Strange sound when winding

Archer

··Omega Qualified WatchmakerI'm thoroughly enjoying reading this thread and have great respect for the two main parties. As a mechanical engineer who is now enjoying the magnificent world of horology in general, I have to say that in this case I have to come out on the side of Horlogerie when it comes to the manual winding of automatic watches. His views on winding, bearing loading and wear are in alignment with my own.

The most important thing is that these types of discussions are put across in a friendly and informative manner with good reasoning.

I always welcome the input of a fellow engineer, but I disagree with the conclusions being drawn here, but I will explain in a reply to Rob...

"Open your eyes, look in front, look at the back, look at any angle and you will see something that is an engineer's creation."

Geo!

·I await with interest Al. I always keep an open mind with things, and have no problem with being proved wrong if that is the case.

Archer

··Omega Qualified WatchmakerHi Rob - I have a few comments on some statements you are relying on for your arguments...

This characterization is very misleading in many ways, and no not everyone agrees. Yes the weight is small compared to many things in the world (like a car, or a house) but in the context of a watch movement, it really isn't. Most weights at the low or mid-tier level like Rolex and Omega are brass, but high end watches often use precious metals for the weight portion, so 22k gold in some cases - small but heavy. The rotor in my old Blancpain was solid gold, so not exactly light weight by any means:

Gratuitous watch shot...

I'm not sure how you can argue it provides a low energy input - for the weight to service it's function, it has to provide enough energy to move all the gearing in the automatic winding system, and right down to the ratchet wheel, turning the barrel arbor and winding the spring. Because watch companies don't want complaints about a watch not winding on someone's wrist, they tends to use more weight than would be necessary in a perfectly functioning watch. In the real world people neglect their watches and don't keep them serviced, yet they still wind and wind as pivots wear, oils dry up, etc. So there is plenty of extra energy to overcome these faults built into these designs in the real world.

And as any watchmaker will tell you, even in it's fully wound state the mainspring will continue to be wound by the automatic, so it has to overcome all the tension in the spring and the braking grease on the barrel wall, and yet it still provides enough force to wind and wind. This is why you watch is fully wound when you take it off at the end of wearing it for a day. The very function of this system would not work if it didn't provide enough torque (which is the important thing here, not "weight"), to power the winding system.

Also the assertion it's powered by gravity is false - yes gravity plays a part but so does inertia. This is why automatic watches work fine in zero gravity. You say it's slow moving, and yes if I placed my watch on a watch winder that turned slowly the weight would be slow moving. But by ignoring inertia you ignore the fast moving that happens of the weight in daily use as you flick your wrist around. Winding speed is highly variable with the movements of your wrist.

Most of the next area really assumes the "low load and low velocity" argument, which I do not believe is the case in the real world, so calculations aside, I believe it's flawed reasoning. The only thing that piqued my attention here is the statement about not finding escape wheel pivot wear...this is not my experience is all I'll say...

Yes certainly - and you fail to mention the parts that provide this decoupling - the reversing wheels. I know of no modern automatic watch that does not have some way of decoupling such as reversing wheels. They are sometimes called by different names, so known as the "winding wheel" in the 55X, and 56X series this thread was started about, but they serve the purpose of decoupling the system during manual winding.

What this paragraph tells me is what I have been saying all along - in a properly serviced and maintained watch, there is no need to be overly cautious with winding it. Certainly if the parts that do the decoupling are not working, you can damage the watch by manual winding. I've already said and show two videos where that is happening, and as I said then, I advise people not to wind the watch at all when this happens.

You seem to believe from what I read in your arguments that only two positions can exist here. One being that manual winding can never do harm (you have tried to make my argument that "manual winding never wears parts" already once in this thread, which is something I have not ever said), or that it always does damage. The truth is in the middle somewhere. Clearly anything that moves can wear, so if it moves during manual winding it can wear during manual winding - I've never said it could not. What I have said is the concern here is being overblown, and again in a watch that has been properly serviced and has no defect, manual winding is not something that has to be done "very slowly and very gently."

