Deafboy

··His Holiness Puer SurdusHi All,

I'm having a few issues servicing a Longines 23M movement and perhaps members can offer insight. I've successfully serviced several manual vintage movements but this is my first with a flat hairspring - the others had an overcoil design.

There are three issues:

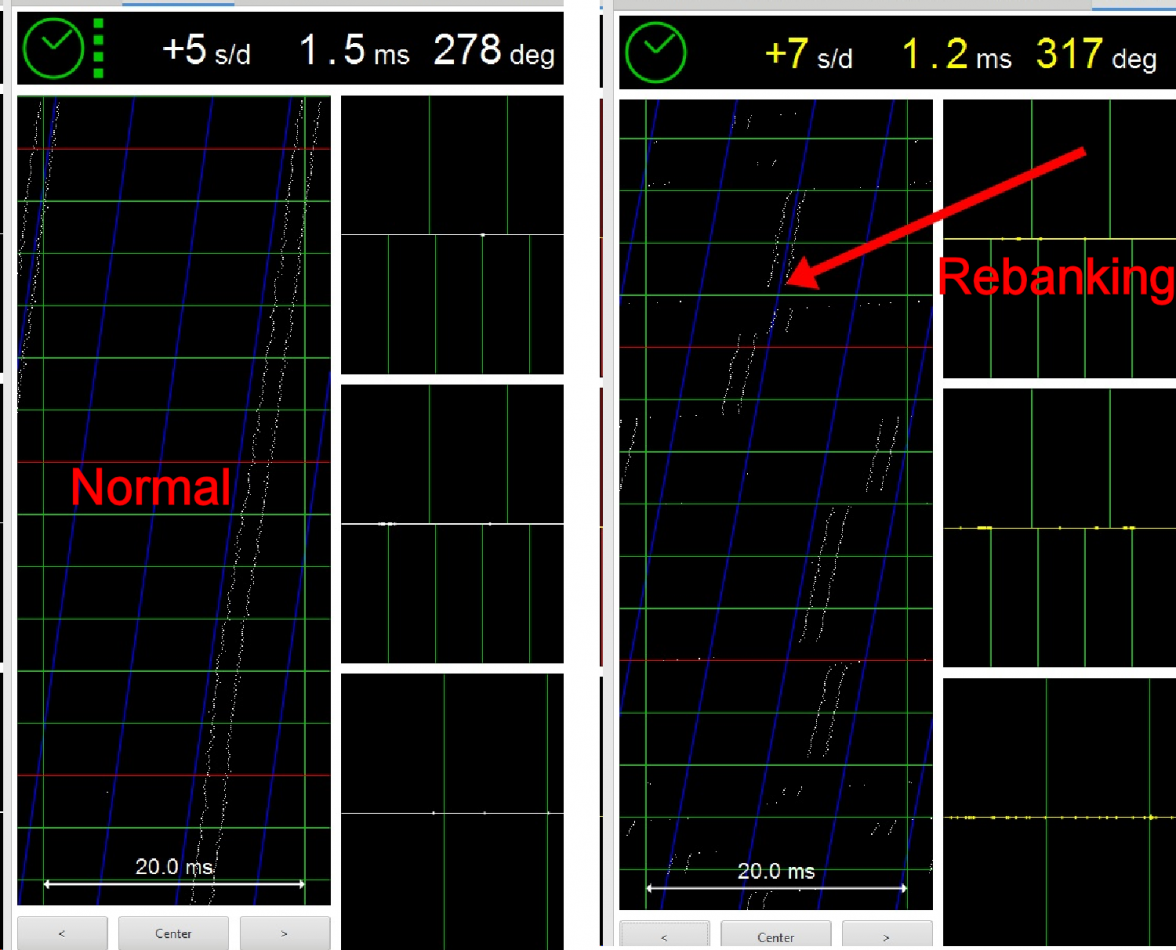

