Dear me........almost a week away from this job. Amazing how other issues in life can get in the way, I must learn to ignore them.

Following oiling guidance from Al I ordered some quartz oil (only a day lost waiting for delivery) but before I could get back to it, my mate (whose incapacitated) needed a storage solution for his kayak, so another day lost in travelling over there, organising all the parts etc. Then another day lost as we had lunch in the city with friends but I eventually managed to get back to work.

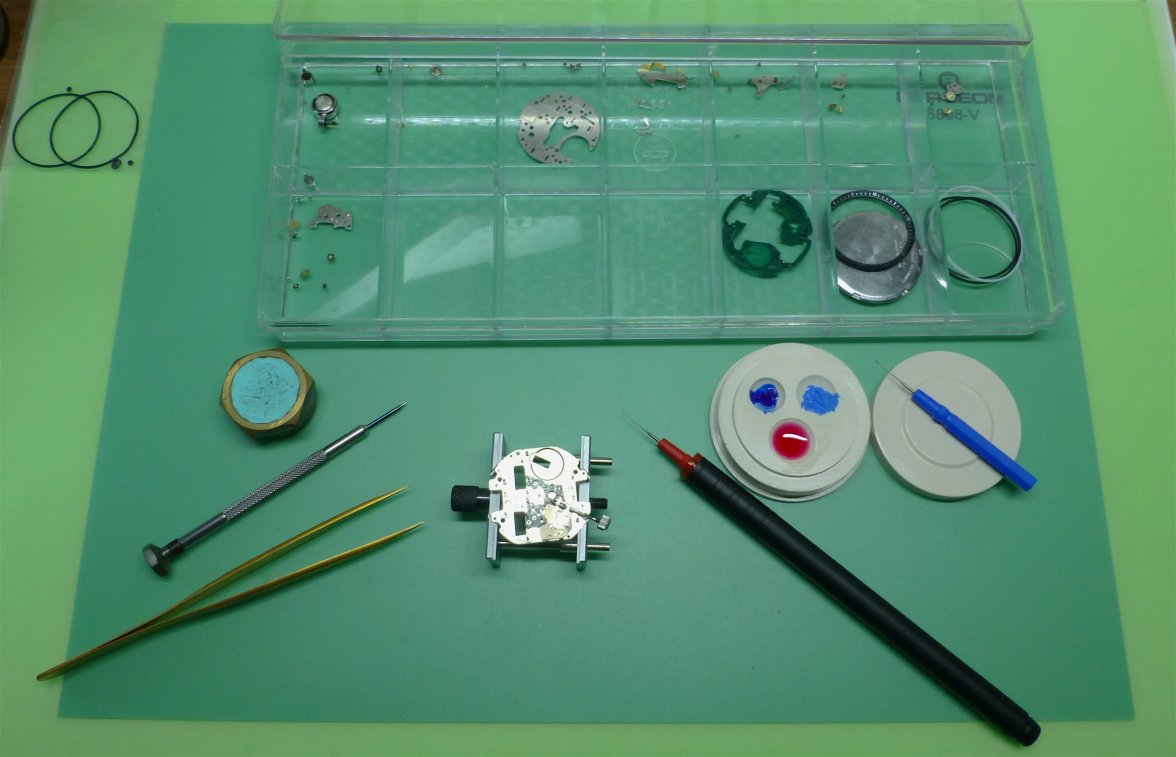

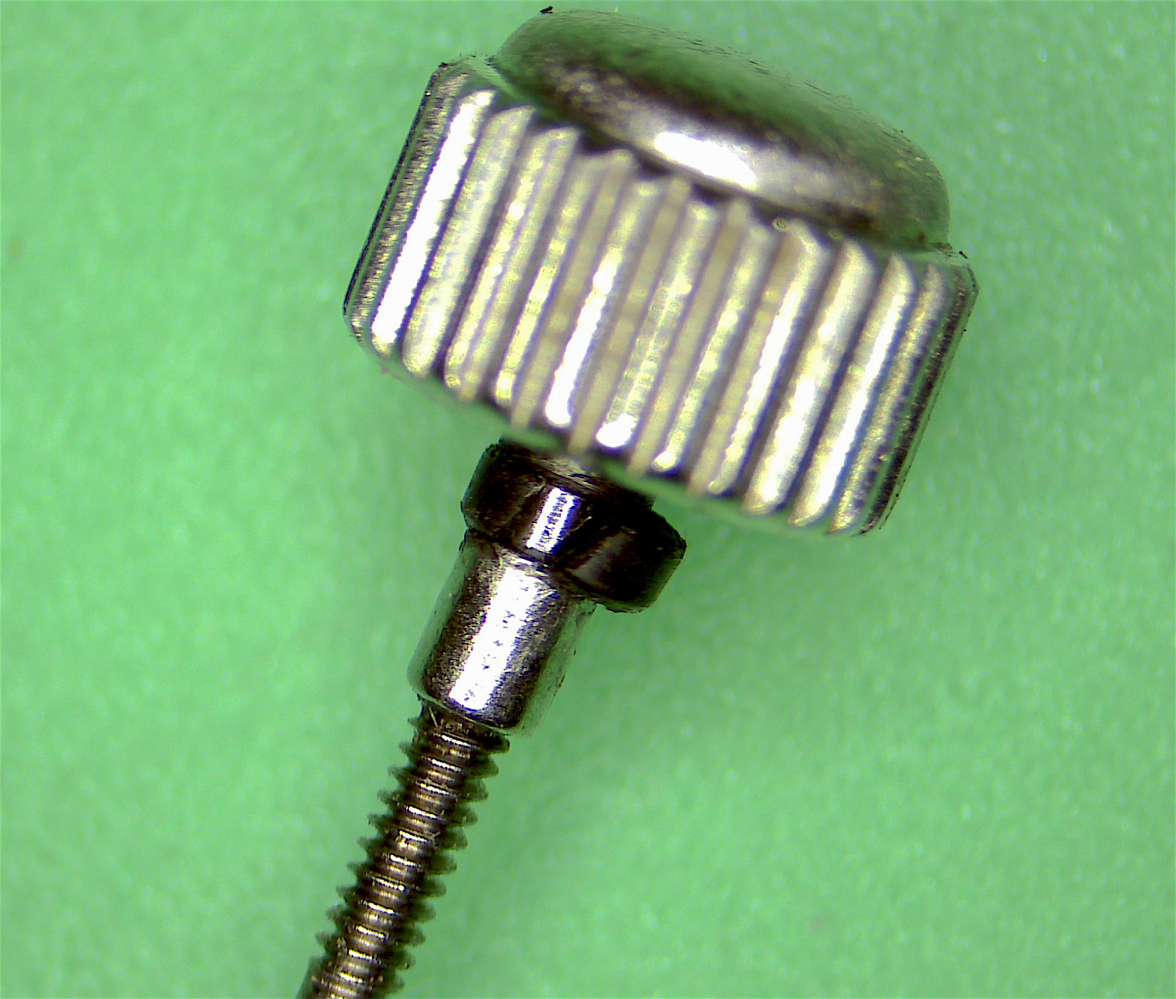

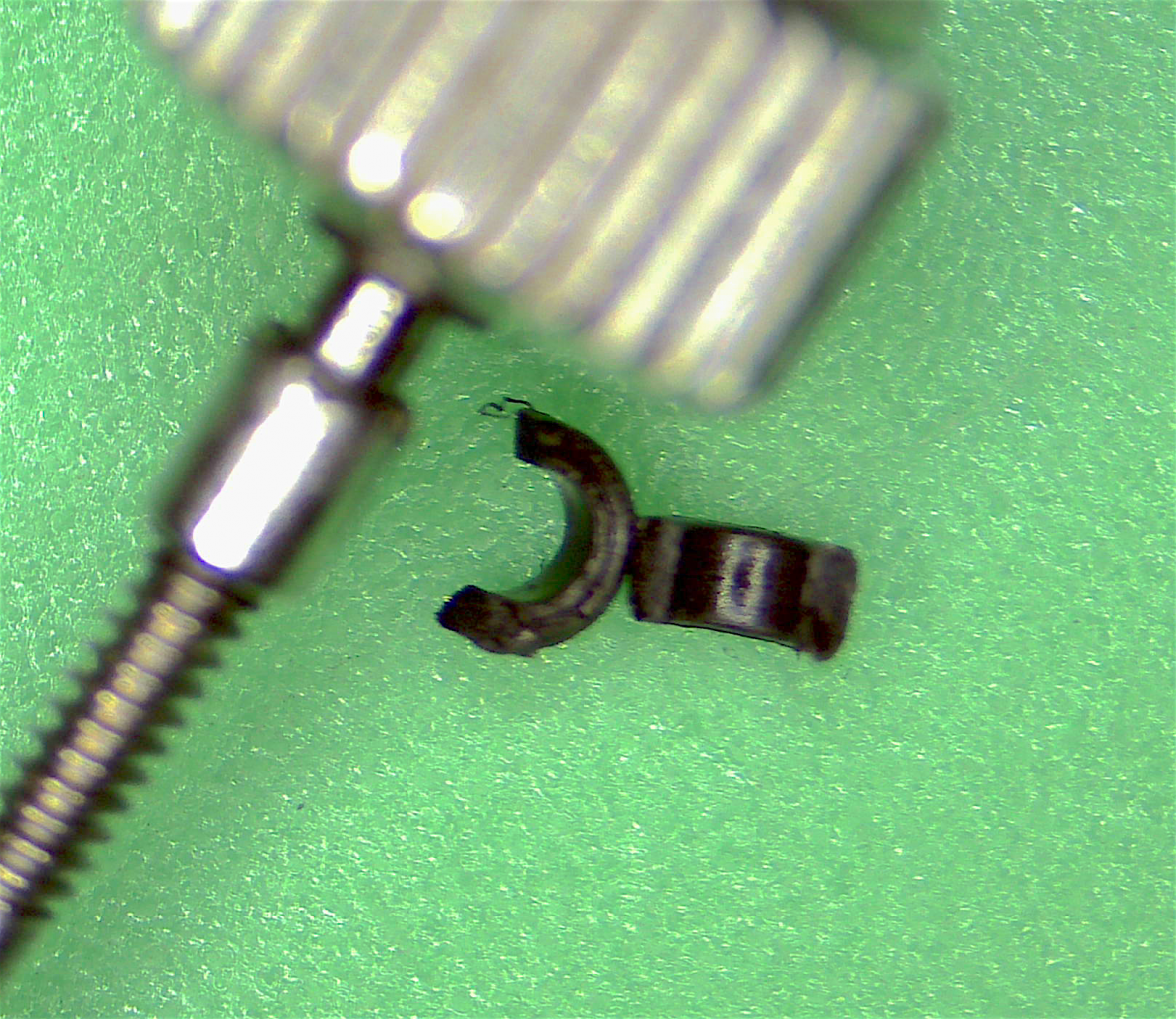

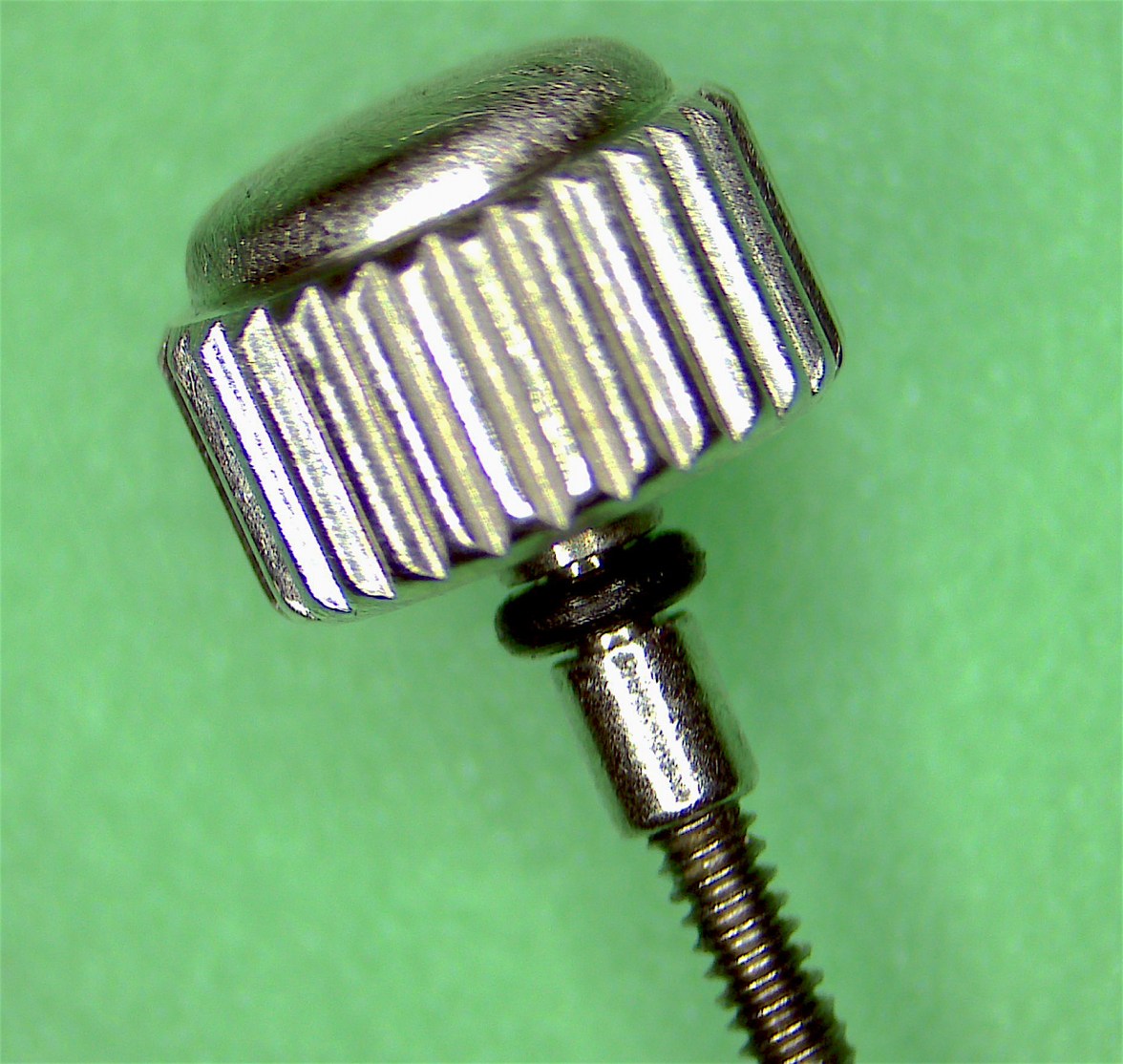

With the bare plate ready, the rotor stators were put on their respective posts, minute wheel and centre wheel/pinion dropped in and then the setting parts were lubricated and fitted. Only one spring involved and it was quite easy to set it on the plastic plate. So, stators (hard to see here) crown/stem and all setting parts in place.