Cheers, Al

PS - edit to add that aside from all this back and forth about the reasons for the wear I've shown, forgetting this thread for a moment if someone asked me what the cause of all the wear in my photos was from, there is a simple, succinct answer...neglect.

Does number of turns of the rotor alone have the ability to cause extreme wear in the autowinder gearing? When it comes to the rotor, I think everyone will agree that it has a slow velocity and a low energy input, after all it's only a small weight driven by gravity.

This characterization is very misleading in many ways, and no not everyone agrees. Yes the weight is small compared to many things in the world (like a car, or a house) but in the context of a watch movement, it really isn't. Most weights at the low or mid-tier level like Rolex and Omega are brass, but high end watches often use precious metals for the weight portion, so 22k gold in some cases - small but heavy. The rotor in my old Blancpain was solid gold, so not exactly light weight by any means:

Gratuitous watch shot...

I'm not sure how you can argue it provides a low energy input - for the weight to service it's function, it has to provide enough energy to move all the gearing in the automatic winding system, and right down to the ratchet wheel, turning the barrel arbor and winding the spring. Because watch companies don't want complaints about a watch not winding on someone's wrist, they tends to use more weight than would be necessary in a perfectly functioning watch. In the real world people neglect their watches and don't keep them serviced, yet they still wind and wind as pivots wear, oils dry up, etc. So there is plenty of extra energy to overcome these faults built into these designs in the real world.

And as any watchmaker will tell you, even in it's fully wound state the mainspring will continue to be wound by the automatic, so it has to overcome all the tension in the spring and the braking grease on the barrel wall, and yet it still provides enough force to wind and wind. This is why you watch is fully wound when you take it off at the end of wearing it for a day. The very function of this system would not work if it didn't provide enough torque (which is the important thing here, not "weight"), to power the winding system.

Also the assertion it's powered by gravity is false - yes gravity plays a part but so does inertia. This is why automatic watches work fine in zero gravity. You say it's slow moving, and yes if I placed my watch on a watch winder that turned slowly the weight would be slow moving. But by ignoring inertia you ignore the fast moving that happens of the weight in daily use as you flick your wrist around. Winding speed is highly variable with the movements of your wrist.

Most of the next area really assumes the "low load and low velocity" argument, which I do not believe is the case in the real world, so calculations aside, I believe it's flawed reasoning. The only thing that piqued my attention here is the statement about not finding escape wheel pivot wear...this is not my experience is all I'll say...

With Al mentioning the WOSTEP Theory of Horology manual, I had a read through mine and came across this interesting section:

Section 8.3.6, first para which states in part:

"When the wearer winds his or her self-winding watch using the winding stem, it is important that there is a system which uncouples the reduction gearing train in order to keep it from rotating too quickly, which would cause excessive wear or even the breakage of one or several parts"

Yes certainly - and you fail to mention the parts that provide this decoupling - the reversing wheels. I know of no modern automatic watch that does not have some way of decoupling such as reversing wheels. They are sometimes called by different names, so known as the "winding wheel" in the 55X, and 56X series this thread was started about, but they serve the purpose of decoupling the system during manual winding.

What this paragraph tells me is what I have been saying all along - in a properly serviced and maintained watch, there is no need to be overly cautious with winding it. Certainly if the parts that do the decoupling are not working, you can damage the watch by manual winding. I've already said and show two videos where that is happening, and as I said then, I advise people not to wind the watch at all when this happens.

You seem to believe from what I read in your arguments that only two positions can exist here. One being that manual winding can never do harm (you have tried to make my argument that "manual winding never wears parts" already once in this thread, which is something I have not ever said), or that it always does damage. The truth is in the middle somewhere. Clearly anything that moves can wear, so if it moves during manual winding it can wear during manual winding - I've never said it could not. What I have said is the concern here is being overblown, and again in a watch that has been properly serviced and has no defect, manual winding is not something that has to be done "very slowly and very gently."

Cheers, Al

PS - edit to add that aside from all this back and forth about the reasons for the wear I've shown, forgetting this thread for a moment if someone asked me what the cause of all the wear in my photos was from, there is a simple, succinct answer...neglect.

Edited:

Archer

··Omega Qualified WatchmakerI await with interest Al. I always keep an open mind with things, and have no problem with being proved wrong if that is the case.

It's not about being proved right or wrong mate. As I have been saying all along, the answer is in the middle somewhere, not at either extreme....

vinn2

·very interesting. thank you

ChrisN

·"Open your eyes, look in front, look at the back, look at any angle and you will see something that is an engineer's creation."

Great quote Al! After all the discussions here, you piqued my interest. I'm no Watchmaker but I am an Aerospace Engineer... I'm sure all of this has been covered but here's my two cents in non horological terms. Might help those with less knowledge?

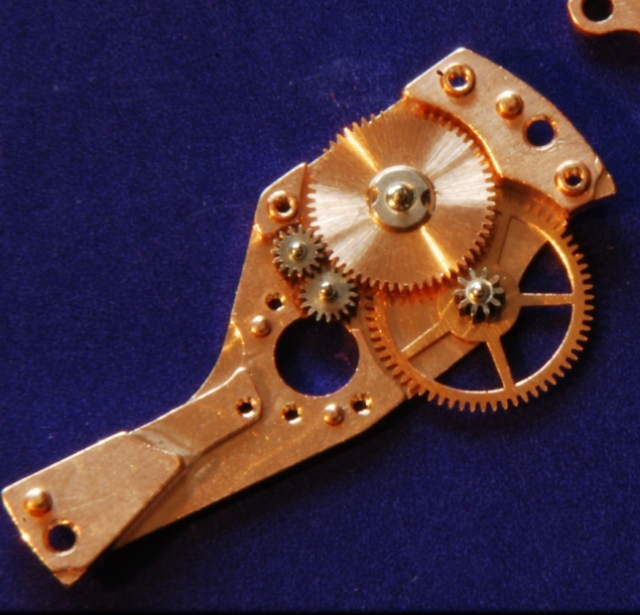

Here's a 561 auto mechanism. When the rotor turns, it turns one tiny gear which turns the next one. The two tiny gears turn the big copper coloured assembly wheel (reversing wheel) which then turns the big spoked wheel. The little gear on that is directly connected to the ratchet wheel and winds the spring.

As the ratchet wheel is also turned to wind the spring when you wind from the crown, that big spoked wheel turns by default. This is not required but is a by product of the design. The clever part about the reversing wheel is it freewheels when the torque is applied from that side and not the rotor (unless it's all gummed up and then turning the crown also turns the rotor - as has been mentioned, not good). So, when you turn the crown, you are only turning the big spoked wheel and about one third of the reversing wheel assembly (not the parts you can see).

Because of the freewheeling, the torque dissipated here is a very small amount in comparison to when the rotor turns this lot to wind the mainspring. Most of your torque on the crown is used up to wind the spring.

If there's no torque being transmitted by the big spoked wheel and the reversing wheel then, if they are properly oiled, the wear on the pivots due to the rotation will be a tiny fraction of what you would see from the rotor winding action. This is kind of intuitive to me but you can imagine how little wear you are doing to, for example, your washing machine if you ran it all day without loading it. Possibly a poor analogy for a primarily men's forum😀. How about running your power drill without doing any drilling so it's under no load?

I could draw lots of diagrams explaining how forces on gears/pivots are balanced but, that would be confusing and probably no clearer if you don't have the background.

As an aside, the torque applied to the crown to wind the mainspring is a constant to overcome the resistance of the mainspring whether you try to wind it gently or not. The forces are the same. It does vary a little depending on how much the spring is wound but spring design aims to give a constant release torque and hence winding torque. Anyway, the statement that the torque is the same winding either gently or not, holds true when we neglect stiction (let's do that as otherwise it is too complex👍).

Winding it slowly will just slow the wheel rotations and I can see some logic in doing that as faster rotation would give more wear (typically, I don't want to get into how the oil supports the shafts on the bearings but Jaguar relied on this for their wide tolerances XK engine as the revs increase). However, I'd be worried only about the parts that are transmitting torque (for example, the crown wheel) not those that are freewheeling.

