Unknown Watchmaker

·(I have uploaded and posted pictures and descriptions on this Omega site for those who don't have a Facebook account. Originally uploaded on Facebook)

This is a perfect time to discuss about burnish and polish on the Jacot tool)

A lot of hobbyist attempts to do this by cleaning and oiling is not a proper service in a professional sense, and most hobbyists don't realise this, in the real watchamaking world, it takes more than just cleaning and oiling to have a good performance and the reason I mentioned this is that over the last four years I have seen quite a lot of posts on Facebook groups and watch forums that when one hobbyist service a watch, dismantle, cleans, and apply new fresh lubricant and put it back together, and then test it on the timegrapher, it still shows problems on the timegrapher screen showing with erratic readings and poor amplitude and asked for help, many hobbyists suggest that either a mainspring needs a replacement, or something is wrong with escape wheel, pallet fork, or balance wheel, however, that isn't always the case, it likely that parts are too worn and it causes friction and resistance and it leads to poor performance by not giving a correct consistency of power from mainspring to the pallet fork and then to the balance wheel and that's why it showing erratic readings on timegrapher screen. To eliminate with this problem and to achieve a clean straight reading on timegrapher with equal/consistent power and good amplitude, is to replace the worn out parts with new parts or do a burnish and polish with the Jacot tool.

Burnish and polish is the most important tool and skill to have in watchmaking assets to repair the pivots. Over time, the pivot will eventually be worn out after constant of use for many years even with fresh lubricants, but of course, that old or lack of lubricants will speed up damaging the pivots over the time . The pivot surface will lose it's hardness and expose the soft surface under.

This is why overhaul service is very important and recommended at least one overhaul service after every five standard services. My watchmaker is a master watchmaker who told me this many years ago and he taught me how to use the Jacot tool.

Using a Jacot tool is never an easy task, it took me fours years to master it property with over 1000 hours of practicing it just to get it right, in my 15 years of watchmaking, I definitely would say burnish and polishing on Jacot tool is the hardest thing to learn, looks simple but yet so many complicated tasks that involved, back and forth stroke, long stroke, middle stoke, short stroke, slow stroke, fast stoke, light stroke, and hard stoke, the list goes on but very an effective to repair worn/damaged pivots. Vintage watches almost always have worn and damaged parts, burnishing, and polishing is a very slow process, but it does remove material, real life repairs always require a balance between perfection and reality. If scoring is completely removed, it might remove so much material that the pivot begins to have too much sideshake and endshake, especially for balance staff. Instead, some surface finish might sometimes be sacrificed in favor of pivot diameter. A properly burnished and polished pivot not only has less friction but it wears less over time. The act of burnishing actually compresses the metal, making it denser and harder to corrode.

Many brands and movement manufacturers have acid washed and tumbled pivots, this technique is cheaper and creates a hard outer surface, but once that hardened surface wears through, the softer insides degrade quickly. This is where burnishing shines, it's a rare practice, a good repair technique, and an extreme challenge to master.

Here I have omega Seamaster 1020 from the 1970’s. The customer has sent this Omega off to London for full service, they have serviced the Omega and the issue stills occurs. The timekeeping is still poor and it has a low amplitude in all six sided positions. So they have told the customer that omega is a write off because it no longer can be used for timekeeping, and they are no longer interested to replace the parts also I am assumed they don’t want to go through all that hassle and trouble because It’s cost time and money to search and find parts, especially for vintage movements. This is not uncommon these days.

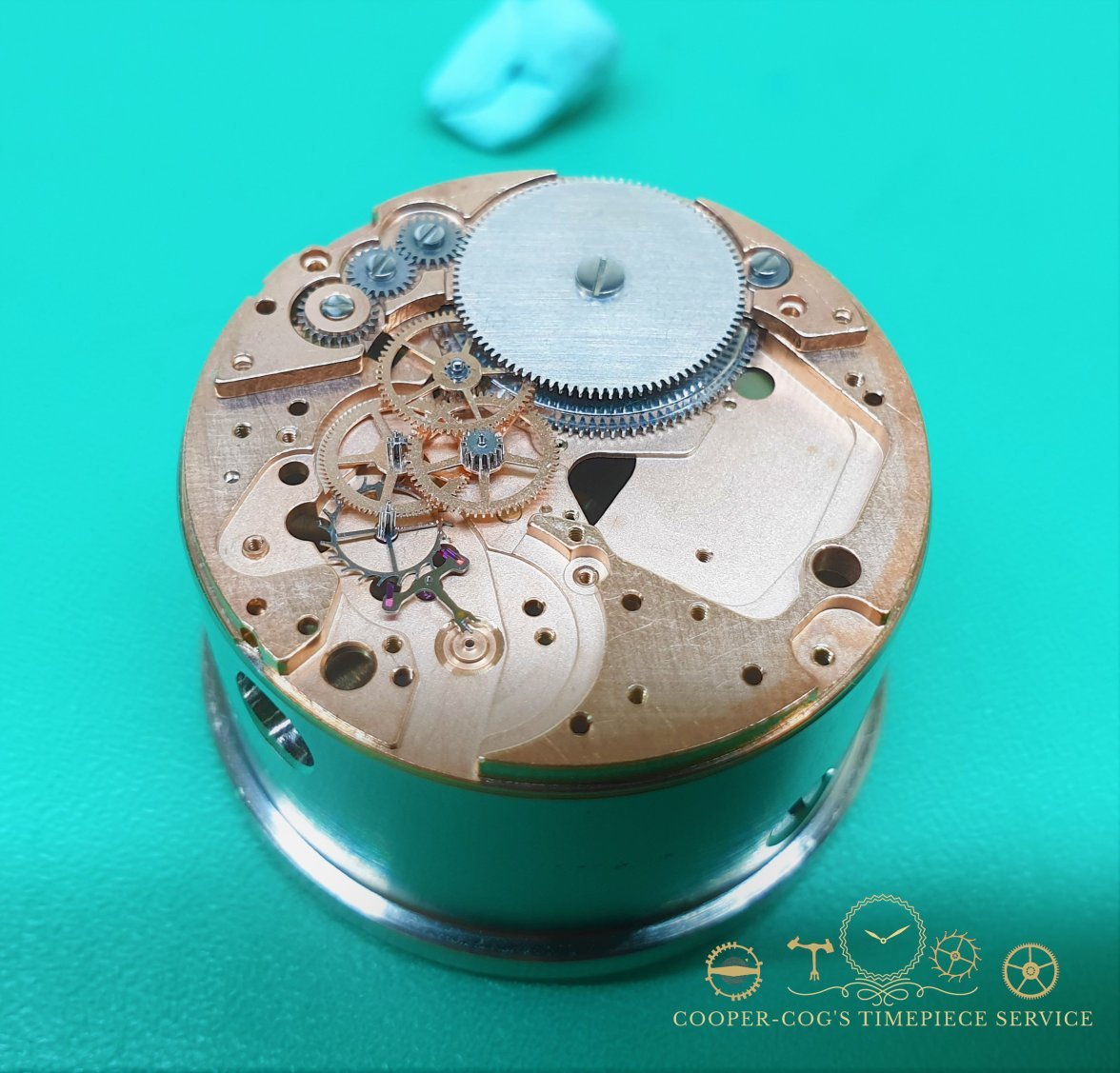

I had an unexpected phone call and they asked me if I want to take on this Omega Seamaster and tackle the problem. So basically they want to dump this problem on me instead and to keep their customer happy. So I said yes, go ahead and send it to me and see what I can do. So the omega Seamaster finally arrived at me. So I investigated the omega Seamaster parts and oh boy, the pivots were in such a bad state. No wonder it runs poorly after a fresh service. The arbor, escape wheel, third wheel, fourth wheel, center wheel, and balance staff was seriously worn and needs to be taken care of. The mainspring barrel wall is worn and damaged and needs to be repaired on the lathe machine.

The overhaul service went extremely well after burnished and polished and then cleaned, oiled, and put back together. Timekeeping and amplitude have been vastly improved on timegarpher. The reading results is now a straight line and slight deviation when tested at all six angle positions. This will allow me to do proper regulator adjustments for all six positions in the next few days.

