - taken just now from the Omega Extranet:

72208601728 | HAMMER MOUNTED WITHOUT GRINDING MIN.FUNC

"Without grinding min, function" - this means...you guessed it, that this requires hand fitting by the watchmaker in situ. This is because when the hammer is fully on the cam for the chronograph wheel, there is a very slight gap between the hammer and the cam on the minute counting wheel. They leave the minute counting part of the hammer long, and you have to file it to the correct length to get that clearance. The minute counter is not located by the cam at rest - it's located by the minute counter jumper, so this play allows for proper locating using that jumper.

So yes, you are correct that one part in a 321 required fitting by hand, but the same part requires the same fitting by hand on an 861, and also on an 1861. Omega still has all the procedures listed in the technical documents for the 861/1861. This part is rarely replaced to be honest, so it's something I've done on an 861/1861 maybe once or twice off the top of my head. So this had slipped my mind on the previous reply as it's not a typical issue that one would come across.

When I think of a watch that requires hand fitting, I think of watches made before there were even standardized parts available, so no part was interchangeable between two different watches. In this case it's one part, and that part still requires hand fitting to this day.

Note that other brands built in adjustments in this area, so you didn't actually have to fit them by hand, and you could adjust the contact point easily without having to file off excess material.

Cheers, Al