I suspect people see wear in the auto winders because they are not well oiled or the reversing wheels (I know they sometimes have different names) are gummed up.

I bet this has not helped at all.... So, look away and see something created by an Engineer😀

I forgot to say, as @Canuck says, if you hear strange noises when winding, go and see your Watchmaker (or your doctor in case you have tinnitus!).

Cheers, Chris

Edited:

Geo!

·Excellent description Chris, it's greatly appreciated! 😀

Me being me, I'll still wind them more slowly than no- automatic watches. It's the same way I feel about the launch control in my car. I know it has been designed not to harm any components, but sitting with one foot on the brake while the other holds the throttle wide open (even though it's restricted to 3000rpm at that point) before releasing the brake sounds and feels all wrong.

Me being me, I'll still wind them more slowly than no- automatic watches. It's the same way I feel about the launch control in my car. I know it has been designed not to harm any components, but sitting with one foot on the brake while the other holds the throttle wide open (even though it's restricted to 3000rpm at that point) before releasing the brake sounds and feels all wrong.

Canuck

·To quote Chris N. My point exactly, in my most recent post. Automatic winding puts much more strain on the automatic winding components than manual winding does! But, IF the automatic winding components have deteriorated over years of automatic winding (scored pivots, faulty reverser, etc.), some effect may be felt during manual winding. I just finished doing a calibre 561 for a friend. The reverser was shot. You could definitely feel it during manual winding! To anticipate any follow up. The reverser did NOT fail from manual winding!

Archer

··Omega Qualified WatchmakerGreat quote Al!

I actually didn't know that Geo was a fellow engineer before this thread, but I knew you would appreciate that one!

Winding it slowly will just slow the wheel rotations and I can see some logic in doing that as faster rotation would give more wear (typically, I don't want to get into how the oil supports the shafts on the bearings but Jaguar relied on this for their wide tolerances XK engine as the revs increase). However, I'd be worried only about the parts that are transmitting torque (for example, the crown wheel) not those that are freewheeling.

Cheers, Chris

Hydrostatic bearings...very familiar with them in industrial machinery applications. The manufacturing company I used to work for made bearings (wear and preventing it is nearly a religion there) and many of the grinding machines we used to produce the bearings had hydrostatic spindle bearings. Large grinding machines with wheels weighing 70 or 80 pounds, turning at thousands of rpm, being driven hard in high production manufacturing - it's amazing what can be supported on a very thin layer of oils. But of course if the spindle received a big shock, the bearings would "pick up" and they needed to be stripped and repaired,

We rebuilt a lot of this machinery on site, so our industrial mechanics were very good at scraping in the old Babbitt bearings to a master - scraping is kind of a lost art really, but our guys were very good at scraping in bearings and slides...okay enough nostalgia...sorry to digress here...

Glad you are finding the discussion interesting.

Cheers, Al

Geo!

·All good stuff here, thanks guys!

ChrisN

·I don't know about launch control @Geo! but I like to treat everything gently as possible. To replace the clutch on my main car is an engine out job so, I'm not one for dropping the clutch to get a quick start....

Al, I know about your bearing experience but you were designing them correctly! Jaguar just couldn't be bothered upgrading their machining tools as they got them cheap just after the war so, they relaxed tolerances even further to get the hydrostatic effect. There's a hell of a lot in bearing design that most people don't realise and as you say, for example, the old scraping skills are long gone now, I suspect.

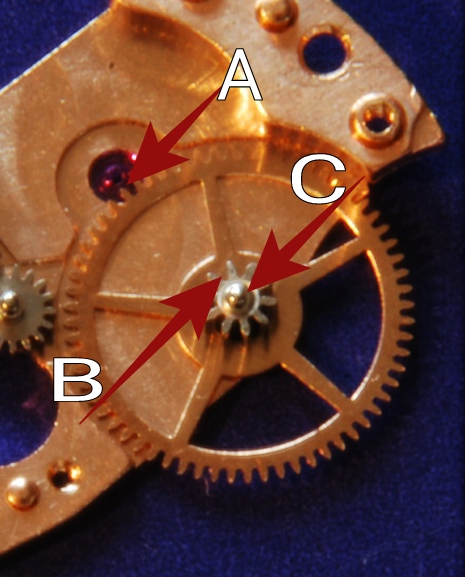

I think you're absolutely right @Canuck about when the stresses are highest. For the less technical (although, I think the few people flogging through this thread now are all Engineers) and as I'm definitely enjoying this discussion, here's a load balance of a wheel which happens to be the large spoked wheel above. I hope the "spoked wheel" description is sufficiently technical for you, Rob and Al 😁.

Loads on the wheel:

If something (in this case, the rotor via the little gears and the reversing wheel) exerts a force on the outer gear that becomes force A above, then to balance the torque, force B on the inner tooth is about 5 times force A as it's offset from the pivot is about one fifth of force A. So, it is five times greater. In this movement, B is on the other side of the pivot but let's keep it simple.

You can try this at home, ask your wife/girlfriend to try and open a door at the handle and you stand on the other side and try and stop her by pushing against her but at a point only 6 inches from the door hinge. You need a lot of force there to resist her. I can't resist my wife so, it's a moot point....

Anyway, so the torque is balanced but as B=5A, we have an out of balance force which is trying to move the whole wheel to the top right of the picture. We can only react this as force C on the pivot and, as drawn, it's equal to the difference, that being 4A. So, only transmitting torque, we have a side load on the pivot which causes it to wear.

It makes sense that if we are not transmitting torque then C is very small and wear is also very small.

It's a bit simplified but might explain why we have a side load on the bearing and shaft just by transmitting torque and this causes wear. It also explains why shafts (staffs, why are you Watchmakers using such strange terms..) need to be bigger on those areas where we have high torque, as force C is bigger.

Next, how to design the mechanism of a pressure resistant door in an aircraft fuselage. We might need a few months...

Very interesting discussion, thanks Guys.

Cheers, Chris

Edit: Obviously, work done =Force*distance moved is maintained above as the inner gear only moves a distance one fifth of the outer. To paraphrase Homer, "In this house we follow the laws of energy conservation;". No, that's not the Greek Homer...

Al, I know about your bearing experience but you were designing them correctly! Jaguar just couldn't be bothered upgrading their machining tools as they got them cheap just after the war so, they relaxed tolerances even further to get the hydrostatic effect. There's a hell of a lot in bearing design that most people don't realise and as you say, for example, the old scraping skills are long gone now, I suspect.

I think you're absolutely right @Canuck about when the stresses are highest. For the less technical (although, I think the few people flogging through this thread now are all Engineers) and as I'm definitely enjoying this discussion, here's a load balance of a wheel which happens to be the large spoked wheel above. I hope the "spoked wheel" description is sufficiently technical for you, Rob and Al 😁.

Loads on the wheel:

If something (in this case, the rotor via the little gears and the reversing wheel) exerts a force on the outer gear that becomes force A above, then to balance the torque, force B on the inner tooth is about 5 times force A as it's offset from the pivot is about one fifth of force A. So, it is five times greater. In this movement, B is on the other side of the pivot but let's keep it simple.

You can try this at home, ask your wife/girlfriend to try and open a door at the handle and you stand on the other side and try and stop her by pushing against her but at a point only 6 inches from the door hinge. You need a lot of force there to resist her. I can't resist my wife so, it's a moot point....

Anyway, so the torque is balanced but as B=5A, we have an out of balance force which is trying to move the whole wheel to the top right of the picture. We can only react this as force C on the pivot and, as drawn, it's equal to the difference, that being 4A. So, only transmitting torque, we have a side load on the pivot which causes it to wear.

It makes sense that if we are not transmitting torque then C is very small and wear is also very small.

It's a bit simplified but might explain why we have a side load on the bearing and shaft just by transmitting torque and this causes wear. It also explains why shafts (staffs, why are you Watchmakers using such strange terms..) need to be bigger on those areas where we have high torque, as force C is bigger.

Next, how to design the mechanism of a pressure resistant door in an aircraft fuselage. We might need a few months...

Very interesting discussion, thanks Guys.

Cheers, Chris

Edit: Obviously, work done =Force*distance moved is maintained above as the inner gear only moves a distance one fifth of the outer. To paraphrase Homer, "In this house we follow the laws of energy conservation;". No, that's not the Greek Homer...

Edited:

M'Bob

·I think I need an aspirin.

Archer

··Omega Qualified WatchmakerHey Chris - thanks for the geek out.

Since I became a watchmaker I don't get conversations like this - when I start talking about anything technical my wife's eyes just roll, and I know it's time to stop.

All I can say is "give me a moment to think about those torques!" Haha...

See humour like that is what caused my artsy friend to wear this tee shirt to a BBQ I hosted once...

Heading out to see some friends shortly, and he is also a geek so I'll be wearing my Schrodinger's cat tee shirt without fear of mockery...at least from him...

And yes, watchmaker speak was strange to me also at first...gears become wheels, shafts become staffs, some springs become jumpers - I have enough trouble when my wife starts talking about her jumpers (sweaters here)...

I'm sure I've related the story to you of an instructor talking about poise in a class, and I had to convert his watchmaker speak to something meaningful for me. Thankfully when I put it in my own terms and said "So what you really are saying is that the acceleration through the lift angle should be zero" he knew what I was saying...

Cheers, Al

Since I became a watchmaker I don't get conversations like this - when I start talking about anything technical my wife's eyes just roll, and I know it's time to stop.

All I can say is "give me a moment to think about those torques!" Haha...

See humour like that is what caused my artsy friend to wear this tee shirt to a BBQ I hosted once...

Heading out to see some friends shortly, and he is also a geek so I'll be wearing my Schrodinger's cat tee shirt without fear of mockery...at least from him...

And yes, watchmaker speak was strange to me also at first...gears become wheels, shafts become staffs, some springs become jumpers - I have enough trouble when my wife starts talking about her jumpers (sweaters here)...

I'm sure I've related the story to you of an instructor talking about poise in a class, and I had to convert his watchmaker speak to something meaningful for me. Thankfully when I put it in my own terms and said "So what you really are saying is that the acceleration through the lift angle should be zero" he knew what I was saying...

Cheers, Al

ChrisN

·I think I need an aspirin.

As Al says, sometimes we see things in a way that others don't, whether they're Engineers or not.

Enjoy the weekend!

Cheers, Chris

M'Bob

·I've added a cool compress to the forehead region...all good now.

So if I distill all this down: have your watch fully serviced, don't ever wear or wind it, and no wear to any parts! Yes! I think I understand!

So if I distill all this down: have your watch fully serviced, don't ever wear or wind it, and no wear to any parts! Yes! I think I understand!

Geo!

·I think somebody needs to help M'Bob! 😁

dsio

··Ash @ ΩFThis is slightly irrelevant to the current discussion but from memory the Calibre 601 is more or less a Calibre 550 with the auto winder removed, so a manual wind version of the 550.

Looking at this sheet, half the parts in the 601 actually even have the 550, 470 or 330 part prefix from the automatic versions:

Is there any actual "re-enforcement" that went into making the 601 stronger or more robust than the 550/470/330 or did they just change the mainspring and barrel (I'm guessing just to non-slipping versions so it stops when fully wound) and the main plates (as the auto winding mechanism no longer needed to bolt onto the top)?

The 601 incidentally has a reputation for being one of the most solid and trouble free hand wound Omega movements ever made.

Looking at this sheet, half the parts in the 601 actually even have the 550, 470 or 330 part prefix from the automatic versions:

Is there any actual "re-enforcement" that went into making the 601 stronger or more robust than the 550/470/330 or did they just change the mainspring and barrel (I'm guessing just to non-slipping versions so it stops when fully wound) and the main plates (as the auto winding mechanism no longer needed to bolt onto the top)?

The 601 incidentally has a reputation for being one of the most solid and trouble free hand wound Omega movements ever made.