Hope you enjoy reading my post and hopefully this is useful for those who are learning something new.

Many thanks

Mat

Received this from a watch repairer in London. It's been fully serviced but performance is failed due to heavily worn parts. The omega acrylic glass is scratched and needs to be buffed later on.

The performance is very poor after being freshly serviced in London a week ago before being sent to me to do the overhaul service.

Time to dismantle the Omega Seamster into little pieces

The old school work, here I am, sitting down, and doing the burnishing and polishing of the seven parts on Jacot. started at 6am this morning and finished at almost 9am. Just in time before my workshop opens. I really wanted this exhausting task out of the way before I start the day.

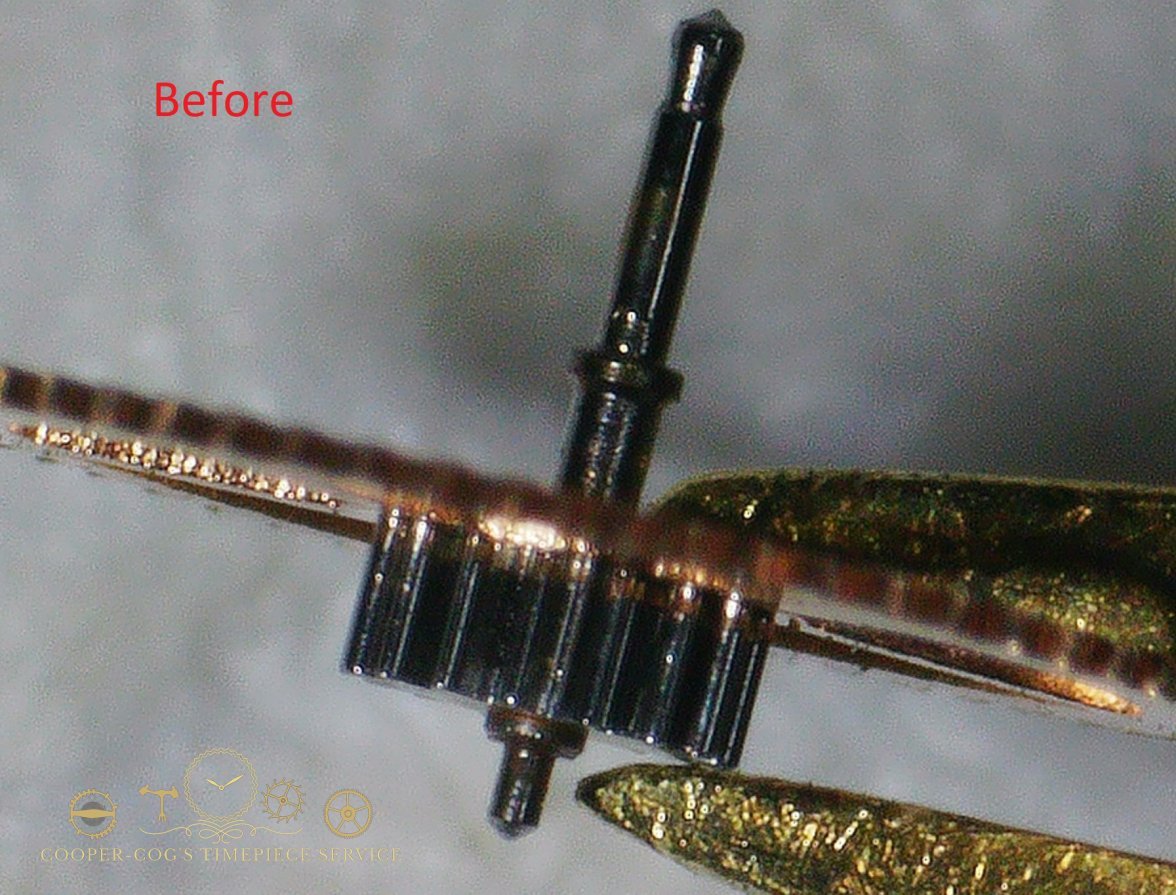

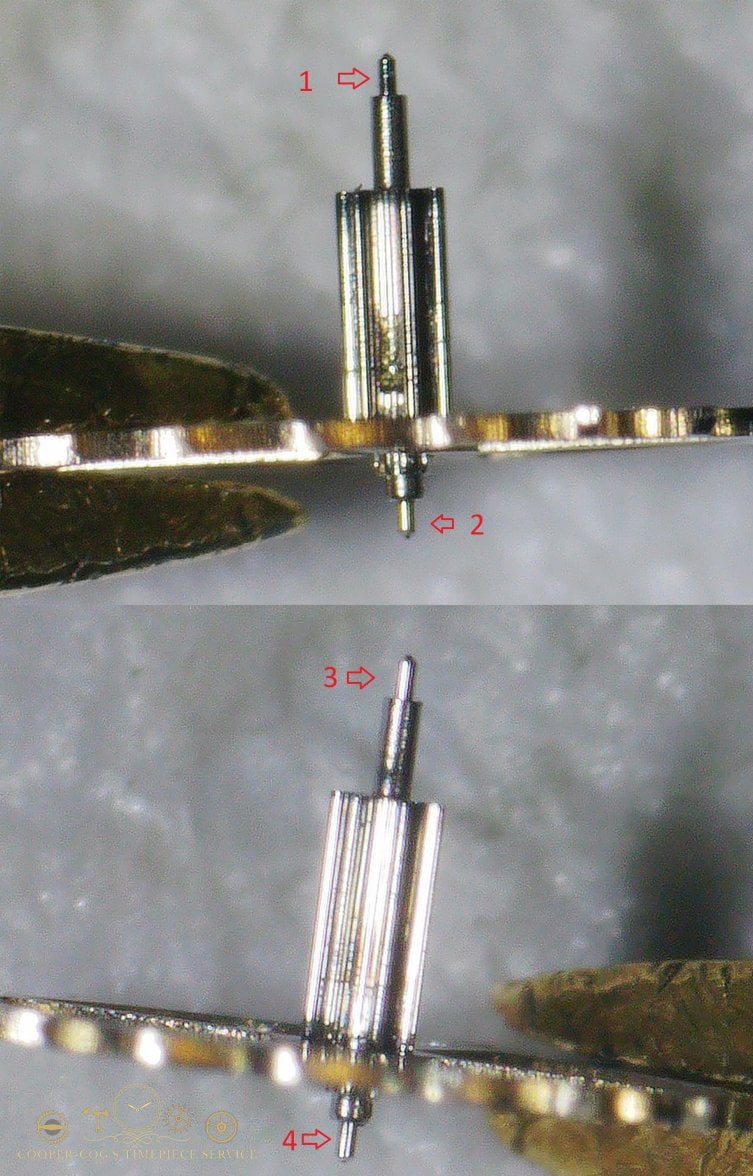

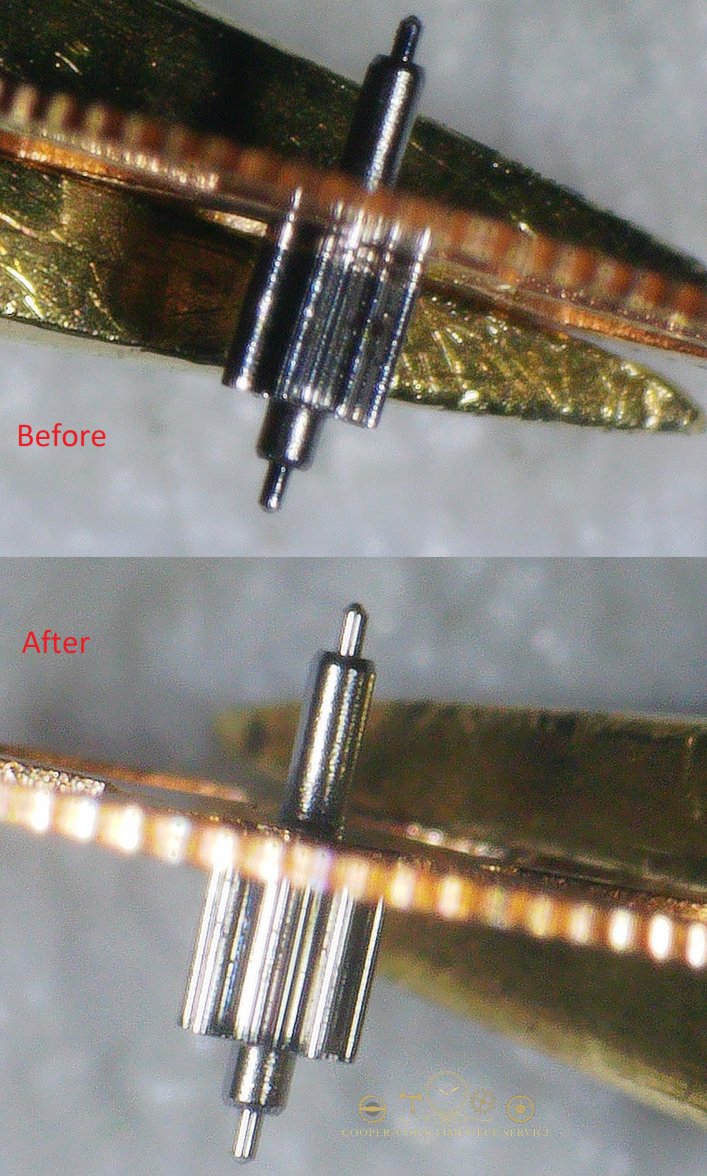

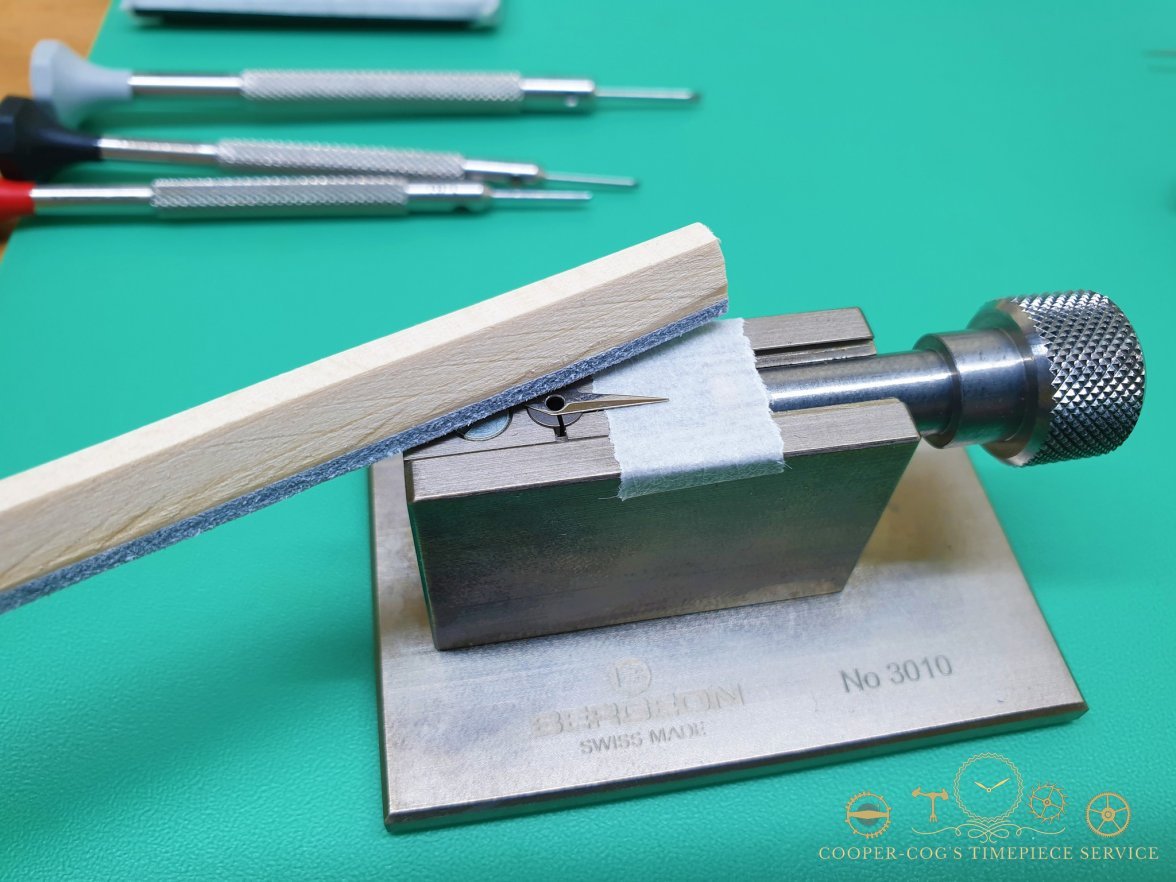

Escape wheel on the Jacot tool, burnishing, and then polishing the pivot.

Again, the Escape wheel on the Jacot tool.

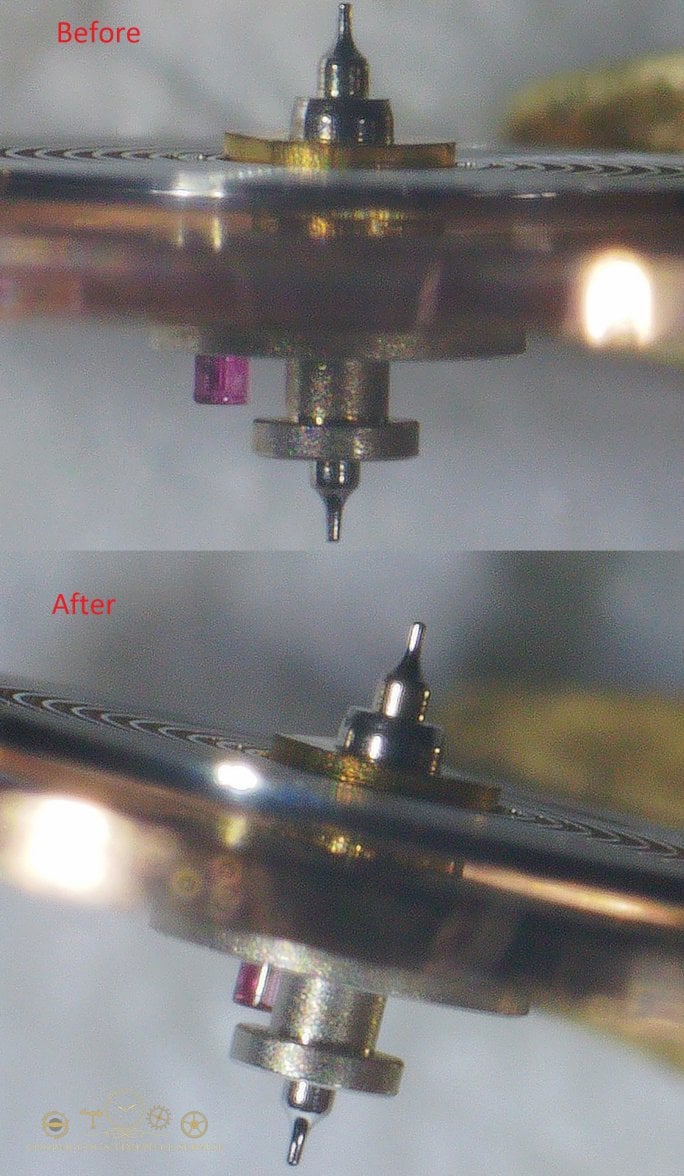

Same for the balance staff pivot

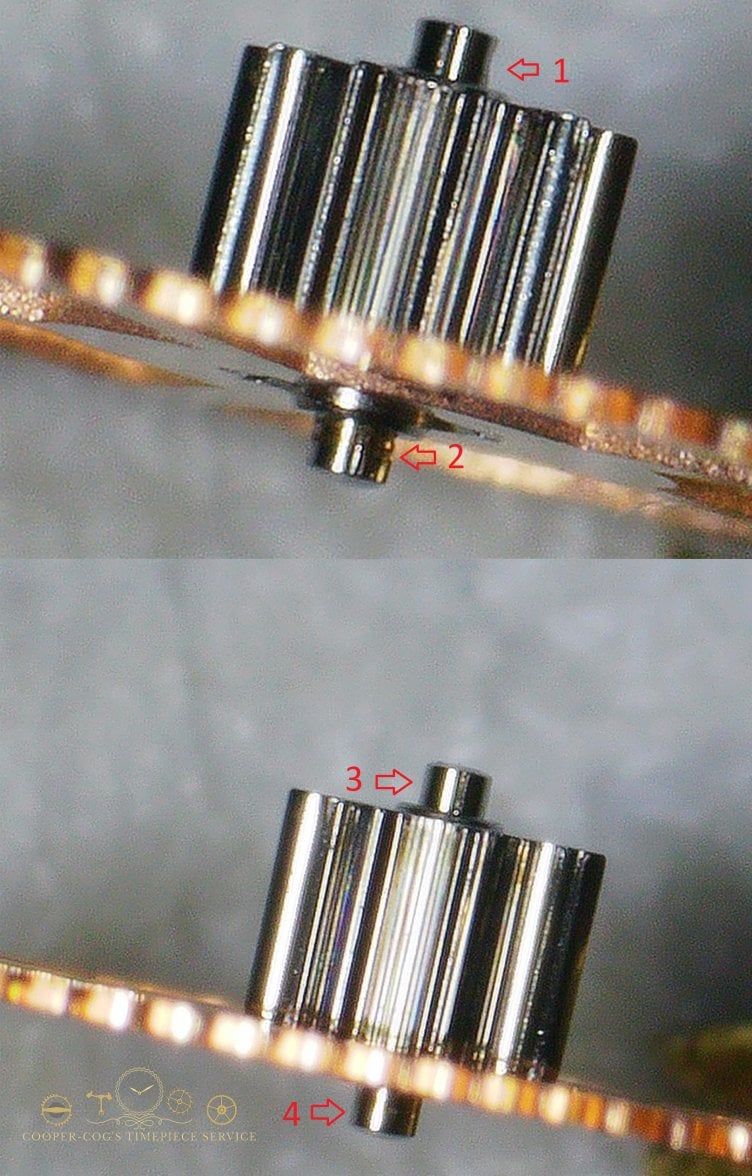

The fourth wheel on the jacot tool, burnishing and then polishing the pivot.

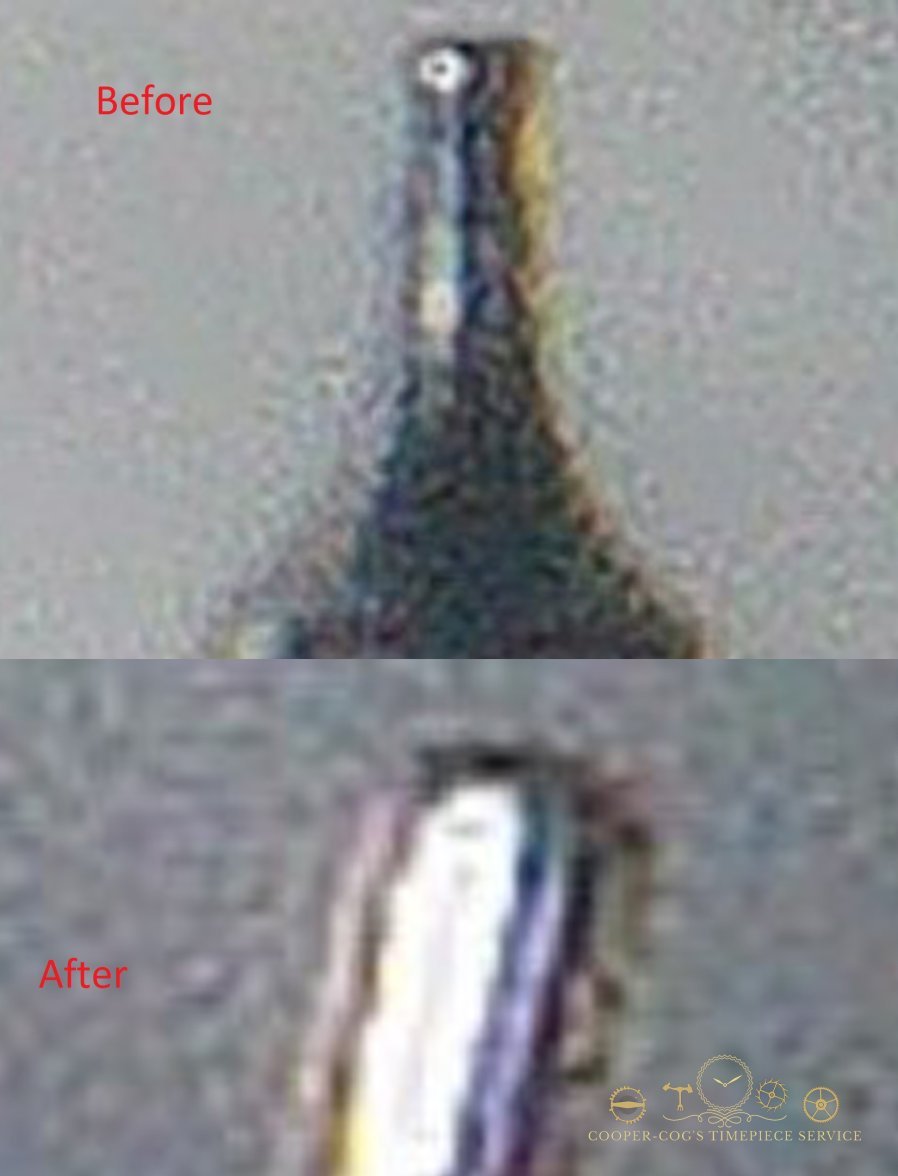

After doing work, I use my strong magnifier to see any results.

