lindo

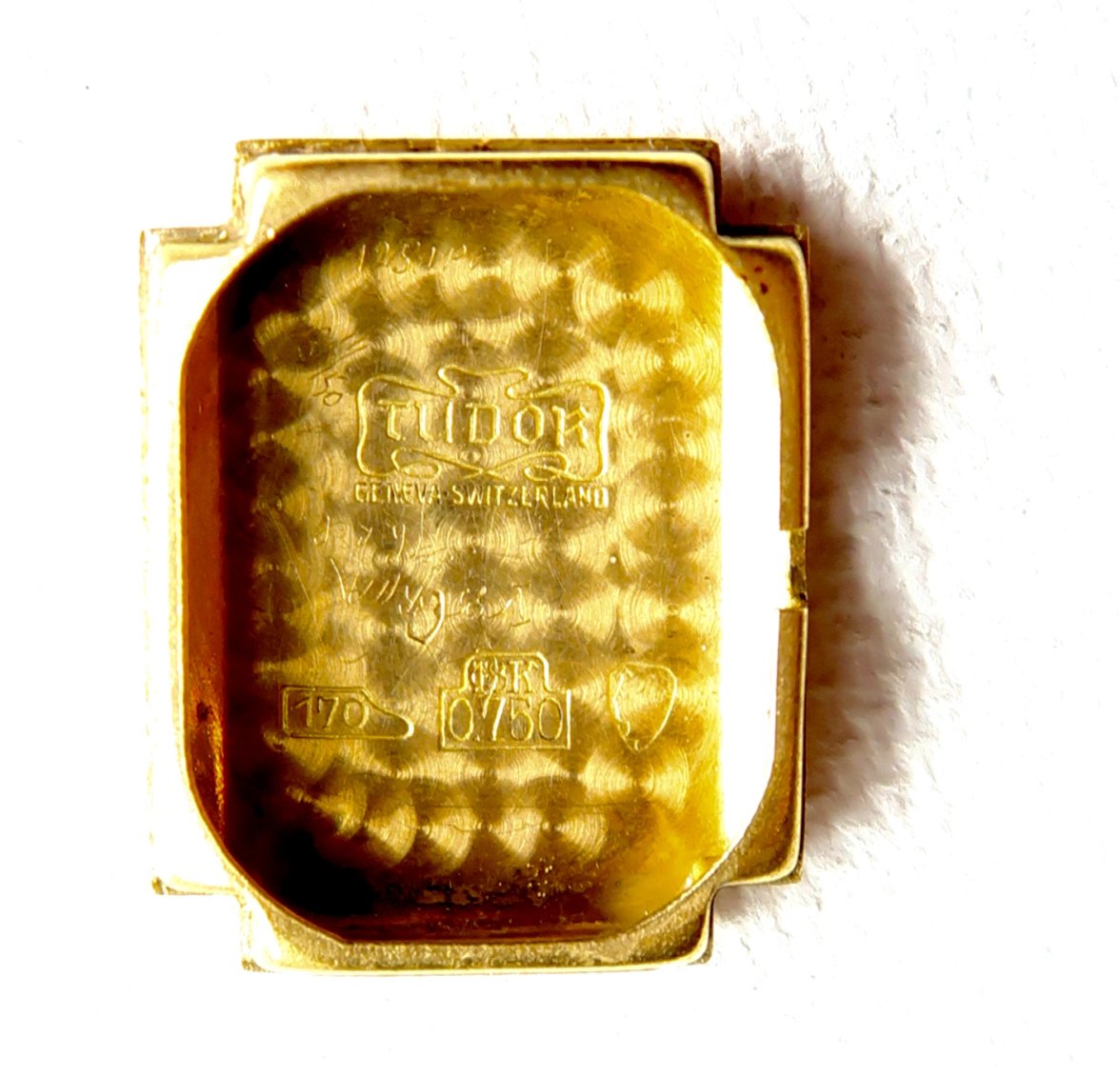

·Recently my charity shop lurking wife brought home a $2 special. It was a ladies dress watch by Tudor cased in 18k gold, so she knew she had found a bargain. Its case was also in very good condition, but the dial was a wreck.

Knowing how much my life is lifted by restoration projects, she gave it to me. Yes, I know I am a lucky man.

I had never tackled a dial restoration before, but had read some interesting stuff on line. I thought that as the watch was basically a lost cause - other than scrapping the case for its gold value - I would see what I could do to improve the dial.

I knew I could not remove the peeling layer without losing the Tudor brand print and the Swiss Made print, but decided to go ahead anyway. As the movement and the case back are both signed Tudor, I felt that was a reasonable compromise.

Methylated spirits applied carefully with a wooden tooth pick removed the top layer (and all the print). Then a favoured silver cleaner applied with a toothpick slowly removed the tarnished areas around the indices.

This is the result. It obviously is not a professional job and could do with more work, but for a $2 investment it will do.

So here is the cleaned up watch.

Knowing how much my life is lifted by restoration projects, she gave it to me. Yes, I know I am a lucky man.

I had never tackled a dial restoration before, but had read some interesting stuff on line. I thought that as the watch was basically a lost cause - other than scrapping the case for its gold value - I would see what I could do to improve the dial.

I knew I could not remove the peeling layer without losing the Tudor brand print and the Swiss Made print, but decided to go ahead anyway. As the movement and the case back are both signed Tudor, I felt that was a reasonable compromise.

Methylated spirits applied carefully with a wooden tooth pick removed the top layer (and all the print). Then a favoured silver cleaner applied with a toothpick slowly removed the tarnished areas around the indices.

This is the result. It obviously is not a professional job and could do with more work, but for a $2 investment it will do.

So here is the cleaned up watch.