Archer

··Omega Qualified WatchmakerNice summary Chris. 👍

François,

I'll answer some of your questions...

I'm not 100% sure what item you are asking me is true. Is it true that Rolex doesn't dynamically poise? I have no idea, but if they didn't I would be surprised. Any free sprung balance that has weights on it for timing adjustment (like the Microstella that Rolex uses, or the Gyromax that Patek uses, or the square and other screws that Omega uses) will potentially affect poise when they are moved for regulation purposes. This is why regulating these watches is not something for the inexperienced to do - it's not like turning a regulation screw on a base ETA movement. So in a way you could argue that any time someone moves one screw a little more than the one opposite and creates an error, then works to fix it, they are dynamically poising the balance.

I've never seen an explicit declaration from Rolex saying they don't do this, or that trained watchmakers are not allowed to do this when servicing a Rolex. Not sure where this information comes from, so it doesn't sound particularly legit to me.

Dynamic poising can have detrimental effects, in particular if not done right, which is why it's not something you likely should be doing right now. If you are working on a watch that has a smooth balance with no screws, it requires removing material from the balance, and this is not reversible. If too much weight is removed chasing an error, then you risk problems certainly (affecting Q). It can affect amplitude in ways you might not expect, and of course as amplitude changes, timing changes.

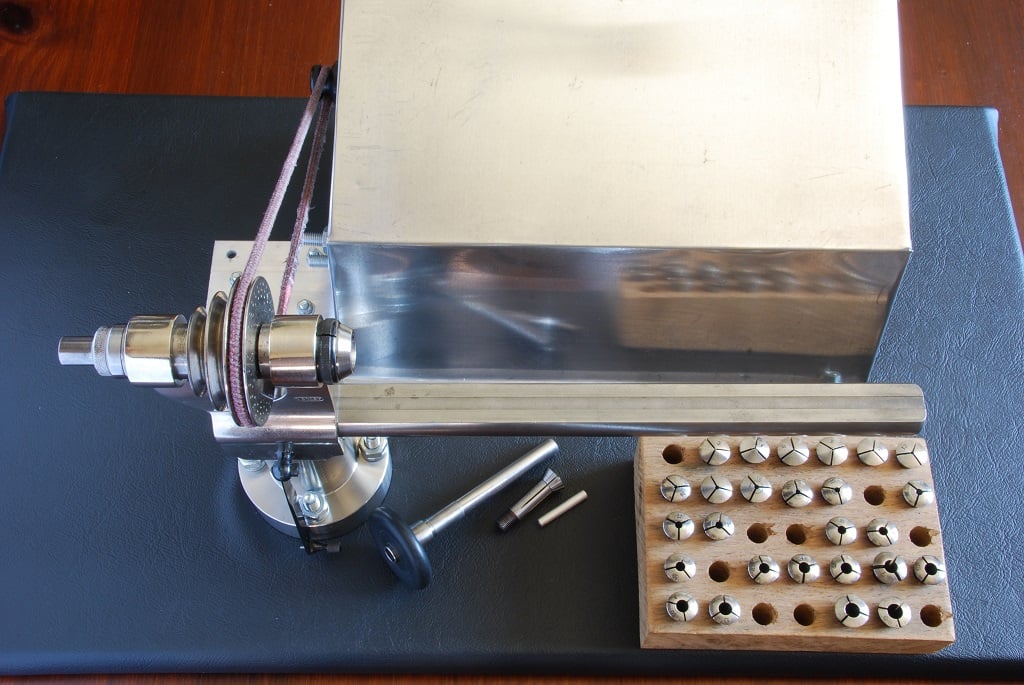

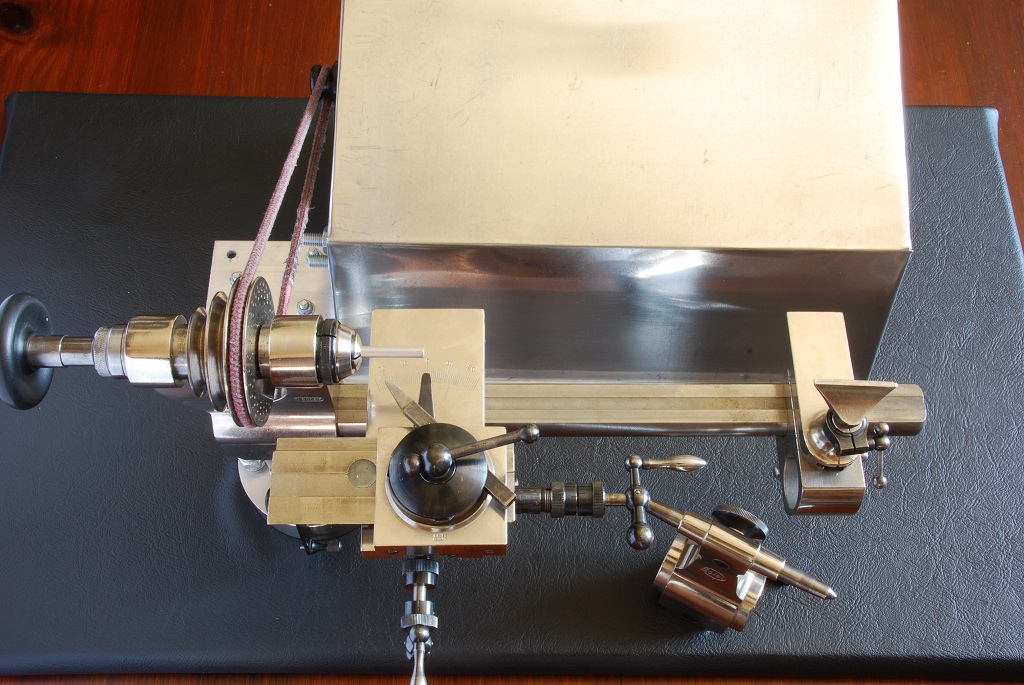

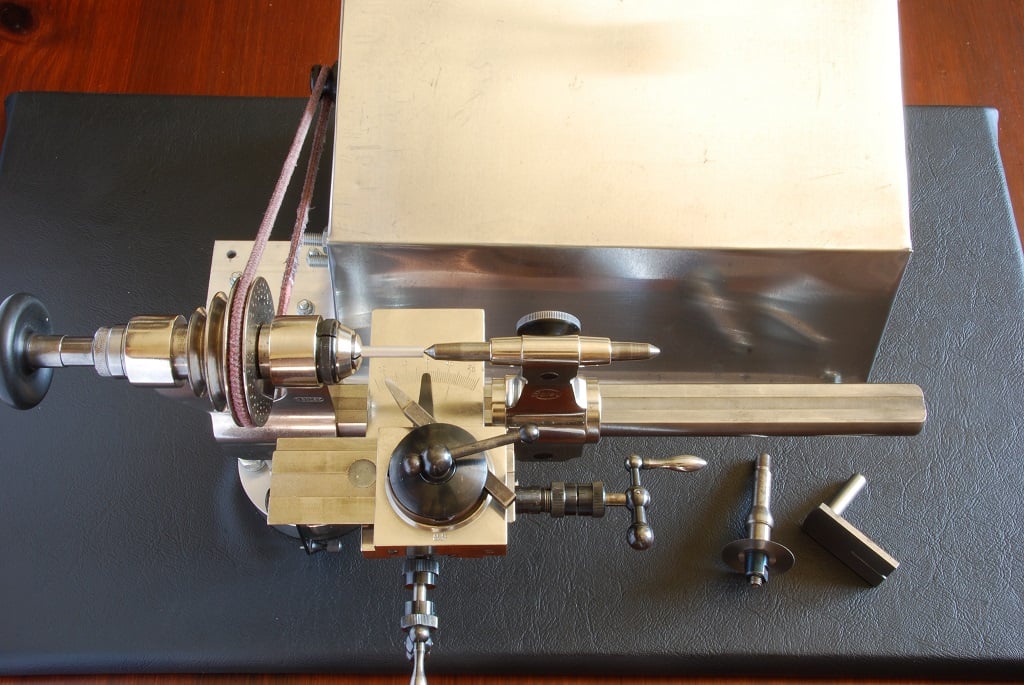

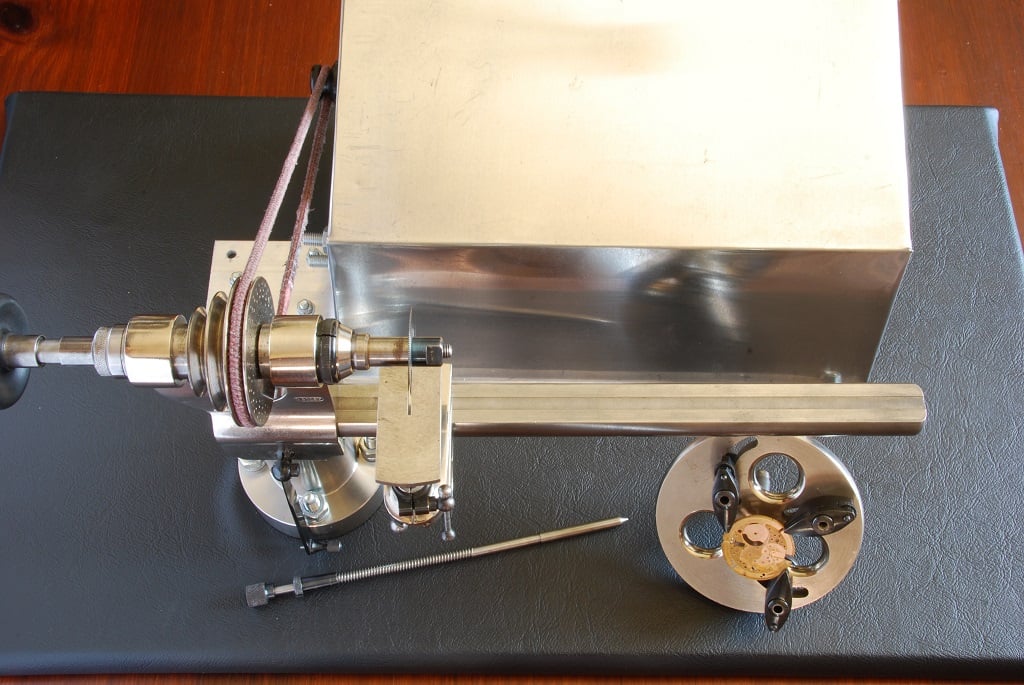

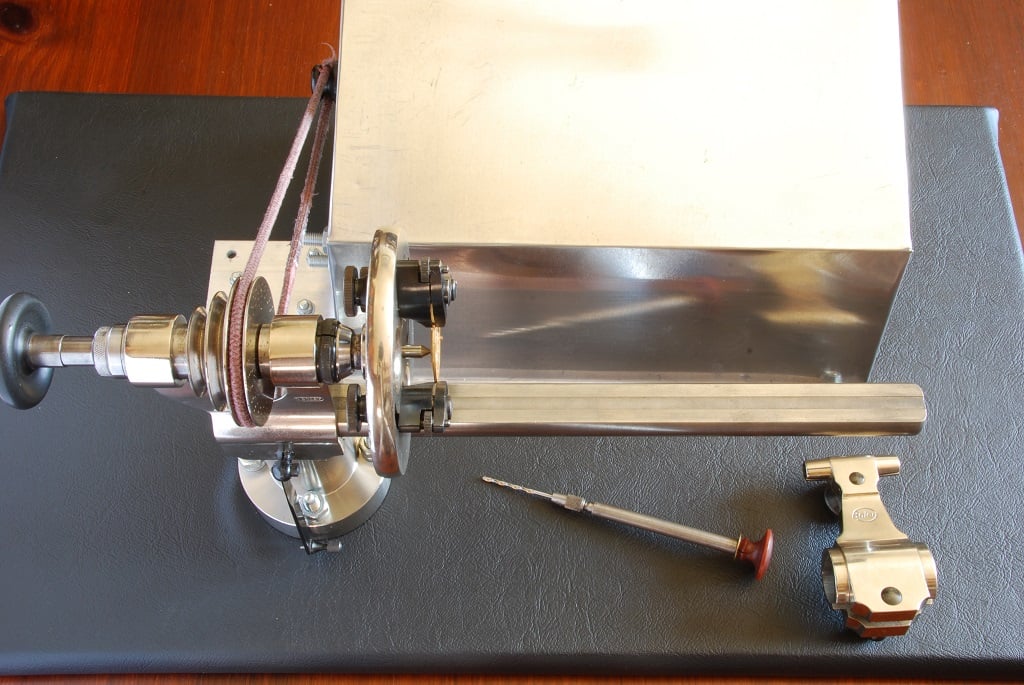

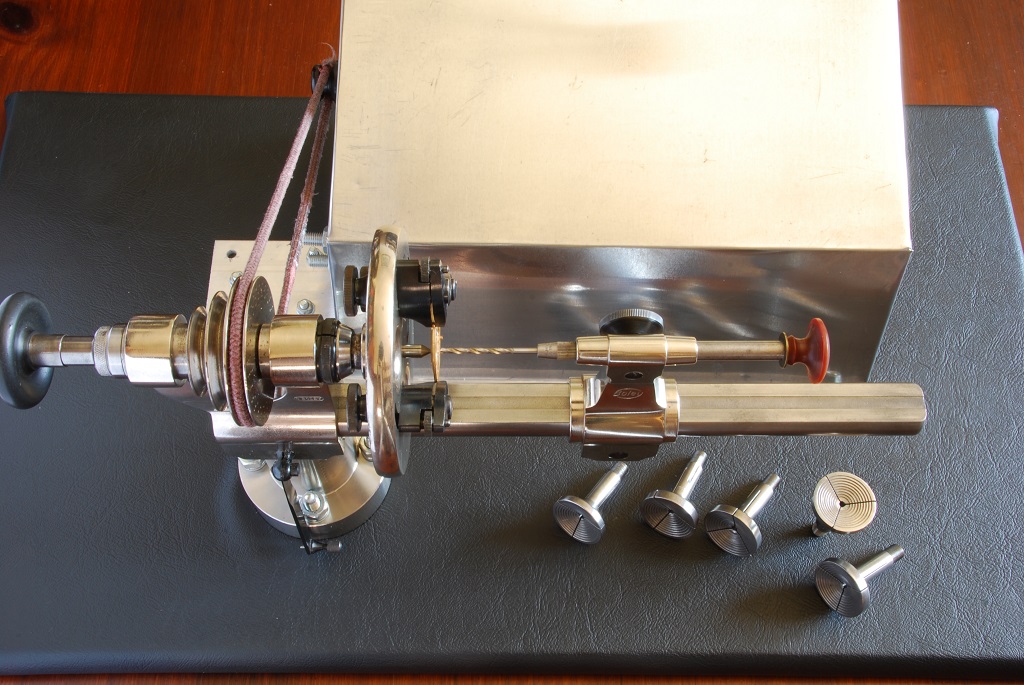

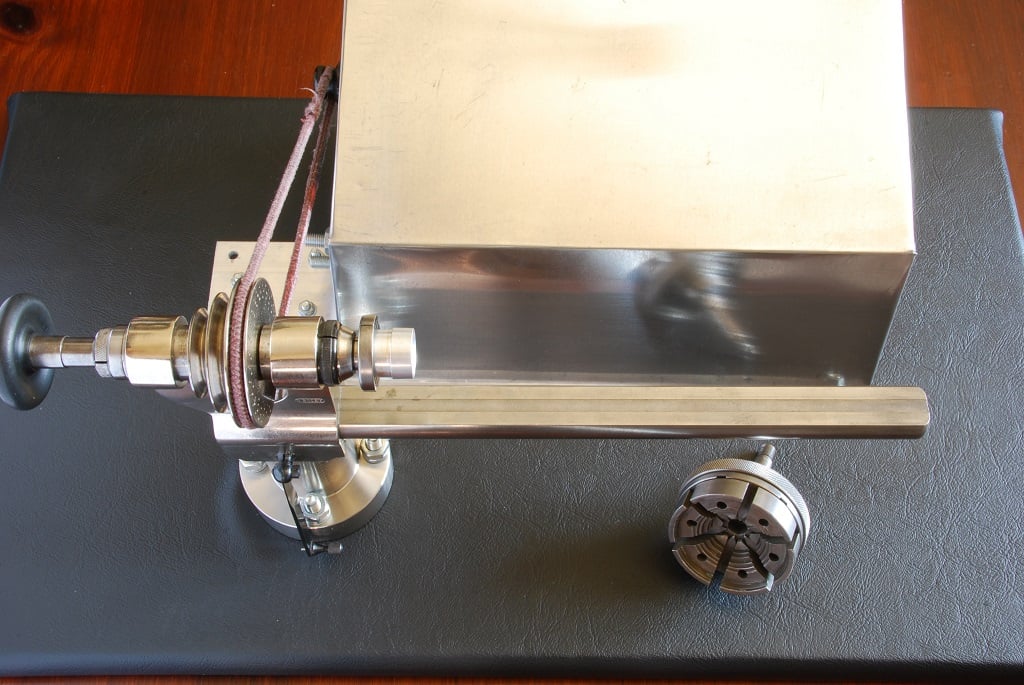

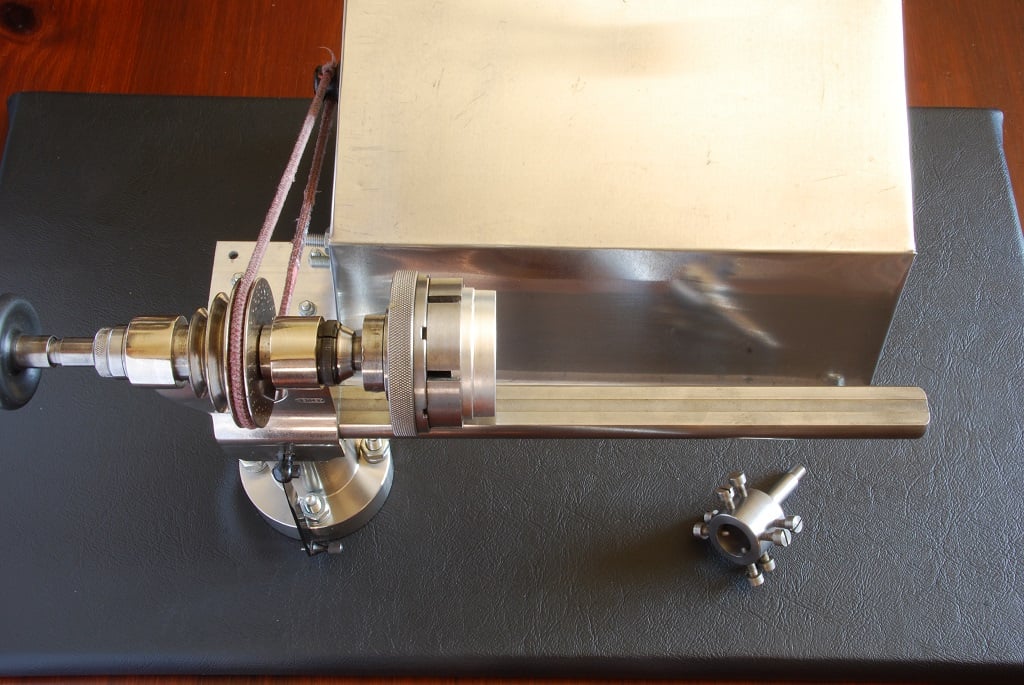

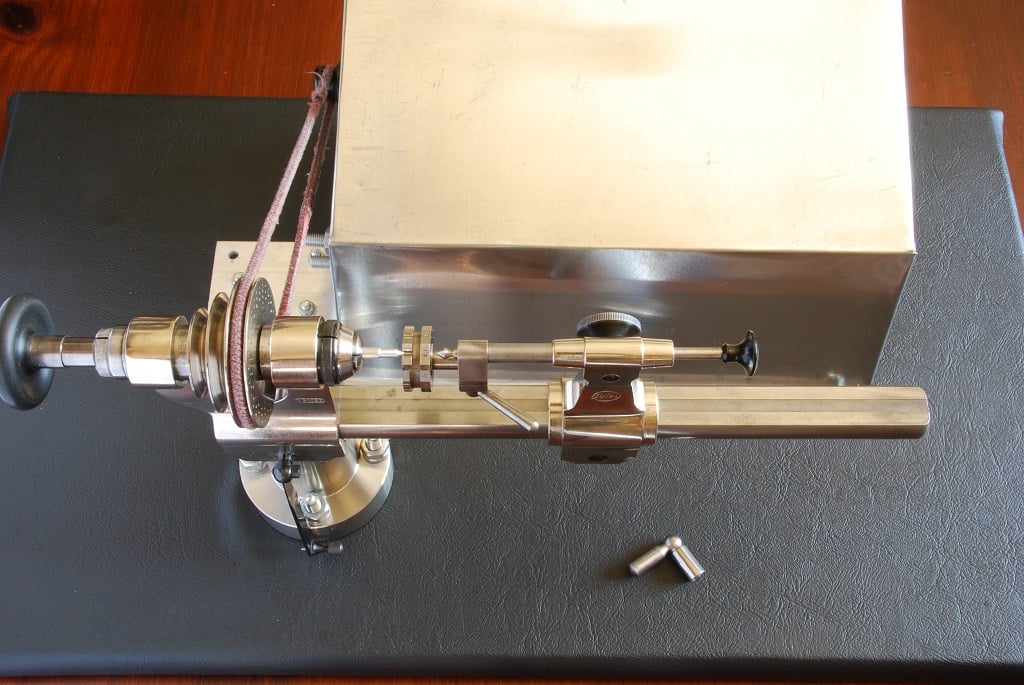

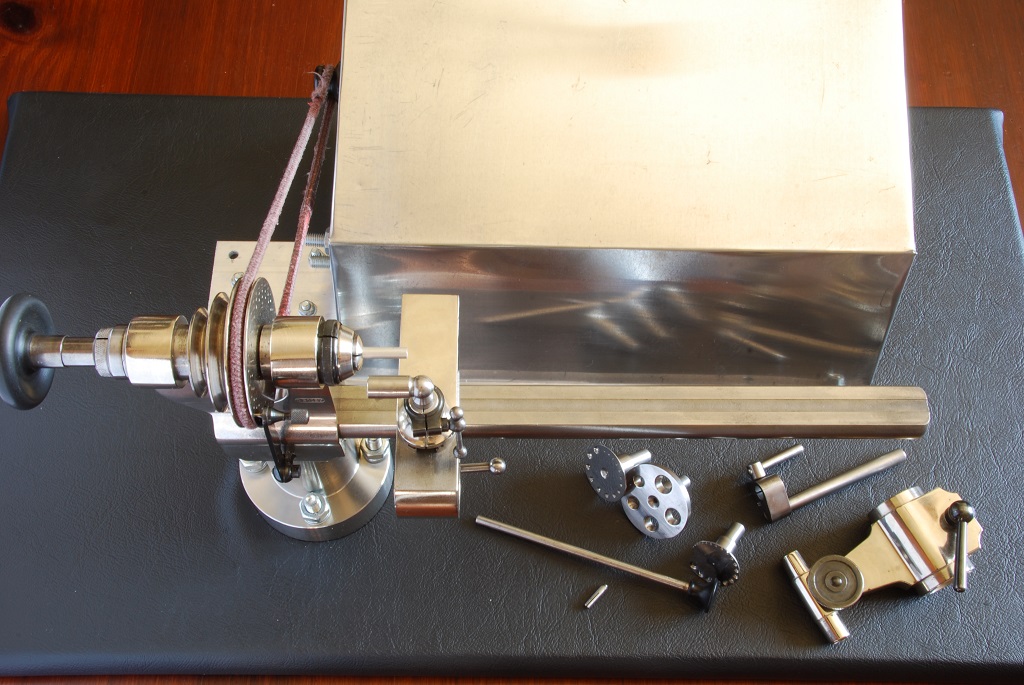

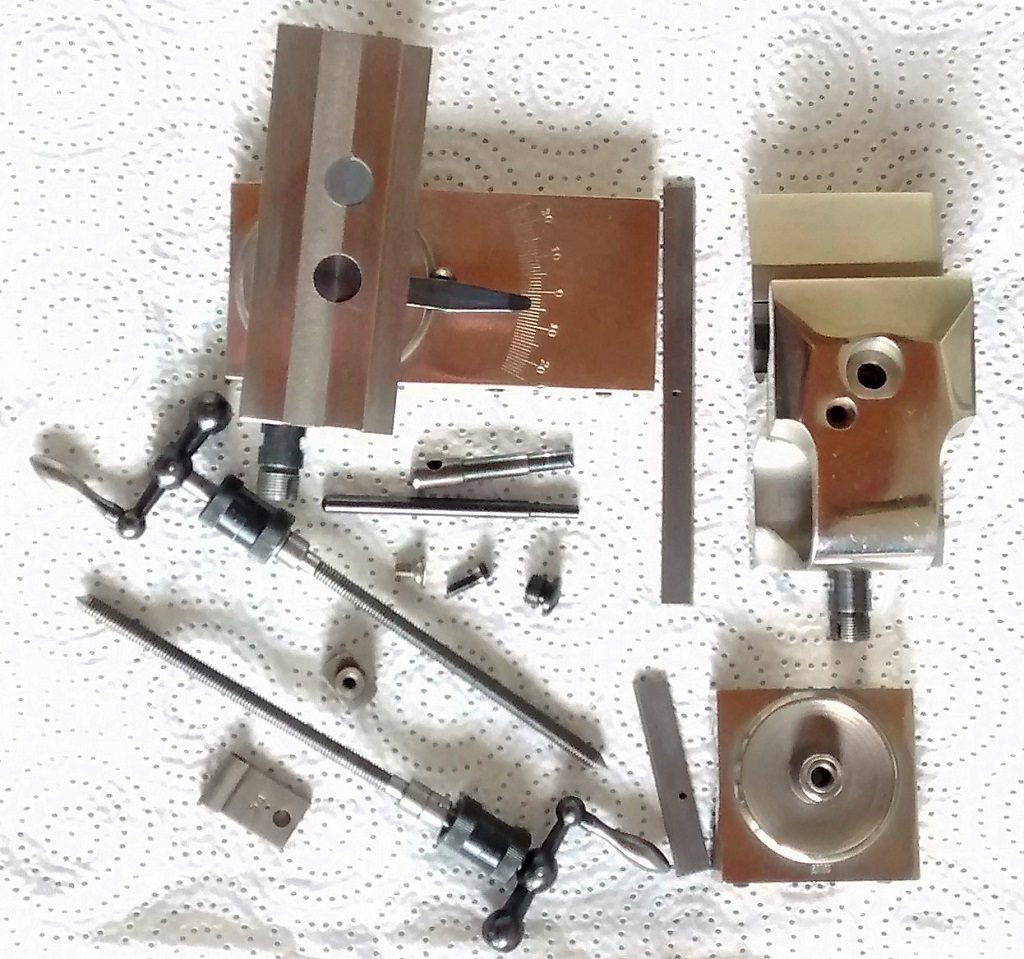

But keep in mind this is usually something done for very fine adjustment, not normally for gross adjustments. So the amount of material being removed here is VERY small. So taking a watch from this:

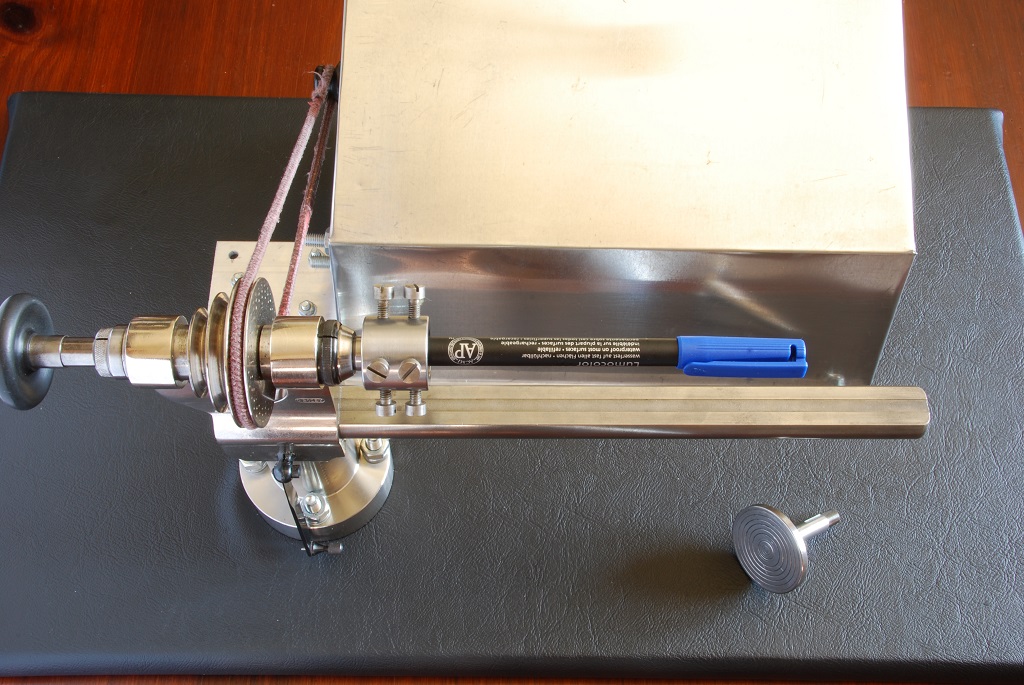

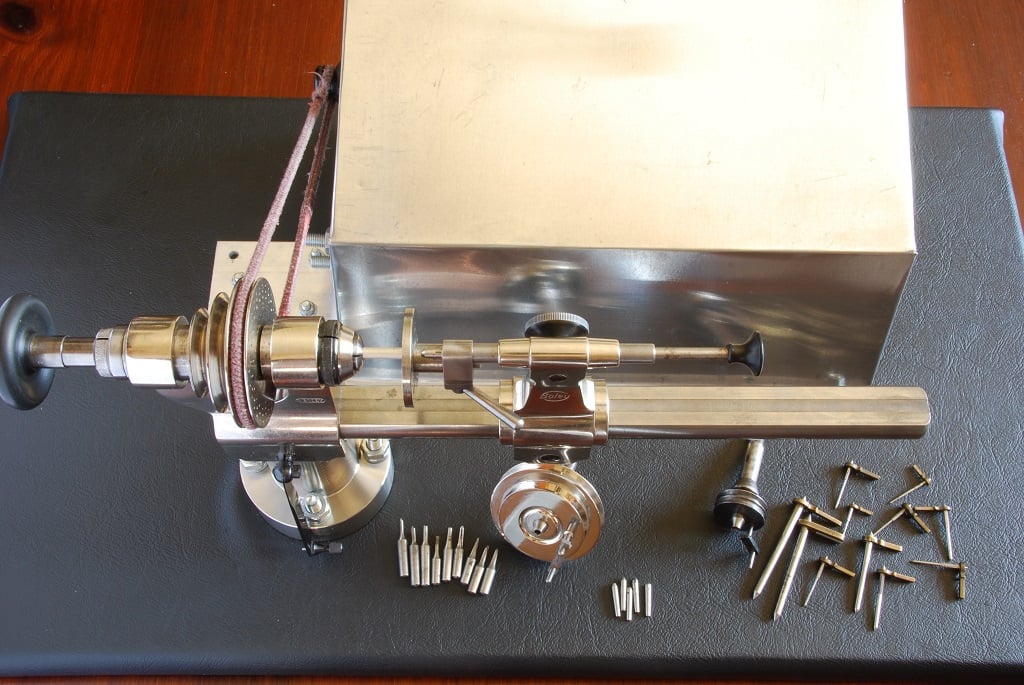

To this:

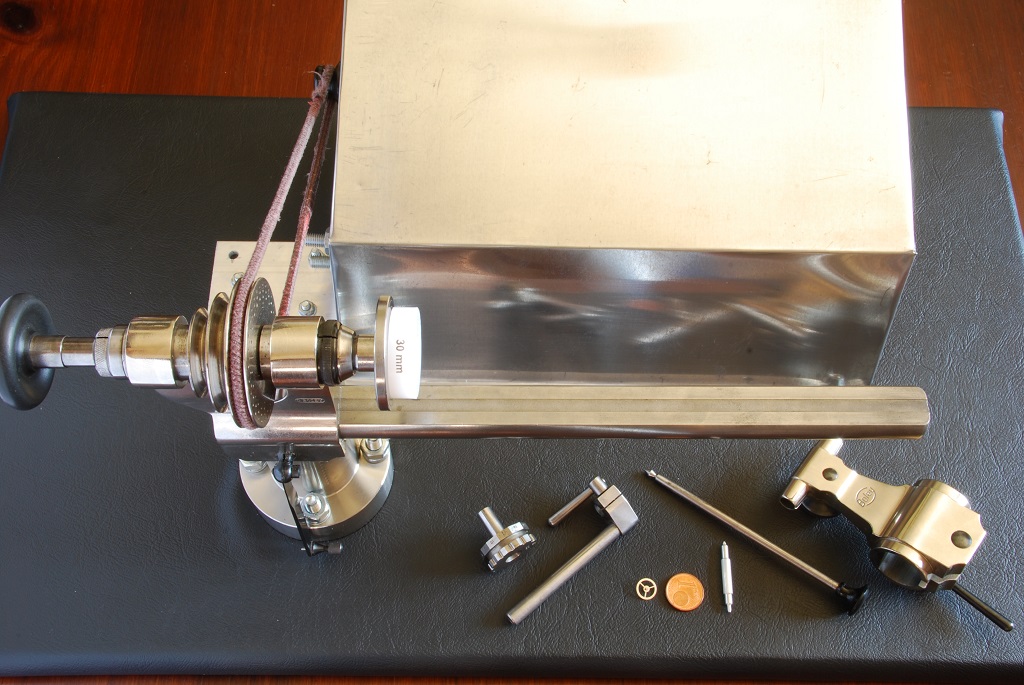

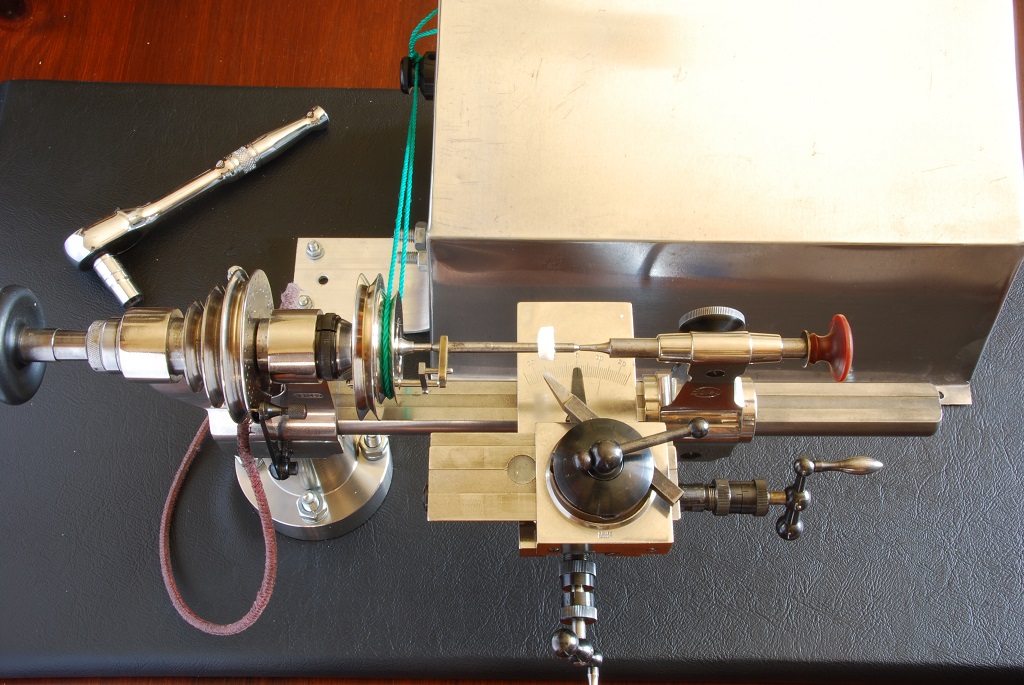

Only requires removing this:

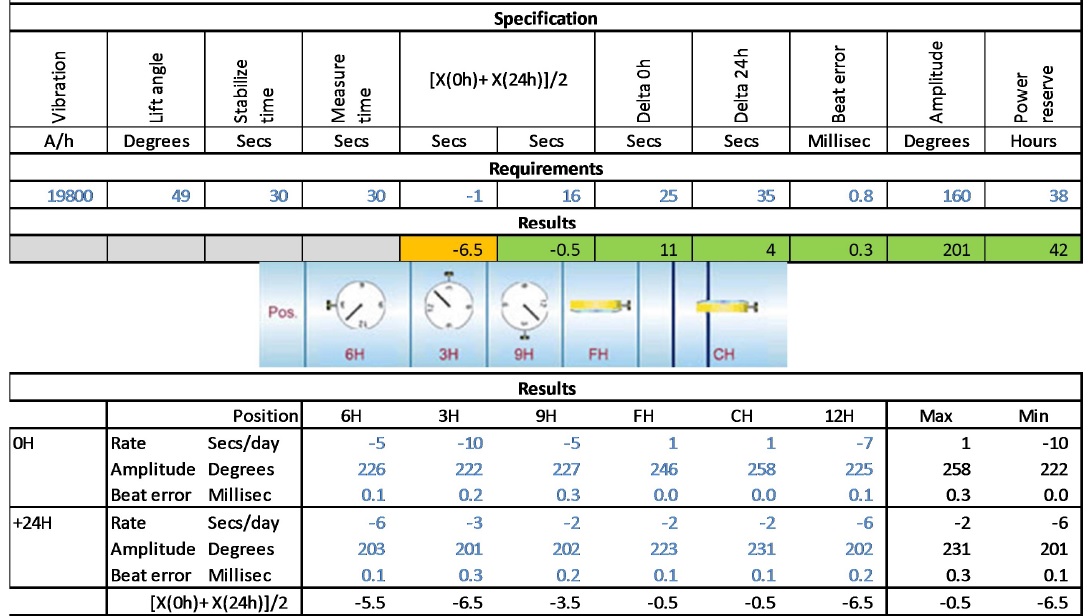

The watch was well within specs when I started (Omega allows 12 seconds of Delta over 5 positions and I started with 8.5 over 6 positions), but seeing a poise error that would be easily reduced, I went ahead and corrected it.

Short answer is - physics! 😁 If you want send me your address and I'll dig up my old dynamics textbooks from college and send them to you - I haven't used them in 30+ years so I'm not going to try to explain it in detail here. 😉

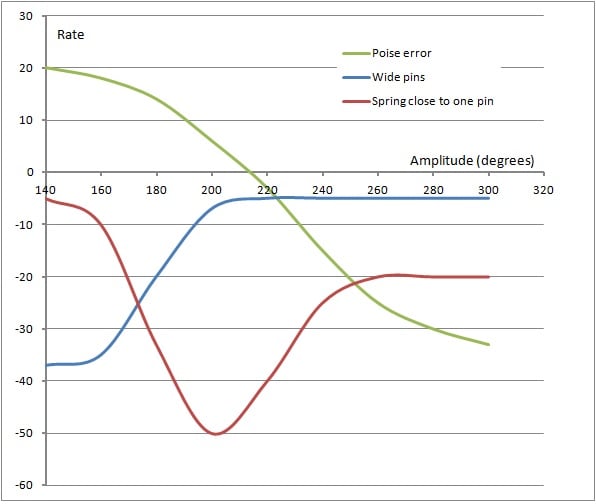

You can see the affect of amplitude on various parameters in the chart Chris posted above. In the case of dynamic poising, I was taught to use 160 degrees of amplitude, as this magnifies errors to make them more easily seen. But you need to understand the amplitude point where the errors flip, so if you want to use a high amplitude you can, just understand the implications of doing that when you decide where to remove material (or add it if possible) on the balance.

When you can make balance springs perfect in the round and in the flat, adjust the regulating pins to minimize Delta, and ensure that all other issues are resolved, then we can talk about doing dynamic poising. Based on what you have written, I don't think you are there yet. I would be interested to see a balance spring photo (static) that you have corrected - this usually tells me how far along someone is.

I recall posting a spring once on a forum that was a long way from being centered, and some people commented that they could not see the error really - looked fine to them. It's not that I have any special ability built into my eyes at birth, but just that I have seen and corrected enough errors that you learn to recognize what is good and what isn't. What might look great to you will most likely not look so to me, but I have looked at and corrected thousands of springs - there is no short cut to learning this stuff as it takes time and experience.

Cheers, Al

François,

I'll answer some of your questions...

2) I have read that the sort of heavy point the dynamic poising creates - or to put it in another way, the fact it modifies a perfectly staticly poised balance - could produce troubles if the amplitude changes. This statement - made by a watchmaker on another forum - seems to suppose that dynamic poising has some "side effects". It would be why Rolex did no longer pratice it after trying it for a while.

Is that true? Why is that?

I'm not 100% sure what item you are asking me is true. Is it true that Rolex doesn't dynamically poise? I have no idea, but if they didn't I would be surprised. Any free sprung balance that has weights on it for timing adjustment (like the Microstella that Rolex uses, or the Gyromax that Patek uses, or the square and other screws that Omega uses) will potentially affect poise when they are moved for regulation purposes. This is why regulating these watches is not something for the inexperienced to do - it's not like turning a regulation screw on a base ETA movement. So in a way you could argue that any time someone moves one screw a little more than the one opposite and creates an error, then works to fix it, they are dynamically poising the balance.

I've never seen an explicit declaration from Rolex saying they don't do this, or that trained watchmakers are not allowed to do this when servicing a Rolex. Not sure where this information comes from, so it doesn't sound particularly legit to me.

Dynamic poising can have detrimental effects, in particular if not done right, which is why it's not something you likely should be doing right now. If you are working on a watch that has a smooth balance with no screws, it requires removing material from the balance, and this is not reversible. If too much weight is removed chasing an error, then you risk problems certainly (affecting Q). It can affect amplitude in ways you might not expect, and of course as amplitude changes, timing changes.

But keep in mind this is usually something done for very fine adjustment, not normally for gross adjustments. So the amount of material being removed here is VERY small. So taking a watch from this:

To this:

Only requires removing this:

The watch was well within specs when I started (Omega allows 12 seconds of Delta over 5 positions and I started with 8.5 over 6 positions), but seeing a poise error that would be easily reduced, I went ahead and corrected it.

3) I have read that the effect of a heavy point, whatever caused it, could not be seen on a timegrapher at an amplitude of 220. Is that true? Why is that?

Short answer is - physics! 😁 If you want send me your address and I'll dig up my old dynamics textbooks from college and send them to you - I haven't used them in 30+ years so I'm not going to try to explain it in detail here. 😉

You can see the affect of amplitude on various parameters in the chart Chris posted above. In the case of dynamic poising, I was taught to use 160 degrees of amplitude, as this magnifies errors to make them more easily seen. But you need to understand the amplitude point where the errors flip, so if you want to use a high amplitude you can, just understand the implications of doing that when you decide where to remove material (or add it if possible) on the balance.

I feel confident with correcting hairsprings because I got some good results - very rewarding in those cases! But I have also killed several hairsprings! And I have not ever changed a balance staff or used a lathe.

Long story short: I can service a good movement and fix some issues, but I am only an improving amateur.

When you can make balance springs perfect in the round and in the flat, adjust the regulating pins to minimize Delta, and ensure that all other issues are resolved, then we can talk about doing dynamic poising. Based on what you have written, I don't think you are there yet. I would be interested to see a balance spring photo (static) that you have corrected - this usually tells me how far along someone is.

I recall posting a spring once on a forum that was a long way from being centered, and some people commented that they could not see the error really - looked fine to them. It's not that I have any special ability built into my eyes at birth, but just that I have seen and corrected enough errors that you learn to recognize what is good and what isn't. What might look great to you will most likely not look so to me, but I have looked at and corrected thousands of springs - there is no short cut to learning this stuff as it takes time and experience.

Cheers, Al

....

....