ashleysteadman

·Hi All,

I recently replaced the Hesalite Crystal on my Speedmaster Professional and by popular demand I’ve put together a DIY. This is provided for informative purposes only – I do not take any responsibility for anyone’s actions but my own!

Note that given the cost of required tools etc. this shouldn't be viewed at as a cost saving exercise, but a fun exercise for a hobbyist - if you're not comfortable doing this, do not take apart your watch - take it to your watchmaker!

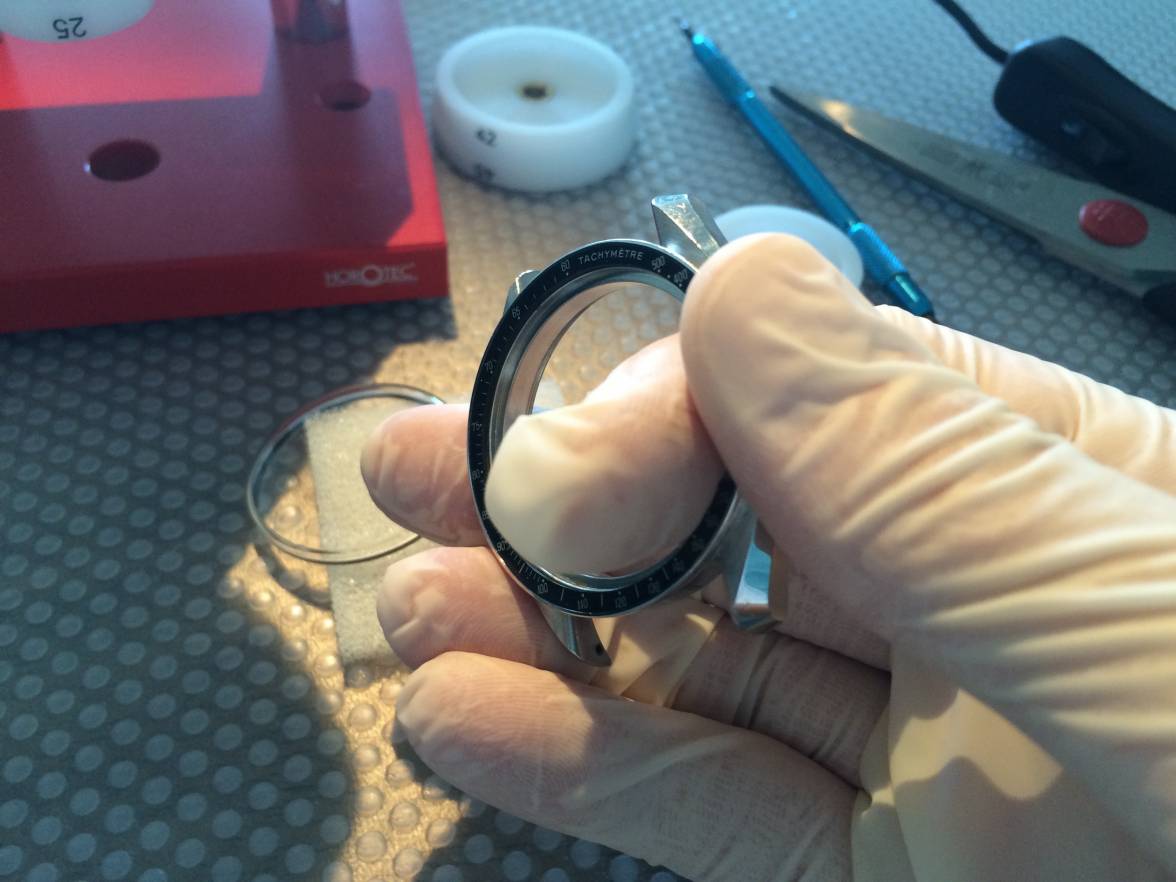

This particular watch is a Speedmaster Professional Case # 145.022 with 861 movement. I believe that you can apply the same process to sapphire crystal cases (someone please confirm/deny!).

Preparation:

As you will be opening your watch, make sure that your work area is clean, tidy, and dust-free.

Tools:

Replacing the Crystal on your Speedmaster Professional is actually a somewhat simple process as long as you have the right tools for the job:

Step 1:

This is somewhat optional, but I prefer to work on my watches sans-strap so I get my trusty spring bar removal tool out and remove the strap.

Step 2: Case back removal.

Get your case back wrench and align the teeth with the indents on the back of the case and twist counter-clockwise. I put a thick sheet of clear plastic over the case back to prevent nicks and scratches whilst still being able to see what I’m doing.

This will expose the inside of the watch where you can see the dust cover.

Step 3: Dust cover removal.

There is a dust cover over the back of the movement which also serves a purpose of anti-magnetism and a spacer to hold the movement in-place. This cover is simply held by friction onto the back of the movement so you just pull it off.

To avoid pulling the movement out and potentially bending the crown, hold down the movement on the side opposite the crown. You can lever the cover off using a screwdriver or pull it off by hand (it depends how tight it’s on). I found that using a bit of Bergeon Rodico gum to hold the cover and pull upwards is a neat trick, but you must clean the area carefully afterwards.

Step 4: Stem and movement removal.

We now need to get the movement out so you can work on the case. The movement is only being held in-place now by the crown/stem.

To remove the stem on the 861 movement, there is a small screw that needs a few counter-clockwise turns to loosen. After a couple of turns, gently try to pull the crown and stem out straight from the case. The screw should remain where it is.

I now put the dust cover back on to protect the movement.

A safe way to remove the movement from the case is by letting gravity take over! Taking one of your plastic containers, place it upside down on top of the case and movement and invert. Hold onto the case and vice carefully. Pull the case/vice straight upwards and the movement will stay where it is. Hold onto the case and vice carefully (I can’t state this enough).

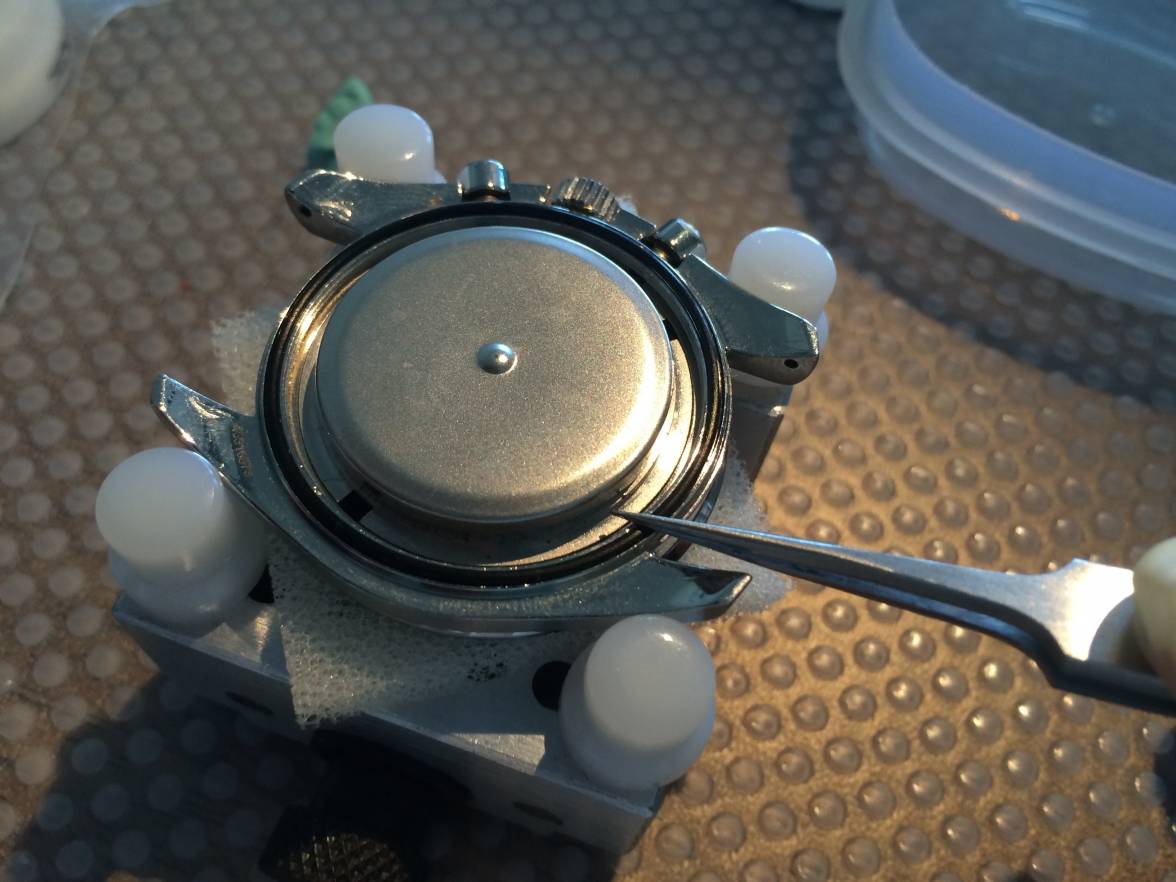

You should now be faced with something resembling this!:

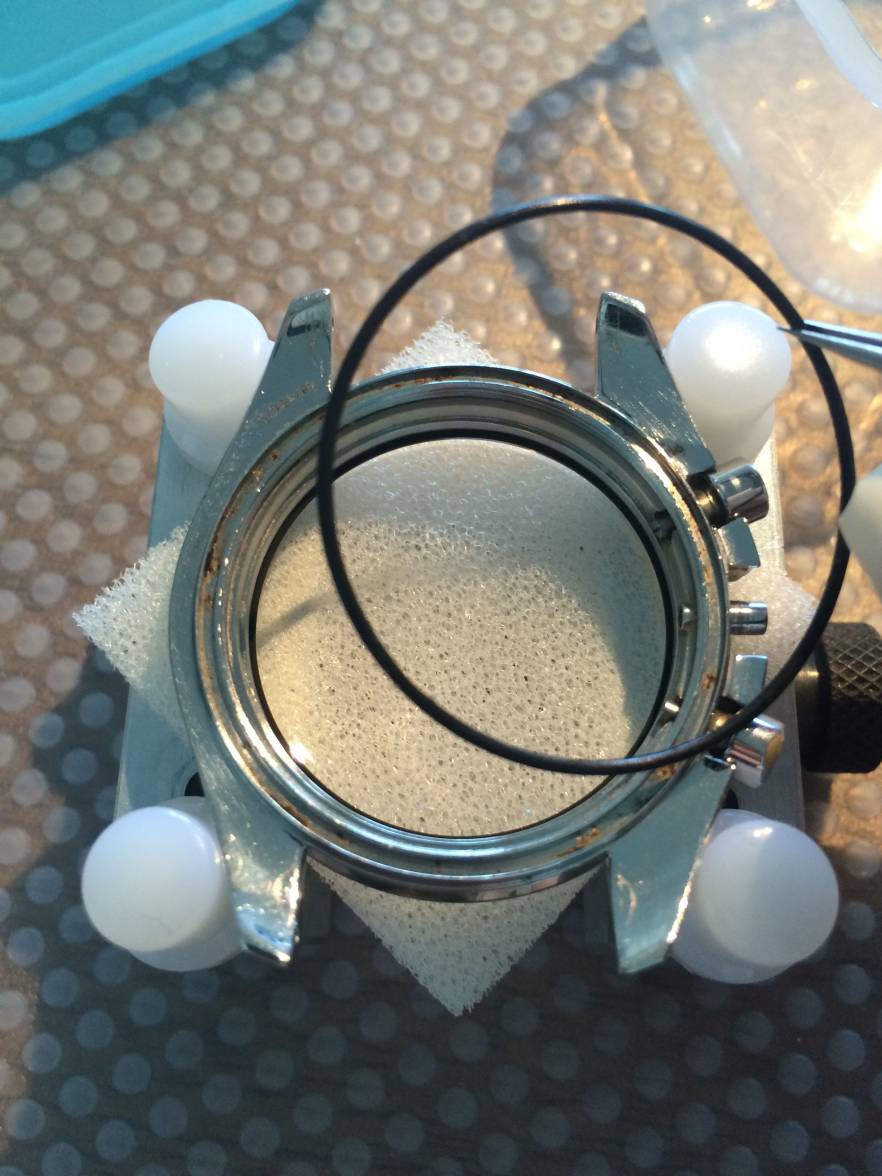

There is a gasket/”O-ring” on the back of the case that should be removed very carefully so as to not damage it. Place this in a container by itself to avoid it getting stretched.

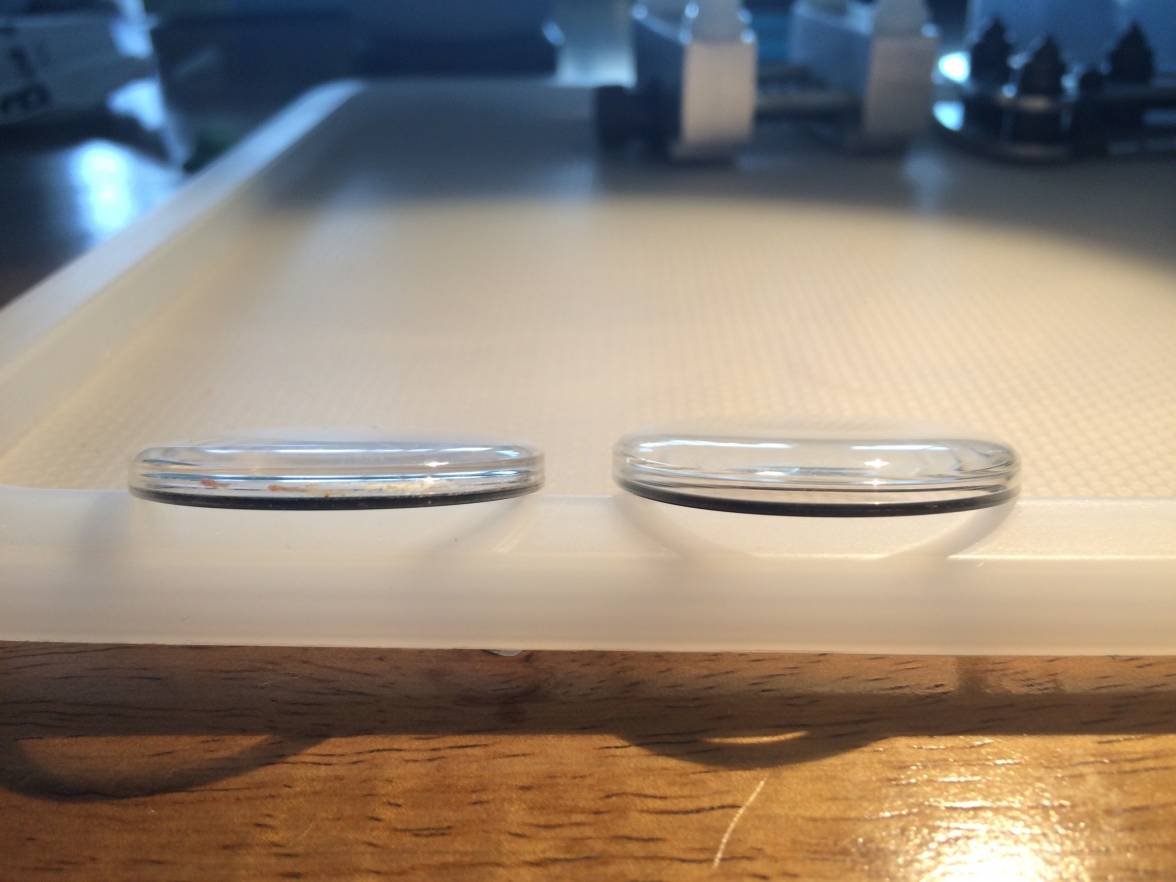

Here you can see the steel tension ring around the inside of the crystal that pushes outwards and holds the crystal firmly in place.

I recently replaced the Hesalite Crystal on my Speedmaster Professional and by popular demand I’ve put together a DIY. This is provided for informative purposes only – I do not take any responsibility for anyone’s actions but my own!

Note that given the cost of required tools etc. this shouldn't be viewed at as a cost saving exercise, but a fun exercise for a hobbyist - if you're not comfortable doing this, do not take apart your watch - take it to your watchmaker!

This particular watch is a Speedmaster Professional Case # 145.022 with 861 movement. I believe that you can apply the same process to sapphire crystal cases (someone please confirm/deny!).

Preparation:

As you will be opening your watch, make sure that your work area is clean, tidy, and dust-free.

Tools:

Replacing the Crystal on your Speedmaster Professional is actually a somewhat simple process as long as you have the right tools for the job:

- Spring Bar Removal Tool

- Case Opener/Wrench

- Case Holder/Case Vice

- Watchmaker’s Tweezers

- Watchmaker’s Screwdrivers

- Plastic containers or clean place to store parts

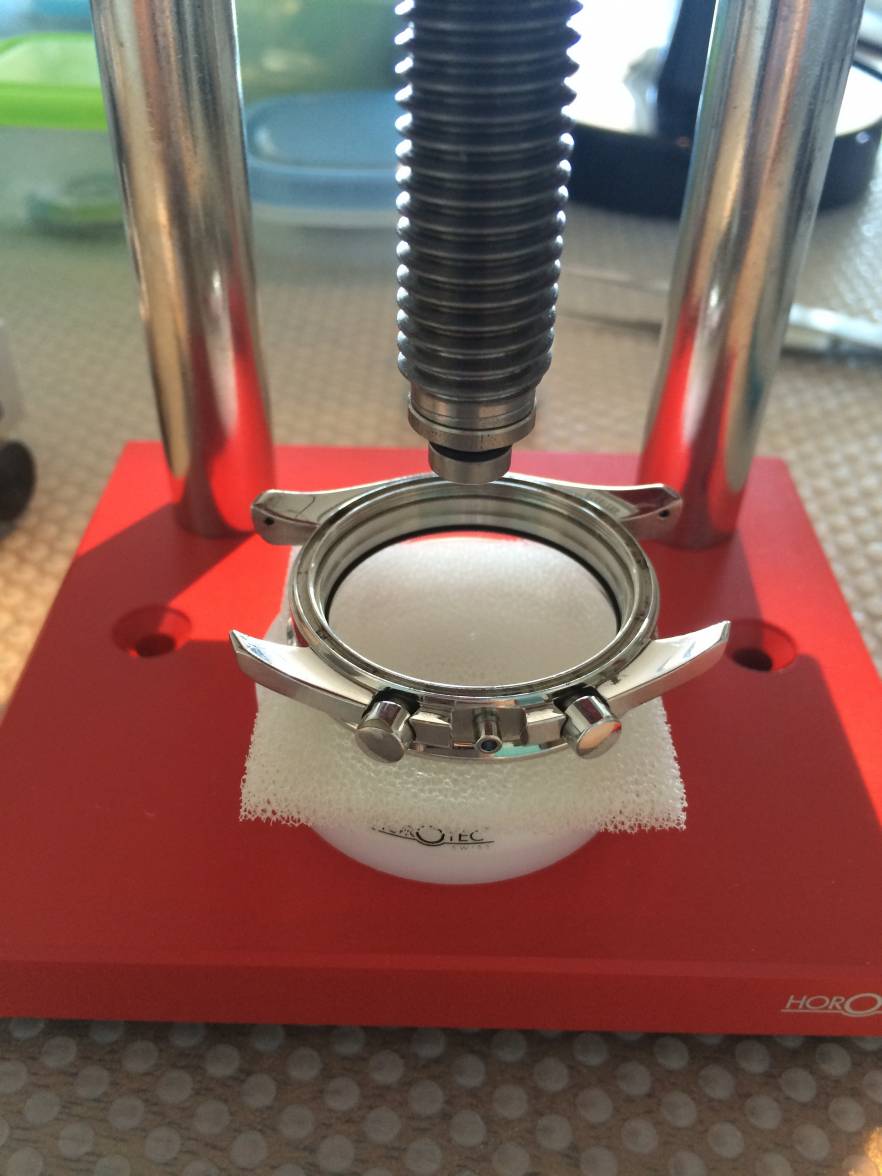

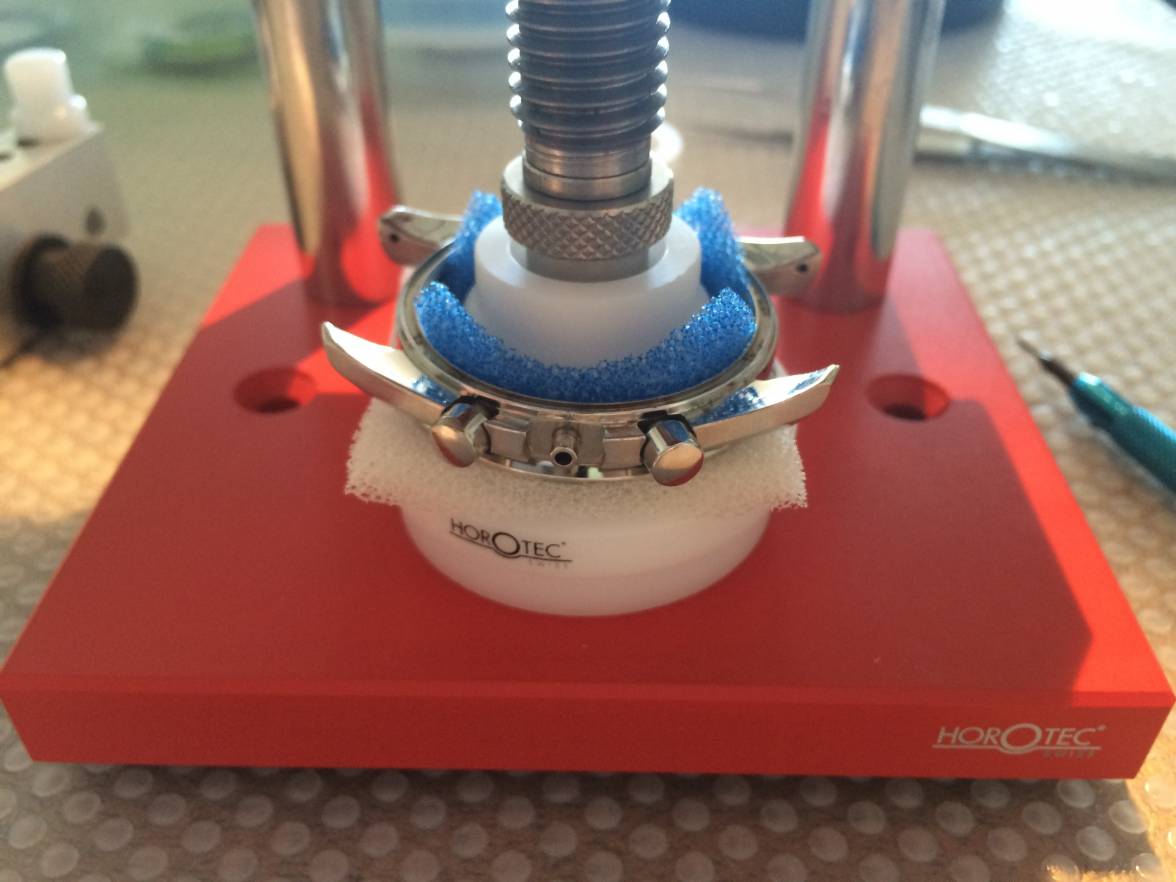

- Crystal Press/Multi Press

- I have been able to get a crystal out by hand, but getting it back in is nigh on impossible – get yourself a good press!

Step 1:

This is somewhat optional, but I prefer to work on my watches sans-strap so I get my trusty spring bar removal tool out and remove the strap.

Step 2: Case back removal.

Get your case back wrench and align the teeth with the indents on the back of the case and twist counter-clockwise. I put a thick sheet of clear plastic over the case back to prevent nicks and scratches whilst still being able to see what I’m doing.

This will expose the inside of the watch where you can see the dust cover.

Step 3: Dust cover removal.

There is a dust cover over the back of the movement which also serves a purpose of anti-magnetism and a spacer to hold the movement in-place. This cover is simply held by friction onto the back of the movement so you just pull it off.

To avoid pulling the movement out and potentially bending the crown, hold down the movement on the side opposite the crown. You can lever the cover off using a screwdriver or pull it off by hand (it depends how tight it’s on). I found that using a bit of Bergeon Rodico gum to hold the cover and pull upwards is a neat trick, but you must clean the area carefully afterwards.

Step 4: Stem and movement removal.

We now need to get the movement out so you can work on the case. The movement is only being held in-place now by the crown/stem.

To remove the stem on the 861 movement, there is a small screw that needs a few counter-clockwise turns to loosen. After a couple of turns, gently try to pull the crown and stem out straight from the case. The screw should remain where it is.

I now put the dust cover back on to protect the movement.

A safe way to remove the movement from the case is by letting gravity take over! Taking one of your plastic containers, place it upside down on top of the case and movement and invert. Hold onto the case and vice carefully. Pull the case/vice straight upwards and the movement will stay where it is. Hold onto the case and vice carefully (I can’t state this enough).

You should now be faced with something resembling this!:

There is a gasket/”O-ring” on the back of the case that should be removed very carefully so as to not damage it. Place this in a container by itself to avoid it getting stretched.

Here you can see the steel tension ring around the inside of the crystal that pushes outwards and holds the crystal firmly in place.