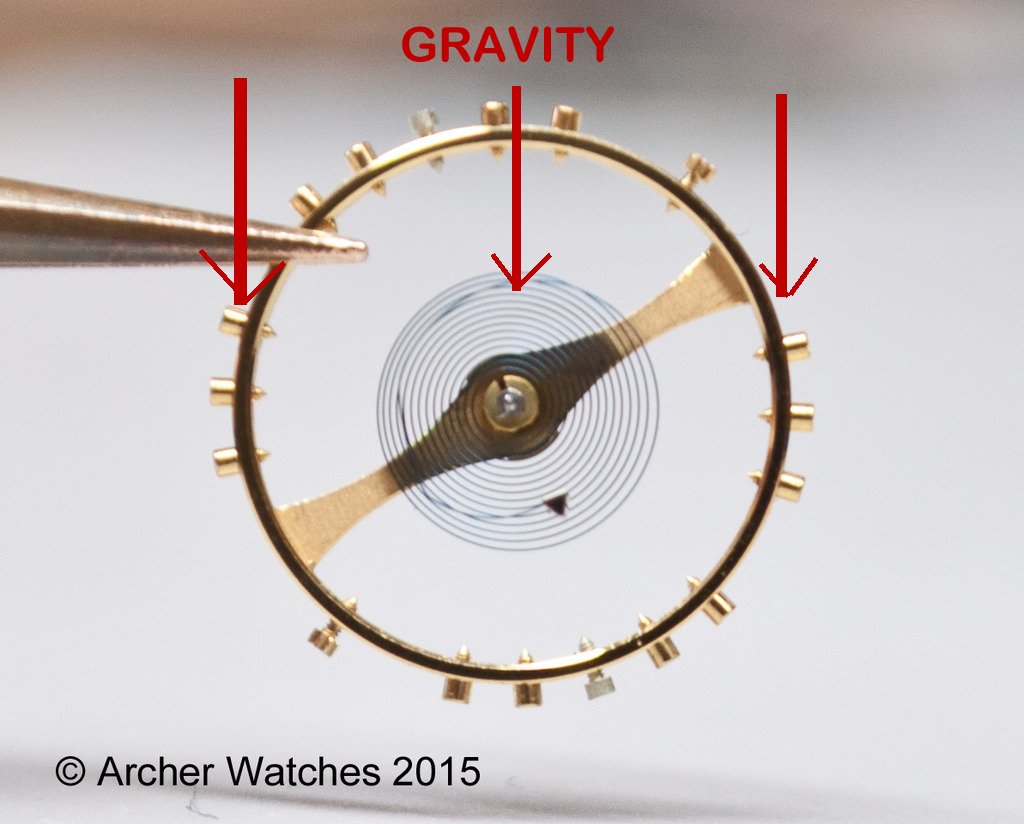

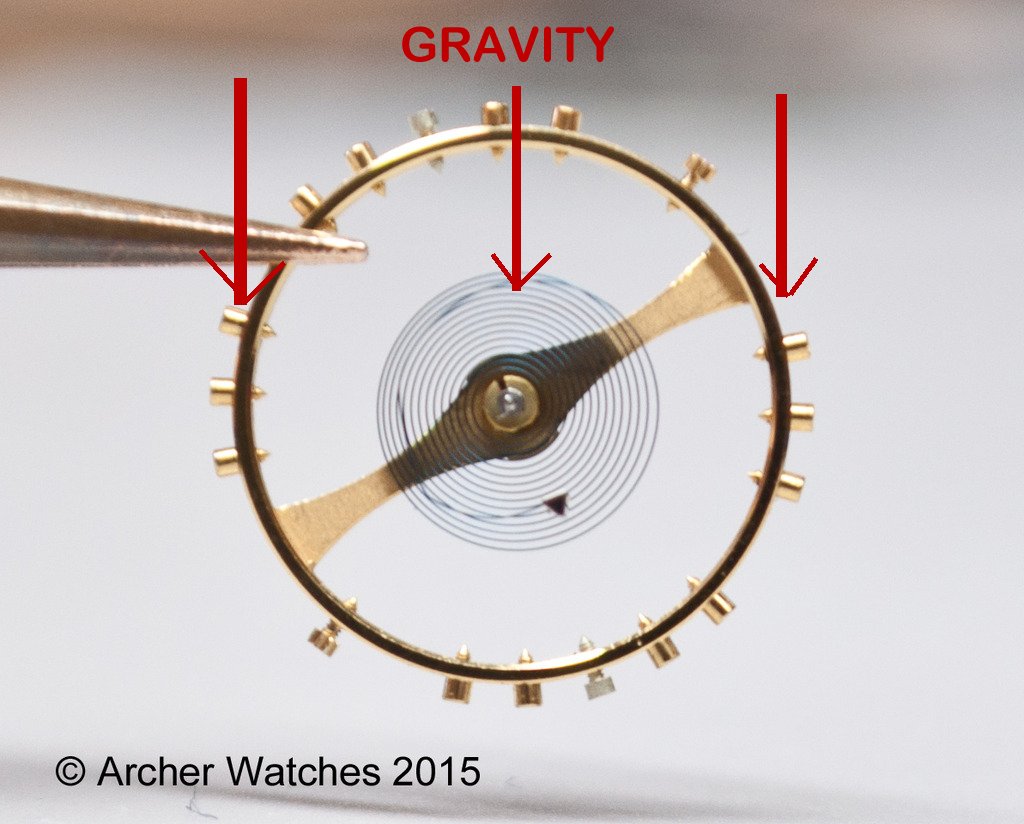

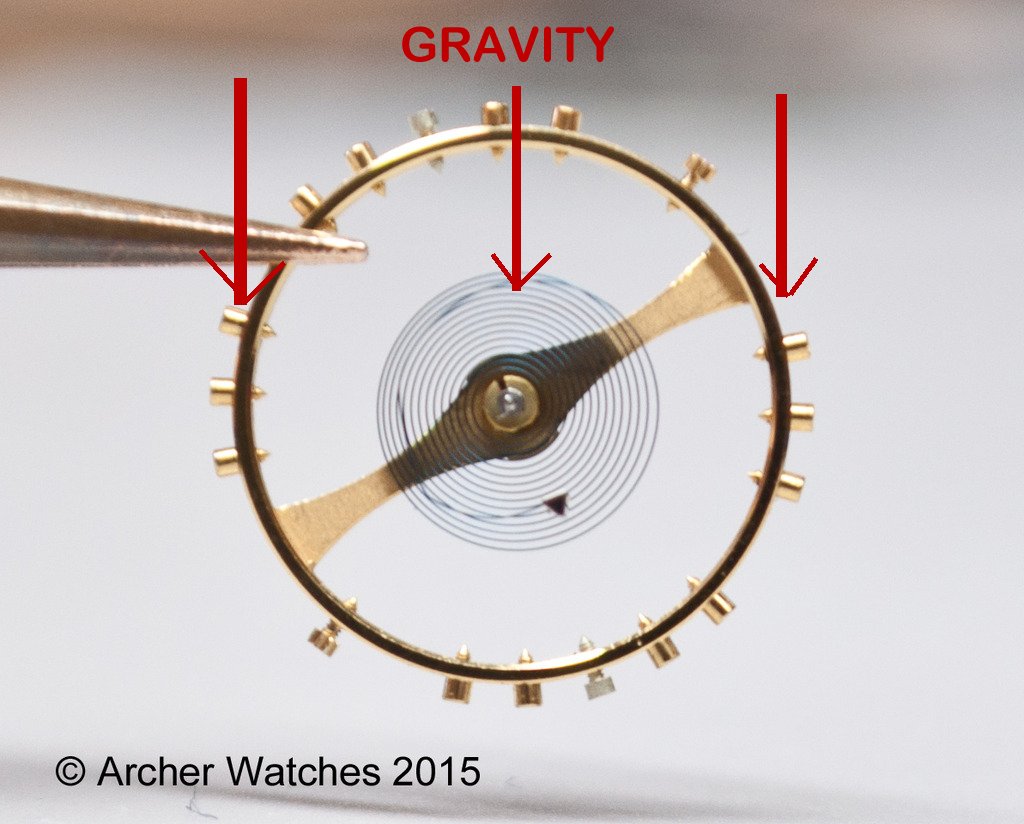

The balance wheel is subjected to drag, and not much friction. And now you've illustrated the effect of gravity on the pivots. And there is much more to it than these two. Your post just proves my point even more, i.e. that the position of the watch affects the time keeping (which can be used to speed up or slow down the watch).

If your point is that watches have variation in positions, and that can be used to self regulate by storing it in different positions at night, then yes of course that is common knowledge - there's nothing to prove there. Just keep in mind that the bulk of the work in timing the watch is to eliminate as much positional variation as possible, so having less variation is the goal. It's very difficult to get zero variation, but sometimes you can get very close - total variation over 6 positions of 1.6 seconds:

The balance certainly has aerodynamic drag, and how much drag a particular balance may have is greatly affected by the style and shape. For example all else being equal a smooth balance like this:

Will have less drag than a balance with screws, like this:

But the amount of aerodynamic drag is constant, and doesn't change with the position of the watch - it would only change if the balance was changed somehow. If you are asserting that it does change with position, you will have to explain exactly how that happens.

The friction in the system isn't huge certainly (or the manufacturer isn't doing their job very well), but you appear to be underestimating it's effects. The photo of the pivot I showed in a previous post was one I was burnishing round again, as it had flattened over years of running. Just to give some perspective on how much a small amount of added friction can make on balance amplitude, this is the pivot before the final burnishing was done - you can see it has a rather large flat spot, and only a small radius on the end:

Burnishing in the Jacot tool:

And the pivot end is almost completely rounded:

This pivot is 7/100ths of a mm in diameter, and just this amount of additional burnishing making it rounder and eliminating a very small amount of friction, changed the balance amplitude 20 degrees in the horizontal position, so although the amount of friction is indeed very small, it doesn't take a lot of it to have a large impact on balance amplitude.

Positional variation is made of up of a lot of things and balance amplitude loss from frictional loads is one of them. There are a host of different factors that come into play, so everything from pinning point of the balance spring, spacing of regulating pins, location of balance spring between regulating pins, how well the balance is poised both statically and dynamically in particular (acceleration through the lift angle being -ve or +ve), and many other things determine how a watch runs in positions. But all the work I do on a watch to get it running properly is meant to compensate for these problems.

As I've been saying all along, it's a complex system that is not well suited to simple generalizations.

Cheers, Al