lenndon

·Hello everyone,

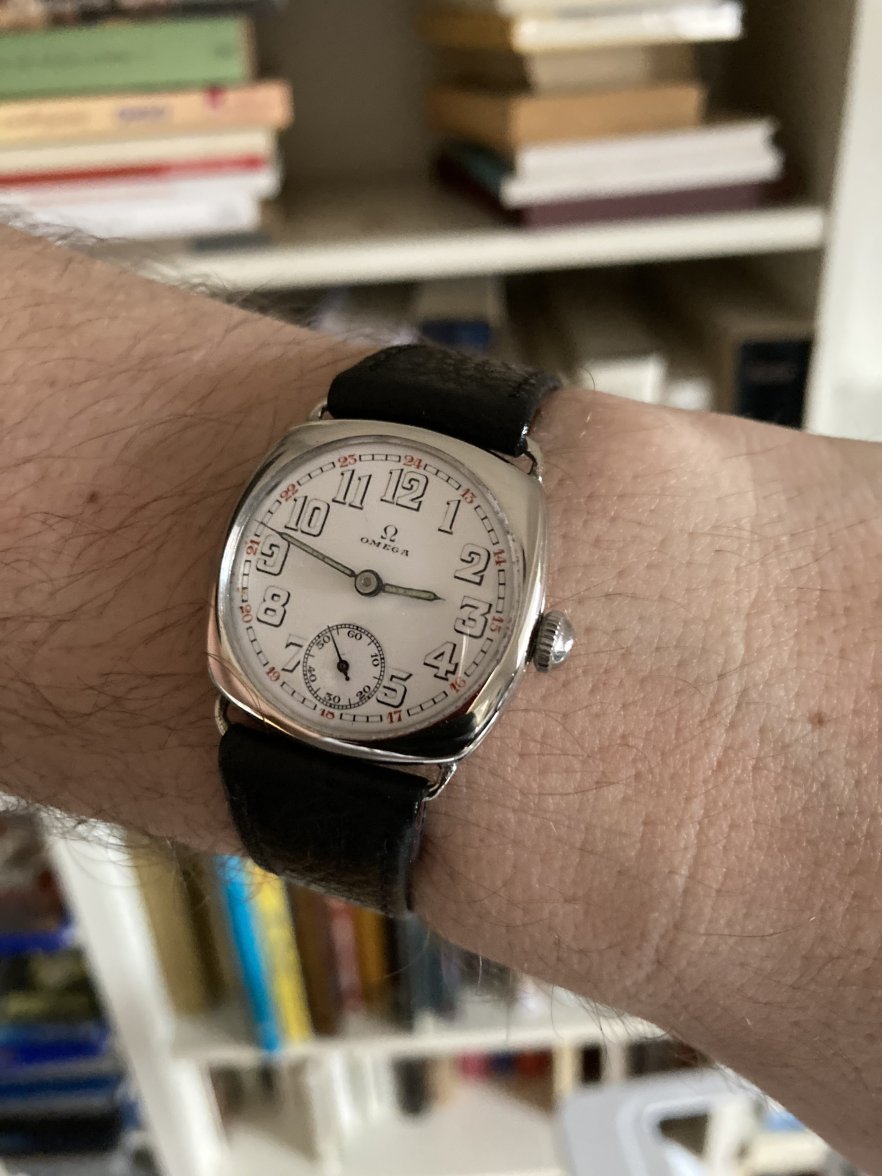

I am currently restoring an Omega Military Wristwatch with a Cal. 26.5. The Movement needed a lot of love but is running again. The case on the other hand probably needs even more attention.

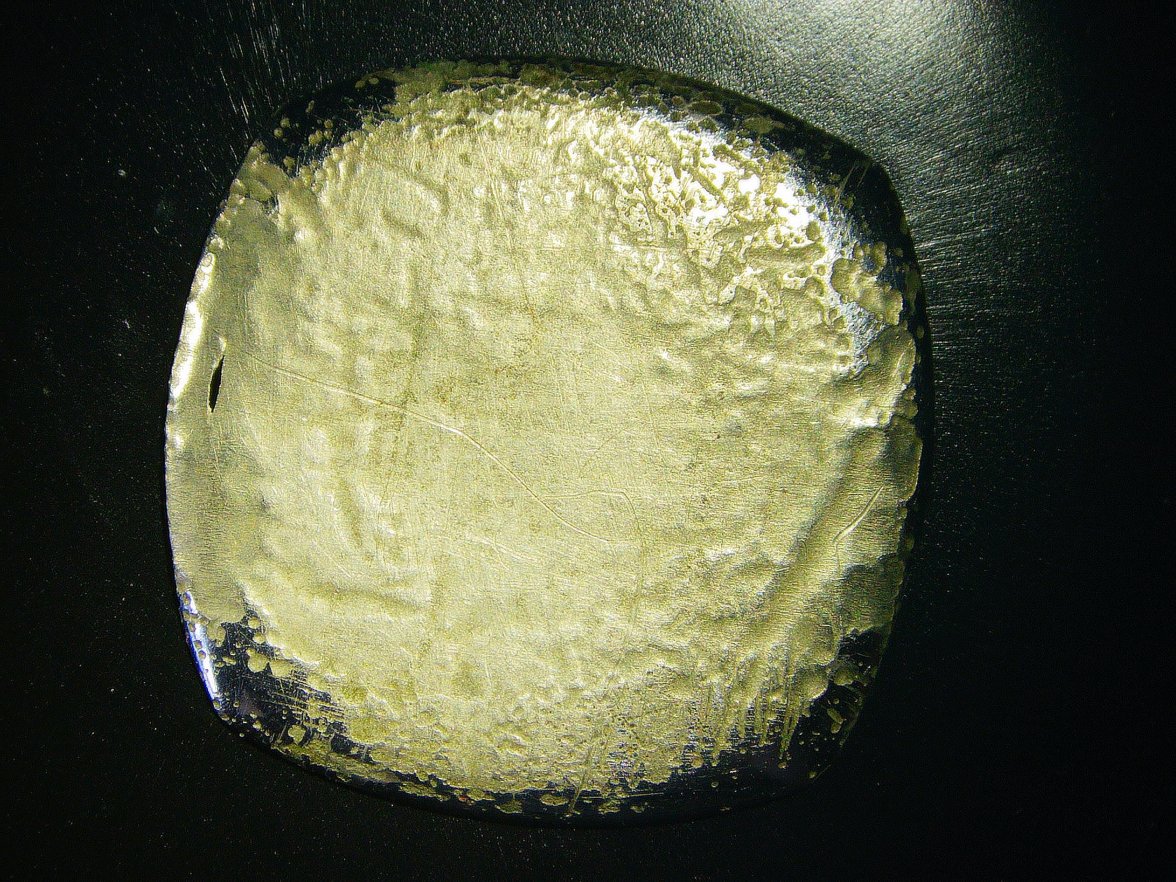

I would like to do a complete case job on it, meaning I want to sand the case, polish and nickel/chrome plate it (whichever it was genuine). Sadly the case has a hole in it, as visible in the pictures. I would like to close it, but I am not sure, which material it is made of. My first guess was messing, but I asked two goldsmiths and they said they have no clue what it is and don't want to work on it. I thought it might be possible to close it up with silver solder, then file it down and nickel plate. But if the case is some different alloy I might destroy something, which I definitely do not want.

Does anyone here have any idea about the material of that case (Or the Omega cases of that time, 7 million serial numbers) and how I could tackle the problem that I have?

Thank you in advance 😀

I am currently restoring an Omega Military Wristwatch with a Cal. 26.5. The Movement needed a lot of love but is running again. The case on the other hand probably needs even more attention.

I would like to do a complete case job on it, meaning I want to sand the case, polish and nickel/chrome plate it (whichever it was genuine). Sadly the case has a hole in it, as visible in the pictures. I would like to close it, but I am not sure, which material it is made of. My first guess was messing, but I asked two goldsmiths and they said they have no clue what it is and don't want to work on it. I thought it might be possible to close it up with silver solder, then file it down and nickel plate. But if the case is some different alloy I might destroy something, which I definitely do not want.

Does anyone here have any idea about the material of that case (Or the Omega cases of that time, 7 million serial numbers) and how I could tackle the problem that I have?

Thank you in advance 😀