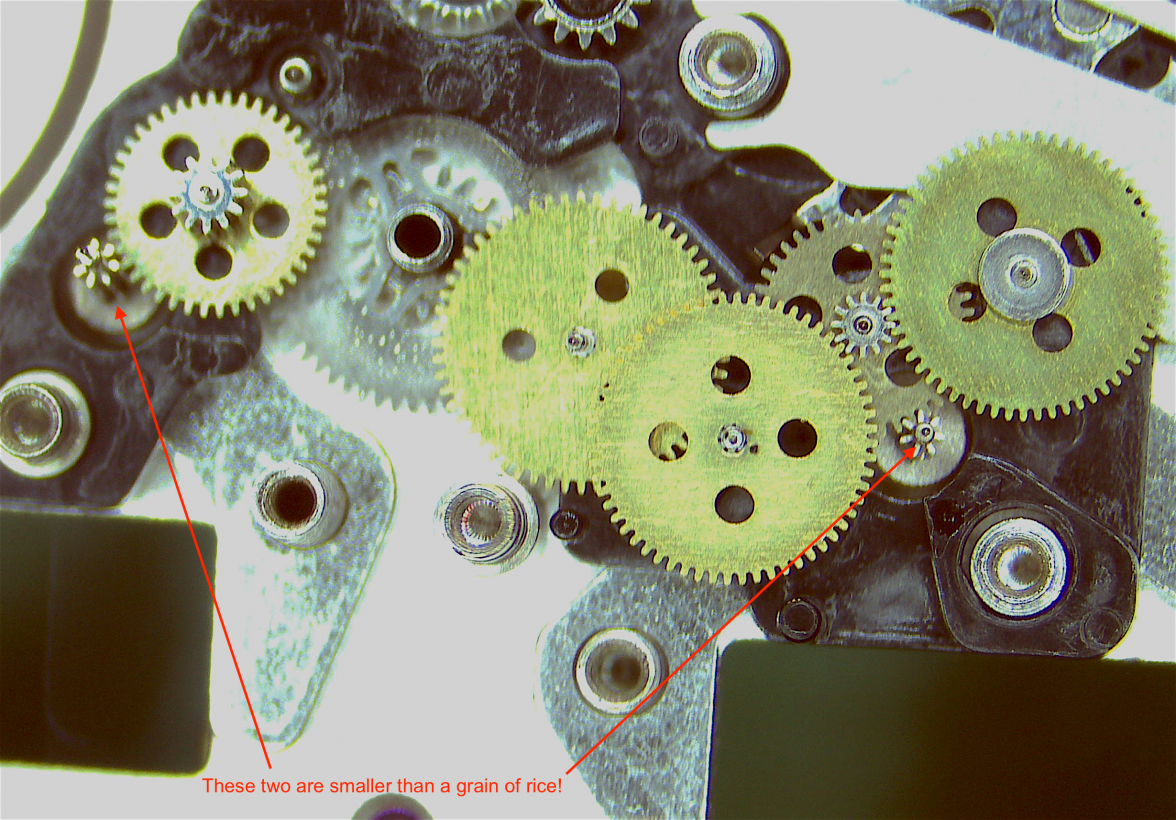

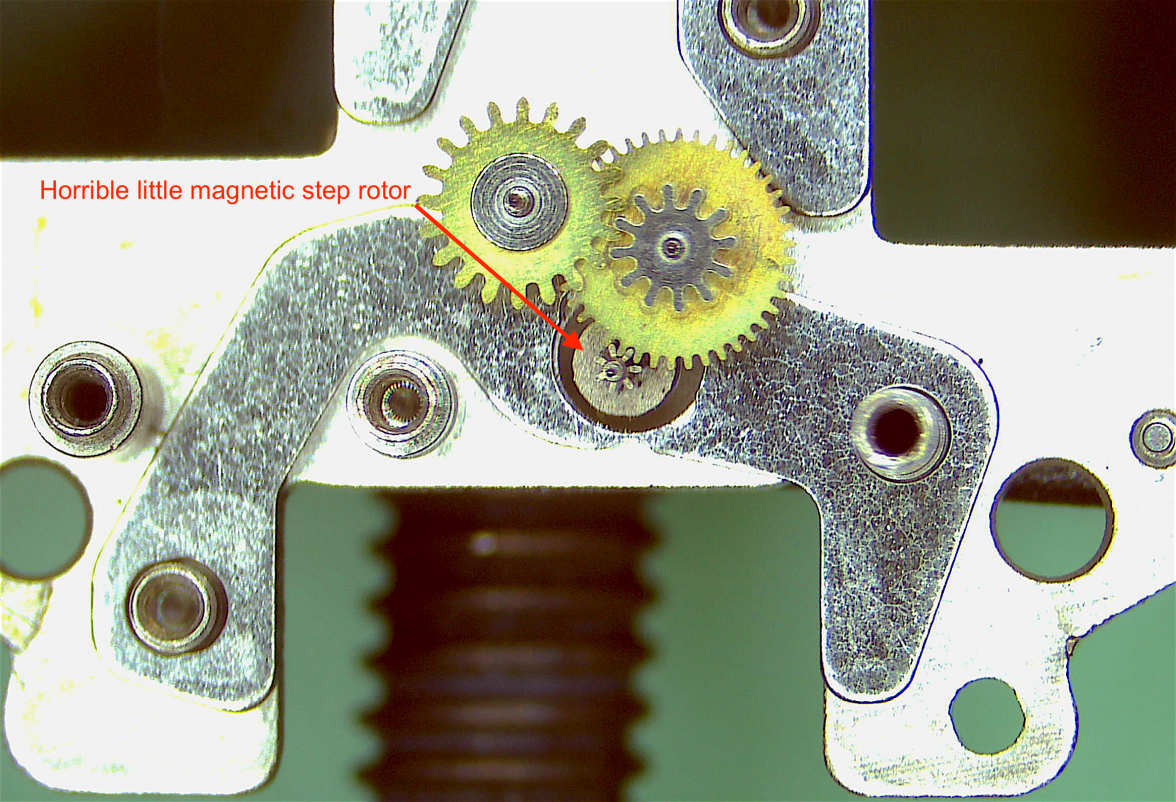

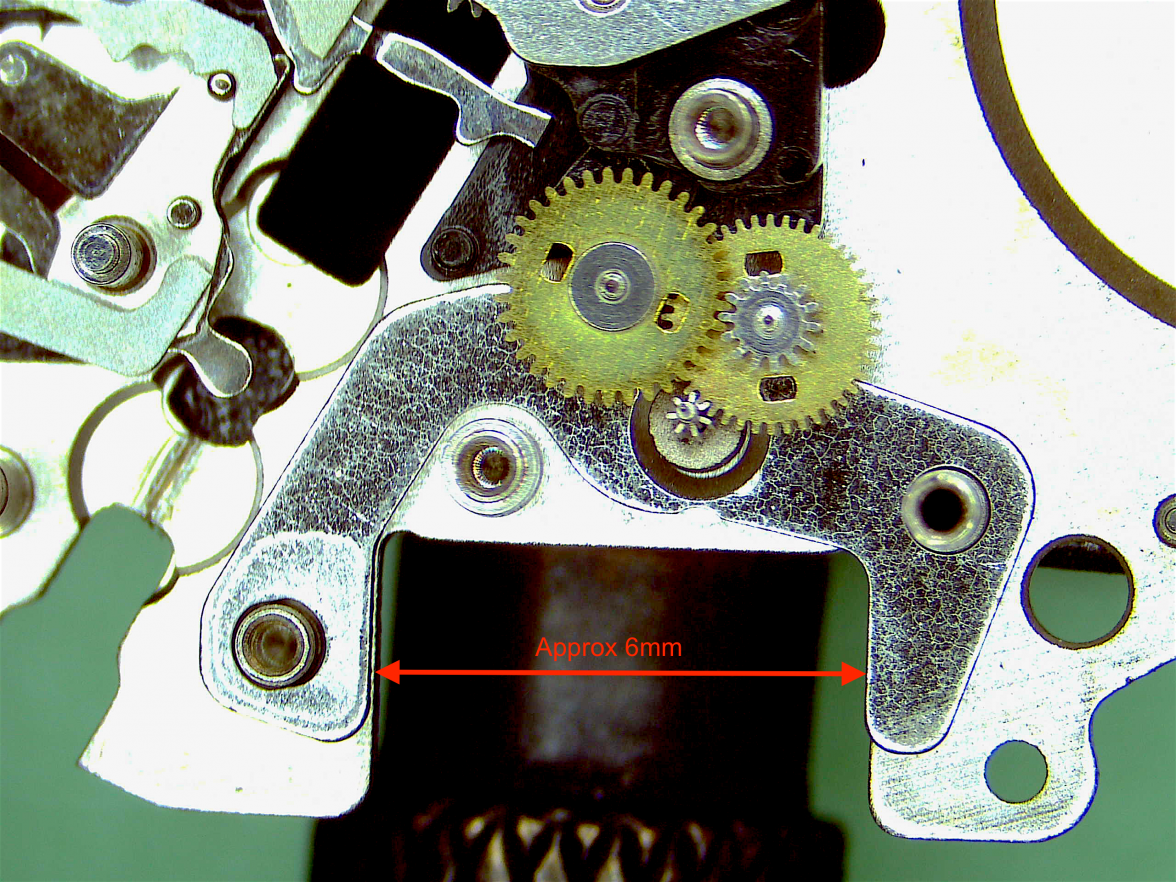

Then the fun part started, assembling the gear trains. The main one is a PITA, there are ten wheels/rotors and getting them all aligned (with the two rotors being magnetic) is a real test of patience. This is a shot of the train after I had removed the bridge. Those wheels are TINY!

After much cursing at tiny parts under my breath, a couple of "get up and walk away" breaks I had the main bridge on without crushing anything. The other three bridges followed quickly, some of the wheels needed to be oiled before installation and being so small made it a bit of a challenge not to get too much oil on them, all went fine though.

A couple of shots of the other gear trains so you can see how tiny they are.

The gap in the rotor stators is only about 5 or 6mm.

It was a real sense of satisfaction getting them all nailed down. Next step was to fit the coil blocks, delicate copper wire windings are thinner than a human hair so very careful picking them up from their temporary home and fitting them on the plate (in their correct locations!).

The main plastic spacer could then be put on, followed by the circuit block (or rather the "circuit film"). Lastly, the main cover plate and battery parts and the movement was back in one piece again. The old battery was fitted and the movement checked visually to ensure it was working.

So here we are, getting close. The next step is to fit the dial side parts, dial and hands.