perlunk

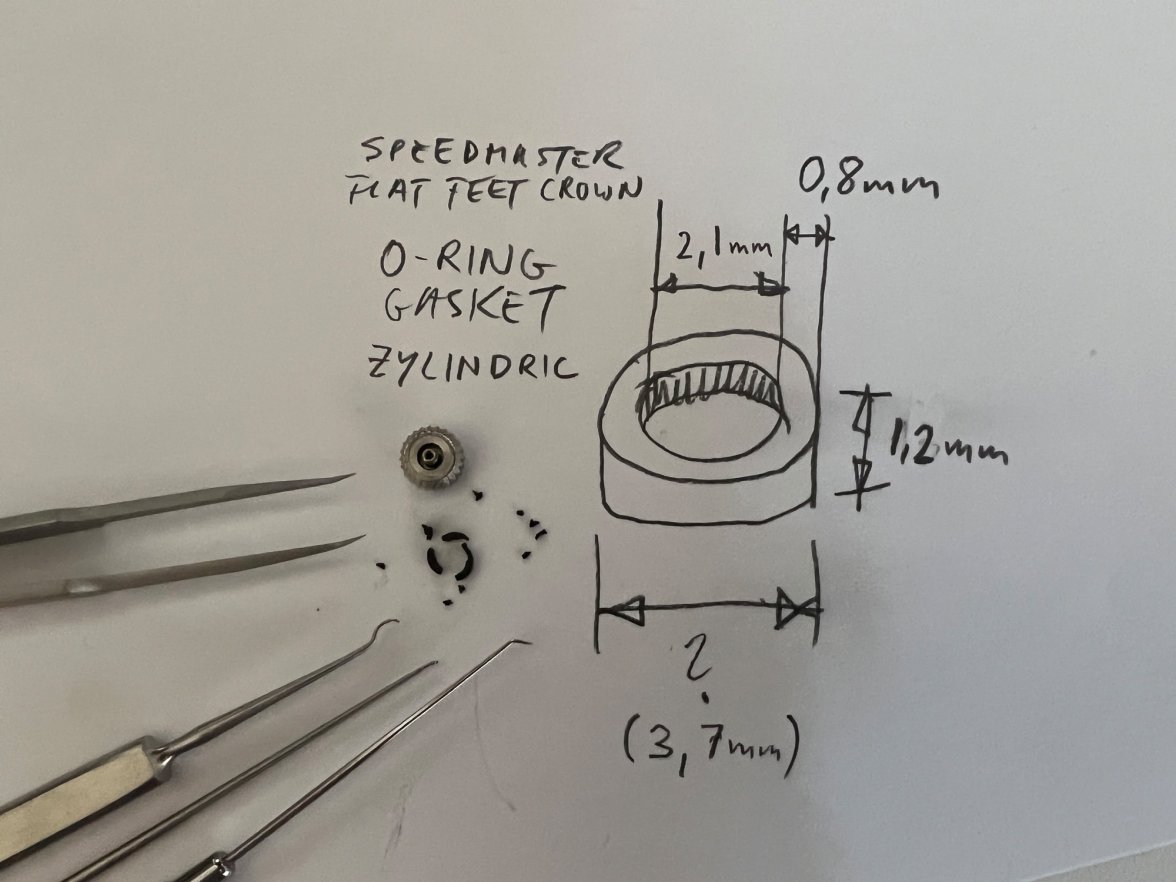

·Is there any advice on how to remove the old gasket from a vintage "Narrow Flat Feet" crown?

I would like to replace it.

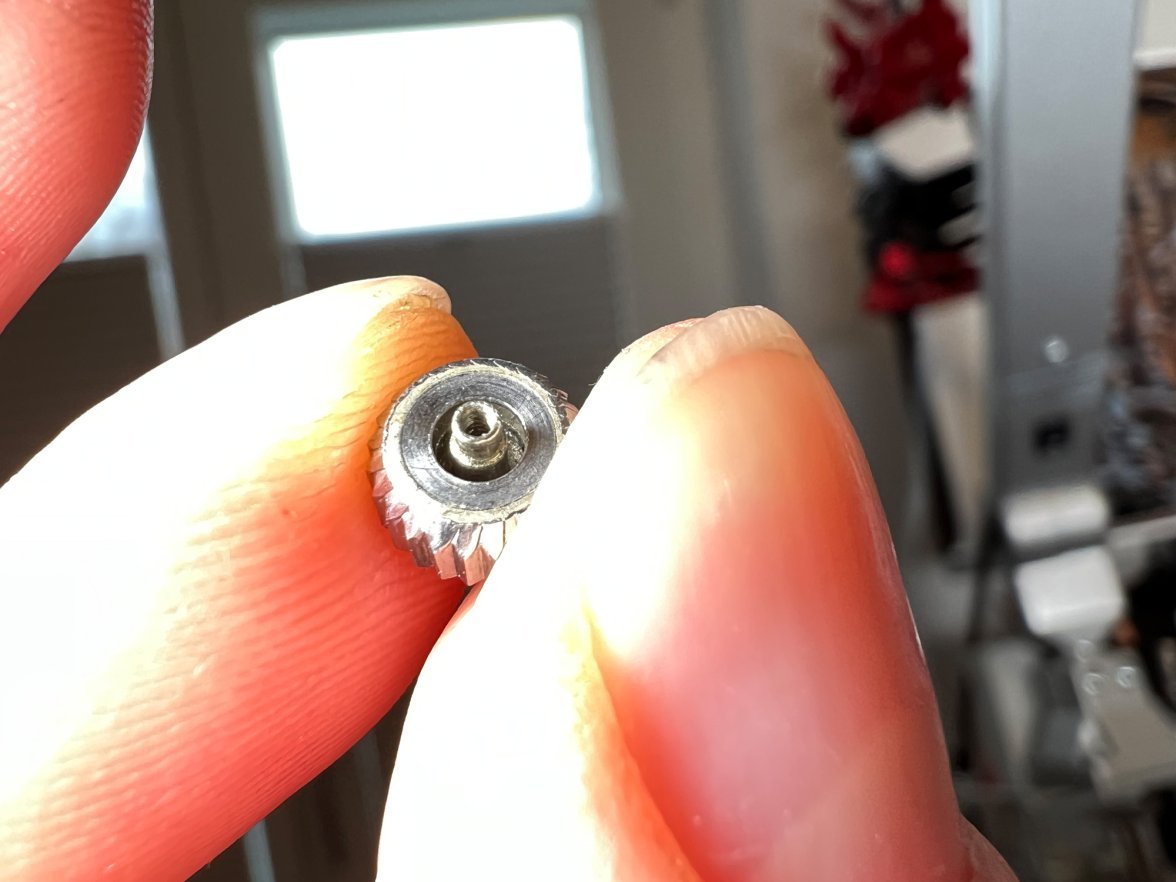

I did it on two of my other watches' crowns where the gaskets were already falling apart when I mechanically removed it step by step with fine tools. But this one's gasket is really tough and it doesn't work.

Can I bath the crown in any chemical to get it dissolve? Any hint or recommendation would be appreciated.

Thank you!

I would like to replace it.

I did it on two of my other watches' crowns where the gaskets were already falling apart when I mechanically removed it step by step with fine tools. But this one's gasket is really tough and it doesn't work.

Can I bath the crown in any chemical to get it dissolve? Any hint or recommendation would be appreciated.

Thank you!