Wryfox

·Finishing up a project rifle Mauser K98 I had this project on the back burner for too long time to finish the rifle up. The rifle came to me after it was caught in a flood. The original stock was toast. I found a good deal on a stock from a Remington 798 the price was good so it was a no brainer to use the stock.

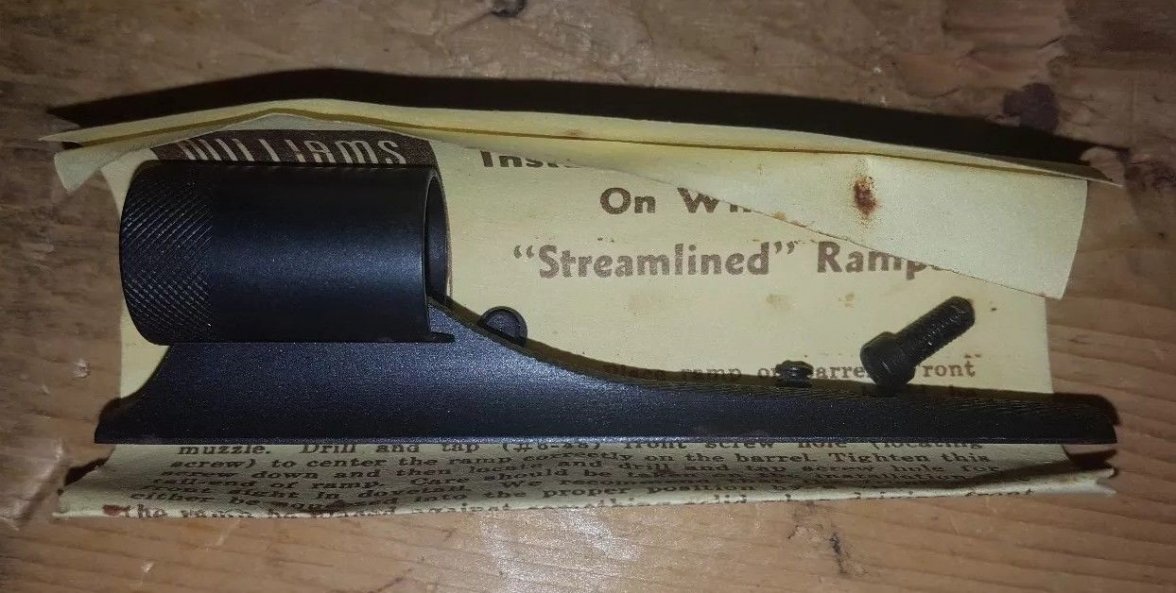

I removed the original sights, shortened and re crowned the barrel. I had to do some wood work around the safety to get it to operate properly. I bedded the stock free floated the barrel and I have been removing pitting from the metal. Now it's good enough to drop off at the refinisher to have a matte finish done. I'll go low buck with a bead blasted blue finish. I'll leave the bolt high polished just for another look.

The stock is a laminate which is good it should not warp. For a spare rifle it will be fine. I would like to put sights on the rifle however the cost for the sights I like would be too $$ rich for this project rifle. I'll refinish the stock after I get the rifle up and shooting. I like to do the stocks last on these projects. These projects keep me busy and out of trouble with my better half my "wife".

Those Interarms actions are smooth as butter. I've owned several Mark X in various small calibers. They always seem to go to better homes as I have none currently. One thing about them...I've found they benefit from just a tad of pressure at the forend tip against the barrel. For me anyway they didn't seem to like free floating, but they were rather thin barrels...yours appears heavier, likely due to caliber. And shorter is good too to minimize barrel whip....I have an awesome barrel whip video that'll blow you mind just how much barrels flex while firing(if I can figure how to put it on youtube...never done that before but if a 10yr old can do it well...📖).

I did the ladder method years ago to develop a load for a Rem 700 in 7mm. The difference between firing at an accuracy "node" vs not was 1.5" groups to holes touching. Only diff was powder weight(ie velocity).