Hello,

I have been palying with watches again lately, so I thought I could talk a little bit about some service. I have also practiced changing staff, with rather "good" and so so good results, but that will be for another post.

First, let me introduce you the new visage of one of the watches I have talked about here, my Omega 30T2 in 18K solid gold. I eventually found a dial from the correct size and decided to replace the "original" but redone dial. I switched the hands as well:

As I still was not happy with the timegrapher results, I took the occasion to change some worn parts and service the watch again. I changed the 3th and the 4th wheels, the former with a used one in better condition and the latter with a new old stock one. I wanted to change the 2th wheel as well as it has straches (yes!), but I could not find one that could engage correctly with the barrel - and I did not want to change the barrel as it would have ended in a new watch! By the way, I realised at that occasion that the cal 30 have (at least) two kinds of teeth for the barrel and the second wheel.

As a result, the amplitude get better and more regular - even if it is still not perfect, maybe due to the 2th wheel issue. So now I guess I am happy with this watch!

Second, I would like to talk about two other solid gold cal 30 - I like this stuff! I serviced them those last few days and could use the kind advices I received here. It is also a good example of the difference between a worn movement and a movement in a very good condition.

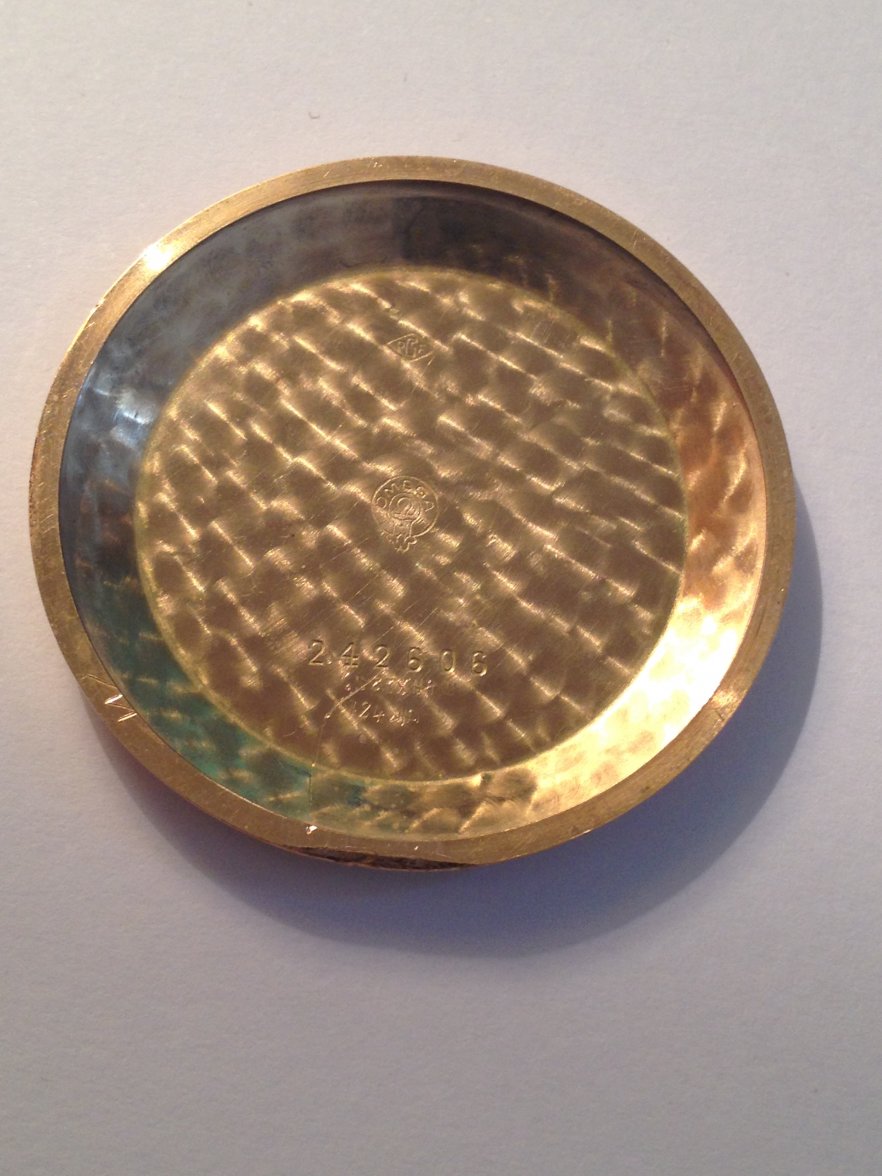

First, I got this Dennison cased 283. Quite a big size with its 3,6 cm but I like it nevertheless - I am rather a 32-35 guy!

I have serviced other watches for the last post of this thread - I barely spend a week without servicing a watch! But this time I had plenty ot time and decided to do the very best I could.

Well, there was not much to do! I was only very careful in everything I did, in particular when oiling. I remembered Chris' advice about the oiling of the mainspring: I already did like he adviced me - oiling the entire mainspring before putting it into the barrel instead of adding three points of oil when it is in the barrel - but thanks to him I have understood better the importance of doing that. Same thing with the oiling of the pallets - thanks Al this time!

I only had to correct the hairspring as it was out of shape. But I only had to touch the overcoil, so it was not too difficult. I kept the mainspring I found in the watch because it was like new.

The timegrapher results are very good, but there were at some point an issue... Excellent amplitude, even too good! Around 340 at full wind in dial up and dial down positions! I thought the mainspring could be too strong, but eventually I think it is something else - will talk about that in a few sec. Good delta over 6 positions (25 sec) without doing any dynamic posing. I could have slightly reduced it (25 sec between 3up and 9up, so I could simply have added some weight at 9), but that wasOK for me.

But I had an irregular line in some position. I mean : the line was perfectly straight, but the "points" were not "clean". I thought it could be because of the pallets. So I cleaned the pallets and the pallets bridge again, but it did not change anything. I tried to change the pallets with a used one in good condition. It changed the amplitude - back to 270 dial up and down - but not my issue. I have to say that at this point the movement was in the case.

What puzzled me was the fact that the first try of the movement on the timegrapher was very good... So I thought the issue could be due to the case. After some head scracthing I eventually found the issue:

I had not srewed tigh enough the 2 screws holding the movement into the case! Usually, I screw those tigh like the other screws, but this time not...

So now, the timegrapher results are good, with the bigger amplitude I have ever seen on a 30 cal: 340-350 dial up and down at full wind - without any rebanking, which surprised me - and 310-315 in the vertical positions.

Now I have some questions for Al, Chris and the other experts.

i) First, I would have thought a watch would rebank with a 350 amplitude. Is it strange? Maybe my cheap timegrapher does not give me the exact amplitude...

ii) Second, I know (in theory!) that the "achevage" (I do not know the English term) - the precise settings of the pallets in their relation to the escape wheel and the balance - is important and can have an effect on the amplitude. But I was suprised to see that my 340 amplitude with the current pallets became a 270 amplitude with another ancor. Is that normal?

I have changed pallets stones and corrected them in order to have a decent relation with the escape wheel. But I have not done any real "achevage" and I am reall surprise to see this difference of amplitude.

Second, a 284 in a French case. This watch came with the original band and a rare French made Omega buckle - see here:

https://omegaforums.net/threads/about-omega-buckles.37347/page-5

The service was badically like the previous one -and I kept the mainspring as well. I only had to slightly correct the hairspring: it was actually very good but a little bit out of center. I had also to correct the end shakse of the barrel, vertical and horizontal. I am not sure wether the bushing of the barrel bridge had been redone during a former service. But the bushing was a little bit to low and to tigh. Solved thanks to the staking tool, a file and an "equarissoire" - I think there are better tools but I did with what I have!

This time, the results were very good, maybe the best ones I have ever had:

Full wing + 30 min

pos rate ampl beat error

DU 6 309 0.4

DD 6 304 0.4

6up -4 272 0.4

9up -2 272 0.4

3up -3 279 0.6

Delta over 6 pos : 10

Full wind+ 24h

DU 5 300 0.5

DD 7 292 0.5

6up -4 266 0.5

9up -2 267 0.3

3up - 9 267 0.7

12h -4 271 0.6

Delta over 6 pos: 13

Please, note that I am fully aware that these results are due to the movement condition! I barely did anything to get that. Well, I think I have done my best, but obviously the movement was in a very good condition. It is really nice to see a 30 cal in its best! What a difference with my 30t2!

Thanks for reading this, and thanks for any constructive criticisms and advices you may have!

![IMG_5927[1].JPG IMG_5927[1].JPG](https://omegaforums.net/data/attachments/375/375067-ed03c29758fa8c7f497ffe3b7401a18d.jpg?hash=7QPCl1j6jH)

![IMG_5928[1].JPG IMG_5928[1].JPG](https://omegaforums.net/data/attachments/375/375068-17eac81581545891046e4658a71b4b9f.jpg?hash=F-rIFYFUWJ)

![IMG_5929[1].JPG IMG_5929[1].JPG](https://omegaforums.net/data/attachments/375/375087-f9e3d63a72607e24424003611cfa738e.jpg?hash=-ePWOnJgfi)

![IMG_5958[1].JPG IMG_5958[1].JPG](https://omegaforums.net/data/attachments/375/375608-9097ce53c22ad0598392651c0b766d7b.jpg?hash=kJfOU8Iq0F)

![IMG_5956[1].JPG IMG_5956[1].JPG](https://omegaforums.net/data/attachments/375/375609-55eead1e79de1a215b096984e08d12f0.jpg?hash=Ve6tHnneGi)

![IMG_5960[1].JPG IMG_5960[1].JPG](https://omegaforums.net/data/attachments/375/375611-05654ddb2217d86c0579c493031f55b9.jpg?hash=BWVN2yIX2G)

![IMG_5961[1].JPG IMG_5961[1].JPG](https://omegaforums.net/data/attachments/375/375612-4ae76894e5025cd9c72b3e3dab5c7eb6.jpg?hash=SudolOUCXN)

![IMG_5957[1].JPG](/data/attachments/375/375607-26f32498a4ea490431d56f6400186390.jpg?hash=JvMkmKTqSQ)

![IMG_5959[1].JPG](/data/attachments/375/375610-aa331bed3a7afdfd8f9af0576e06302b.jpg?hash=qjMb7Tp6_f)