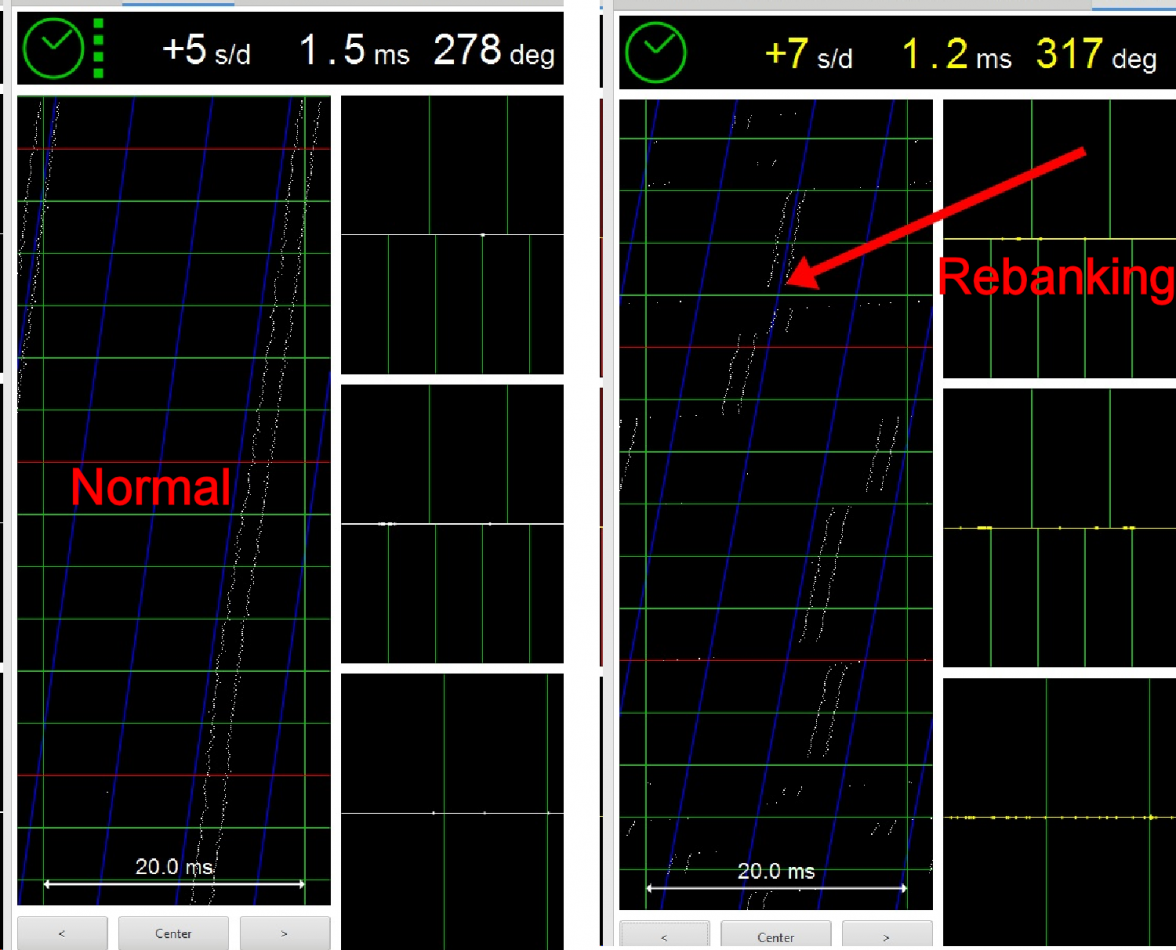

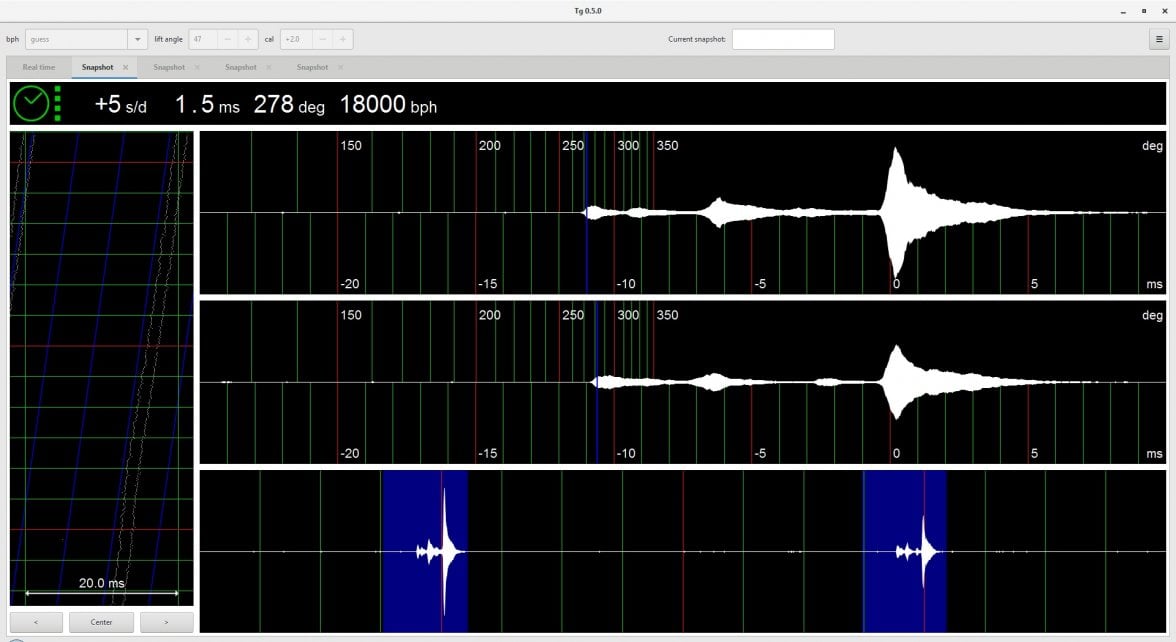

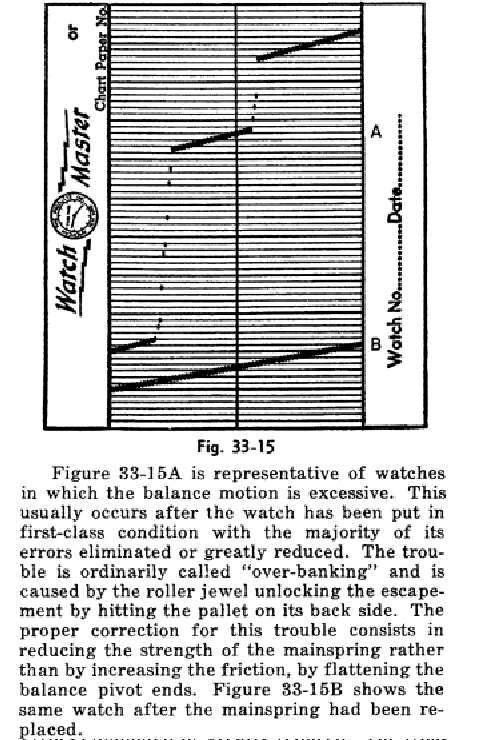

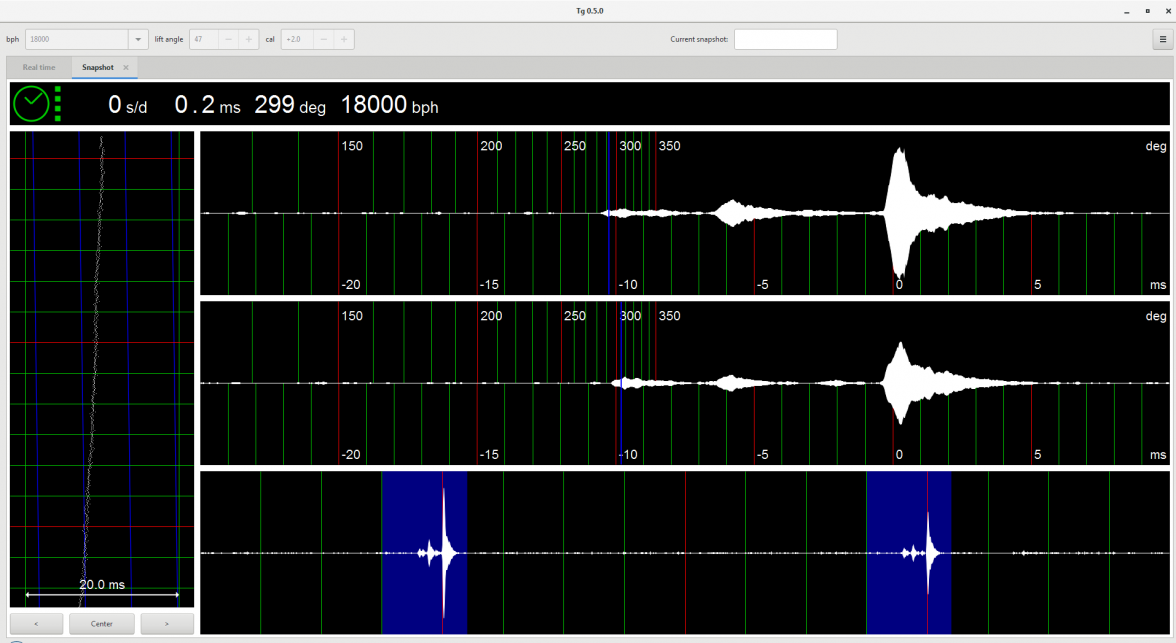

1) Way too much amplitude. I replaced the mainspring ("white alloy" type) because the blue steel mainspring that came with the watch had "set". This replacement is supposed to be made for the 23M but the I'm getting over-banking in the horizontal positions even half-wound. Fully wound the vertical positions have an amplitude around 300 degrees. Could it be vintage Longines had been designed with more friction in mind (e.g. in the form of lubricants) or is it that my new mainspring simply too powerful?

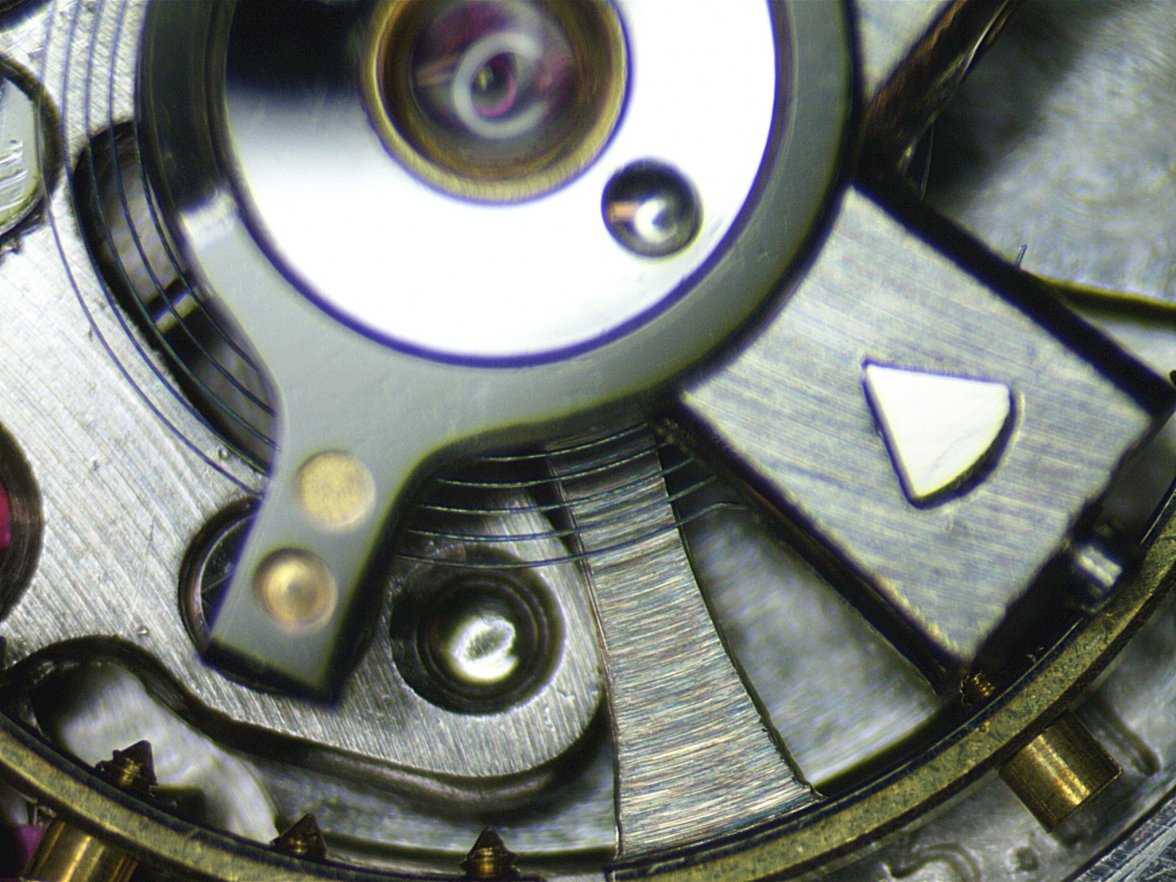

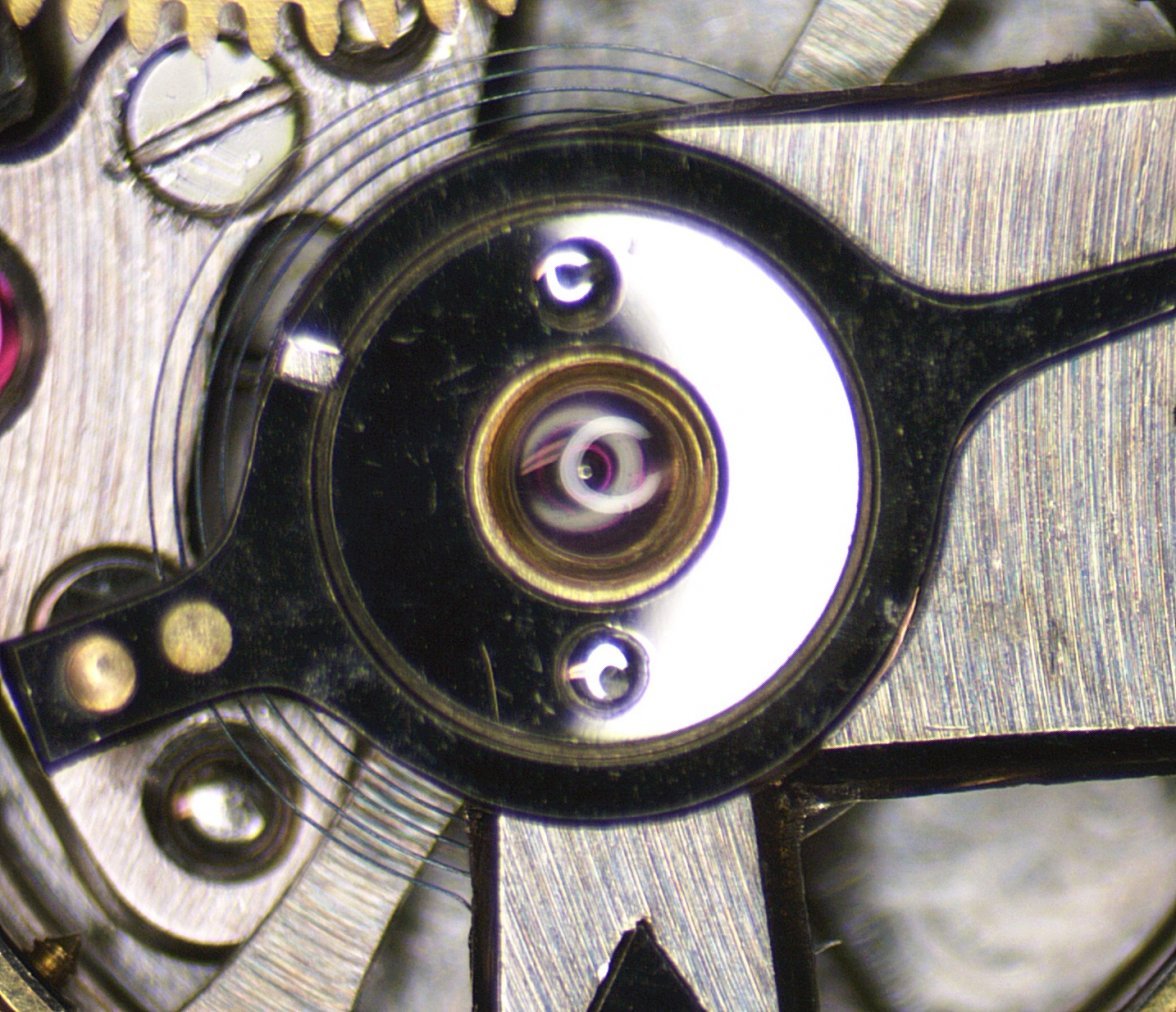

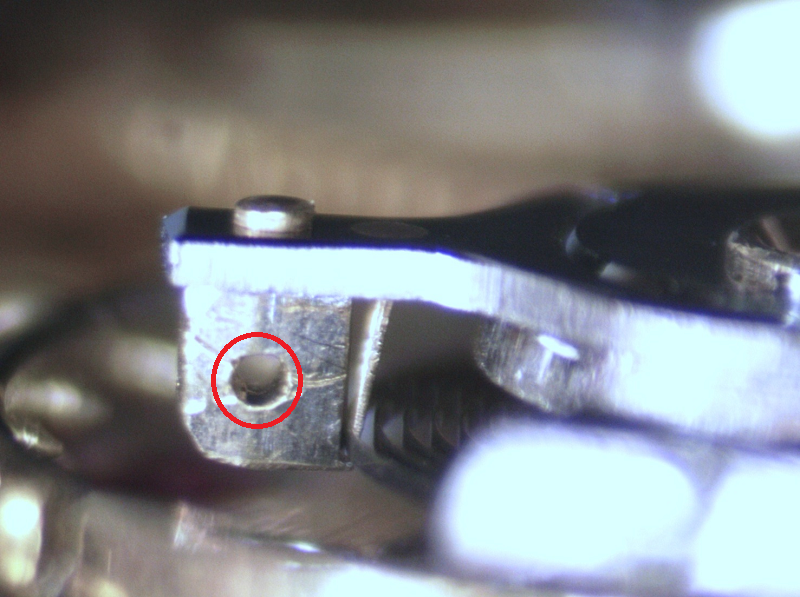

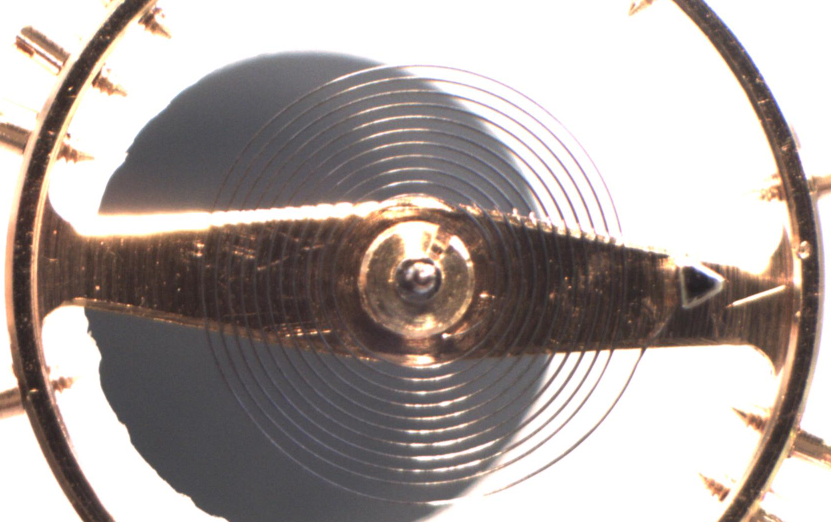

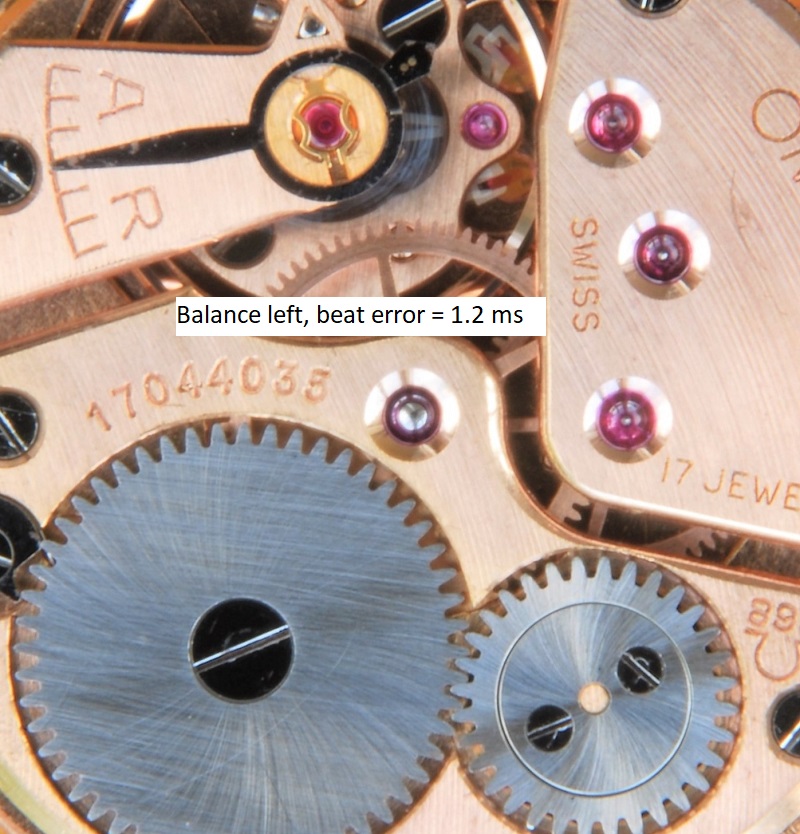

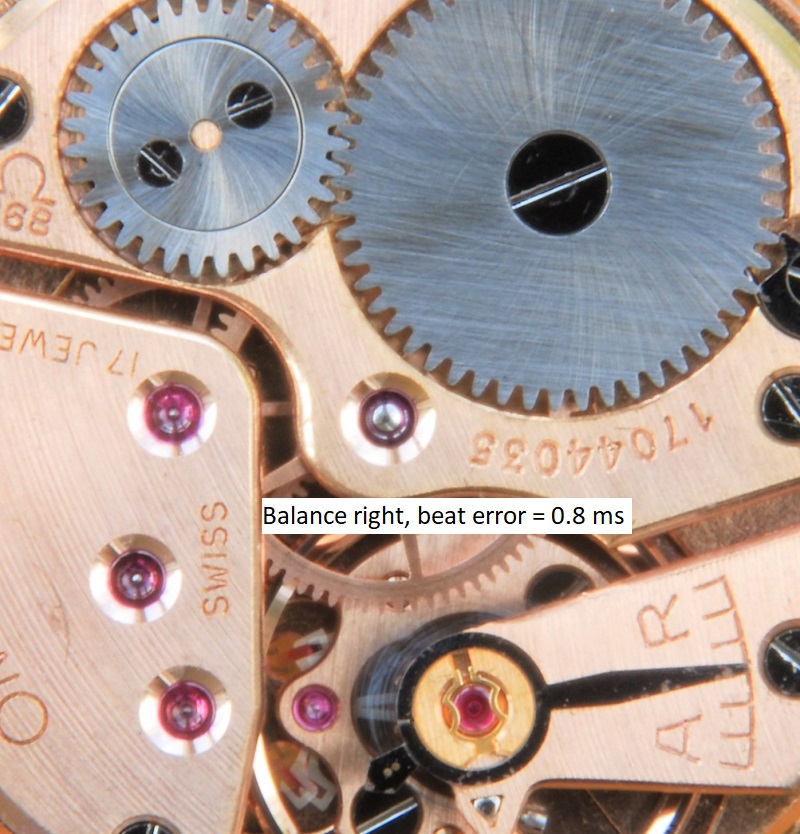

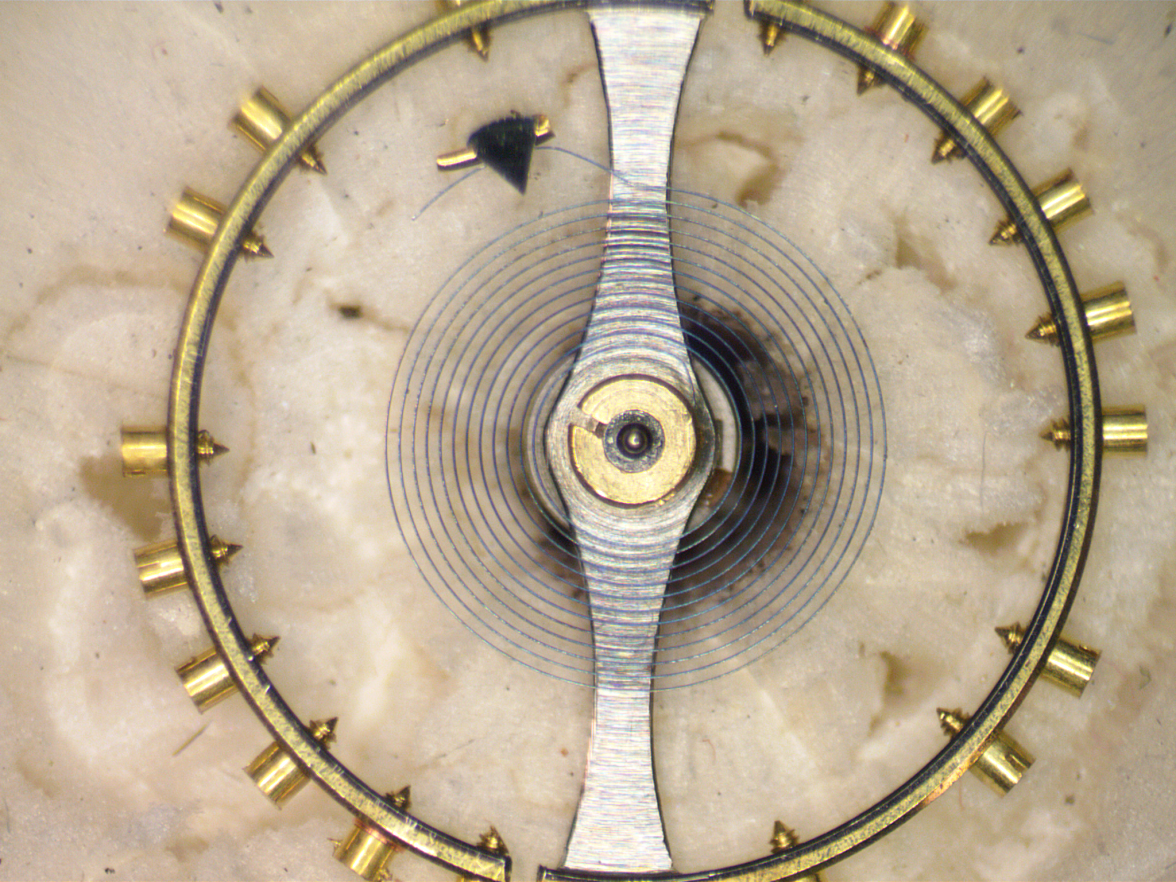

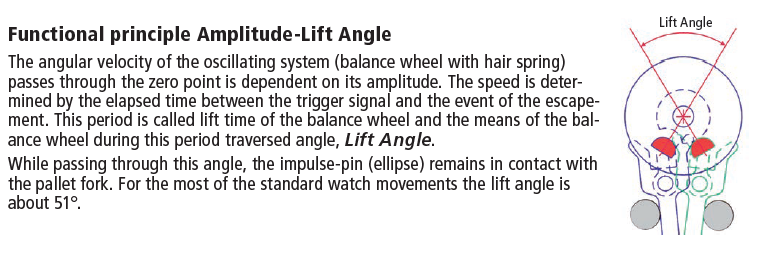

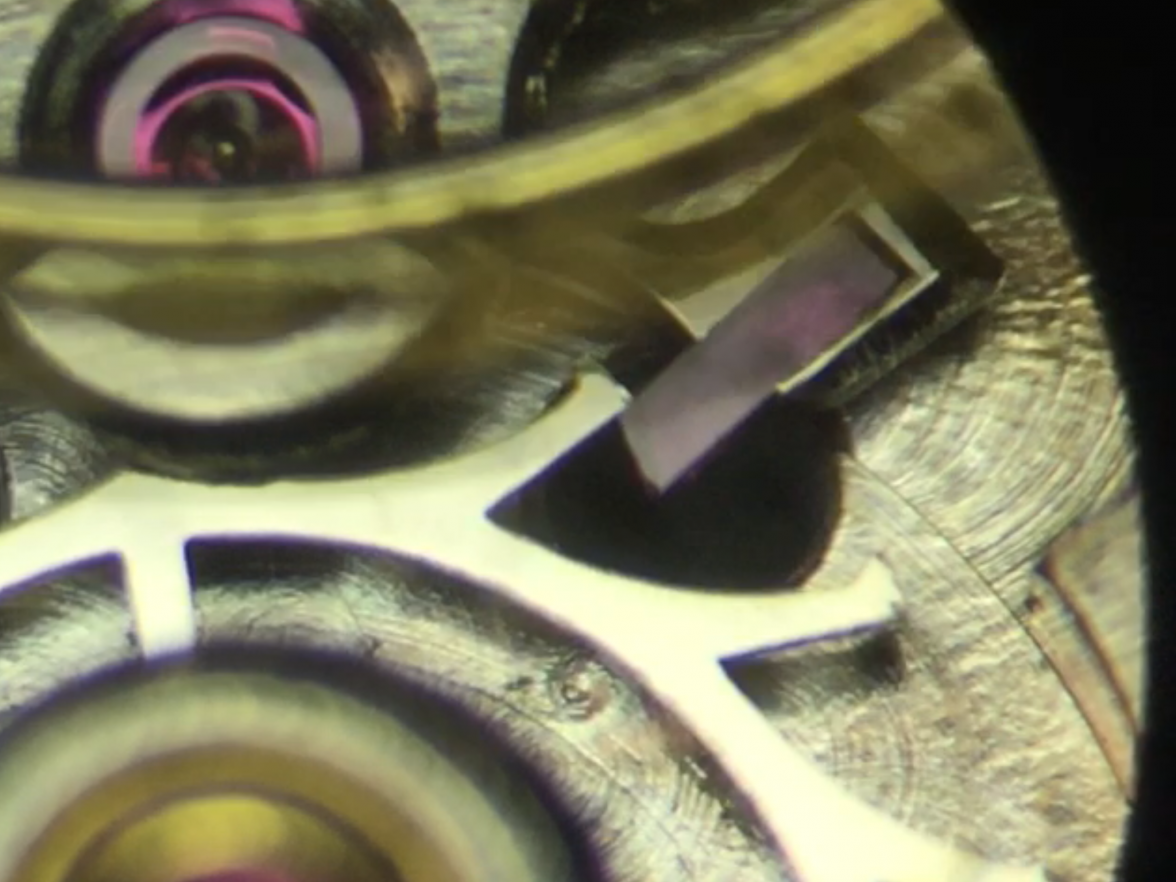

2) Hairspring movement. The hairspring is a flat design but curiously the there is no "terminal curve" in the region of the regulator. It is simply the spring spiral going through the regulator (see picture). The spring is bent close to the stud (can just be seen in the picture below). The regulator is not a pair of pins but a pin on the inside and a larger block on the outside. If I leave the pin vertical then the second spiral hits the pin during oscillation. If I bend the pin towards the outside (closer to the block, reducing the gap) the pin is no longer vertical but at least the second spiral doesn't rub against the pin.

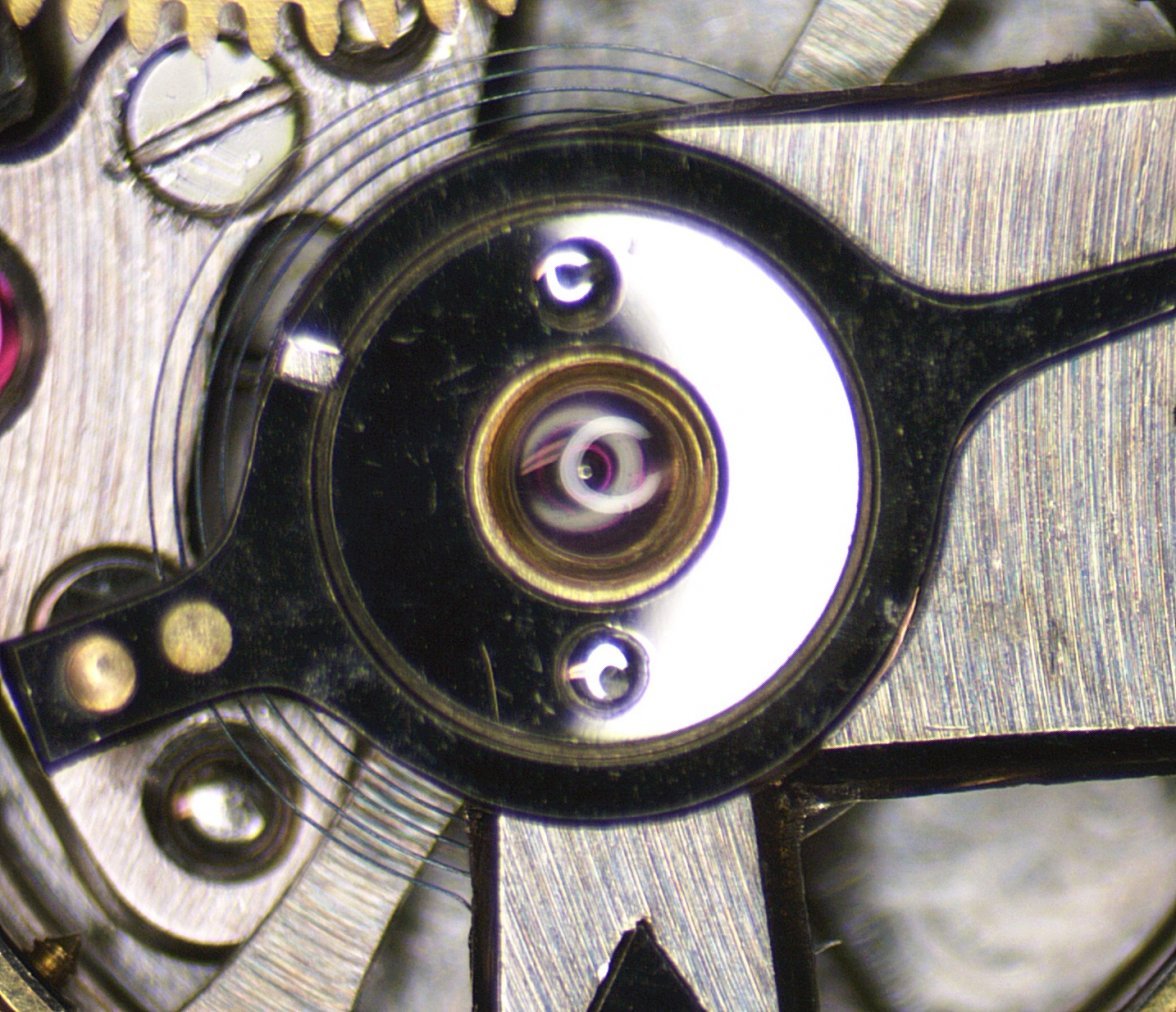

3) Hairspring movement. Again because there is no terminal curve, while oscillating the second spiral hits the outer spiral near the stud. Here's a link to a video that shows the motion of the hairspring. The file is about 20MB and recorded at 120 fps, so if you are using VLC to view it you can reduce the playback speed to have a slow-motion view.

I'm not sure what is happening with the hairspring. Was it a replacement that was never properly formed? or a design that I haven't figure out...

I'm having a few issues servicing a Longines 23M movement and perhaps members can offer insight. I've successfully serviced several manual vintage movements but this is my first with a flat hairspring - the others had an overcoil design.

There are three issues:

1) Way too much amplitude. I replaced the mainspring ("white alloy" type) because the blue steel mainspring that came with the watch had "set". This replacement is supposed to be made for the 23M but the I'm getting over-banking in the horizontal positions even half-wound. Fully wound the vertical positions have an amplitude around 300 degrees. Could it be vintage Longines had been designed with more friction in mind (e.g. in the form of lubricants) or is it that my new mainspring simply too powerful?

2) Hairspring movement. The hairspring is a flat design but curiously the there is no "terminal curve" in the region of the regulator. It is simply the spring spiral going through the regulator (see picture). The spring is bent close to the stud (can just be seen in the picture below). The regulator is not a pair of pins but a pin on the inside and a larger block on the outside. If I leave the pin vertical then the second spiral hits the pin during oscillation. If I bend the pin towards the outside (closer to the block, reducing the gap) the pin is no longer vertical but at least the second spiral doesn't rub against the pin.

3) Hairspring movement. Again because there is no terminal curve, while oscillating the second spiral hits the outer spiral near the stud. Here's a link to a video that shows the motion of the hairspring. The file is about 20MB and recorded at 120 fps, so if you are using VLC to view it you can reduce the playback speed to have a slow-motion view.

I'm not sure what is happening with the hairspring. Was it a replacement that was never properly formed? or a design that I haven't figure out...

Edited: