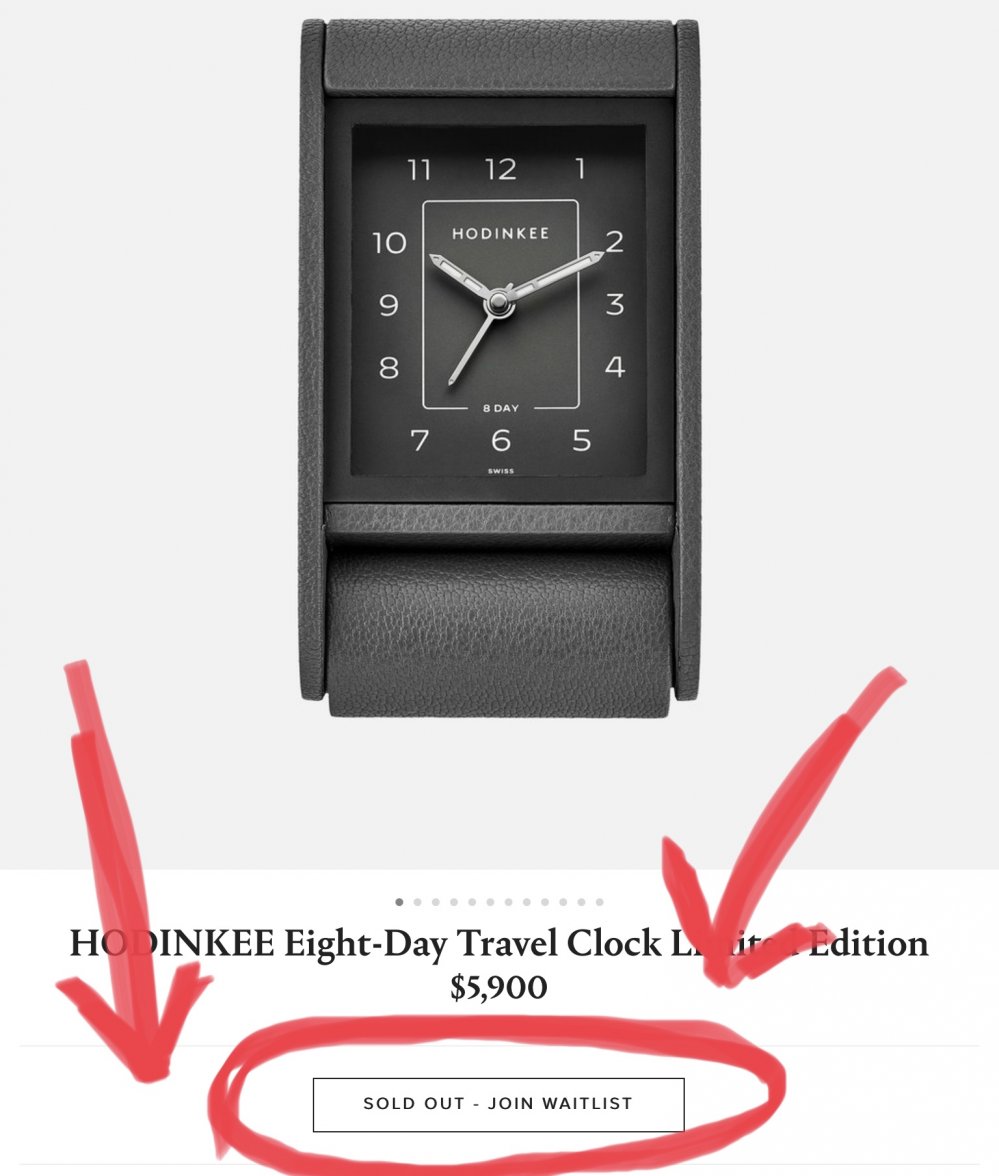

Hodinkee Eight-Day Travel Clock LE

Togri v. 2.0

··Wow! Custom title... coolCan you post a screenshot of the commments (or is that allowed? 👎) for us kids who are not in Facebook? 😁

Here are some 😁

Stripey

·Reading the comments on the Instagram post that followed it, it seems like they locked Instagram comments, then unlocked them, but now it's locked again 😬

kanye_mouse

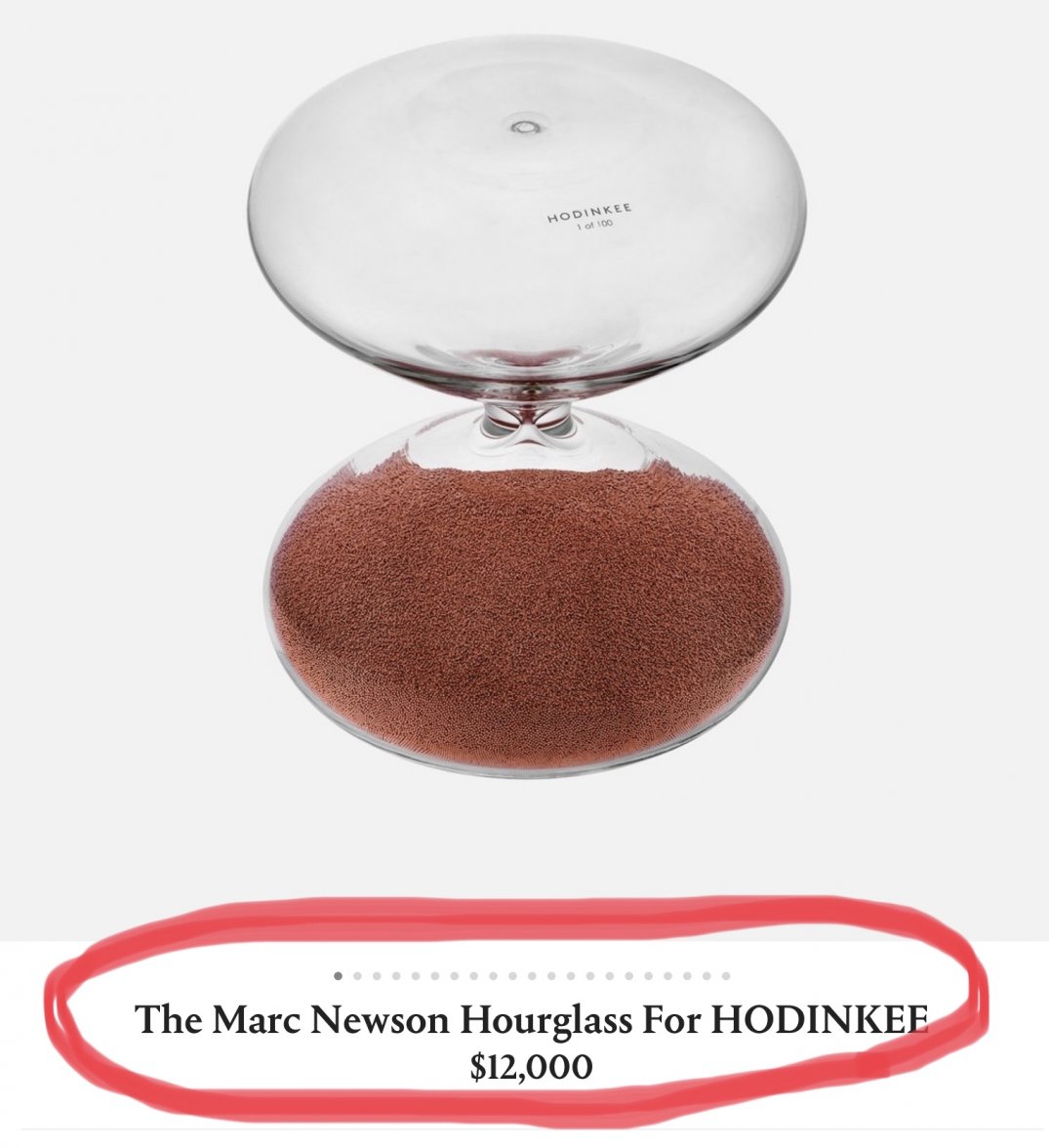

·What else is there to say? Hodinkee is a massive success by most conventional business metrics -- size, growth, valuation (I'm assuming), etc. But seeing products like this make one wonder what the point of having a business that's a "success" by these conventional metrics even is. Companies are going bankrupt left and right -- J Crew, Brooks Brothers, the list goes on -- but honestly if Hodinkee's is the formula for success, then perhaps it's best those others brands are dying now. "Live long enough to become the villain" ... or something like that. Or perhaps Hodinkee will buy the licensing rights for those brand names and make us a Brooks Brothers "ghost" travel clock. Either way, they're laughing all the way to the bank.

Edited:

sxl2004

·It appears they have a clear understanding about their customer base. 100 customers in a few hours. There are so many people in NYC alone that have insane amounts of disposable income, Hodinkee can go on forever. Kudos for their business model.

They should have asked more.

Just not my cup of tea or business I want to be associated with.

They should have asked more.

Just not my cup of tea or business I want to be associated with.

rcs914

·Maybe it is gauche and impolite, but I'm not going to hesitate calling anyone who bought this a complete fool.

MoclovFlop

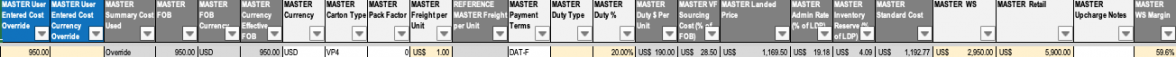

·As someone who does product development for a living, here's a theoretical breakdown:

Let's assume, generously, they wanted a 60% margin (few things have that good of margin).

If true, working backwards, the FOB cost (cost from the factory) would have to be around $950.

- This is assuming they went for a $2950 wholesale cost (50% retail margin), 20% duty (because the HS code for the teriff is confusing since I don't know the specifics of their movement). I don't know their freight charges and the packaging costs, so let's say it's $1.00 per unit per carton. Landing at the port, the total would be $1,169.

So $950 to make each one.

If they were working on a lower margin, like 50%, the cost to make it would be $1,175. And if the duty rates are better than 20%, then it would be even more expensive. 15% duty and 50% margin puts it $1,225

I guess they might amortize the mold fees into each unit, and if they are genuine when they say it's 100% made in Switzerland (including every single mold cost, nut, and bolt, drop of ink, leather, etc), then it would obviously be more expensive than those same bits from China. Labor rate is higher too.

Here's my math:

It seems really high, and they could have probably done a better job at sourcing some stuff. But I don't know the Swiss clock industry right now, maybe this is a good price. 😕😕😕

Either way, who want's to carry a travel clock anymore?

Let's assume, generously, they wanted a 60% margin (few things have that good of margin).

If true, working backwards, the FOB cost (cost from the factory) would have to be around $950.

- This is assuming they went for a $2950 wholesale cost (50% retail margin), 20% duty (because the HS code for the teriff is confusing since I don't know the specifics of their movement). I don't know their freight charges and the packaging costs, so let's say it's $1.00 per unit per carton. Landing at the port, the total would be $1,169.

So $950 to make each one.

If they were working on a lower margin, like 50%, the cost to make it would be $1,175. And if the duty rates are better than 20%, then it would be even more expensive. 15% duty and 50% margin puts it $1,225

I guess they might amortize the mold fees into each unit, and if they are genuine when they say it's 100% made in Switzerland (including every single mold cost, nut, and bolt, drop of ink, leather, etc), then it would obviously be more expensive than those same bits from China. Labor rate is higher too.

Here's my math:

It seems really high, and they could have probably done a better job at sourcing some stuff. But I don't know the Swiss clock industry right now, maybe this is a good price. 😕😕😕

Either way, who want's to carry a travel clock anymore?

Evitzee

·Meh.......the world is full of hipster's who think brands like Hodinkee are something special. I guess Hodinkee is an influencer and in today's world that means something to the hipsters. Many a watch forum have tried to figure out how to monetize themselves, Hodinkee seems to have actually done it. Clymer is full of BS most of the time but you have to admire his chutzpah.

NGO1

·NGO1

·Davidt

·It's not classic or timeless, it's uninspired, boring and incredibly bland.

The only thing justifying the price tag are reams of utter bullshit.

The only thing justifying the price tag are reams of utter bullshit.

redzer007

·Please please please let this be peak nonsense

Cannot wait to see hodonkee IG

Cannot wait to see hodonkee IG

MoclovFlop

·Not yet, still waiting for the Supreme/Hodinkee colab.

queriver

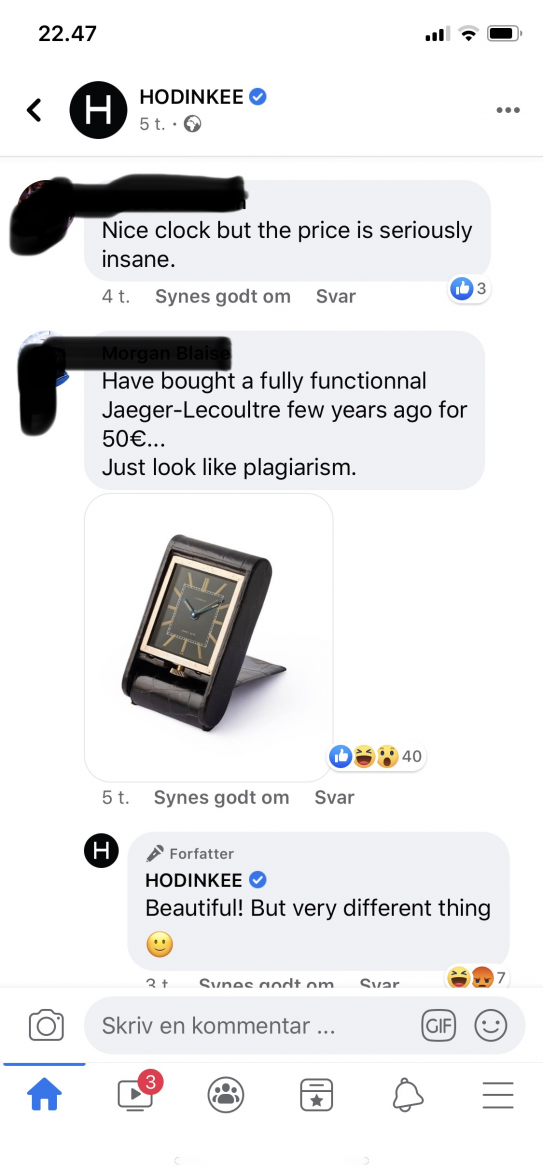

·Hodinkee should be embarrassed stooping that low to shamelessly rip off another's design, and then diminish it, and then spin it the way they have. For sure, they aren't embarrassed but what price does a CEO put on his brand's reputation? I would have thought more than ($5999 x 96) - Costs.

But, thank you for one thing Hodinkee : I'll never again complain how much my Apple "aide-mémoire" (a.k.a. iPhone) cost when it wakes me in the morning.

But, thank you for one thing Hodinkee : I'll never again complain how much my Apple "aide-mémoire" (a.k.a. iPhone) cost when it wakes me in the morning.

dsacks30

·I believe this is their first collaboration for a watch or clock that is solely branded “Hodinkee” rather than Hodinkee x IWC, Hodinkee x Blancpain, etc. (with Hodinkee only engraved on the caseback, out of view). This is a clear indication of how strong they think their Hodinkee brand is. They no longer feel as though they need a big Swiss watch brand stamped on the dial to sell their products. People will fork over $6K for a clock with HODINKEE in all caps as the only word on the dial - and this sold out.

I wouldn’t be surprised if they tried to start a Hodinkee watch brand down the road. Why split profits with the Swatch Group when they can have the entire pie?

I wouldn’t be surprised if they tried to start a Hodinkee watch brand down the road. Why split profits with the Swatch Group when they can have the entire pie?

SkunkPrince

·I wouldn’t be surprised if they tried to start a Hodinkee watch brand down the road. Why split profits with the Swatch Group when they can have the entire pie?

I can see it now, cases made in China, blingy dials, flashy hands, and a Seiko Instruments movement if you're lucky, or Miyota if you're not.

$1500 for a $150 watch.