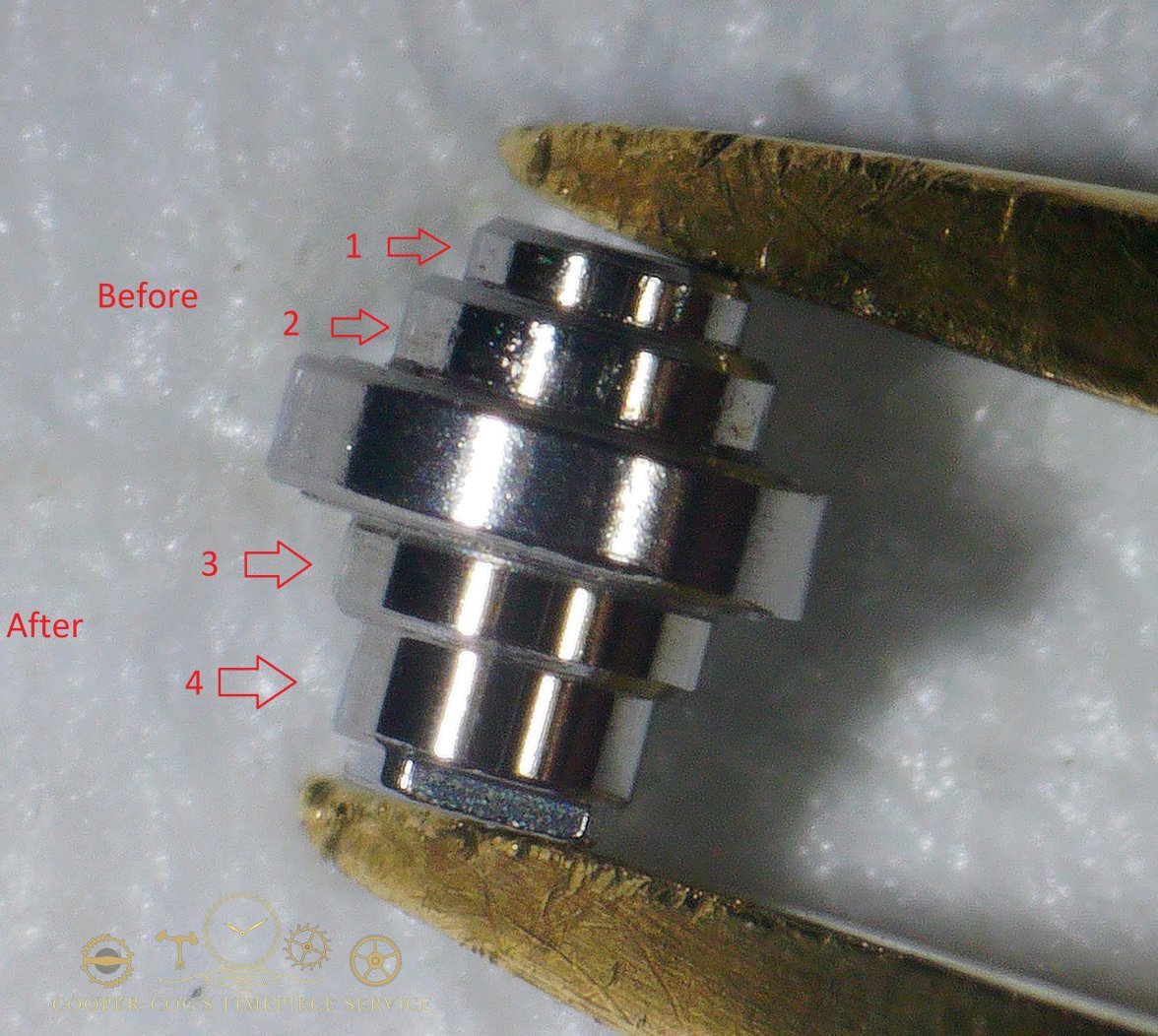

You can see the clear results before and after on the barrel arbor.

1 and 2 before treatment.

3 and 4 after treatment.

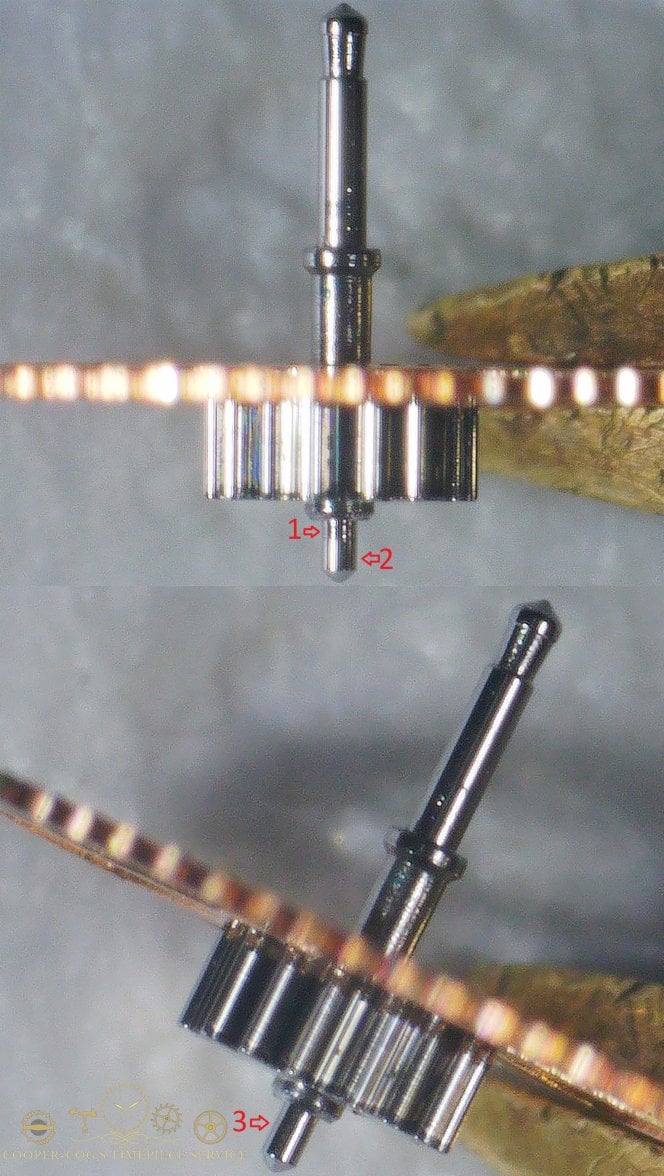

Third wheel before burnishing and polishing.

Again third wheel,

1- not treated

2- half treated

3- fully treated

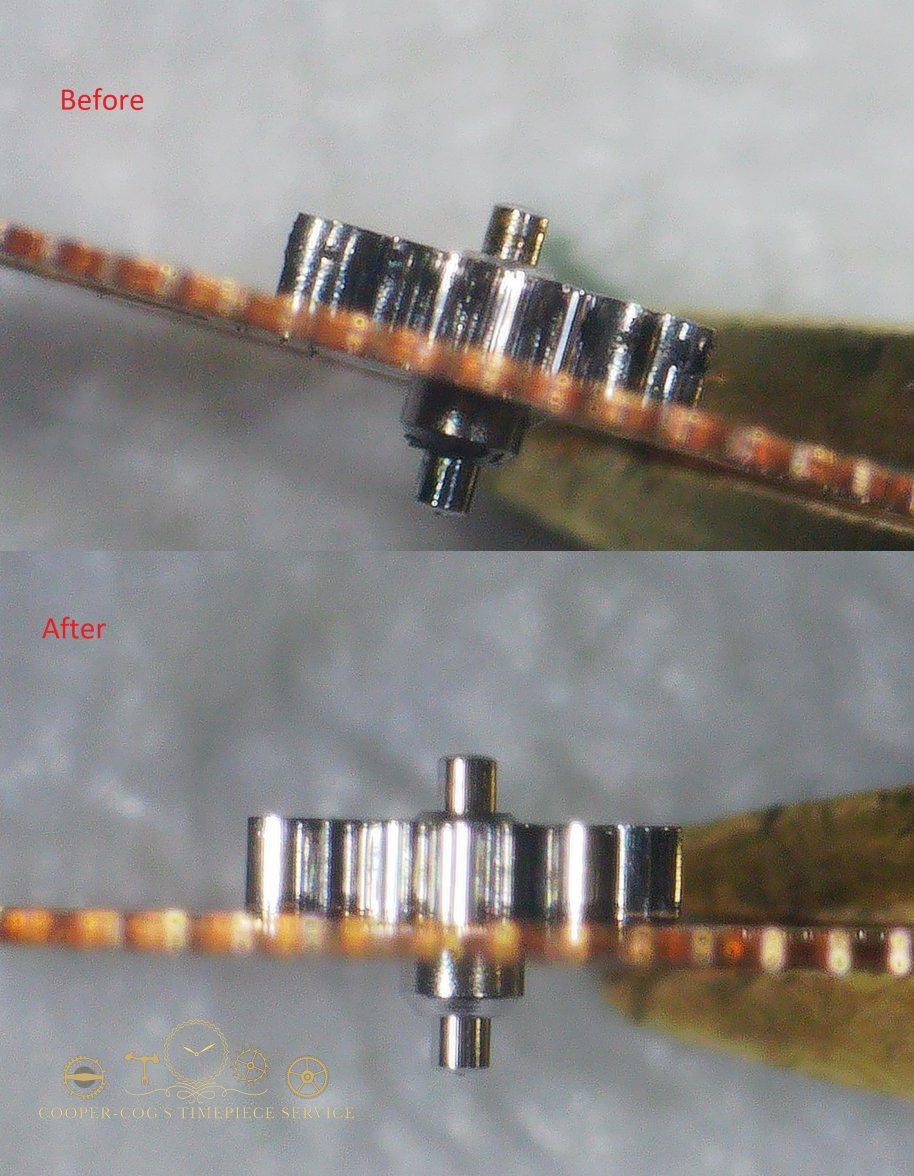

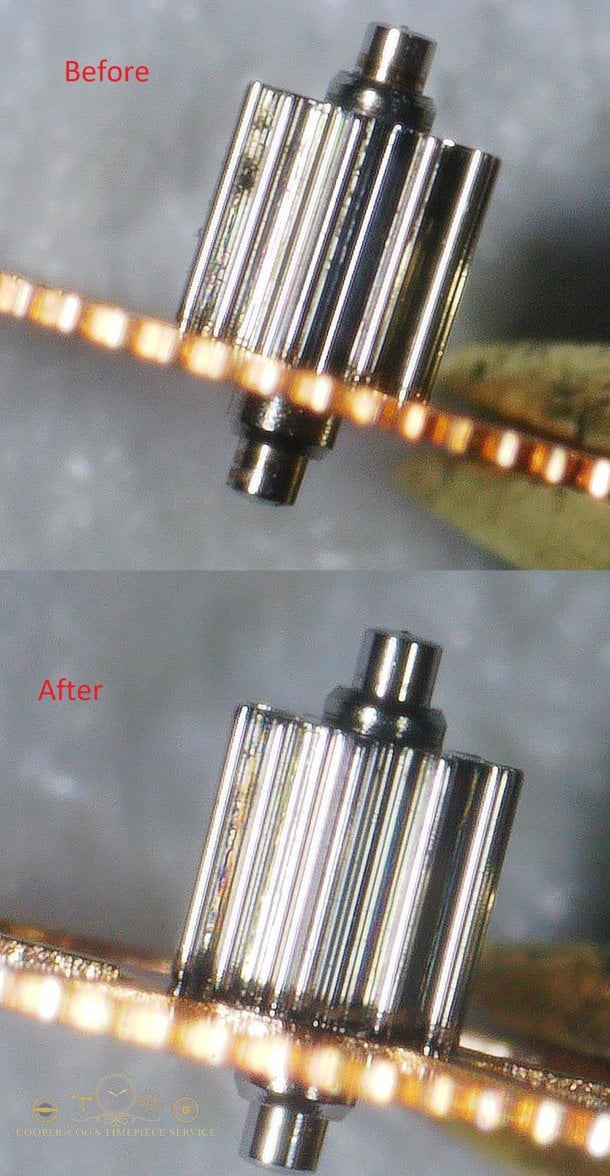

Driving gear for ratchet wheel, before and after, results clearly shows

The escape wheel pivot.

1- before treated

2- after treated

3- after treated

4- after treated

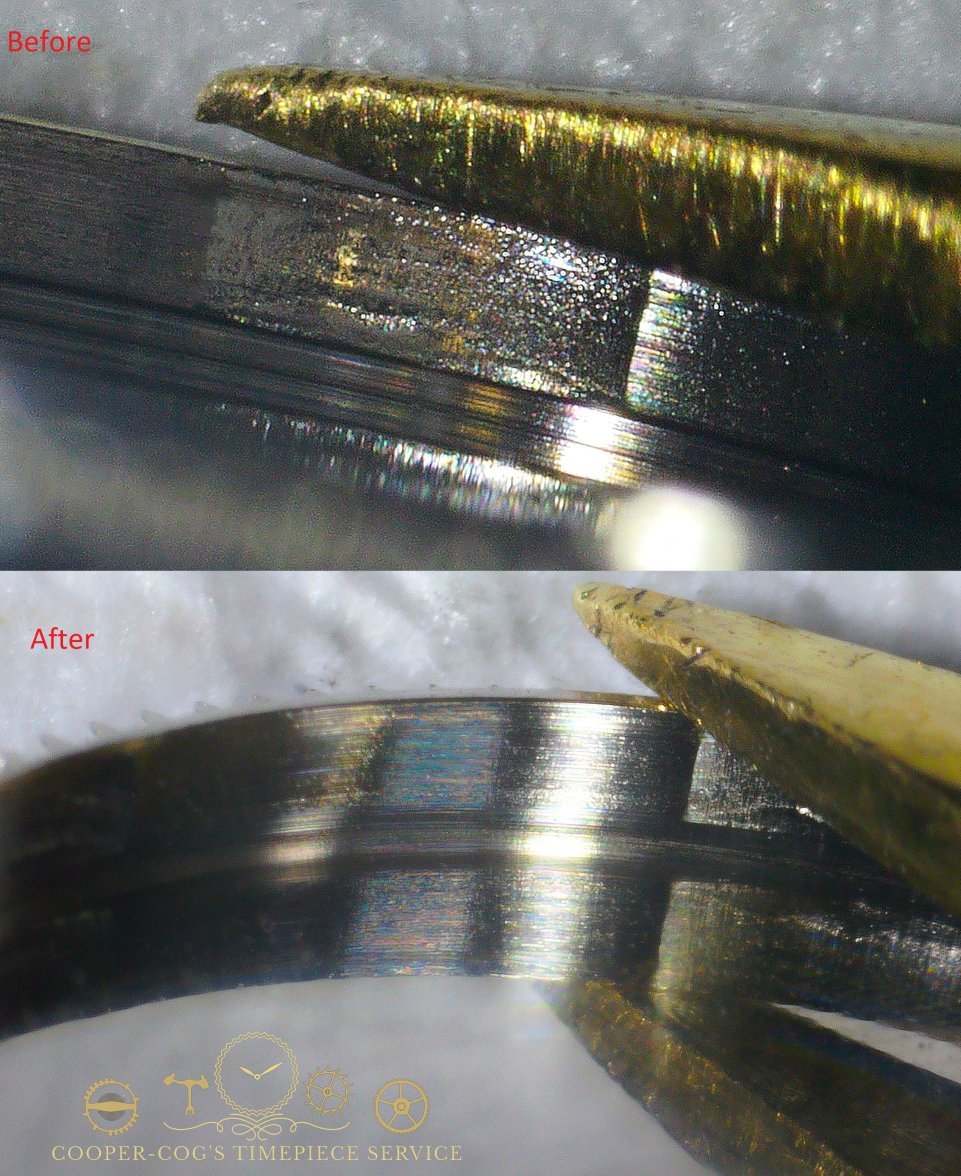

Center cannon pinion wheel. Before and after. Burnish and polish on Jacot tool.

Great wheel, Before and after. Burnish and polish on the Jacot tool.

Fourth wheel. Before and after. Before and after. Burnish and polish on the Jacot tool.

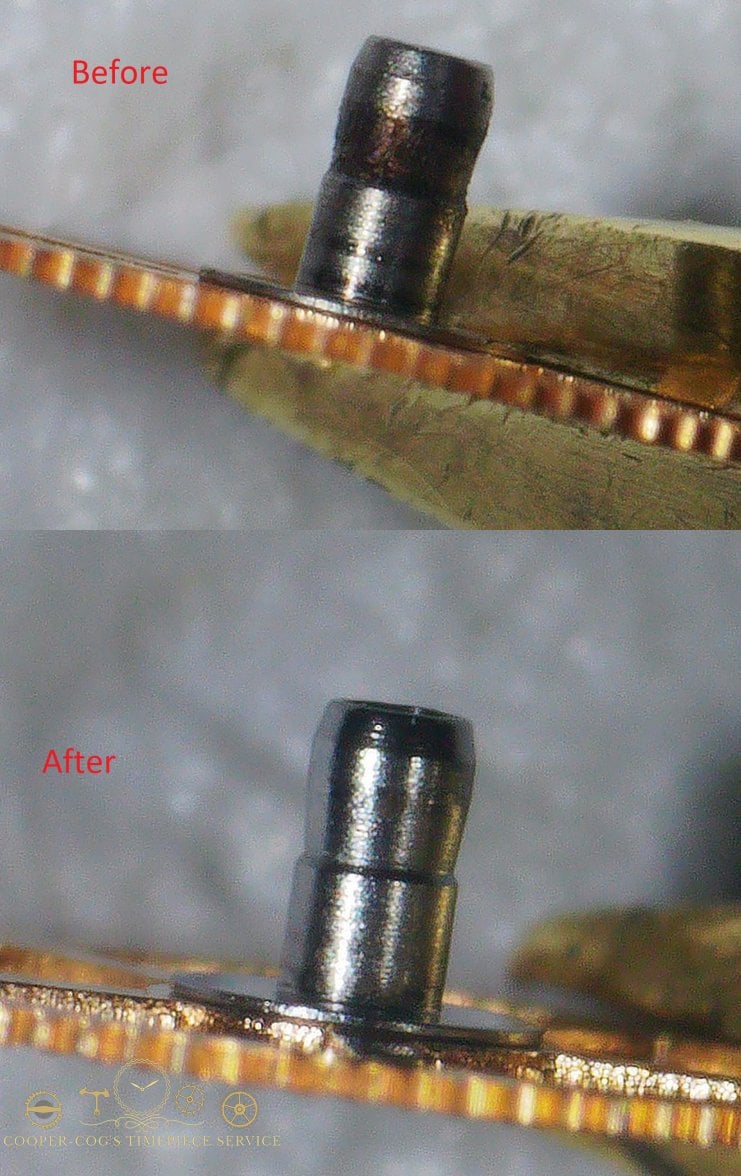

balance staff, Before and after. Burnish and polish on the Jacot tool

Same again but a close up shot of the balance staff, before, the balance staff is flat, and after balance staff is rounded.

Mainspring barrel is worn and scratched. same for the inside barrel wall.

Lathe machine with a compound slider along with fine graver.

No room for error, 0.02mm - very slight material was taken off inside the mainspring barrel wall.

Then polish the surface inside the barrel wall

Inside mainspring barrel wall

Before, Rough and scratches on the surface

After, Smooth surface. almost scratch free

It's very important to have a scratch-free inside barrel wall. this will fully optimize with power, especially for low power. therefore it will allow the mainspring bridle to sit and touch the barrel wall with maximum grip along with Kubler P125 grease and deliver a good consistency of high and low power to the balance wheel.

It has to be scratched free or otherwise breaking grease will be useless and it will not do its job properly. More scratches mean less surface, less surface means less grip, less grip means more slippage, and it will wear out faster too because of slippage when the mainspring is winding up and sending power through the train wheel. This will result in amplitude loss and smooth, clean power as well.

The barrel wall looks new and clean and almost scratch free. Applying grease Kubler P125 inside the barrel wall.

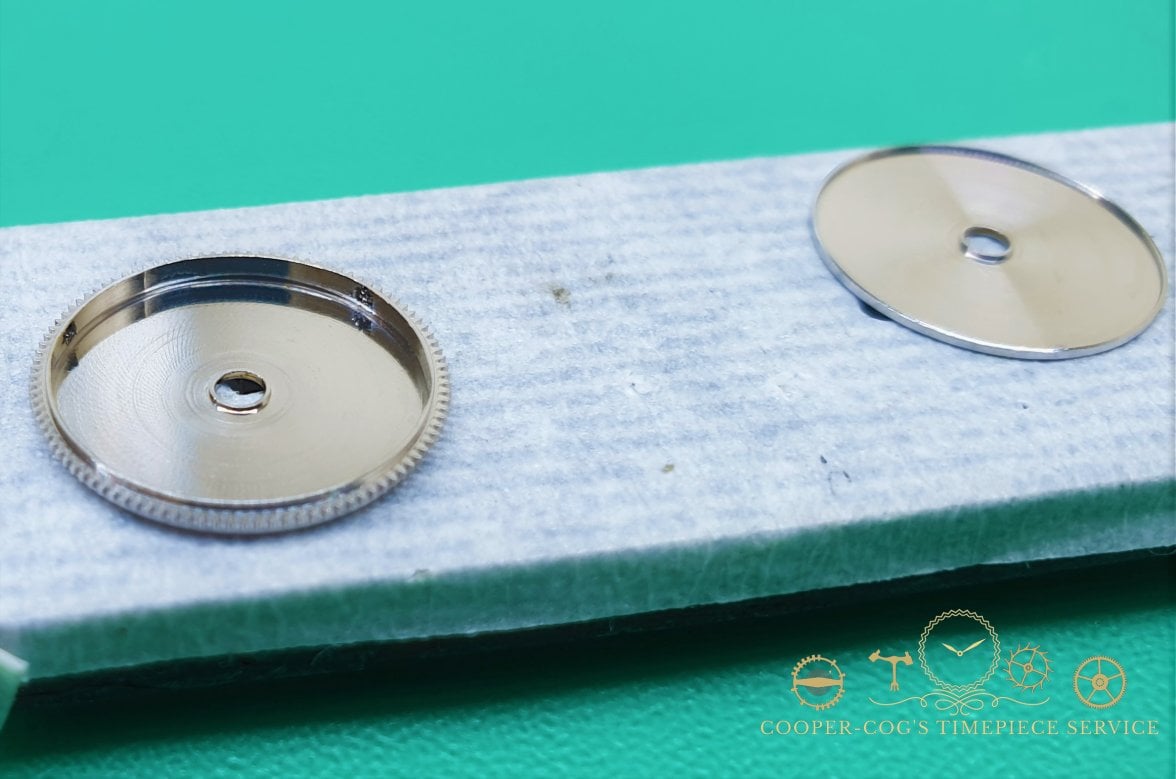

Begeon Barrel drum size 7 with size 6 handle winder.

Installing off center cannon pinion.

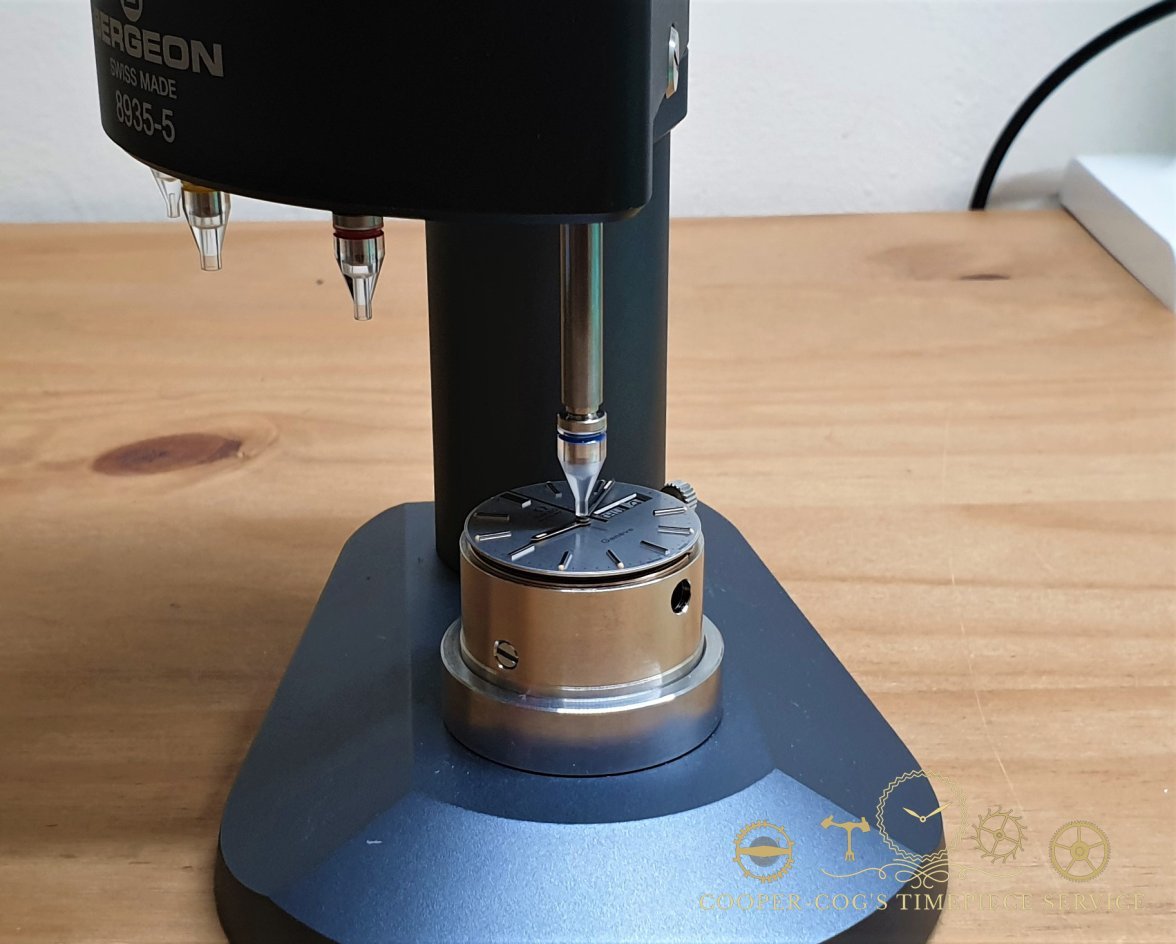

The Bergeon movement holder with screw support in the center. This will help to install the second hand onto the sweep second pinion without damaging it.

Installing cannon Pinion

Second-hand installed with Bergeron hand presser

Make sure the movement holder screw pin is supporting/contacting the sweep second pinion under the movement.

Installing the original omega acrylic glass with tension ring on the Bergeon presser.

Fully fitted in the case.

After three days Timekeeping and amplitude are great with all six sides positioned at full wind mainspring power. This will allow me to do proper regulator adjustments for all six positions in the next few days

The final look, the original acrylic glass has been buffered to remove scratches.

Hope you enjoyed this thread. Thanks for reading.

Mat

This is a perfect time to discuss about burnish and polish on the Jacot tool)

A lot of hobbyist attempts to do this by cleaning and oiling is not a proper service in a professional sense, and most hobbyists don't realise this, in the real watchamaking world, it takes more than just cleaning and oiling to have a good performance and the reason I mentioned this is that over the last four years I have seen quite a lot of posts on Facebook groups and watch forums that when one hobbyist service a watch, dismantle, cleans, and apply new fresh lubricant and put it back together, and then test it on the timegrapher, it still shows problems on the timegrapher screen showing with erratic readings and poor amplitude and asked for help, many hobbyists suggest that either a mainspring needs a replacement, or something is wrong with escape wheel, pallet fork, or balance wheel, however, that isn't always the case, it likely that parts are too worn and it causes friction and resistance and it leads to poor performance by not giving a correct consistency of power from mainspring to the pallet fork and then to the balance wheel and that's why it showing erratic readings on timegrapher screen. To eliminate with this problem and to achieve a clean straight reading on timegrapher with equal/consistent power and good amplitude, is to replace the worn out parts with new parts or do a burnish and polish with the Jacot tool.

Burnish and polish is the most important tool and skill to have in watchmaking assets to repair the pivots. Over time, the pivot will eventually be worn out after constant of use for many years even with fresh lubricants, but of course, that old or lack of lubricants will speed up damaging the pivots over the time . The pivot surface will lose it's hardness and expose the soft surface under.

This is why overhaul service is very important and recommended at least one overhaul service after every five standard services. My watchmaker is a master watchmaker who told me this many years ago and he taught me how to use the Jacot tool.

Using a Jacot tool is never an easy task, it took me fours years to master it property with over 1000 hours of practicing it just to get it right, in my 15 years of watchmaking, I definitely would say burnish and polishing on Jacot tool is the hardest thing to learn, looks simple but yet so many complicated tasks that involved, back and forth stroke, long stroke, middle stoke, short stroke, slow stroke, fast stoke, light stroke, and hard stoke, the list goes on but very an effective to repair worn/damaged pivots. Vintage watches almost always have worn and damaged parts, burnishing, and polishing is a very slow process, but it does remove material, real life repairs always require a balance between perfection and reality. If scoring is completely removed, it might remove so much material that the pivot begins to have too much sideshake and endshake, especially for balance staff. Instead, some surface finish might sometimes be sacrificed in favor of pivot diameter. A properly burnished and polished pivot not only has less friction but it wears less over time. The act of burnishing actually compresses the metal, making it denser and harder to corrode.

Many brands and movement manufacturers have acid washed and tumbled pivots, this technique is cheaper and creates a hard outer surface, but once that hardened surface wears through, the softer insides degrade quickly. This is where burnishing shines, it's a rare practice, a good repair technique, and an extreme challenge to master.

Here I have omega Seamaster 1020 from the 1970’s. The customer has sent this Omega off to London for full service, they have serviced the Omega and the issue stills occurs. The timekeeping is still poor and it has a low amplitude in all six sided positions. So they have told the customer that omega is a write off because it no longer can be used for timekeeping, and they are no longer interested to replace the parts also I am assumed they don’t want to go through all that hassle and trouble because It’s cost time and money to search and find parts, especially for vintage movements. This is not uncommon these days.

I had an unexpected phone call and they asked me if I want to take on this Omega Seamaster and tackle the problem. So basically they want to dump this problem on me instead and to keep their customer happy. So I said yes, go ahead and send it to me and see what I can do. So the omega Seamaster finally arrived at me. So I investigated the omega Seamaster parts and oh boy, the pivots were in such a bad state. No wonder it runs poorly after a fresh service. The arbor, escape wheel, third wheel, fourth wheel, center wheel, and balance staff was seriously worn and needs to be taken care of. The mainspring barrel wall is worn and damaged and needs to be repaired on the lathe machine.

The overhaul service went extremely well after burnished and polished and then cleaned, oiled, and put back together. Timekeeping and amplitude have been vastly improved on timegarpher. The reading results is now a straight line and slight deviation when tested at all six angle positions. This will allow me to do proper regulator adjustments for all six positions in the next few days.

Hope you enjoy reading my post and hopefully this is useful for those who are learning something new.

Many thanks

Mat

Received this from a watch repairer in London. It's been fully serviced but performance is failed due to heavily worn parts. The omega acrylic glass is scratched and needs to be buffed later on.

The performance is very poor after being freshly serviced in London a week ago before being sent to me to do the overhaul service.

Time to dismantle the Omega Seamster into little pieces

The old school work, here I am, sitting down, and doing the burnishing and polishing of the seven parts on Jacot. started at 6am this morning and finished at almost 9am. Just in time before my workshop opens. I really wanted this exhausting task out of the way before I start the day.

Escape wheel on the Jacot tool, burnishing, and then polishing the pivot.

Again, the Escape wheel on the Jacot tool.

Same for the balance staff pivot

The fourth wheel on the jacot tool, burnishing and then polishing the pivot.

After doing work, I use my strong magnifier to see any results.

You can see the clear results before and after on the barrel arbor.

1 and 2 before treatment.

3 and 4 after treatment.

Third wheel before burnishing and polishing.

Again third wheel,

1- not treated

2- half treated

3- fully treated

Driving gear for ratchet wheel, before and after, results clearly shows

The escape wheel pivot.

1- before treated

2- after treated

3- after treated

4- after treated

Center cannon pinion wheel. Before and after. Burnish and polish on Jacot tool.

Great wheel, Before and after. Burnish and polish on the Jacot tool.

Fourth wheel. Before and after. Before and after. Burnish and polish on the Jacot tool.

balance staff, Before and after. Burnish and polish on the Jacot tool

Same again but a close up shot of the balance staff, before, the balance staff is flat, and after balance staff is rounded.

Mainspring barrel is worn and scratched. same for the inside barrel wall.

Lathe machine with a compound slider along with fine graver.

No room for error, 0.02mm - very slight material was taken off inside the mainspring barrel wall.

Then polish the surface inside the barrel wall

Inside mainspring barrel wall

Before, Rough and scratches on the surface

After, Smooth surface. almost scratch free

It's very important to have a scratch-free inside barrel wall. this will fully optimize with power, especially for low power. therefore it will allow the mainspring bridle to sit and touch the barrel wall with maximum grip along with Kubler P125 grease and deliver a good consistency of high and low power to the balance wheel.

It has to be scratched free or otherwise breaking grease will be useless and it will not do its job properly. More scratches mean less surface, less surface means less grip, less grip means more slippage, and it will wear out faster too because of slippage when the mainspring is winding up and sending power through the train wheel. This will result in amplitude loss and smooth, clean power as well.

The barrel wall looks new and clean and almost scratch free. Applying grease Kubler P125 inside the barrel wall.

Begeon Barrel drum size 7 with size 6 handle winder.

Installing off center cannon pinion.

The Bergeon movement holder with screw support in the center. This will help to install the second hand onto the sweep second pinion without damaging it.

Installing cannon Pinion

Second-hand installed with Bergeron hand presser

Make sure the movement holder screw pin is supporting/contacting the sweep second pinion under the movement.

Installing the original omega acrylic glass with tension ring on the Bergeon presser.

Fully fitted in the case.

After three days Timekeeping and amplitude are great with all six sides positioned at full wind mainspring power. This will allow me to do proper regulator adjustments for all six positions in the next few days

The final look, the original acrylic glass has been buffered to remove scratches.

Hope you enjoyed this thread. Thanks for reading.

Mat

Edited: