ChrisN

·Hi Maurice

I'm sure the sort of work you're doing in making parts must be terribly time consuming and expensive so, as you say, just for something rare. Sounds like you were happy with the result and it was clearly worth it. I think most people forget how small these parts are and the skill involved in fabricating them from scratch.

Both you and Rob are absolutely correct about the parts supply issues but I don't see an easy way out at the moment. Certainly, it's easy enough to stamp out, for example, a 565 setting lever spring as the tolerances and finish are not that critical but when you get into balance staffs and wheels, the problems are huge. I've seen some calibres where the end shake on the balance staff is not adjustable so that's another issue for a batch run when the allowable shake is measured in hundredths of a mm.

In the sixties, I think I'm right in saying that the biggest movement manufacturers in the world were a British company called Smiths. I am pretty sure they made everything except for hairsprings so, I don't know who would feel they could do that now. Very specialised I believe so we'll not see those being made cheaply.

Ah well, we'll see if anyone has any luck getting Swatch to change their mind.

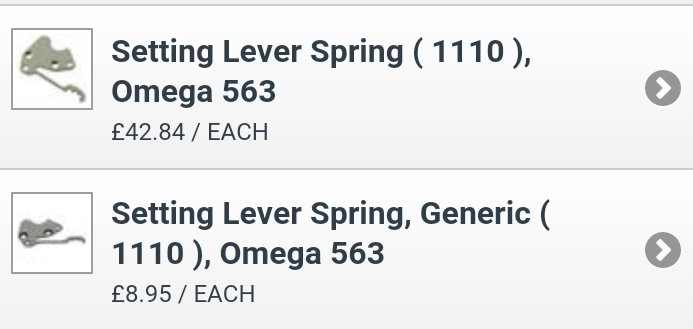

By the way, I used that spring as an example because they are made. Here, from Cousins and you need to add VAT to these so, the Omega part is about €70 and the pattern part about €15. Out of interest, I bought one of these to see how it compared when I bought the Omega part. The finish was poor in comparison but it was correct. I think with half an hours polishing, it would be indistinguishable from the €70 part but, the labour then removes virtually all the cost saving!

Cheers, Chris

I'm sure the sort of work you're doing in making parts must be terribly time consuming and expensive so, as you say, just for something rare. Sounds like you were happy with the result and it was clearly worth it. I think most people forget how small these parts are and the skill involved in fabricating them from scratch.

Both you and Rob are absolutely correct about the parts supply issues but I don't see an easy way out at the moment. Certainly, it's easy enough to stamp out, for example, a 565 setting lever spring as the tolerances and finish are not that critical but when you get into balance staffs and wheels, the problems are huge. I've seen some calibres where the end shake on the balance staff is not adjustable so that's another issue for a batch run when the allowable shake is measured in hundredths of a mm.

In the sixties, I think I'm right in saying that the biggest movement manufacturers in the world were a British company called Smiths. I am pretty sure they made everything except for hairsprings so, I don't know who would feel they could do that now. Very specialised I believe so we'll not see those being made cheaply.

Ah well, we'll see if anyone has any luck getting Swatch to change their mind.

By the way, I used that spring as an example because they are made. Here, from Cousins and you need to add VAT to these so, the Omega part is about €70 and the pattern part about €15. Out of interest, I bought one of these to see how it compared when I bought the Omega part. The finish was poor in comparison but it was correct. I think with half an hours polishing, it would be indistinguishable from the €70 part but, the labour then removes virtually all the cost saving!

Cheers, Chris